The influence of nano-additives on the technical properties of drilling mud for drilling and well reconstruction

Автор: Abusal Yousef A.Y., Chetvertneva I.A., Ismakov R.A., Yakhin A.R., Loginova M.E.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: System solutions for technological problems

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Drilling and reconstruction of oil and gas wells are key stages in the development of hydrocarbon fields. One of the most significant technological elements that greatly influences the efficiency of the process is the drilling fluid (DF). It performs many functions, including cooling and lubrication of rock-cutting and special tools, bottomhole cleaning from drilled rock, maintaining well wall stability and many others. In recent years, special attention has been paid to the use of nanomaterials in the DF drilling fluid composition. Nanoscale additives can significantly improve technological properties of water-based muds, increase their efficiency and reduce drilling costs. Methods and Materials. The influence of additives on general technological parameters of Clay-Free Drilling Mud (CFDM) was evaluated. Special attention was paid to revealing the influence of the developed experimental additives on the friction coefficient and antifriction properties of (CFDM), which were determined using modified friction machine AI5018. Results and discussion. This study focuses on the investigation of the impact of nano-additives on the technical properties of water-based mud (WBs) and their effectiveness for drilling and well reconstruction. In the course of the work, comprehensive laboratory studies have been carried out to evaluate the effect of nano-additives of different nature, such as nano-graphite and nano-carbon materials, on the lubricating properties of water-based mud (WBs), which helps to reduce the wear of drilling equipment, increase the mechanical speed of drilling and, as a consequence, reduce the time and financial costs of well construction and re-construction. Conclusion. The introduction of nano-additives allowed significantly in improving the technological properties of drilling fluid DF. The obtained results can be used to improve the compositions of solutions based on the use of nanomaterials, which will increase the efficiency and reliability of well drilling processes.

Drilling, nano additives, drilling mud, well injection, lubricating additives

Короткий адрес: https://sciup.org/142242750

IDR: 142242750 | DOI: 10.15828/2075-8545-2024-16-6-576-586

Текст научной статьи The influence of nano-additives on the technical properties of drilling mud for drilling and well reconstruction

Original article

Abusal Yousef A.Y., Chetvertneva I.A., Ismakov R.A., Yakhin A.R., Loginova M.E. The influence of nano-additives on the technical properties of drilling mud for drilling and well reconstruction. Nanotechnologies in Construction. 2024; 16 (6): 576–586. – EDN: PCRKCQ.

N owadays, nanotechnology has become a rapidly developing field of research with both new scientific and practical applications. The properties of the created nanomaterials differ from the properties of macromaterials with the same chemical composition at the nanoscale.

Drilling of oil and gas wells is a complex and expensive process due to great depths, high pressures and geo- graphical conditions. The study of the effect of various additives, including nano-additives, on the technological parameters of water-based drilling fluids is promising, especially for well reconstruction by sidetracking. A large number of scientific and experimental studies by Russian and foreign scientists are carried out in this area. Thus, conceptual studies in the field of physical and chemical properties of drilling fluids are reflected in the scientific works of Ovchinnikov V.P. [1], Konesev V.P. [1], Kone-

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS sev V.P. [2]. [1], Konesev G.V. [2], A.S. Savenkov. [3], Is-makov R.A. [4, 5], Gray J.R. [6], Mahamathozhaev D.R. [7], Konate N. and other scientists [8].

To develop further research in the field of additives influence on drilling mud properties, the authors of the article chose water-based biopolymer drilling mud (WBM), because this initial system allows to overcome effectively complicated drilling intervals and to open productive formations qualitatively. As lubricating additives we used graphene oxide nanoplates (G-T1), sawdust (in the form of flour) and lubricating additive Sonbur 1101.

Nano-graphene G-T1 (manufacturer RUSGRAFEN LLC), is a black powder with particles of 3–10 nm in size. Three concentrations of graphene oxide RG-T1 (0.05; 0.100 and 0.50% by weight of the initial CFDM) were used to study the effect of graphene oxide RG-T1 on the solution structure, its physical, mechanical and rheological properties.

