The physical and mechanical properties of concrete with multifunctional additive

Автор: Perevoshchikova A.N., Valtsifer I.V., Kondrashova N.B., Voronina N.S.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 2 Vol.16, 2024 года.

Бесплатный доступ

Introduction. It is known that concrete is the main building material, despite the introduction of new technologies. The combination of strength and durability makes this material indispensable for the construction of civil and industrial infrastructure. However, the impact of aggressive external factors on concrete structures, such as an acidic or alkaline environment, temperature fluctuations, and the presence of water at low temperatures, can lead to a significant decrease in their strength characteristics. The introduction of various additives based on organic and inorganic compounds into the composition of concrete allows for the regulation of its performance properties and protect concrete structures from the negative impact of the environment. Therefore, research works aimed at improving physical and mechanical properties and quality of concrete structures are relevant. Methods and materials. The objects of our research were concrete samples, prepared with and without the use of a multifunctional additive called “Betomix-ITH Gel”, which was developed by the researchers of the Institute of Theoretical and Applied Mechanics of the Ural Branch of the Russian Academy of Sciences (ITC UB RAS). The physical and chemical properties of the compared samples were studied in accordance with Russian and interstate regulatory documents in accredited laboratories of the Russian Federation and the Republic of Turkey. Results and discussion. As a result of the research, we have found that the introduction of the multifunctional additive "Betomix-ITH Gel" to the concrete mixture significantly increases the water resistance, frost resistance, and strength of concrete samples, compared to samples without the additive. It has been shown that Betomix-ITH Gel imparts the property of "self-healing" to concrete, with cracks up to 0.5 mm in size, and increases the resistance of steel reinforcement to corrosion. Conclusion. The research has proved experimentally the effectiveness of the Betomix-ITH Gel additive for improving the quality characteristics for concrete of various classes, which allows the use of this additive in concrete mixtures in the construction of reinforced concrete structures located in aggressive conditions.

Concrete, concrete additive, waterproofness, self-healing, compressive strength

Короткий адрес: https://sciup.org/142240857

IDR: 142240857 | DOI: 10.15828/2075-8545-2024-16-2-170-179

Текст научной статьи The physical and mechanical properties of concrete with multifunctional additive

Original article

C oncrete is remained to be the main material of civil and industrial structures construction for today.

However, the high concrete hydrophilic property negatively affects the strength characteristics and can lead to the destructive processes. The problem of concrete protection is especially acute during the direct contact with water or aggressive environments, including sulfate soils; in this cases water penetrates into the concrete body through the capillary-porous structure [1–8].

Achievement of concrete high performance characteristics is possible in the traditional way, by utilization of increased cement content in the concrete mixture alongside the surface types of waterproofing utilization, or by more effective way – introduction of active functional additives, which can increase the performance properties of the whole structure, into the concrete mixture at the stage of its preparation, [9–15].

The protective properties of such multifunctional additives are often based on the ability to react with concrete components even at the stages of mixing and hardening

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS in the presence of an aqueous medium [16–21]. This interaction can cause the appearance of new spatial structures, such as crystallohydrates, which, during the growth process, bind surrounding water and increase in volume providing pore blocking and concrete voids clogging. As a rule, these compounds do not change their composition [20–24] and exhibit stability in acidic and alkaline environments, and most importantly, they are able to suppress the recrystallization of ettringite – the main cause of concrete sulfate corrosion. Thus, this type of waterproofing provides high protection of concrete for its entire service life. Investigation of such multifunctional additives effect on concrete samples is an urgent objective.

METHODS AND MATERIALS

Accredited Russian and foreign laboratories tested concrete mixture compositions with and without the “Be-tomix-ITH Gel” additive to determine the technological properties of the concrete mixture and concrete physical and mechanical characteristics.

The concrete additive “Betomix-ITH Gel” is manufactured in accordance with TS 5745-047-04740886-2013 and contains a mixture of water-soluble polymers and surfactants with a water-reducing effect. Consumption of the additive “Betomix-ITH Gel”: 1.0% by weight of cement in the concrete mixture. “Betomix-ITH Gel” is compatible with antifreeze, plasticizing and other additives.

