The research of thermophysical properties of the working environment for abrasive-extrusion processing

Автор: Pshenko E. B., Shestakov I. Ya., Remizov I. A., Veretnova T. A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.20, 2019 года.

Бесплатный доступ

The most important resource for improving the performance of parts is the reduction of the surface roughness. One of the promising ways to reduce the surface roughness is the abrasive extrusion processing. When developing the AEP technology, it is necessary to know the flow rate (pressure) of the WE, which depends on the viscosity of the latter. In turn, the viscosity of the WE is determined by its temperature. The temperature of the working environment at AEP can be calculated if the coefficients of thermal conductivity and thermal diffusivity of the WE are known. The working environment for AEP consists of two components, therefore, the coefficient of thermal conductivity can be calculated by known formulas. However, the calculation error is significant, therefore, the experimental determination of the abovementioned coefficients is required. The installations for the coefficients research have been presented, the methods of conducting experiments have been developed. After mathematical processing of the experiments results by means of the AdvanceGrapher v. 2.11, the dependences of the thermal conductivity and thermal diffusivity on the abrasive concentration have been obtained. The studies of the thermophysical properties of the working environment have shown that the values of thermal conductivity and thermal diffusivity of the WE are mainly determined by the concentration of abrasive grains in the working environment. The direct dependence of these coefficients on the degree of filling the working environment with abrasive grains has been established.

Abrasive extrusion processing, working environment, thermal conductivity and thermal diffusivity coefficients.

Короткий адрес: https://sciup.org/148321687

IDR: 148321687 | УДК: 621.924 | DOI: 10.31772/2587-6066-2019-20-2-277-283

Текст научной статьи The research of thermophysical properties of the working environment for abrasive-extrusion processing

Introduction. Now there exists the whole class of parts containing open and closed channels of a variable cross-section to which surface layer condition the increased design requirements are imposed. These are aircraft parts (low thrust engine nozzles, impellers of turbopump units), high-precision transport parts (nozzles, sprayers), technical equipment parts (stamps, compression molds, matrixes, nozzles of thermoplastic automatic machines), etc.

The most important resource of the increase in production characteristics of parts is the decrease of roughness of a surface and ensuring parallelism of its direction along the flow of components as well as the removal of tensile and compressive stresses.

The practice of finishing processing showed that the most productive and effective for the formation of the surface layer (SL) of figurine channels is the abrasiveextrusion processing (AEP) which consists in the movement (remolding) of viscoelastic, filled with the abrasive grains (AG) working environment (WE) under the pressure 5–12 MPa along the processed channel surface [1–5].

When developing the AEP technology it is necessary to know the flow rate (pressure) of the WE which depends on the viscosity of the latter [6; 7]. The viscosity of the WE in turn is defined by its temperature. The WE temperature at AEP can be calculated knowing thermal conductivity and thermal diffusivity coefficients of the WE. The working environment at AEP consists of two components, therefore it is possible to calculate a thermal conductivity coefficient by Odelevsky’s [8], Misnara’s [9], Burger’s [10] formulas. The authors [11] consider that Odelevsky's formula is the most universal. The researchers of heat conductivity of composites offer a simple formula for the coefficient calculation, the method of “inversion” [12].

It has been established [13] that the thermal conductivity coefficient significantly depends on the concentration of abrasive and slightly depends on other factors.

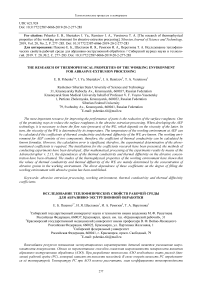

Research method and equipment. The experimental determination of a thermal conductivity coefficient of the WE was carried out by means of the flat layer method [14] on the installation (fig. 1). The working environment contained a viscoelastic component (high-molecular silicone rubber) and abrasive grains (silicon carbide black of graininess 100 or alundum white of graininess 50). During the experiments the content of abrasive grains was changing from 10 to 80 % (on volume basis) with a 15 % interval.

The working environment 3 in the form of the disk with 5 = 1 ■ 10-2 m thickness is located between the heater 1 and the fridge 5. The insulating ring containing the additional security heater 4, which provides one-dimensionality of the heat flux, is located outside. For the same purpose the ratio 5 / D ( D - the disk diameter equal to 16 ^ 10 2 m) has been chosen small. To measure the temperature difference the thermocouples 2 were used.