Sonbur 1101 is a mixture of: salt of monoethanolamine and crude tall oil – 10–12 wt.%; toluene (GOST 1471078) – 5–20 wt.%; oxal (TU 38.103429-83); polyglycols (TU 38.30214-88) – the rest.

Experimental studies to determine the optimum ratio of lubricant additive ingredients

Using the developed mathematical apparatus and correlation analysis method by domestic scientists from Ufa State Petroleum Technical University [9, 10], experimental studies were carried out.

To specify the concentrations of chemical reagents: clay powder and lubricating additive No. 2 (nano-graphite), the experiment planning matrix was used, and calculations were performed in the statgraphics program and manually.

In order to regulate the properties of the drilling fluid and to select the optimum concentrations, a simple 2k type full-factor experiment was used in which all factors are varied at two levels. The concentrations of two reagents, clay powder (X 1 ) and lubricant number 2 (X 2 ), were chosen as the varying factors. The variation interval, upper and lower levels of reagent concentrations for clay powder were 2.5, 3.5, 2.5% and for grease number 2 were 0.05, 0.2, 0.05% respectively. The experiment planning matrix is presented in Table 1.

Further calculations were carried out in the statgraphics program. The obtained data are presented in tabular form (Table 2). The obtained value of the Cochran criterion is 0.36 and the hypothesis of homogeneity of dispersions is accepted.

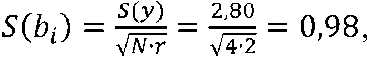

Let us calculate the coefficients of the regression equation by formula (1):

d ^^X0yu (1) 瓦=,W "°% 二 3 • ( 2,45 + 3,45 + 2,3 + 3,3) = 2;

瓦=/ W "1% = 7 ( — 2,45 + 3,45 — 2,3 + 3,3) = 0,5;

Table 1

Significance of Variable Factors

|

Level of varying factors |

Code designation |

Clay powder, % |

Grease No. 2, % |

|

X 1 |

X 2 |

||

|

Basic level |

0 |

1 |

0.15 |

|

Variation interval |

Δ X i |

2.5 |

0.05 |

|

Upper level |

+1 |

3.5 |

0.2 |

|

Lower level |

– 1 |

2.5 |

0.05 |

Table 2

Experimental data and results obtained

|

Experience number |

Y u1 |

Y u2 |

Yn |

Y –Y u n |

(Y u –Y n )2 |

Su2 |

||

|

Y u1 –Y n |

Y –Y u2 n |

(Y u1 –Y n )2 |

(Y u2 –Y n )2 |

|||||

|

1 |

2.5 |

0.05 |

2.45 |

0.05 |

-2.4 |

0.0025 |

5.76 |

5.7625 |

|

2 |

3.5 |

0.05 |

3.45 |

0.05 |

-3.4 |

0.0025 |

11.56 |

11.5625 |

|

3 |

2.5 |

0.2 |

2.3 |

0.2 |

-2.1 |

0.04 |

4.41 |

4.45 |

|

4 |

3.5 |

0.2 |

3.3 |

0.2 |

-3.1 |

0.04 |

9.61 |

9.65 |

|

The sum of Σ |

11.5 |

31.425 |

||||||

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

£>2 = — ' x^yu = — ■ (— 2,45 — 3,45 + 2,3 + 3,3) = — 0,075;

.

Further in the program statgraphics and having carried out calculations manually for definition of mathematical description of the influence of two chemical reagents on properties of drilling mud, the received model of the first order has the form:

Y = 2.875 + 0. 5X 1 – 0. 075X 2 + 0.0 X 1 X 2 . (2)

Statistical significance of the equation coefficients is checked by the condition bi ≤ 2 Δbi , where 2 Δbi is the confidence interval. If this condition is met, the coefficients are insignificant and the equation terms with insignificant coefficients are discarded.