In Russian laboratories, the compressive strength of concrete was determined using cube samples with parameters 100×100×100 mm in accordance with GOST 101802012. The frost resistance of concrete was determined using cube samples with parameters 100×100×100 mm in accordance with GOST 10060-2012. Water resistance was determined according to GOST 12730.5-19 on cylindrical samples with a diameter of 150 mm and a height of 150 mm. Tests for the resistance of steel reinforcement to corrosion in aqueous environment was carried out in accordance with GOST 9.908-85. The objects of research were steel reinforcement samples 10 mm long: cold-drawn, low-carbon steel wire for reinforcement of RCS, diameter 4 mm according to GOST 6727-80; products 6-A240 st3sp according to GOST 5781-82; products 10-A500S according to GOST 52544-2006. The compositions of concrete samples are given in Table 1.

The DSI laboratory of the State Department of Technical Research and Quality Control of Hydraulic Structures of Turkey, Ankara, carried out compressive strength tests in accordance with the TS EN 12390-3 on cubeshaped samples with parameters 150×150×150 mm. The samples were cured in water at a temperature of 20±2 оC for 7, 28 and 56 days. The water resistance of the samples was determined by water depth penetration under pressure according to the TS EN 12390-8. Cube samples with parameters 150×150×150 mm were hardened in water at a temperature of 20±2 оC for 7, 28 and 56 days. Then the samples were dried at a temperature of 20±2 оC and humidity 50±5% for 7 days. The compositions of the samples are presented in Table 2.

RESULTS AND DISCUSSION

Tests by the Russian laboratories “ITC UB RAS” and LLC “IL Orgtekhstroy”, Perm.

During the tests, concrete compositions with and without the addition of “Betomix-ITH Gel” additives were used. The properties of concrete mixtures are shown in Table 3.

Density growth and entrained air volume decrease is observed in samples with the “Betomix-ITH Gel” additive.

Table 4 presents the results of concrete samples strength tests.

A slight strength increase of samples with “Betomix-ITH Gel” additive is observed.

Addition of a well-known plasticizer Poliplast SP-4 (GC “Poliplast” Group of Companies, Russia) to the

Table 1

Composition of concrete per 1 m3 of concrete mixture (for dry aggregates)

|

Material |

Material consumption per 1 m3, kg |

|

|

Composition without additives |

Composition with «Betomix-ITH Gel» |

|

|

Cement CEM I 42.5 N |

255 |

255 |

|

Natural sand |

768 |

768 |

|

Crushed granite fraction 5–20 mm |

1152 |

1152 |

|

Additive «Betomix-ITH Gel» |

– |

2.55 |

|

Supply water |

178 |

178 |

|

Water-cement ratio |

0.70 |

0.70 |

|

r (proportion of sand in aggregate mixture) |

0.4 |

0.4 |

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Table 2

Concrete compositions per 1 m3 of concrete mixture (for dry aggregates) for testing according to international standards

|

Material |

Material consumption per 1 m3, kg |

|||||

|

Марка бетона |

С16/20 |

С20/25 |

С25/30 |

|||

|

Portland cement СЕМ II/А-М (V-L) 42.5 R |

240 |

240 |

330 |

330 |

375 |

375 |

|

Additive «Betomix-ITH Gel» |

2.40 |

3.30 |

3.75 |

|||

|

Water |

221.2 |

206.8 |

241.8 |

224.6 |

245.4 |

227.7 |

|

Water-cement ratio |

0.85 |

0.79 |

0.68 |

0.64 |

0.61 |

0.57 |

|

Sand 0–4 mm |

995.5 |

1069.7 |

976.3 |

995.2 |

948.4 |

967.0 |

|

Crushed granite fraction 7–15 mm |

419.6 |

387.9 |

354.1 |

360.9 |

343.9 |

350.7 |

|

Crushed granite fraction 16–22 mm |

476.4 |

465.2 |

425.0 |

432.7 |

412.4 |

420.5 |

Table 3

Results of concrete mixture properties tests

A significant strength increase of samples with the “Betomix-ITH Gel” additive is observed. A particularly impressive increase (32.8%) appears after the samples were cured in water for 28 days.

Concrete samples frost resistance results are presented in Table 6.