It is known that at a one-dimensional heat flux through the flat layer the thermal conductivity is calculated

X = Q т 5 / F ■ ( T i - T 2 )], (1) where Q т - the heat flux of the heater; 5 - the sample thickness; F – the surface area; T 1 and Т 2 – the temperatures of “hot” and “cold” sample surfaces (working environment).

Therefore for thermal conductivity research by this method the heat flux close to one-dimensional one through the layer of the working environment under study was created and measured and the temperature difference between layer borders was measured as well.

As the temperatures were measured not on sample surfaces, but at some distance from them inside the heater and the fridge, then the temperature differential corrections in the heater layer A T 1 and the fridge A T 2 were made to the measured temperature difference A T m eas The corrections are determined by formulas:

A T 1 = Q т 5 1 / ( F ■X i ); (2)

A T 2 = Q т 5 2 / ( F M (3) where 5 1 and 5 2 = 2 ^ 10 3 м - distances from a thermocouple junction to the sample surface in the heater and the fridge respectively; X 1 and X 2 - thermal conductivity of heater and fridge materials (for steel 12X18H10T X 1 = X 2 = 15.2 W/m ■ K).

Taking into account these corrections the calculation formula is:

X =

Q T s

A T ism

Q T f 5 1 + 5 2 F lX 1 X 2

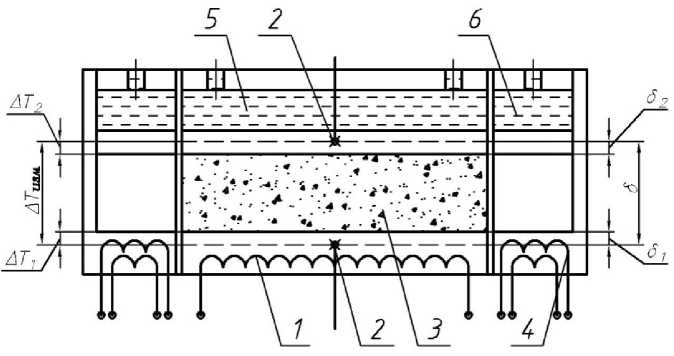

The graph of the dependence of the thermal conductivity coefficient on the concentration of abrasive is presented in fig. 2.

After the experiments results mathematical processing by means of the Advance Grapher v. 2.11 the dependences of thermal conductivity coefficients on concentration of abrasive have been received for alundum white:

λ eк = – 0.046 – 0.045 ⋅ Ка + 0.008 ⋅ Ка2 – 5.6 ⋅ 10–5Ка3; (5)

for silicon carbide black:

λ кк = – 0.322 – 0.016 ⋅ Ка + 0.013 ⋅ Ка2 – 8.56 ⋅ 10–5Ка3. (6)

Except for the abrasive concentration as the factors of variation the grain size (Ba) – the abrasive graininess in the range of 25–100 microns and T slave – the temperature of the working environment in the range of 20–60 0C were studied.

Fig. 1. Installation diagram for determining the coefficient of thermal conductivity by the method of a flat layer:

1 – heater; 2 – thermocouples; 3 – sample under test (working environment);

4 – security heater; 5 – fridge; 6 – fridge security ring

Рис. 1. Схема установки для определения коэффициента теплопроводности методом плоского слоя:

-

1 – нагреватель; 2 – термопары; 3 – исследуемый образец (рабочая среда); 4 – охранный нагреватель; 5 – холодильник; 6 – охранное кольцо холодильника

Fig. 2. Dependence of the coefficient of thermal conductivity of the working environment on the concentration of abrasive

Рис. 2. Зависимость коэффициента теплопроводности рабочей среды от концентрации абразива

As a result of the experiments it has been established that the thermal conductivity coefficient of the WE in the specified interval of change of abrasive graininess and temperature changes no more than by 3 %. Therefore these factors can not be considered when developing technological processes of AEP.