The boundary of the confidence interval is determined by formula (3):

∆ b i = t кр • S ( b i ),

where S ( bi ) – is the mean square error of the regression equation coefficients; t кр – critical value of Student’s criterion.

where S ( y ) – is the experimental error determined by formula (5):

, (5)

where S 2( y ) – is the variance of reproducibility, determined by formula (6):

. (6)

The critical value of Student’s criterion is chosen according to Table 5 depending on the number of degrees of freedom f = N • (r–1) and the given significance level p = 0.05. In our case f = 4•(2 – 1) = 4.

Then ∆ bi = t кр • S ( bi ) = 2,78•0,98 = 2,72 and 2∆ bi = 5,44.

Consequently, the coefficients b 1 , b 2 , b 12 are statistically insignificant, and the equation takes the form: Y = 0.

The hypothesis of adequacy of the regression equation is tested by the condition: Fp ≤ F т where Fp and F т – are the values of Fisher’s criterion.

Calculated value Fp is determined by formula 7:

, (7)

where S ад 2 – is the adequacy variance, determined by formula 8:

, (8)

where λ is the number of significant coefficients of the regression equation;

– calculated value of the optimization parameter for each experiment.

The presented results of the obtained calculations on The results of the obtained equations reflecting the optimal concentrations of additives on the properties of drilling mud are presented in Table 3. To obtain the values of parameters for each experiment, the values of X 1 , X 2 , X 1 X 2 from Table 3 were substituted into the obtained equations and the values of yu and the adequacy variance were determined.

-

(a ) Including all coefficients:

;

-

b) taking into account significant coefficients:

.

Let’s determine the calculated values of Fisher’s criterion:

-

(a ) Including all coefficients:

;

Table 3

Calculated and experimental values of parameters

|

Experience number |

Taking into account the coefficients |

Excluding coefficients |

||||||

|

兀 |

У и -У и |

(九 —У “ ) 2 |

уи |

У “ |

%—У “ |

(О2 |

||

|

1 |

2.45 |

2.45 |

0 |

0 |

2.45 |

2.3 |

0.15 |

0.0225 |

|

2 |

3.45 |

3.45 |

0 |

0 |

3.45 |

3.3 |

0.15 |

0.0225 |

|

3 |

2.3 |

2.3 |

0 |

0 |

2.3 |

2.45 |

–0.15 |

0.0225 |

|

4 |

3.3 |

3.3 |

0 |

0 |

3.3 |

3.45 |

–0.15 |

0.0225 |

|

The sum of Σ |

0 |

0.09 |

||||||

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

-

b) taking into account significant coefficients:

Ғр= ::)=、= 0,022 .

The tabular value of Fisher’s criterion is determined for the corresponding degrees of freedom f ад = N – λ ; fE = N •( r –1) and the accepted significance level p = 0.05.

F Т = 6.9 for f ад = 4–2 = 2 and f Е = 4•(2–1) = 4.

In this case F Р1 < F Р2 < F Т = 6,4.

Consequently, the equations are adequate. In the case when the selected model is not adequate, a new mathematical model is selected and the planning of experiments followed by similar processing of the results is repeated.

To determine the optimal concentrations of reagents, we convert from the coded values of the equation variables to natural values using the data in Table 4.

Then the regression equation will take the form:

Y = 2.875 + 0. 5X1– 0. 075X2 + 0.0 X1X2 =

=2,875 +。, 5•( 会)-。,。 75•(% 萨)+

+ 0 • (8%і%2 - L2X] - 8%2 + 1,2)=

29 + 2%] - 15%2

-

- io .

Let’s determine the concentration of lubricating additive No. 2 x 2 , at K 1 = 0.2, clay powder concentration x 1 = 3%:

KI = 29+(2 ;; 15& t 汽 2 = 0,2 % .

Thus, the optimum concentration of additive No. 2 is 0.2%.