Table 4

Results of concrete samples compressive strength tests

|

Age, days |

Curing conditions |

Average compressive strength of samples, MPa |

Strength growth, % |

|

|

Composition without additives |

Composition with «Betomix-ITH Gel» |

|||

|

3 |

Normal |

14.3 |

14.4 |

0.7 |

|

7 |

Normal |

19.2 |

19.3 |

0.5 |

|

28 |

Normal |

25.9 |

26.2 |

1.16 |

Table 5

Samples tests for compressive strength results

|

Age, days |

Curing conditions |

Average compressive strength of samples, MPa |

Strength growth, % |

|

|

«Poliplast SP-4» (1,7%) |

«Poliplast SP-4» (1,5%) and «Betomix-ITH Gel» (1%) |

|||

|

7 |

Normal |

30.45 |

39.1 |

22.1 |

|

30 |

Normal е |

39.0 |

46.1 |

15.4 |

|

37 |

30 days normal, 7 days in water |

34.1 |

43.4 |

21.4 |

|

58 |

30 days normal, 28 days in water |

33.8 |

50.3 |

32.8 |

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Table 6

Concrete samples control tests results for frost resistance

|

Concrete reference samples |

Main concrete samples after 3 freeze-thaw cycles at –50 оC (F1100) |

||||||

|

Х ср ’ Average strength of concrete, MPa |

Хmin’ Lower limit of the confidence span (with coefficient 0.9), MPa |

Average weight of saturated samples, g |

Change in sample weight, % |

Хср’’ Average strength of concrete after testing, MPa |

Хmin’’ Lower limit of the confidence interval, MPa |

||

|

Before testing |

After testing |

||||||

|

25.8 |

20.7 |

2416 |

2395 |

–0.87 |

25.7 |

22.5 |

|

|

Standard deviation – 1.10; strength variation coefficient – 4.30% |

Standard deviation – 1.30; strength variation coefficient – 4.90% |

||||||

|

羽 |

26.6 |

21.2 |

2424 |

2417 |

–0.29 |

26.8 |

23.2 |

|

Standard deviation – 1,20; strength variation coefficient – 4,60% |

Standard deviation – 1.40; strength variation coefficient – 5.20% |

||||||

The lower limit of the confidence span for the concrete strength of the control samples, taking into account the coefficient of 0.9, is 20.7 MPa (without additive) and 21.2 MPa (with “Betomix-ITH Gel”). The lower limit of the confidence span for the concrete strength of the main samples is 22.5 MPa ( without additive) and 23.2 MPa (with Betomix-ITH Gel). This observation corresponds to the ratio Хmin” ≥ 0.9 Хmin’ (22.5 > 20.7 without additive; 23.2 > 21.2 with “Betomix-ITH Gel”). All samples were tested 3 cycles using the third (accelerated) method without cracks, chips or peeling of ribs, which corresponds to the design frost resistance grade F1100. Samples with “Betomix-ITH Gel” additive showed better results compared to samples without the additive.

The water resistance of concrete samples was also determined with the “wet spot” method. According to GOST 12730.5-2018, the water resistance of a samples series using this method is determined by the maximum water pressure at which no water percolation is observed on at least four out of six samples. The results are presented in Table 7.

The water resistance grade increase in the composition with the use of the “Betomix-ITH Gel” additive by 4 levels compared to the concrete composition

The resistance of steel reinforcement to corrosion in aqueous environments was carried out. Standard samples of reinforcement were kept for 10 days in aqueous media of the following composition:

-

1. Tap water, pH 7.

-

2. “Betomix-ITH Gel” additive, pH 9.9.

-

3. A mixture of Portland cement class 42.5, normal hardening СEM I 42.5 N GOST 31108-2016 with tap water in the ratio: 1/2.5, pH 11.5.

-

4. A mixture of Portland cement class 42.5, normal hardening СEM I 42.5 N GOST 31108-2016 with tap

Table 7

Water resistance tests results with the “wet spot” method

|

Water percolation through the sample |

Concrete samples, pcs. |

||

|

Pressure, MPa |

Stage |

Composition without additive |

Composition with «Betomix-ITH Gel» additive |

|

0.2 |

I |

0 |

0 |

|

0.4 |

II |

0 |

0 |

|

0.6 |

III |

0 |

0 |

|

0.8 |

IV |

3 |

0 |

|

1.0 |

V |

– |

0 |

|

1.2 |

IV |

– |

0 |

|

1.4 |

IIV |

– |

1 |

|

1.6 |

IIIV |

– |

2 |

|

Water permeability grade |

W6 |

W14 |

|

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS water in the ratio: 1/2.5 with the addition of 1% Betomix-ITH Gel additive by weight of cement, pH 11.4.

