The strength and deformability of cement stone and powder-activated concrete. Part I

Автор: Erofeeva I.V., Maksimova I.N., Svetlov D.A., Bakushev S.V., Shein A.I., Tarakanov O.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. During the operation of buildings and structures, reinforced concrete structures are subject to various loads that can cause deformation and destruction. The strength and elastic-plastic properties, as well as the durability of modern concrete, are controlled using superplasticizers, nanoadditives, fillers, and aggregates. The potential of using nanohydrosilicate technologies is demonstrated. This article examines the physical and mechanical properties of cement stone and powder-activated concrete – one type of next-generation concrete. Materials and methods. The influence of the water/cement ratio, the presence of a carboxylate superplasticizer, and a modifying additive were considered as structure-forming factors for cement stone, and the influence of the water/cement ratio, modifying additive, superplasticizer, finely dispersed filler, rheological fillers and reactive fillers were considered for concrete. Results. The article presents the results of a study establishing the relationship between the density of cement stone and powder-activated concrete with the porosity and strength indicators under static and dynamic loads. The rational compositions of the developed composites are characterized by a set of improved physical and mechanical properties. It was found that an increase in the W/C ratio from 0.267 to 0.35 causes a decrease in the compressive and tensile strength of cement stone when splitting by 22–30%. The addition of the superplasticizer ”Melflux 1641F“ led to a significant decrease in the water-cement ratio – from 1.56 times compared to the composition of normal consistency and by 2.04 times – compared to the composition with an increased W/C ratio, as well as a corresponding increase in compressive strength properties – by 1.20 times and 1.72 times – in flexural tensile strength. Conclusion. It was found that the introduction of finely dispersed fillers into the composition of sand concrete led to an increase in compressive, flexural, and tensile strength when splitting by 1.62 to 2.55 times, which is explained by a denser packing of quartz filler, causing an increase in the density of such samples by 9.5%, the plasticizing effect of microquartz, and the high activity of microsilica. The impact strength of the cement composite was studied. It was found that plasticized highly filled compositions of the new generation demonstrated high values of the maximum contact force, contact duration, and impulse magnitude. The composite containing microquartz, quartz filler, fine aggregate, and Melflux 1641F superplasticizer has a maximum contact force of 4.530 N, compared to a similar value of 2.073 N for a cement stone composition made from normal consistency paste. Moreover, the contact duration and impact impulse magnitude are approximately twice as high. The addition of microsilica to the highly filled compositions caused even better results. The maximum contact force at which the samples failed was 4.530 N. This is more than twice that of cement paste based on normal consistency.

Cement stone, concrete, powder-activated concrete, structure-forming factors, physical and mechanical properties of concrete, porosity, compressive and tensile strength, dynamic strength

Короткий адрес: https://sciup.org/142246071

IDR: 142246071 | DOI: 10.15828/2075-8545-2025-17-5-500-517

Текст научной статьи The strength and deformability of cement stone and powder-activated concrete. Part I

Review article

Ерофеева И.В., Максимова И.Н., Светлов Д.А., Бакушев С.В., Шеин А.И., Тараканов О.В. Прочность и деформативность цементного камня и порошково-активированных бетонов. Часть I. Нанотехнологии в строительстве. 2025; 17(5):500–517. – EDN: LICSRG.

Concrete is a complex, heterogeneous, multi-layered artificial composite material with a sharply disrupted mass continuity and internal structural stress, with the simultaneous presence of solid, liquid, and gaseous phases. Traditional concrete is produced by the hardening of a concrete mixture composed of a binder, water, various additives, and fine and coarse aggregates. During its life cycle, the material undergoes (simultaneously) various stages: formation, hydration, and hydrolysis, a long period of hardening, aging, and degradation due to interaction with the external environment.

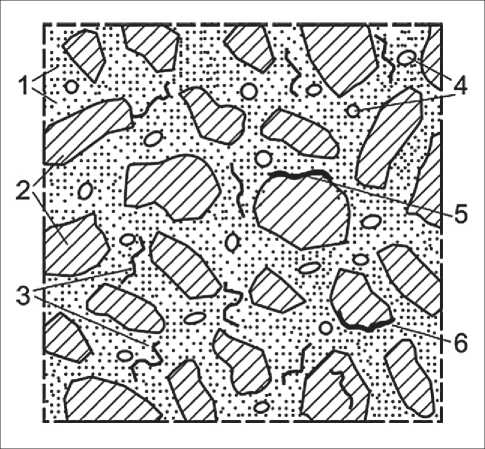

Concrete has a complex internal structure [1] (Fig. 1).

