The role of industrial production localization in the import substitution policy

Автор: Kotlyarova Svetlana Nikolaevna, Lavrikova Yuliya Georgievna, Averina Lidiya Mikhailovna

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Branch-wise economy

Статья в выпуске: 5 (53) т.10, 2017 года.

Бесплатный доступ

The article is devoted to defining the role of localization of industrial production in the implementation of the import substitution policy. The methodological framework of the research consists of the system approach, methods of structural, object, functional, and statistical analysis, as well as the method of expert estimations. The article reviews the concept of “import substitution” and “localization”; it is concluded that the implementation of the import substitution policy is inextricably linked with the localization. It provides examples of successful localization policy in individual industries (automotive, pharmaceutical and railway engineering), proves its effectiveness in creating high-tech industries for industrial output. The mechanism of localization in the railway engineering sector, whose competitiveness is currently provided largely by imported technology, is discussed in the case of locomotive engineering and rolling stock manufacturing for high-speed operation...

Import substitution, localization, regional policy, economic modernization, industrial production, technological development

Короткий адрес: https://sciup.org/147223973

IDR: 147223973 | УДК: 332.14 | DOI: 10.15838/esc.2017.5.53.8

Текст научной статьи The role of industrial production localization in the import substitution policy

Introduction. The government of the Russian Federation implements the modernization of domestic economy through the policy of import substitution. For effective application of tools and mechanisms of import substitution it is important to determine the priorities and understand which branches of industry require import substitution and what approaches need to be used to achieve the goals.

The highest share of imports now accounts for machine tool building, mechanical engineering and textile industry. In terms of import substitution it is advisable to refer to the experience of the localization policy which creates new jobs and industries on its own territory, and stimulates the development of knowledge-intensive industries turning domestic companies into strong competitors on the global level. Thus, the industrial policy should be aimed at developing of Russian products in order to replace imports (import substitution) and, as a consequence, increase the volume of domestic products (production localization). In this regard, the purpose for the study is to determine the role of localization of industrial production in the import substitution policy based on systematization of theoretical and methodological approaches to the definition of localization, to systematize localization experience in specific industries and study the legal framework for promoting import substitution in Russia and its regions.

Theoretical and methodological substantiation of the role of production localization

The category of “import substitution” has lately received increased attention from both public authorities and scholars. In particular, import substitution is regarded as a type of industrial policy aimed at replacing imported industrial goods with domestic ones [15]. Production of commodities similar to the imported ones and reduction or elimination in this context of their imports is a different approach to the definition of import substitution1. At the same time, these products should possess higher consumer properties, their price should be lower that of the imported ones [10]. V.V. Zaryankin formulates three alternative approaches to the definition of import substitution [8]. Import substitution may be regarded as: an economic category representing a system of economic relations aimed at substitution of the imported goods; an economic process where increased production, consumption and exports of domestic goods and services take place amid reduced consumption of similar imported goods and services; public economic policy on rationalization and optimization of the imports of goods and services by promoting local producers.

The key success factor for the implementation of the policy of import substitution is often export-oriented localization and not only focused on import substitution. The substitution must be a tool of economic policy whose result must be the support of the development of enterprises whose products are aimed for the domestic market, and further improvement of the export potential of companies to occupy a niche in the global production market [6, 19].

In Russia, the concept of “localization” began to be widely used in the early 2000-s along with the increasing interest of foreign investors to our market. Lack of serious competition on the part of domestic manufacturers, along with rapid economic growth and potentially large market made Russia attractive to international corporations, which resulted in the establishment of multinational industries [14].

There are various interpretations of the term “localization” in recent scientific publications. A.M. Vaz’yanskii and S.Y. Obydennova define localization of production as the process of producing original goods of foreign origin on the territory of another country [4]. According to A.N. Makarov, localization involves the supply to foreign companies of components produced on the national territory on the basis of previously existing industries by local producers [13].