The research results revealed that in environment No. 1 corrosion is active on all reinforcement samples. In environments No. 2 - 4, no corrosion of the reinforcement was detected. At a pH = 9–12, steel passivation occurs. Thus, the introduction of the Betomix-ITH Gel additive into the concrete solution preserves the stable-passive corrosion state of steel reinforcement.

Tests by DSI laboratory, Ankara, Turkey.

Concrete testing laboratory researchers of the State Department of Technical Research and Quality Control of Hydraulic Structures of Turkey also carried out series of tests of the Betomix-ITH Gel additive according to interstate standards. In this system, the strength class of concrete is designated as ... C16/20, C20/25, C25/30... and corresponds to the concrete class ... B20, B25, B30..., according to the Belarusian regulatory document CSRB 5.03.01-02 “Concrete and reinforced concrete structures” (National complex of normative and technical documents in construction. Construction Standards of the Republic of Belarus). Application of such designations is connected with the fact that several European countries use a cylinder with a height twice bigger than the diameter to test the compressive strength of concrete. The performance of cylinder samples will differ from cube-shaped specimens.

Samples were prepared with the compositions presented in Table 2. Investigation results of concrete mixtures technological parameters are presented in Table 8.

In with the Betomix-ITH Gel additive, an in

Density growth and mobility decrease of concrete mixture samples with the “Betomix-ITH Gel” additive were observed compared to samples without the additive. Compressive strength tests are presented in Table 9.

Strength increase of samples using the “Betomix-ITH Gel” additive is observed. Results of strength increase during the samples hardening in water are much higher than during hardening in air since conditions play a significant role on the strength of concrete structures. Class C25/30 (B30) strength gain decrease is probably associated with the initial high strength of this class; the higher class of concrete is, the more difficult is to improve its strength by additives.

The water resistance of the samples was also determined by the depth of of water under pressure penetration. The test results are presented in Table 10.

Waterproof grade W was classified according to GOST 12730.5-2018. Since the correlation of different methods is not accurate in terms of particularly low water resistance, it is difficult to judge the number of steps by which the grade of concrete has been increased, especially for classes C20/25, C25/30. Water resistance increase of class C16/20 concrete with the “Betomix-ITH Gel” additive for at least 2 levels was observed.

In article [25], an attempt was made was performed to independently establish the assignment of water resistance grade according to GOST 12730.5-2018 and according to EN 12390-8. The mentioned data showed that waterproof

Table 8

Technological properties of the concrete mixture tests results

|

Parameter |

Parameter value |

|||||

|

Composition without additive |

Composition with «Betomix-ITH Gel» additive |

|||||

|

Concrete grade |

С16/20 |

С20/25 |

С25/30 |

С16/20 |

С20/25 |

С25/30 |

|

Average density, kg/m3 |

2352.7 |

2373.2 |

2326.7 |

2348.4 |

2325.0 |

2346.4 |

|

Entrained air volume, % |

2~3 |

2~3 |

2~3 |

2~3 |

2~3 |

2~3 |

|

Cone slump test, cm |

8 |

6 |

14 |

8 |

13 |

9 |

Table 9

Test results of compressive strength according to TS EN 12390-3

|

Age, days |

Concrete grade |

Average compressive strength of samples, MPa |

Strength growth, % |

|

|

Composition without additive |

Composition with «Betomix-ITH Gel» additive |

|||

|

7 |

С16/20 |

12.2 |

14.1 |

15.57 |

|

28 |

С16/20 |

17.8 |

20.1 |

12.92 |

|

56 |

С16/20 |

20.1 |

23.4 |

16.42 |

|

56 |

С20/25 |

27.2 |

34.6 |

27.20 |

|

56 |

С25/30 |

32.3 |

36.1 |

11.76 |

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Table 10

Results of water resistance tests by the depth of water under pressure penetration according to the TS EN 12390-8

Taking in account the research data from Russian laboratories, compositions using the “Betomix-ITH Gel” additive unconditionally show a significant water resistance increase. This water resistance increase allows the use of weakly sulfate-resistant Portland cements group with the “Betomix-ITH Gel” additive in aggressive soils containing sulfates, according to SP 28.13330.2017.