METHODS AND MATERIALS

The need to build similar machines, structures, and facilities has given rise to the process of modeling, the basis of which is the similarity of physical processes according to a number of features. Experiments without a properly constructed model of the process, as a rule, turn out to be incorrect and inaccurate. For accurate modeling it is necessary to apply criteria of physical similarity of processes. Earlier such experimental studies were carried out by Russian and foreign scientists. Thus, I.I. Dubov developed an innovative technology for the use of anti-seize additive in sidetrack drilling [11]. A group of scientists Akhmetzyanov R.R., Zhernakov V.N. [13] developed a mathematical model reflecting the assessment of the influence of different compositions and concentrations of inorganic salts on the properties of drilling fluids.

The oil and gas industry, like other industries, involves the introduction of new technologies, construction of facilities, modeling of various processes. They are accompanied by calculation of similarity criteria for this or that action. Let’s consider the application of similarity criteria specifically in the construction of oil and gas wells.

In oil and gas well drilling there are many examples of calculation of similarity criteria for modeling various operations.

At the preliminary stage, the effect of additives on the general technological parameters of the (CFDM)was evaluated. Particular attention was paid to revealing the influence of the developed experimental additives on the indicators of antifriction properties of (CFDM), which were determined on a modified friction machine AI5018.

The necessity to evaluate the efficiency of using flushing fluids in drilling oil and gas wells, including lubricating

Table 4

Main results of experimental studies for oxide-graphene RG-T1

|

No. |

Load Н |

Lubricant additive % |

RPM speed |

Time Minutes |

Friction torque |

Coefficient of friction |

|

1 |

100 |

0.5 (nano-graphene) |

150 |

10 |

1.18 |

0.168571 |

|

2 |

200 |

150 |

10 |

1.34 |

0.095714 |

|

|

3 |

300 |

150 |

10 |

1.51 |

0.071905 |

|

|

1 |

100 |

0.1 (nano-graphene) |

150 |

10 |

1.18 |

0.168571 |

|

2 |

200 |

150 |

10 |

1.35 |

0.095714 |

|

|

3 |

300 |

150 |

10 |

1.48 |

0.071905 |

|

|

1 |

100 |

0.05 (nano-graphene) |

150 |

10 |

1.19 |

0.17 |

|

2 |

200 |

150 |

10 |

1.31 |

0.093571 |

|

|

3 |

300 |

150 |

10 |

1.50 |

0.071429 |

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS additives and reagents on the basis of complex effects in relation to friction “metal-to-metal” or “metal-rock”, which was previously investigated [14–17], is explained by the lack of friction test experiments to ensure the modes and conditions of rolling (crushing) of casing pipes.

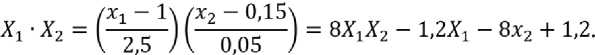

The tests were conducted on our modernized friction machine AI 5018. In the process of laboratory tests the friction torque, clamping force and shaft speed were adjusted and measured. The main technical characteristics of AI 5018 allow modeling the process of friction of a pair “metal-to-metal”. The maximum and minimum rotational speed of the lower shaft is 2000 and 50 rpm respectively, the pressing force of the samples reaches 5000 N, and the range of friction torque measurement is from 0.5 to 20 Nm.

Thus, the AI 5018 friction machine can be used to carry out tests with different specimens, loads and rotation speeds of specimens, as well as slip coefficients.

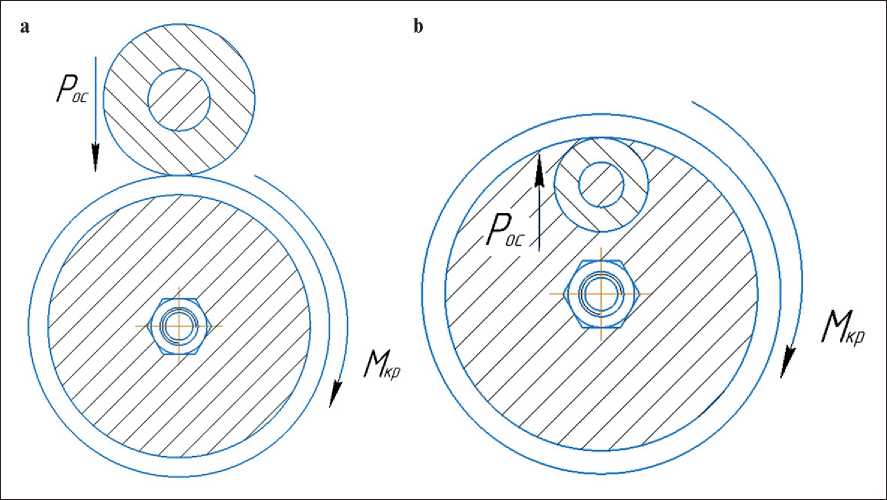

Figure 1 the circuit diagram of the machine.