A number of authors develop this approach with an emphasis on opportunities to reduce the prime cost by saving on transaction and transport costs, taxes and costs for the development of technological solutions [17]. I.D. Kotlyarov considers localization as a complex phenomenon representing the development by foreign companies of their own production capacity on the territory of the country. At the same time, domestic manufacturers are mastering a certain number of production stages of the final product (from one to a full cycle) [9]. Based on this interpretation of the term “localization” D. Kotlyarov distinguishes between the following forms: primary, secondary, and tertiary localization depending on the number of production stages, their technological complexity, market characteristics, etc. We agree with the author that the national economy need to focus on the third stage as it gives an opportunity to form our own global value chain and enter the global market with the final product ( Tab. 1 ).

According to V.K. Akinfiev, the term “production localization” means the process of transferring technologies to the territory of Russia, their adaptation and organization of assembly production of samples of foreign equipment with partial manufacturing of particular parts and components at Russian enterprises [2]. The degree of production localization characterizes the share of costs of Russian companies in the total production cost of equipment sample.

The concept of “localization” is inextricably linked with the concept of “production” used in economic geography. One may say that localization is a special case of location with a number of features. From our point of view, the essence of production localization lies in the supply by local manufacturers of parts and components manufactured within the country on the basis of previously existing or newly established industries to foreign companies. The framework conditions for localization are: availability of capital, availability of technology and production capacities, and availability of market. The main role of localization in import substitution in the region is modernization and creation of new industries in the country, increased production of imported

Table 1. Stages of localization and their content

Domestic experience of localization in particular industries

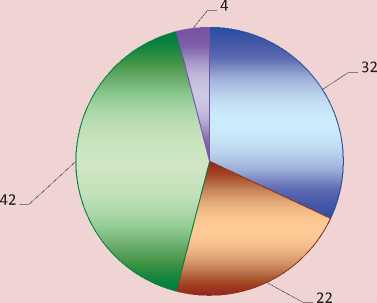

A successful example of the localization policy is the promotion of domestic goods in the automotive industry. Since the beginning of the 2000-s, Russia has imposed reduced customs duties on imported automotive products provided that the importer relocates part of its production to Russia. The producers were also supported through signing of investment contracts providing for certain obligations (e.g. an obligation to annually increase the share of local value added and production of a certain amount of goods), and the Russian Government, in turn, received a zero duty on imported components necessary for production. Such benefits are applied today in almost all spheres of the automotive industry (cars, trucks, car parts). The level of localization at motor plants ranges from 30% (Toyota) to 95% (Chevrolet (Niva)) [7]. The largest automotive clusters have formed in the Volga region, in the North-West and the center part of the country (Figure).

The pharmaceutical industry also demonstrates the growth of localization. The objective to increase by 2018 the share of vital domestic pharmaceuticals to 90% set by the President of the Russian Federation is almost complete: 76% of pharmaceuticals on this list are produced in the country. Moreover, an active process of clustering of the pharmaceutical industry is taking place. The total number of cluster projects is close to fifteen. The main characteristics of the pharmaceutical cluster are presented in Table 2 .

Distribution of automotive production by cluster, %

-

□ Northwestern cluster

-

□ Central cluster

-

□ Volga cluster

-

□ other

Table 2. Pharmaceutical clusters in Russia

|

Cluster |

Russian constituent entity |

Year of establishment |

Number of participants |

Included/Non included in the list of pilot territorial innovative clusters |

|

Pharmaceutics, biotechnology and biomedicine |

Kaluga Oblast |

2012 |

> 50 |

Included |

|

Altai biopharmaceutical cluster |

Altai Krai |

2008 |

> 10 |

Included |

|

Tomsk Oblast cluster of pharmaceutics, medical equipment and information technology |

Tomsk Oblast |

2013 |

> 50 |

Included |

|

Innovative cluster of information and biopharmaceutical technology of the Novosibirsk Oblast |

Novosibirsk Oblast |

2013 |

> 60 |

Included |

|

Pushchino biotechnological innovation territorial cluster |

Moscow Oblast |

2012 |

> 70 |

Included |

|

Saint Petersburg cluster of medical, pharmaceutical industry and radiotechnology |

Leningrad Oblast |

2011 |

> 10 |

Included |

|

Ural biomedical cluster |

Sverdlovsk Oblast |

2010 |

> 40 |

Not included |

The policy of localization has proven effective in creating high-tech industries in manufacturing products of railway engineering . Consumers of railway equipment place demands on its quality and performance parameters. The demand for locomotives, wheeled containers, units and components of outdated design will weaken; therefore, among mechanical engineering companies only those will survive who provide their consumers with modern products. The most obvious way of obtaining the necessary technology is the search for strategic partners, technology transfer and subsequent localization [5].