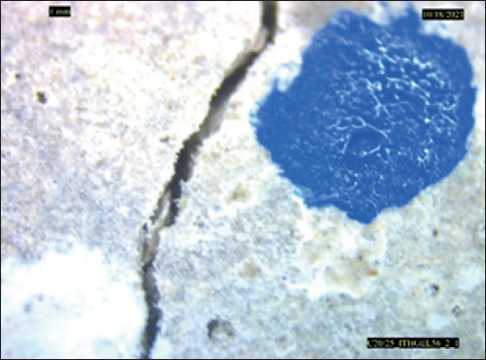

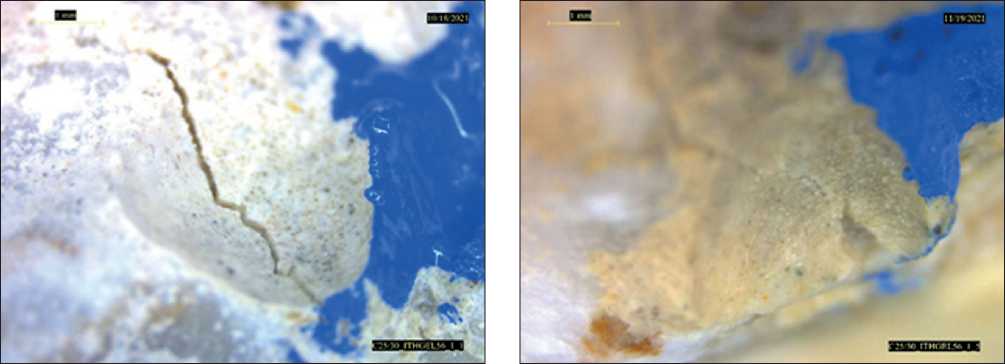

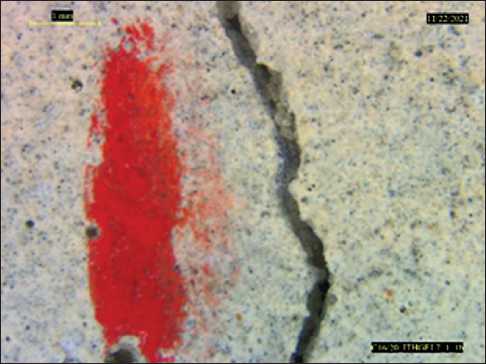

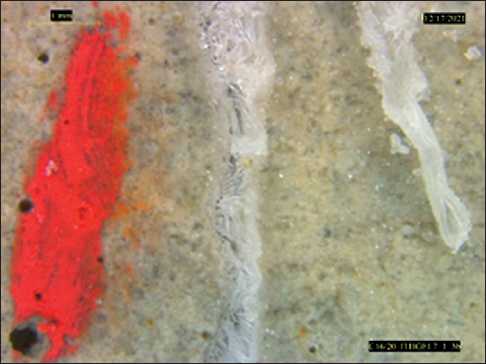

In addition to physical and mechanical tests, a visual assessment of the regeneration of previously destroyed concrete samples of various classes containing the “Betomix-ITH Gel” additive was carried out by optical microscopy method. Hardening of the samples occurred in water at a temperature of 20±2 оC for 7 and 56 days and then the samples were dried at a temperature of 20±2 оC, humidity 50±5% for 7 days. After that the samples were mechanically destroyed and stored in water for 26–31 days. Microphotographs of the samples were taken before immersion in water and after 26–31 days in water (Figures 1–4).