Calculation results of the thermal conductivity coefficient of working environments by Odelevsky's, Misnara’s formulas give the error of the required value determination in the comparison with the experimental one more than 60 %, by the inversion method the error makes 20–45 % in the specified range of abrasive concentration research. Such inaccuracy of thermal conductivity determination coefficient is unacceptable at projection of AEP technology.

The formulas for calculation of thermal diffusivity of composites have not been found now, therefore this parameter was defined experimentally.

To determine the thermal diffusivity coefficient of the working environment the method based on the measurement of the heating rate and time lag of the maximum (minimum) temperature on the free surface of a sample relative to the moment of switching on (switching off) the input into the sample power was used [15].

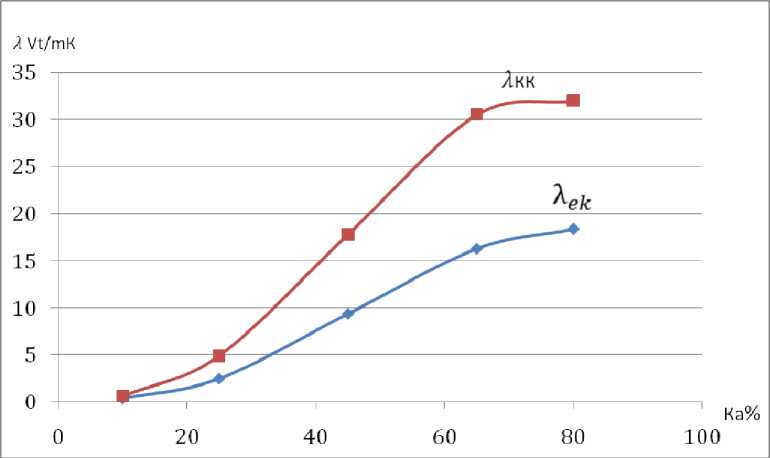

The working environment limited by a metal cylinder with the height of 11 mm and the diameter of 160 mm was used as a sample. The experiments were carried out on the installation (fig. 3). The installation consists of the heating element 1 with 100 W power on which the sample – the working environment 2 in the cylinder 3 was located. The measurement of temperatures was performed by means of thermocouples 4 in three different points which are located at the free surface of the sample on the depth of 1 mm. The thermocouples were located on one circular axis with the 20 mm diameter located concentrically relatively the center of the sample cylinder. The operation of the heating element was controlled by means of the thermocouple 5. Fixing of measurement results was carried out via the analag-to-digital converter 6 to the personal computer 7 on the virtual digital oscillograph.

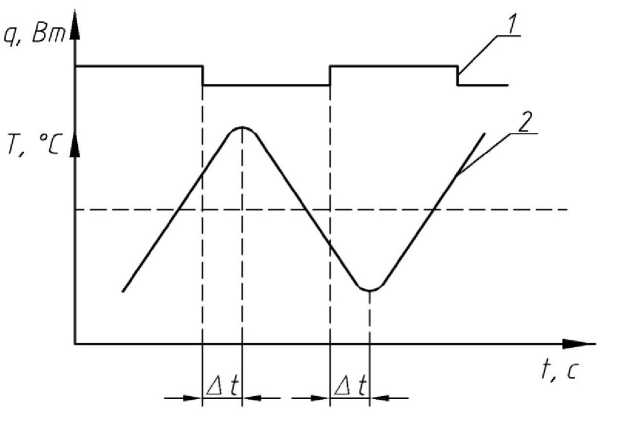

The measurements were carried out in intervals 20-60 ° С that is the operating temperature at AEP. The data received from three thermocouples were averaged to decrease a random error of measurement due to possible heterogeneity of a working environment structure. The graphs of change of the input electric power and temperature are provided on the oscillogram (fig. 4)

The thermal diffusivity coefficient of samples was calculated by formula:

a = 5 2 / ( A t - K ) -a , (7)

where 5 - the thickness of the studied sample, 0.01 m; A t - the time which passed between switching on (switching off) the power of the heater and the achievement of a maximum (minimum) temperature on the sample surface, c; K – the time constant of the measurement circuit defined on the model, 0.5 c: a - the dimensionless coefficient depending on the input power in our installation a = 8 - 10-4