Let us consider the mechanism of localization in the case of certain sectors of the Russian railway industry whose competitiveness is currently largely ensured by foreign technology: this is locomotive engineering and rolling stock for high-speed rail. In recent years in Russia there appeared a number of new series of traction rolling stock: locomotives, electric locomotives and electric trains whose production is mastered in the framework of joint ventures with foreign manufacturers (Transmashholding CJSC and a French company Alstom Transport, Sinara Group JSC and a German company Siemens).

Sinara Group JSC unites enterprises of different sectoral focus. One of priority business directions of the company is mechanical engineering. The engineering holding of Sinara-Transport machines JSC includes Ural locomotives JSC whose key activity is production of freight DC and AC locomotives, electric trains “Lastochka”. The manufacturing is based on Siemens technology with gradual localization of production.

The first project of the company in electric locomotive engineering was the manufacturing of electric locomotives with asynchronous traction engine “Granit” (series 2es1). In 2015, the level of its localization reached 80%. More recent developments of the company include TMH-EP20 and 2ES5 locomotives: their level of production localization in 2015 reached 55 % and 45 % respectively. It is planned to achieve the 80% level of local production for EP20 in 2017, and for 2ES5 – by 2020.

The most important direction of enterprise’s activity is manufacturing of Desiro RUS highspeed trains (“Lastochka”) launched in May 2013. The contract with Russian Railways JSC provides for strict conditions of localization of component production. The level of localization from the launching of production was expected to reach 55%, and by 2017 – 80%. By 2014, around Ural Locomotives have formed a cluster of more than 100 Russian suppliers of parts and components capable of operating according to international standards, adapting technology to customer needs and Russian conditions; the degree of localization reached 62%. In 2016, the level of localization of production of “Lastochka” was more than 70%, it is expected that in 2017, the localization will reach the target level of 80%2.

At this enterprise, the first and the second form of localization became the stages of transition to tertiary localization. The complexity of tertiary localization explains the situation with components. Increased importance of components is determined by industry-specific features of railway engineering, i.e., its technological complexity and significant metal consumption3. At the same time, according to strategic documents of transport engineering development, there is no serial production of components in the country; without it, it is impossible to create technology corresponding to international standards. The share of foreign components in most manufactured types of machinery and equipment is 10–25%, in some cases – up to 80% of production costs. To create a modern production enterprises of transport engineering are forced to buy components of foreign production. Russia does not possess technology for serial production of components.

Given the existing experience, the main direction of the industry development in the near and medium term is production of modern rolling stock, including fast and high-speed rail traffic, in the required volume using foreign experience, taking into account Russian conditions and localization of the third type.

The activity of the Ural cluster of railway engineering is an example of successful implementation of the catching-up import substitution policy: with the use of foreign technology in order to establish in Russia assembly and then localized production of foreign technology on the basis of domestic materials, components, and resources (labor, raw materials and energy) [17]. The strategic goal of import substitution in sectors of railway engineering is to create new types of products which would provide Russia’s technological equality along with advanced countries in transport development, and active influence on the world market of technology and knowledgeintensive products.

Thus, localization stimulates the emergence of Russian producers of final products with new technology and imposes requirements applicable to providers at different levels. Producers of the final product focus producers of materials, logistics, service and financial institutions and thus form clusters [13].

Study of the legal framework in promotion of import substitution in Russia and its regions

Analysis of domestic experience of import substitution suggests that in Russian constituent entities, producers of import-substituting goods are supported in various ways: favorable environment (legal, administrative, financial, etc.), various regional preferences, formation and development of related infrastructure; promotion of local producers on the Russian market, assistance in cooperation with federal authorities, etc.