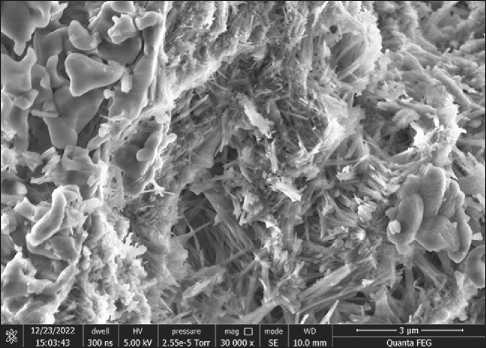

The microphotographs (Figures 1–4) reveal that after a storage of previously destroyed concrete samples with “Betomix-ITH Gel” additive in water during the month, the cracks self-healed and became clogged with needleshaped crystals. This property of concrete allows increasing concrete products service life, since needle-shaped crystals can prevent the diffusion of water drops through pores and microcracks inside the concrete, thereby improving the characteristics of concrete in terms of water resistance and frost resistance. After the concrete dries, unreacted functional chemical additives remain in the pores of the concrete. In cases where a new source of water appears, additives are able to pass into a saturated brine solution and form additional needle-like structures (Fig. 5), giving the concrete a “self-healing” property.

Fig. 1. Concrete sample microphotograph of C20/25BG (additive “Betomix-ITH Gel”, 56 days of hardening) after mechanical destruction and exposure to water for 31 days

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Fig. 2. Concrete sample microphotograph of С25/30BG (additive “Betomix-ITH Gel”, 56 days of hardening) after mechanical destruction and exposure to water for 31 days

Fig. 4. Concrete sample microphotograph of С16/20BG (additive “Betomix-ITH Gel”, 7 days of hardening) after mechanical destruction and exposure to water for 26 days

Fig. 3. Concrete sample microphotograph of С16/20BG (additive “Betomix-ITH Gel”, 7 days of hardening) after mechanical destruction and exposure to water for 26 days

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Fig. 5. Formation of a needle-like structure of the multifunctional additive “Betomix-ITH Gel”, magnification ×30000

CONCLUSION

Current research established:

-

1. Introduction of the “Betomix-ITH Gel” additive provided density increase and a mobility decrease of the concrete mixture.

-

2. The addition of “Betomix-ITH Gel” leads to the strength of concrete increase, especially in water environment.

-

3. The introduction of the “Betomix-ITH Gel” into the concrete solution preserves the stable-passive corrosion state of steel reinforcement.

-

4. The water resistance of concrete with the “Betomix-ITH Gel” additive increases by 2–4 levels, which allows the use of weakly sulfate-resistant Portland cements group in aggressive soils containing sulfates.

-

5. “Betomix-ITH Gel” additive gives concrete the “self-healing” property.

Thus, concretes with the “Betomix-ITH Gel” additive showed, among other improved qualities, a noticeable water resistance growth by at least 2 grades. For some classes of concrete the water resistance increase occurred by 4 grades. Such results make it possible to utilize the additive in the construction of a wide range of civil and industrial facilities, as well as to use a group of weakly sulfate-resistant Portland cements in soils containing sulfates. An exceptional property of “Betomix-ITH Gel” was also discovered - the ability of cracks to “self-heal”. This means that this additive can also be used to obtain leak-proof “cold” joints in concrete. In addition, the introduction of a plasticizing additive based on naphthalene sulfonic acid into the concrete mixture together with “Betomix-ITH Gel” promotes a synergistic effect and a significant compressive strength increase of concrete samples revealing wide opportunities for “Betomix-ITH Gel” additive with other plasticizing additives combination.

Список литературы The physical and mechanical properties of concrete with multifunctional additive

- Bazhenov Yu.M. Concrete technology. M.: ASV; 2002.

- Moshchansky N.A. Increasing the durability of building materials and structures operating in aggressive environments. M.: Gosstroyizdat; 1962.

- Akramov A.A., Muminov A.K., Nizirov Ya.G. Water resistance of concrete with single and complex additives. Polytechnic Bulletin. Series Engineering Research. 2021; 1(53): 107-111.

- Massalimov I.A.,Yanakhmetov M.R., Chuykin A.E. Strength and durability of concrete modified by sulfur-based impregnating compounds. Nanotechnologies in construction. 2015; 7(3): 61–75. https://doi.org/10.15828/2075-8545-2015-7-1-63-72

- Kornyukhin A.V., Knyazev N.V. Protection of concrete from moisture using hydrophobic agents. Education and science in the modern world, innovations. 2022; 2(39): 161-165.

- Nikishin V.A. Microstructure of cement stone as a factor determining the water resistance and strength of concrete. Concrete Technologies. 2015; 5-6: 32-36.