The general structure of concrete is divided into nano-, submicro-, micro-, meso-, and macrostructures [2, 3, 4, 5, 6, 7]. At each scale level, the composite is represented by two generalized components: the matrix and the filler. That is, each structural level consists of a capillary-porous deformable matrix, which includes larger grains of filler (aggregate). Several important elements in the structure of concrete are distinguished (Fig. 1), which are associated with such properties as creep, shrinkage, and swelling [1, 7, 8]:

– in the macrostructure – the contact zone around the grains of coarse aggregate and defects in the structure of concrete (structural cracks in the matrix and at the boundary of the grains of the aggregate, large pores

Fig. 1. Concrete structure and its characteristic elements [1]: 1 – matrix; 2 – aggregates; 3 – structural cracks in the matrix and at the boundaries of aggregate grains; 4 – large pores and capillaries; 5 – voids above coarse aggregate grains; 6 – loosened pore structure of cement stone beneath individual coarse aggregate grains

and capillaries, voids above the grains of coarse aggregate, the loosened pore structure of the cement stone under individual grains of coarse aggregate);

– in a mesostructure that has similar components and defects, only on a smaller scale;

– the microstructure is characterized by microcracks that is formed due to defects in the crystalline structure of the material. This part also includes micropores smaller than 5×10–3 µm, which, like the space between layers, are usually filled with water, as well as particles of microsilica, fly ash, and other fillers. Coagulation contacts with their properties are maintained in the gel for a long time.

– the ability to recover, high mobility due to the liquid layer. The number of coagulation contacts decreases over time, but remains significant. When exposed to external energy, a structural restructuring may occur, with the appearance of defects and a decrease in resistance to external influences [9];

– the nanostructure is described at the level of 10–6 mm (10–3 µm) [5]. Cement gel makes up about 75% of the volume of cement stone and consists of colloidal-sized particles. The gel part refers to a weakly crystallized solid phase (submicrocrystals) with a predominantly layered structure and consisting primarily of calcium hydrosilicates (CSH), between which intermolecular Van der Waals adhesion forces act through thin water layers, i.e., the particles of the solid phase in the gel are linked by reversible coagulation contacts. Cement stone based on a cement binder consists of unhydrated cement grains, pores between them, and capillary voids with trapped gaseous and residual (after hardening) liquid phases [7, 8]. The pores have a random shape and are often close to defects in the form of pointed holes, which are described by a submicrostructure with pores characterized by a size of 10–4 mm and a characteristic element size of 5×10–4 mm.

The physical and mechanical properties of high-quality concrete are largely determined by its microstructure [10], which is quite complex. It is formed from cement (or composite binder), superplasticizers and other modifying additives, nanoparticles, and finely dispersed fillers [5, 7, 8].

The concept of mesostructure is commonly applied to the matrix of conventional concrete, where the fine aggregate is most often particles 1.25–5 mm in size, and the matrix is hardened cement stone [3, 6].

The macrostructure includes large aggregates and a matrix in the form of a cement-sand mortar. In this model, the matrix is considered a volumetrically continuous component, while the aggregates are considered a discrete component [1, 2].

Recent advances in concrete technology have led to the development of a new generation of materials known

CONSTRUCTION MATERIAL SCIENCE as reactive powder concretes (RPCs). RPCs are ultra-high-performance concretes (UHPCs) that provide both ultra-high strength and remarkable ductility through microstructural enhancement techniques [11, 12]. UHPCs are defined with a minimum specified strength of 120 MPa [11]. However, according to ACI Committee 239, the minimum specified strength of these concretes is even higher, at 150 MPa [12].

The strength properties and durability of concrete are increased by introducing pozzolanic additives [13], nanoparticles [14], modifying water-soluble polymers [15, 16, 17], superplasticizers [18, 19, 20], introduced into concrete as part of composite binders or directly into the compositions of the prepared concrete mixtures.