On the described machine it is possible to simulate various schemes of interaction of friction pairs: “disk– disk”, “disk–pad” or “shaft–bushing” – including the use of a special chamber for placing the rubbing samples in a liquid medium.

This list of interaction schemes was extended by us due to partial modernization of the machine. To realize the idea, it was necessary to change the experimental setup from material friction testing to a possible increase in the diameter of the workpiece. When implementing the first scheme of testing the specimen, the load is applied to a disk that is placed over the workpiece under study (Fig. 2, a). In our case, the modernization of the setup will be to apply the load to the inside of the workpiece, and accordingly, it was necessary to fix the working disk inside the test specimen (Fig. 2, b).

To realize this test method, an auxiliary circuit was designed and fabricated through which the load on the specimens is carried and regulated.

Experimental part

The tests were carried out on a modified device “AI-5018” with two above mentioned types of drilling muds with different percentage of each reagent. The load on the AI-5018 device was changed stepwise – 10, 20, 30, 40 kg.

Figure 3 shows the process of experiments to further determine the friction coefficient of the metal-to-metal pair in the drilling fluid medium.

RESULTS AND DISCUSSION

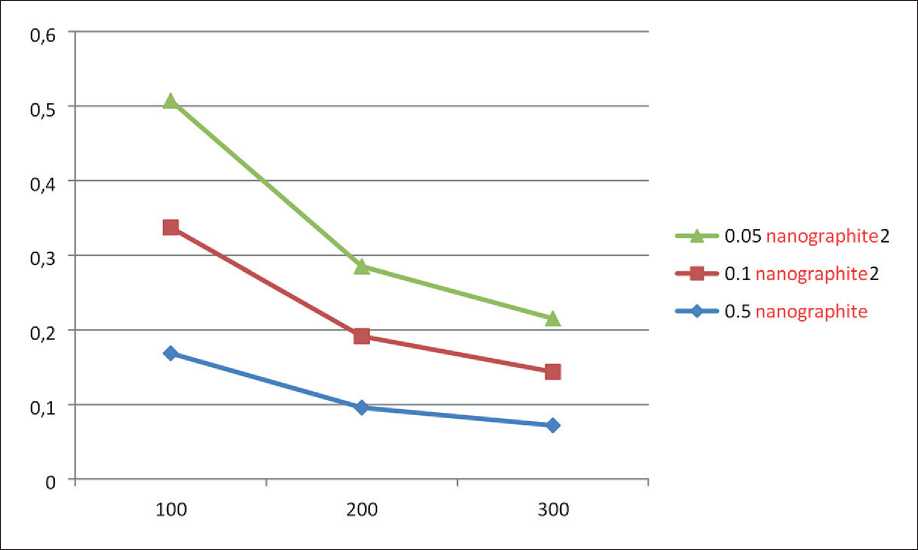

The main experimental results are summarized in Table 4 and Figure 4.

From the obtained data we can conclude that the highest efficiency of nano-graphene is observed at small values of load 100–200 N, and then the effectiveness of reducing the coefficient of friction is less pronounced (at 300 N). Also with changing the concentration of nanographene observed a decrease in the friction coefficient on average by a factor of 3 when increasing the concentration from 0.05 to 0.5.

Further studies were directed to investigate the frictional properties of Sonbur 1101 lubricant additive.