However, the emergence of individual programs of import substitution in a number of regions, large departments, companies and enterprises is more political in nature; regional and sectoral programs of import substitution often become inconsistent and contradict each other. The result is more severe restrictions than those specified in applicable federal regulations, or the expanding range of goods and services falling under restrictions [1].

The study of the regulatory framework in promoting import substitution in Russia and its regions indicates that the introduction of import substitution measures is observed. A condition for success in this direction is the development of appropriate legal acts, including programs of import substitution at both federal and regional level [16]. Most regions adopted plans to ensure sustainable economic development and social stability, plans to promote import substitution (action plans) ( Tab. 3 ).

Table 3. Legal acts of Russian constituent entities regulating the processes of import substitution

|

RF constituent entity |

Legal act |

Localization |

|

1 |

2 |

3 |

|

Programs |

||

|

Astrakhan Oblast |

Import substitution program of the Astrakhan Oblast for 2015–2017 1) |

Yes |

|

Vladimir Oblast |

State program “Development of industry in the Vladimir Oblast, raising its competitiveness and ensuring import substitution for 2015–2020”2) Sub-program “Development of intra-oblast and inter-regional cooperation, promotion of import substitution”. |

No |

|

Penza Oblast |

Import substitution and expansion of production release program of the Penza Oblast for 2015–20173) |

No |

|

Sverdlovsk Oblast |

State program “Development of industry and science in the Sverdlovsk Oblast up to 2020”4) Sub-program “Development of import substitution and production cooperation in industries in the Sverdlovsk Oblast” |

No |

|

Chelyabinsk Oblast |

State program “Development of import substitution and production cooperation in industries in the Chelyabinsk Oblast for 2015–2020” |

No |

|

Chuvash Republic |

Program of the Chuvash Republic “Economic development and innovation economy for 2012–2020”5) Sub-program “Development of import substitution in specific economic sectors of the Chuvash Republic” |