It is known that the potential of Portland cement and its varieties, estimated by the compressive strength of cement stone within the range of 150–200 MPa, is realized in practice at a level of no more than 50%. New technical solutions for increasing the strength of cement materials are possible and based on a deeper understanding of the patterns of the relationship between the structure and properties of cement stone. Structure formation during hydration hardening of mineral binders and concretes based on them is a process of development of a polydisperse polymineral system, which is based on the evolution of the geometric structure caused by an increase in hydrate mass in relation to the volume of the original binder. With regard to Portland cement and its modifications, the nature of a significant, more than twofold increase in volume in this process is due to the chemical binding of water, the porosity of the formed highly dispersed hydration products, and their lower density in relation to the original binder material [21].

Composite binders developed in recent years, which include microfillers and plasticizing additives in addition to cement, form low-basicity calcium hydrosilicates and other compounds after hardening [22]. The solid phase of the cement stone can be divided into gel and crystalline parts. Ultrafine microsilica, for example, is used as nanoparticles, and fly ash, which is coarser than microsilica, and other materials, are used as fillers [9, 23]. In most cases, fly ash contains an increased amount of free lime and a significant volume of unburned residues. Therefore, fly ash is recommended for the production of concrete with special properties.

Various superplasticizers serve as plasticizing additives [24, 25, 26]. The expansion of the production and use of new superplasticizers with diverse chemical bases, developed in recent decades, is currently considered one of the main areas of technical progress in concrete technology. The action of new generation plasticizers should consist not only of high rheological activity, but also of minimal impact on the hydration activity of cements in the initial hardening phase [27]. The effectiveness of superplasticizers in dispersed systems can be increased by

varying the procedure for their introduction or by combining them with finely ground mineral fillers of various chemical natures.

The superplasticizers contained in cement composites, in combination with fillers, help to reduce the water content and calcium hydroxide, improve the microplastic properties of the crystalline structure, reduce the grain and pore sizes of the cement gel and distribute them more evenly in microvolumes, etc. [24, 28]. As a result of the introduction of the superplasticizer and filler, the fracture toughness, crack resistance and strength of the material as a whole ultimately increase.

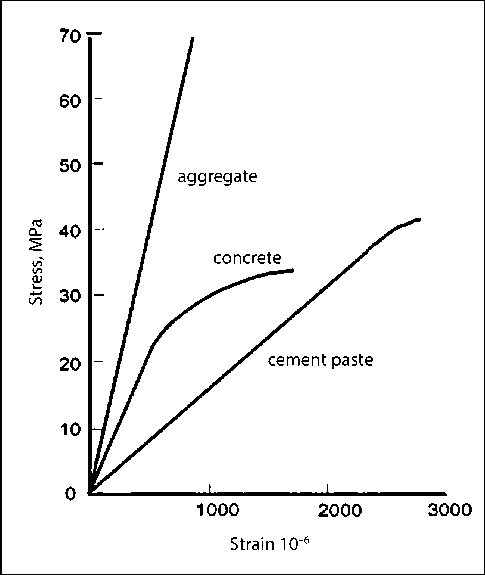

Various empirical relationships are used to predict the physical and mechanical properties of high-strength concrete [29, 30]. The mechanical properties and durability of concrete depend on the intensity of the bond between the aggregate and the matrix, where microcracks can occur, which then propagate to the matrix itself [31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41]. The critical role of the matrix is evident when comparing the stress-strain curves for cement paste, aggregate, and concrete under compressive loading, as can be seen in Fig. 2.

To characterize the pore space when describing the relationship between porosity and strength and other properties of cement stone (CS) and cement concrete, integral structural parameters are usually used, and in particular, such CS structural parameters as total (Pt) and capillary porosity (Pc) [21].

Fig. 2. Graph comparison of stress-strain diagrams for cement stone, aggregate and concrete [36]

CONSTRUCTION MATERIAL SCIENCE

From theoretical assumptions it follows that the relationship between the strength of CS and capillary and total porosity is differentiated depending on the W/C ratio [40].

The dependences presented in Table 1 reflect the actually observed intensive nature of the increase in strength with a decrease in porosity. This is due to the fact that with an increase in porosity, the greatest stress on the pore contour increases faster than the decrease in the effective cross-sectional area [41].

Cement paste and aggregate exhibit distinct elasticity and brittle behavior. Concrete, on the other hand, exhibits plasticity, which can be explained by the development of cracks in the interfacial zone.