- Dobshits L.M. Ways to increase the durability of concrete. Construction materials. 2017; 10: 4-9.

- Fedosov S.V., Rumyantseva V.E., Krasilnikov I.V., Konovalova V.S., Karavaev I.V. Determination of safe service life of structures made of concrete containing hydrophobic additives. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil’noi Promyshlennosti. 2017; 6(372): 268-276.

- Kudyakov A.I., Simakova А.S., Kondratenko V.A., Steshenko A.B., Latypov A.D. Vliyanie organicheskikh dobavok na svoistva tsementnogo testa i kamnya [Cement pastes and brick properties modified by organic additives]. Vestnik Tomskogo gosudarstvennogo arkhitekturno-stroitel’nogo universiteta – Journal of Construction and Architecture. 2018; 20(6): 138-147.

- Altayskaia E.V. Waterproofing. Colloquium-Journal. 2019; 13(37). 8-10.

- Galyaev A.P. Ways of improving the water resistance of concrete. Construction equipment and technologies. 2018; 1(13): 21-24.

- Shishkina D.A. Waterproofing of underground buildings and structures. Scientific electronic journal Meridian. 2020; 8(42): 375-377.

- Sheinfeld A.V., Artamonova O.V. Effect of the dosages of complex organo-mineral modifier on the processes of structural formation of cement stone. News of Higher Educational Institutions. Construction. 2023; 9(777): 36–45. https://doi.org/10.32683/0536-1052-2023-777-9-36-45

- Melnichenko M.S., Ilyichev V.A. Modern methods of waterproofing underground structures. Universum: Technical science. 2022; 7-2(100): 5-7. https://doi.org/10.32743/UniTech.2022.100.7.14038

- Murtazaev S-A.Yu., Salamanova M.Sh., Saidumov M.S. Development of waterproof concrete compositions using a complex multifunctional additive. System Technologies. 2018; 26: 93-98.

- Nasryeva L.I., Izotov V.S., Lygina T.Z., Shinkarev A.A. Waterproofness of concrete after treatment with waterproofing impregnation systems. Izvestia KazGASU. 2010; 1(13): 319-324.

- Leonovich S. N., Poleyko N. L., Temnikov Yu. N., Zhuravskiy S. V. Physico-mathematical properties of concrete with application of “Kalmatron” system. Bulletin of Volgograd State University of Architecture and Civil Engineering Series: Civil Engineering and Architecture. 2013; 31(50): 124-131.

- Fedosov S.V., Rumyantseva V.E., Konovalova V.S., Karavaev I.V., Evsyakov A.S. On the issue of improving adhesion of composite reinforcement withcement concrete. Bulletin of the Volga State Technological University. Ser.: Materials. Constructions. Technologies. 2020; 1(13): 95-102. https://doi.org/10.25686/2542-114X.2020.1.95

- Dobshits L.M. Physico-mathematical model of concrete destruction at alternate freezing and thawing. Zhilishchnoe stroitel`stvo [Housing Construction]. 2017; 12: 30-36.

- Nikishin V.A. Microstructure of cement stone and its influence on the water resistance of concrete. Tekhnologii betonov [Concrete Technologies]. 2012; 5-6: 6-9.

- Antonyan A.A. Water resistance of concrete with superplasticizers. Tekhnologii betonov. [Concrete Technologies]. 2017; 3-4: 36-39.

- Chernyshov E.M., Korotkikh D.N. Nanoreinforcement of cement stone structures with the help of crystals of ettringite for concrete fracture strength increasing. Scientific Herald of The Voronezh State University of Architecture and Civil Engineering. Construction and architecture. 2009; 2: 21-29.

- Samchenko S.V., Makarov E.M. The formation and increase of crystals ettringite with polymer functional additives. Advances in modern science and education. 2016; 12(5): 118-122.

- Matyukhina O.N., Evdokimova I.V. Crystallization of ettringite in the presence of functional additives for dry construction mixtures. Sukhiye stroitel’nyye smesi [Dry construction mixtures]. 2016; 1: 15-18.

- Antonyan A.A. On some features of modern methods for determining the water resistance of concrete. Tekhnologii betonov [Concrete Technologies]. 2017; 9-10: 29-33.