Yes |

End of the Table 3

Concepts Volgograd Oblast Concept of import substitution in the Volgograd Oblast for 2015–2017 and plan of measures for promoting import substitution in the Volgograd Oblast for 2015–20176) No Saratov Oblast Concept of import substitution in the real economic sector of the Saratov Oblast No Plans Altai Krai Action plan to promote import substitution in Altai Krai up to 20207) Yes Republic of Bashkortostan Action plan to promote import substitution in the Republic of Bashkortostan for 2015–20178) Yes Belgorod Oblast Action plan to promote import substitution in the Belgorod Oblast for 2016–2018 Yes Voronezh Oblast Plan to promote import substitution in industry in the Voronezh oblast, 2017 Yes Irkutsk Oblast Plan to promote import substitution for 2016–2018. Establishment of regional expert council on import substitution (2016 ) No Kursk Oblast Regional plan on import substitution in the Kursk Oblast for 2016–20209) No Saratov Oblast Plan to promote import substitution in the real economic sector of the Saratov Oblast for 2015–201610) No Republic of Tatarstan Action plan to develop import substitution in the industry of the Republic of Bashkortostan for 2016 Concept of import substitution in construction for 2015–2016 in the Republic of Tatarstan11) Yes Vologda Oblast Regional plan on import substitution in the Vologda Oblast for 2016–202012) Yes 1) Order of the Government of the Astrakhan Oblast No. 52-P “On the Import substitution program of the Astrakhan Oblast for 2015–2017”, dated 04.03.2015. Electronic periodical directory “Sistema GARANT”. Available at: (accessed: 23.08.2016). 2) Decree of the Vladimir Oblast Administration No. 562 “On the approval of the state program of the Vladimir Oblast “Development of industry in the Vladimir Oblast, raising its competitiveness and ensuring import substitution for 2015–2020””, dated 16.06.2015. Electronic periodical directory “Sistema GARANT”. Available at: (accessed: 20.08.2016). 3) Resolution of the Government of the Penza Oblast No. 179-PP “On the approval of the program of import substitution and expansion of production in the Penza region for the years 2015-2017”, dated 09.04.2015. Electronic periodical directory “Sistema GARANT”. Available at: (accessed: 23.02.2017). 4) Resolution of the Government of the Sverdlovsk Oblast No. 1293-PP “On the approval of the state program of the Sverdlovsk Oblast “Development of industry and science in the Sverdlovsk Oblast up to 2020””, dated 24.10.2013. Ministry of Industry and Science of the Sverdlovsk Oblast. Available at: 5) Resolution of the Cabinet of Ministers of the Chuvash Republic No. 398 “On the state program of the Chuvash Republic “Economic development and innovation economy for 2012–2020””, dated 21.09.2011 6) Resolution of the Volgograd Oblast Administration No. 527-p “On the approval of the Concept of import substitution in the Volgograd Oblast for 2015–2017 and plan of measures for promoting import substitution in the Volgograd Oblast for 2015–2017”, dated 14.09.2015. Electronic periodical directory “Sistema GARANT”. Available at: (accessed: 23.08.2016). 7) Resolution of Altai Krai Administration No.187-p “On the approval of the Action plan to promote import substitution in Altai Krai up to 20207”, dated 30.06.2016. AO “Kodeks”. Available at: (accessed: 23.09.2016). 8) Order of the Government of the Republic of Bashkortostan No. 838-p “On the approval of the Action plan to promote import substitution in the Republic of Bashkortostan for 2015–2017”, dated 07.08.2015. AO “Kodeks”. Available at: 9) Resolution of the Kursk Oblast Administration No. 654-PA “On the approval of the Regional plan on import substitution in the Kursk Oblast for 2016–20209”, dated 06.09.2016. Electronic periodical directory “Sistema GARANT”. Available at: (accessed: 23.08.2016). 10) Resolution of the Government of the Saratov Oblast No. 5-P “On the approval of the Concept of import substitution in the real sector of economy of the Saratov Oblast and plan for the promotion of import substitution in the real sector of economy of the Saratov Oblast for 2015–2016”, dated 20.01.2015. Official website of the Government of the Saratov Oblast. Available at: aspx?61154 (accessed: 22.08.2016) 11) Decision of the Cabinet of Ministers of the Republic of Tatarstan No. 639 “On the Action plan to develop import substitution in the industry of the Republic of Bashkortostan for 2016”, dated 13.09.2016 Electronic periodical directory “Sistema GARANT”. Available at: http://www. (accessed: 20.11.2016). 12) Resolution of the Government of the Vologda Oblast No. 858 “On the approval of the Regional plan on import substitution in the Vologda Oblast for 2016–2020”, dated 29.09.2016. Portal of the economic development of the Vologda Oblast. Available at: http:// http://economy. (accessed: 23.02.2017).

Table 4. Main organizational forms of localization

Analysis of the legal framework in the sphere of promoting import substitution at the national and regional levels has shown that regions are actively involved in the development of regulations encouraging the development of import substitution, they implement measures on import substitution. However, the issues of localization of industrial production are not fully covered in the documents. Inconsistent and sometimes contradictory regulations are also noted.

The industrial policy should be aimed at developing production of Russian goods, which should replace imported goods (import substitution) and, as a consequence, increase the volume of domestic production (production localization).

For Russia import substitution on the basis of localization of industrial production is a platform for economic diversification, the end of the era of oil and gas dependence, and the transition to production of high-value-added technology-intensive products. Increasing the number of operating enterprises located in the country provides opportunities for economic growth, attracting new technology, and creating jobs.

Список литературы The role of industrial production localization in the import substitution policy

- Akimov A. Obespechenie importozameshcheniya cherez lokalizatsiyu proizvodstva produktsii, rabot, uslug . Ofits. sait Ministerstva promyshlennosti i torgovli Rossiiskoi Federatsii . Available at: http://minpromtorg.gov.ru/common/upload/files/docs/M.E.Akim.pdf..

- Akinfiev V.K. Vybor investitsionnykh reshenii pri transfere zapadnykh tekhnologii v otrasli transportnogo mashinostroeniya . Upravlenie bol'shimi sistemami , 2014, issue 48, pp. 151-171..

- Borodkina V.V., Ryzhkova O.V., Ulas Yu.V., Ushalova A.A. Issledovanie Programm razvitiya importozameshcheniya v regionakh Rossiiskoi Federatsii . Kreativnaya ekonomika , 2015, no. 9(11), pp. 1397-1414..