It was noted above that each structure can have its own defects – process and strength. In the macrostructure (see Fig. 1), significant defects arise in the form of cavities at the boundary between the coarse aggregate and the matrix. As a result of the sedimentation effect, cavities can be located predominantly beneath the aggregate grains, leading to different concrete properties along and perpendicular to the concreting layers [1].

The authors experimentally demonstrated the superiority of powder-activated concrete in terms of crack

resistance. These studies are presented in Part 2 of this article.

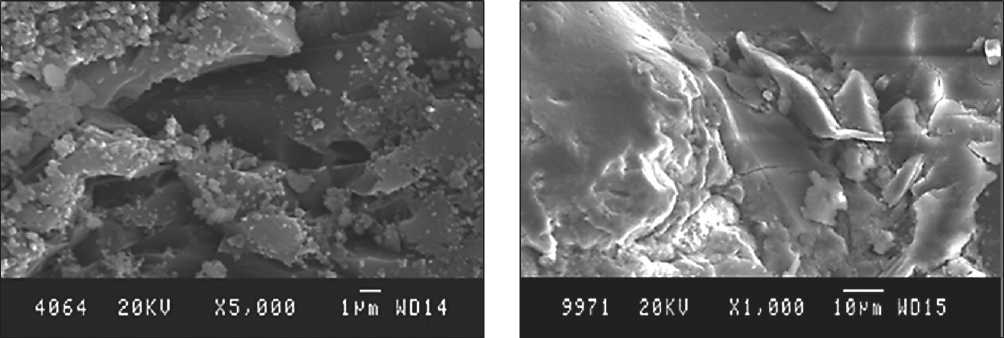

One of the most important factors improving the structure of concrete is the removal of coarse aggregates and their replacement with quartz sand, which promotes an increase in the bond strength of the components within the concrete structure. This improves homogeneity [45, 46] and the efficiency of particle packing, while reducing the mechanical effects of microstructural heterogeneity, minimizing internal material defects such as pore space and microcracks [30, 47, 48, 49, 50]. The low cement content of RPC contributes to a significant reduction of porosity (Fig. 3).

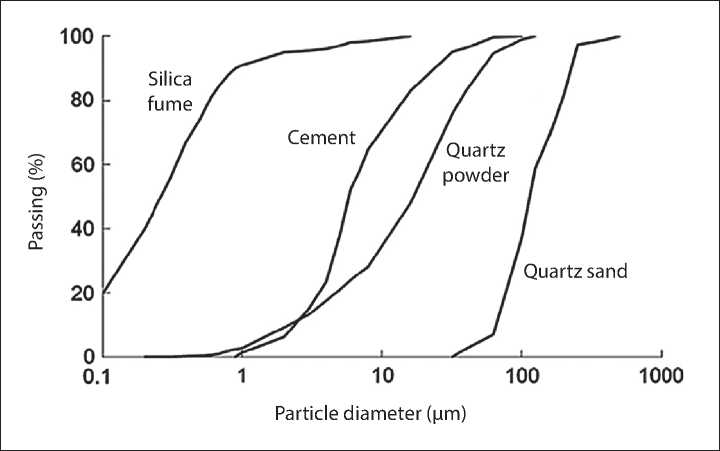

The addition of smaller particles promotes a compact microstructure without obvious pores. Also, the removal of coarse aggregate changes some properties, such as the autogenous shrinkage age, at which the shrinkage value of UHPC containing coarse aggregates is approximately 60% of the experimental RPC [51]. An optimal grain size distribution curve will facilitate the production of materials with the most favorable packing (Fig. 4).

The work [53] demonstrates the efficiency of using nanohydrosilicate technologies. In this case, a combina-

Fig. 3. Microstructure of RPC showing porosity in the contact zone [47]

Table 1. Theoretical assessment of the dependence of strength on porosity

|

Formulae |

Source link |

|

R = R0 ( 1 – P)S , R = R0VS , where R0 is the strength of the dense (non-porous) phase; s is a power-law index reflecting the intensive ( s > 1) nature of the increase in strength R with a decrease in porosity P or with an increase in the relative volume concentration of the solid phase (relative density) V = 1 – P |

[42] |

|

R = R0e–b P , where R0 is the strength of the non-porous material; e is the base of the natural logarithm; b is a constant |

[43] |

|

R = R0 ([ 1 – (P / Pcr)S] , where Pcr is the so-called critical porosity, corresponding to zero strength |

[44] |

CONSTRUCTION MATERIAL SCIENCE

Fig. 4. Grain size distribution curves for RPC components [52]: Passing; Silica fume; Quartz powder; Quartz sand; Particle diameter (µm)

tion of nanosiliceous technologies with nanohydrosilicate technologies in concrete production is promising. They together determine, on the one hand, the reaction of Ca(OH)2 with SiO2, and on the other, the crystallization of hydrosilicates formed in solution on the same substrates [54, 55, 56]. Nanotechnologies are rational because they correspond to the basic principles of the theory of hydrosilicate hardening of lime-siliceous mixtures [53].