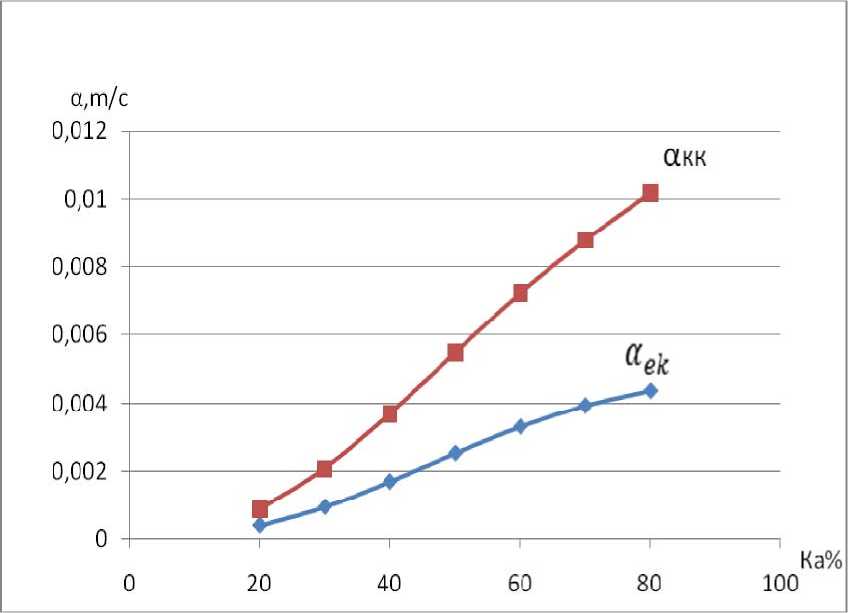

After the mathematical processing of experiments results by means of the AdvanceGrapher v. 2.11 the dependences of thermal diffusivity coefficients on the abrasive concentration have been received for alundum white:

a ek = -6.3 - 10—5 + 9.09 - 10—6Ка +

+ КМ-Ю^Ка2-6.75 - 10—9Ка3; (8)

for silicon carbide black:

а кк = 3,02 - КГ- 5.09 - 10—5Ка +

+ 1.3 - 10—6Ка2-2.94 - 10- 9 Ка3. (9)

The dependence of a thermal diffusivity coefficient of the working environment on the abrasive concentration is presented in fig. 5.

Fig. 3. Installation diagram for determining the coefficient of temperature and conductivity:

1 – heater; 2 – sample under test (working medium); 3 – cylinder; 4 – termocouple; 5 – control thermocouple; 6 – analog-to-digital converter; 7 – personal computer

Рис. 3. Схема установки для определения коэффициента температуропроводности:

1 – нагреватель; 2 – исследуемый образец (рабочая среда); 3 – цилиндр; 4 – термопары; 5 – контрольная термопара; 6 – аналагово-цифровой преобразователь; 7 – персональный компьютер

Fig. 4. Oscillograms of power and temperature:

1 – graph of changes in input power; 2 – graph of temperature changes on the free surface of the sample; ∆ t – measured time lag of the maximum (minimum) temperature, s

Рис. 4. Осциллограмма мощности и температуры:

1 – график изменения вводимой мощности; 2 – график изменения температуры на свободной поверхности образца; ∆ t – измеряемое временное запаздывание максимума (минимума) температуры, с

Fig. 5. Dependence of the thermal diffusivity of the working environment on the abrasive concentration

Рис. 5. Зависимость температуропроводности рабочей среды от концентрации абразива

Similarly to the thermal conductivity coefficient, the grain size (Ba) – the abrasive graininess in the range of 25–100 microns and T slave – the temperature of the working environment in the range of 20–60 оC were studied as the factors of variation for thermal diffusivity.

As a result of the experiments it has been established that thermal diffusivity insignificantly depends on the operating temperatures, the abrasive values and other factors not bound to the structure of the WE. In this connection, these factors were excluded from consideration.