- Vaz'yanskii A.M., Obydennova S.B. Lokalizatsiya proizvodstva kak sposob innovatsionnogo razvitiya predpriyatiya . Sbornik nauchnykh trudov NGTU im. R.E. Alekseeva , 2014, no. 7, p. 2..

- Vorob'ev A.A., Obukhova E.A. Lokalizatsiya. Napravlenie zadano. Chto dal'she? . Tekhnika zheleznykh dorog , 2009, no. 4 (8), November, pp. 35-45..

- Gulin K.A., Mazilov E.A., Ermolov A.P. Importozameshchenie kak instrument aktivizatsii sotsial'no-ekonomicheskogo razvitiya territorii . Problemy razvitiya territorii , 2015, no. 3 (77), pp. 7-25..

- Zaitsev A. Nazvany lidery po lokalizatsii sredi vypuskayushchikhsya v Rossii avtomobilei . Informatsionnyi sait Wroom.ru . Available at: http://wroom.ru/news/3670 (Accessed: 13.02.2017)..

- Zaryankin V.V. Rol' importozameshcheniya v sisteme mezhdunarodnykh torgovykh otnoshenii . Belarus' i mirovye ekonomicheskie protsessy: sb. nauch. st. , issue 7. Minsk: BGU, 2010. Pp. 44-50..

- Kotlyarov I.D. Lokalizatsiya proizvodstva kak instrument importozameshcheniya . EKO , 2016, no. 8, pp. 128-140..

- Lavrikova Yu.G., Kotlyarova S.N. Innovatsionnoe razvitie stroitel'nogo kompleksa regiona na osnove klasternogo podkhoda . Ekonomicheskie i sotsial'nye peremeny: fakty, tendentsii, prognoz , 2014, no. 3 (33), pp. 169-181..

- Lavrikova Yu.G., Averina L.M. Strategicheskie osnovy realizatsii potentsiala importozameshcheniya na primere zheleznodorozhnogo mashinostroeniya . Ekonomicheskie i sotsial'nye peremeny: fakty, tendentsii, prognoz , 2015, no. 3 (39), pp. 85-99..

- Luk'yanchuk E. Importozameshchenie: zarubezhnyi opyt . Apteka. online.ua: elektron. nauchn. Zhurn , 2011, no. 786 (15), 18 April. Available at: http://www.apteka.ua/article/79186 (Accessed: 13.01.2017)..

- Makarov A.N. Lokalizatsiya proizvodstva produktsii proizvodstvenno-tekhnicheskogo naznacheniya na territorii regiona kak tendentsiya importozameshcheniya . Gumanitarnye i sotsial'nye nauki , 2011, no. 3, pp. 34-41..

- Mukhanov A.N. Kon"yunkturnye faktory importozameshcheniya v obosnovaniyakh napravlenii i organizatsionno-strukturnykh skhem lokalizatsii proizvodstva . Molodoi uchenyi , 2016, no. 3, pp. 581-585..

- Raizberg B., Lozovskii L., Starodubtseva E. Sovremennyi ekonomicheskii slovar' . Moscow: INFRA-M, 2006. 495 p..

- Fal'tsman V.K. Kriticheskie tochki politiki importozameshcheniya . Rossiiskoe predprinimatel'stvo , 2015, vol. 16, no. 2 (272), pp. 241-262..

- Shuvalova D.G., Markova V.Yu. Otsenka izmeneniya ekonomicheskogo potentsiala integratsii s primeneniem strategii lokalizatsii proizvodstva na regional'nom urovne . Elektronnyi nauchnyi zhurnal "Upravlenie ekonomicheskimi sistemami" , 2013, no. 10 (58), p. 61..

- Bruton H.J. A Reconsideration of Import Substitution. Journal of Economic Literature, 1998, vol. 36, no. 2, pp. 903-936.

- Cook S.A., Watson Ph. Comparison of Regional Export Enhancement and Import Substitution Economic Development Strategies. The Journal of Regional Analysis and Policy, 2011, vol. 41, no. 1, pp. 1-15.