To bind 10–20% of the precipitated portlandite, it is necessary to add at least 12–25% of amorphous nanometric microsilica to the concrete in order to obtain 20–40% calcium hydrosilicates with a basicity close to 1. The effect of the calcium hydrosilicate additive begins to become noticeable between 6–10 hours after the mixture is prepared [53]. After 6 hours, the strength exceeds the control strength by 32 times, after 8 hours – by 10.6 times, and after 10 hours – by 4.3 times. After 24 hours of hardening and subsequently, the strength indicators gradually equalize. It is important that after 9–10 hours, it is possible to strip the forms and ensure curing of the products at a temperature of about 20 °C without heat and humidity treatment. In the study [55], with a content of 3.5% C–S–H additive, the strength of concrete equal to 15 MPa was achieved after 8 hours. The first results indicate that a combination of rheologically active micrometer-sized fillers, such as ground rocks, very fine sands, superplasticizers and nanoparticles of amorphous silica, and nanoparticles of calcium hydrosilicates, can bring concrete micronanotechnology to a new, more promising stage of steam-free and low-steam production.

A promising direction in next-generation concrete technology is the use of finely ground quartz sand instead of the scarce microsilica [56, 57]. However, it should be

noted that the surface of quartz under normal conditions is always hydroxylated. Siloxane bonds are present on the surface of finely ground quartz. Upon contact with water, siloxane groups with double bonds become unstable and attach to water molecules, forming silanol groups. In an aqueous environment, silanol groups dissociate with the elimination of an H+ ion, resulting in the formation of dissociated silanol groups on the quartz surface, creating a negative charge that prevents the adsorption of negatively charged SP and GP molecules. Thus, ground sands are virtually unaffected by SP and GP. The situation changes when some cement is added to quartz sand, and the cement-sand mixture effectively liquefies under the influence of plasticizers. This phenomenon has not been fully studied. However, it is most likely that the surface charge of the quartz changes, which is the cause of the liquefying effect.

To date, the behavior of concrete under static loading has been studied to a greater extent. However, many types of concrete elements and reinforced concrete structures are operated under dynamic loads [58, 59, 60, 61]. In this regard, it is important to establish the dynamic strength of powder-activated concrete [62].

From the above it follows that conducting research into the technology of obtaining and establishing the properties of cement stone and powder-activated concrete is of considerable interest.

PURPOSE AND OBJECTIVES OF THE RESEARCH

The aim of the study is to investigate the porosity, static and dynamic strength of cement stone and powder-activated concrete.

CONSTRUCTION MATERIAL SCIENCE

Research objectives:

-

1. To compile an analytical review of the work of domestic and international authors in the field of studying the physical and mechanical properties of cement stone and powder-activated concrete.

-

2. To study the influence of key structure-forming factors on the main physical and mechanical properties of cement stone and powder-activated concrete by separate and combined introduction of superplasticizer, dispersed additives, biocidal preparations, and fillers of various size levels.

-

3. To justify the compositions of cement matrices for new generation concretes for conducting research: 1) cement, ground filler, plasticizer, water (matrix of the first kind); 2) cement, ground filler, fine filler of fraction 0.1–0.5 or 0.16–0.63 mm, plasticizer, water (matrix of the second kind); 3) matrix of the first kind or matrix of the second kind, including fine filler of fraction 1.0–5.0 or 0.63–5.0 mm (matrix of the third kind).

-

4. When studying cement stone, the influence of the W/C ratio, modifying additive and superplasticizer should be considered as structure-forming factors, and when studying powder-activated concrete, along with the above factors, the influence of finely dispersed filler, rheological and reactive fillers should be considered.

-

5. Conduct research on the porosity, static and dynamic strength of cement stone and powder-activated concrete.

-

6. Conduct an analysis of the obtained results for materials with a separate structure-forming factor, as well as for powder-activated concrete as a whole.