Conclusion. The conducted research of thermal properties of the working environment have shown that the values of thermal conductivity and thermal diffusivity of the WE are generally defined by the concentration of abrasive grains in the working environment. The direct dependence of these coefficients on the degree of filling the working environment with abrasive grains has been established

Список литературы The research of thermophysical properties of the working environment for abrasive-extrusion processing

- Pshenko E. B., Narushevich D. A., Struzik E. S. [Study of the effect of processing temperature on the process of abrasive-extrusion honing]. Reshetnevskie chteniya: Materialy IX Mezhdunarodnoy nauchnoy konferentsii [Reshetnev Readings. Proceedings of the IXth International Scientific Conference]. Krasnoyarsk, SibSAU, 2005, P. 166–167 (In Russ.).

- Pshenko E. B. [Development of methods for determining the calorimetric properties of the working environment during abrasive-extrusion honing]. Reshetnevskie chteniya: Materialy IX Mezhdunarodnoy nauchnoy konferentsii [Reshetnev Readings: Proceedings of the XI International Scientific Conference]. Krasnoyarsk, SibSAU, 2007, P. 198–199 (In Russ.).

- Levko V. A., Lubnin M. A., Snetkov P. A., Pshenko E. B., Turilov D. M. Research the influence finishing canal shape to flow media for abrasive flow machining process. Vestnik SibGAU. 2009, No. 5 (26), P. 93–99 (In Russ.).

- Nonlinear Finite Element Analysis of Elastomers. Available at: http://www.mscsoftware.ru/products/marc (accessed: 10.09.2016).

- Snetkov P. A., Levko V. A., Pshenko E. B., Lubnin M. A. [Experimental determination factor to viscosity, elasticity and plasticity media for abrasive flowmachining process]. Vestnik SibGAU. 2009, No. 5 (26), P. 99–103 (In Russ.).

- Dulnev G. N., ZarichnyakYu. P. Teploprovodnost' smesey I kompozitsionnykh materialov [Thermal conductivity of mixtures and composite materials]. Leningrad, Energiya Publ., 1974, 230 p. (In Russ.).

- Mysnar A. Teploprovodnost' tverdykhtel, zhidkostey, gazoviikhkompozitsiy [Thermal conductivity of solids, liquids, gases and their compositions]. Moscow, Mir Publ., 1968, 221 p. (In Russ.).

- Chudnovsky A. F. Teplofizicheskie kharakteristiki dispersnykh materialov [Thermophysical characteristics of dispersed materials]. Moscow, Fizmatgiz Publ., 1962, 340 p. (In Russ.).

- Kirillov V. N., Efimov V. A., Donskoy A. A. [Thermal conductivity of the systems silicone-organic elastomer-powdered mineral filler]. IFZH. Vol. XXIII, No. 3, 1972, 400 p. (In Russ.).

- Mikheev V. A., Sulaberidze V. Sh., Mushenko V. D. [The study of thermal conductivity of composite materials based on silicone with fillers]. News of universities. Instrument making. 2015, Vol. 58, No. 7, P. 571–575 (In Russ.).

- Liang Fang, Jia Zhao, Kun Sun, Degang Zheng, Dexin Ma Temperature as sensitive monitor for efficiency of work in abrasive flow machining. Wear. 2009, Vol. 266, Iss. 7–8. P. 678–678.

- Uhlmann E., Schmiedel C., Wendler J. Simulation of the Abrasive Flow Machining. Process CFD (Computational fluid dynamics). Procedia CIRP. 2015, Vol. 31, P. 209–214. 15th CIRP Conference on Modelling of Machining Operations (15th CMMO).

- Levko V. A. Nauchnye osnovy abrazivnoekstruzionnoy obrabotki detaley [Scientific bases abrasive extrusion machining parts]. Krasnoyarsk, SibSAU Publ., 2015, 222 p.

- Sysoev S. K., Sysoev A. S. Ekstruzionnoe khoningovanie detaley letatel'nykh apparatov; teoriya, issledovaniya, praktika [Extrusion honing of aircraft parts; theory, research, practice]. Krasnoyarsk, SibSAU Publ., 2005, 220 p.

- Levko V. A. [Features of the rheology of the working environment for abrasive extrusion processing]. Vestnik SibGAU. 2005, No. 7, P. 96–100 (In Russ.).

- Levko V. A. [Abrasive extrusion processing. The modern level, problems and directions of development]. Izvestiya Tomskogo politekhnicheskogo universiteta. 2006, Vol. 309, No. 6, P. 125–129 (In Russ.).