Fig. 1. Scheme of the modernized system of friction machine load creation AI-5018

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

Fig. 2. Traditional method and necessary loading scheme of friction pair

Fig. 3. General view of the modernized friction unit of the AI-5018 machine for testing in the drilling fluid environment

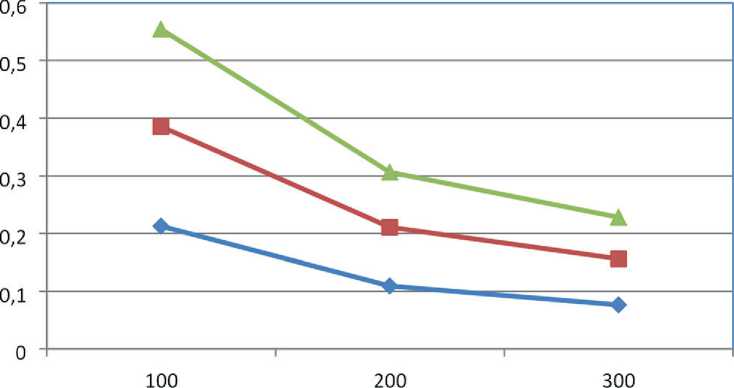

In the experiments, the initial solutions with the content of Sonbur 1101, respectively 0, 5; 1.0 and 1.5% by mass were used. The main results of experimental studies for the additive Sonbur1101 are shown in Table 5 and Fig. 5.

From the obtained data we can conclude that the greatest efficiency of lubricating additive “sonbur” is observed at small values of load 100–200 N, then the effectiveness of reducing the coefficient of friction is less pronounced (at 300 N). Also with the increase of concentration of sonbur is observed reduction of friction coefficient in average in 3 times when increasing the concentration from 0.5 to 1.5. In general, the results are similar to nano-graphene, but the latter is more effective

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

Fig. 4. Dependences of friction coefficient on load for drilling fluid with different concentration of graphene oxide additive RG-T1

Table 5

Main experimental results for Sonbur 1101

In order to determine the optimum ratio of ingredients of the newly developed lubricating additive with nanographene, a water-based drilling mud was prepared with the composition shown in Table 8 and the main parameters shown in Table 6.

The results of experimental studies on measuring the friction coefficient of the pair “metal-to-metal” on the scheme “Shaft–bushing”, modeling the tool rolling, in the environment of the newly developed drilling mud, conducted on the modernized friction machine AI5018, are presented in Table 8.

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

* 0.5% sonbur

■ 1% sonbur

■ ♦■ ■ 1.5% sonbur

Fig. 5. Dependence of friction coefficient on load for CFDM with different concentrations of Sonbur 1101 additive

Table 6

Composition of the test solution

|

Drilling fluid formulation / reagent name |

g/l |

|

Process water |

1 л |

|

NAOH |

0.5 |

|

KCL |

100 |

|

starch |

25 |

|

biopolymer |

2.5 |

|

chalk |

450 |

|

sonbur1101 |

1.5% |

|

graphene oxide RG-T1 |

0.5% |

|

Wood sawdust (wood flour) |

0.3% |

CONCLUSION

Thus, the obtained composition of drilling mud with nanographite showed the best results for reducing the coefficient of friction in the “metal-to-metal” pair in comparison with previously known studies of Russian scientists [12, 15, 16, 20] and freign researchers [19, 21, 22]. The composition was optimized and a patent application was filed. The research results have shown that the introduction of nano-additives into the composition of water-based drilling muds allows to significantly improve their technological properties and increase the efficiency of their application in the processes of sidetrack construction and work with special tools in contact with the metal of casing strings.

In tribotechnical study of drilling fluids, the coefficient of friction, friction torque and wear rate are closely related.

Table 7

Technological parameters of tested solutions

|

Drilling fluid parameters |

Units of measurement |

Values according to API standard |

|

Density |

g/cm3 |

1.32 |

|

Plastic viscosity |

sP |

16 |

|

DNS |

Pound/100Foot2 |

20 |

|

SNA 10 sec. |

Pound/100Foot2 |

3 |

|

SNA 10 min. |

Pound/100Foot2 |

5 |

|

pH |

11.7 |

|

|

UW |

С |

47 |

|

К |

47000 |

|

|

Grease content |

% |

2.7 |

SYSTEM SOLUTIONS FOR TECHNOLOGICAL PROBLEMS

Table 8

Experimental results of measuring the friction coefficient in the “metal-to-metal” pair in the environment of the newly developed drilling mud

|

No. |

Load Н |

RPM speed |

Time Minutes |

Friction torque |

Coefficient of friction |

|

1 |

100 |

150 |

10 |

0.986 |

0.140 |

|

2 |

200 |

150 |

10 |

1.09 |

0.077 |

|

3 |

300 |

150 |

10 |

1.13 |

0.053 |

The coefficient of friction is a measure of the resistance to sliding between two surfaces and depends on various factors such as surface roughness, lubrication and temperature. The friction torque is a measure of the torque required to overcome the friction between two surfaces and is related to the coefficient of friction by the equation:

M = F • d , (9)

where M – moment of friction; F – frictional force; d – distance between two surfaces.

Wear rate is a measure of the loss of material due to abrasion or adhesive wear and depends on the coefficient of friction and friction torque. Generally, a higher coefficient of friction and friction torque can result in a higher wear rate because more energy is transferred to the surfaces, resulting in more material being removed. However, it should be noted that other factors such as surface hardness also play a role in determining wear rate. In summary, coefficient of friction, friction torque and wear rate are important parameters to consider in tribotechnical studies of drilling fluids because they can help optimize drilling performance and reduce equipment wear and maintenance costs. Therefore, minimizing the friction torque and coefficient of friction on the reamer and other drilling tools is the main objective of this study. Taking into account the additives added to both the initial water-based and clay-based drilling fluids, as well as the different percentages of lubricant additives added to them, as described in the article

Список литературы The influence of nano-additives on the technical properties of drilling mud for drilling and well reconstruction

- Technology of drilling oil and gas wells: textbook for university students. In 5 vol. 2 / edited by V.P. Ovchinnikov. V.P. Ovchinnikov. Tyumen: TIU; 2017.

- Konesev G.V. Lubricating action of media in drilling technology / G.V. Konesev, M.R. Mavlyutov, A.I. Spivak, R.A. Mulyukov / Moscow.: Nedra; 1993.

- Savenkov, A.S. Role of lubricating additives in the composition of drilling muds. Alleya nauki. 2019; 1.6(33): 811-815. https://www.alley-science.ru/domains_data/files/03June2019/ROL%20SMAZOChNYH%20DOBAVOK%20V%20SOSTAVE%20BUROVYH%20RASTVOROV.pdf

- Ismakov R.A., Konesev, V.G., Mamaeva O.G., et al. Study of lubricating additives to drilling washing fluids. History of Science and Technology. – 2011. – P. 152–156. https://www.elibrary.ru/item.asp?id=24791742 EDN: UWNLTJ

- Ismakov R.A., Mulyukov R.A., Gaimaletdinova G.L. Influence of drilling mud, treated with a reagent of complex action Devon-2l, on limestone at primary stripping. Drilling and Oil. – 2023. – № 2. – P. 44–49. DOI: https://www.elibrary.ru/item.asp?id=50417841 EDN: MFFRFN

- Gray J.R., Darley G.S.G. Composition and properties of drilling agents (flushing fluids). Moscow: Nedra; 1985.

- Makhamathozhaev D.R. Development of drilling mud compositions with the use of locally modified humate reagent. Chemical Industry. 2015; 92(2):98-104. https://www.isuct.ru/book/files/acquisition/journals/ChemProm/2015/toc-ChemProm-2015-02.pdf

- Konate N., Magzoub M., Salehi S., Ghalambor A., Mokhtar, M. Laboratory Evaluation of Mud Systems for Drilling High Clay Shales in Dynamic Conditions: Comparison of Inhibitive Systems. Presented at the SPE International Conference and Exhibition on Formation Damage Control. Lafayette, Louisiana, USA. February 19-21, 2020. SPE 199316. http://doi.org/10.2118/199316-MS

- Loginova M.E., Chetvertneva I.A., Shammazov A.M., Movsumzadeh E.M., Tivas N.S. Estimation of drilling reagent concentrations by regression analysis. Oil and Gas Business. 2023; 21:16-14. https://www.elibrary.ru/item.asp?id=50502611 EDN: MNXLEK

- Loginova M.E. Possibilities of correlation-regression analysis for justification of drilling fluid formulation. Actual problems and innovations in the field of well construction and workover: a collection of abstracts of the report of the scientific conference dedicated to the anniversary of I.G. Yusupov. Bugulma: TatNIPIneft; 2022: 45-47. https://www.elibrary.ru/item.asp?id=49086629 EDN: ZYZGQA

- Dubov I.I. Innovative technology of application of anti-seize additive FK-2000 Plus A during sidetrack drilling. Drilling and Oil. 2011: 3: 30-31.

- Marshev V.I. Influence of various lubricating additives on anti-seize properties of drilling muds / V.I. Marshev, R.R Valishina, G.L. Uaimaledinova. Proceedings of the 72nd scientific and technical conference of students, postgraduates and young scientists of UGNTU – Ufa: UNPC “Publishing House of UGNTU”; 2021: 106-110.

- Akhmetzyanov R.R., Zhernakov V.N. Modeling of drilling fluid properties at different compositions and concentrations of inorganic salts. Oil economy. 2019; 4:33-37.

- Abusal Yu.A.Yu., Trushkin O.B., Yakhin A.R., Gazizov R.R., Marshev V.I. Device for measuring the friction coefficient of the pair “metal-to-metal”. Patent for invention RU 2805288 C1, 13.10.2023. Application dated 16.02.2023.

- Yakhin A.R., Abusal Y.A.Y., Matyushin V.P., Tsenev N.K. Device for measuring the friction coefficient of the pair “metal-rock”. Patent RU2782817C1 https://www.elibrary.ru/item.asp?id=49785351 EDN: TUVAFO

- Yakhin A.R., Salikhov I.F., Ismakov R.A., Gimaev R.G. Improvement of the method of registration of force parameters of the system “metal - rock” while drilling wells. Electronic scientific journal “Oil and Gas Business”. 2013; 4: 30-40. https://www.elibrary.ru/item.asp?id=20699210 EDN: RKYZIP

- Ismakov R.A., Abusal Y., Marshev V.I. Results of the study of the influence of lubricating additive for drilling washing fluids on the friction coefficient of the pair “metal-metal”. Drilling and Oil. 2022; 7-8: 49-51. https://www.elibrary.ru/item.asp?id=49550758 EDN: XZZPKO

- Yurov V.M., Guchenko S.A., Ibraev N.H. Determination of sliding friction coefficient. International Journal of Applied and Fundamental Research. 2010; 8: 148-148. https://applied-research.ru/ru/article/view?id=789

- Irawan, S., Kinif, B. I., Bayuaji, R. Maximizing Drilling Performance through Enhanced Solid Control. IOP Conference Series: Material Science and Engineering Vol. 267. August 5, 2017. Surabaya, Indonesia. http://doi. org/10.1088/1757-899X/267/1/012038

- Vydrin A.V., Kuznetsov V.I., Yakovleva K.Yu. Intensification of drawing process by expanding the range of applicability of lubricant. Mechanical equipment of metallurgical plants. 2016; 2 (7); 34-40.

- Ping Yu, R. J. Kirkpatrick, B. Poe, Paul F. McMillan, X. Cong. Structure of Calcium Silicate Hydrate (C-S-H): Near-, Mid-, and Far-Infrared Spectroscopy. Journal of the American Ceramic Society. 1999; 82(3): 742-748.

- Xiangjun L., Pingya L., Hong L., Dachuan L., Faqian L. Keeping Shale Formation Stability by Optimizing Drilling Fluids in Yangta Oil Field Western. Presented at the International Petroleum Technology Conference. Doha, Qatar. 7–9 December 2009.China. http://doi.org/10.2523/13313-MS