MATERIALS AND METHODS

The binder used was pure cement produced by Uly-anovskcement LLC. The properties, chemical composition, and mineralogical composition of the cement used are presented in Tables 2 and 3.

The Melflux series carboxylate superplasticizer, Melflux 1641F, was used as a plasticizing additive. It is based on polycarboxylate esters (manufactured by De-gussa Construction Polymers, SKW Trostberg, Germany). These graft copolymers are structurally distinct in that dispersion (deflocculation, agglomerate breakdown, and plasticization) occurs via the electrosteric principle.

The superplasticizer characteristics are presented in Table 2.

The rheologically active dispersed filler was stone flour, using microquartz from the Lipetsk Mining and Processing Plant (LMPP). The microquartz characteristics are presented in Table 3.

Microsilica was used as a reactive-chemical pozzo-lanic additive, the characteristics of which are presented in Table 4.

Fine-grained fillers and aggregate sand were used from the Smolnensky quarry in the Ichalkovsky district of the Republic of Mordovia and the Khramtsovsky quarry in the Ivanovo region. The physicochemical characteristics of the fillers and the grain size distribution of the sands are presented in Tables 5–8.

For the studies, the basic compositions given in Table 9 and the compositions indicated below, modified with biocidal and finely dispersed additives, were selected.

Table 2. Characteristics of the superplasticizer “Melflux 1641F”

|

Characteristics |

Melflux 1641F |

|

External appearance, colour |

Powder, color from yellowish to brown |

|

Loss on drying, % by weight |

max 2.0 |

|

Bulk density, kg/m 3 |

400–600 |

|

Reaction – pH 20% solution t = 20 °C |

6.5–8.5 |

|

Recommended dosage in relation to the mass of the binder, % |

0.05–1.0 |

Table 3. Microquartz characteristics

|

Lipetsk sand (molding) |

||||

|

Sieve sizes, mm |

Residue on sieves, g |

Partial residuals , % |

Total residuals, % |

Size module |

|

5 |

0 |

0 |

0 |

|

|

2.5 |

0 |

0 |

0 |

|

|

1.25 |

0 |

0 |

0 |

|

|

0.63 |

5 |

0.25 |

0.25 |

1.02 |

|

0.315 |

205 |

10.25 |

10.5 |

|

|

0.16 |

1620 |

81.0 |

91.5 |

|

|

less than 0.16 |

155 |

7.75 |

102 |

|

CONSTRUCTION MATERIAL SCIENCE

Table 4. Characteristics of Lipetsk microsilica

|

Name of materials |

SiO2 content, % |

Colour |

Ρtr, kg/m 3 |

p . bulk , kg/m 3 |

S, spec kg/m 3 |

|

|

total |

including amorphous |

|||||

|

Lipetsk MK-65 powder |

70 |

60–65 |

Dark Grey |

2.3 |

178 |

6000 |

Table 5. Characteristics of sand from the Ichalkovsky quarry of the Republic of Mordovia

|

Item No. |

Characteristic |

Units of measurement |

Indicator |

|

1 |

Sand class |

– |

1 |

|

2 |

Fineness modulus |

– |

1.7 |

|

3 |

Bulk density |

g/sm 3 |

1.35 |

|

4 |

Content of dust and clay particles |

% |

2.0 |

|

5 |

Clay content in lumps |

% |

0.2 |

|

6 |

Filtration coefficient |

m/day |

3 |

Table 6. Characteristics of sand from the Khramtsovsky quarry in the Ivanovo region

|

Item No. |

Name of indicators |

Requirements of GOST (State Standard) 8736-2014 |

Actual indicators |

|

1 |

Fineness modulus |

2.5–3.0 |

2.76 |

|

2 |

Content of dust and clay particles, % |

No more than 2.0 |

1.0 |

|

3 |

Clay content in lumps, % |

No more than 0.25 |

Absent |

|

4 |

Bulk density, kg/m 3 |

1 580 |

|

|

5 |

Content of harmful components and impurities: SO3, % amorphous SiO2, mmol/L |

0–1.0 0–50 |

0.37 28.83 |

|

6 |

Specific effective activity of natural radionuclides in sand, Bq/kg |

Up to 370–1 st sort. |

39 |

Table 7. Characteristics of the grain size composition of quartz sand from the Ichalkovsky quarry of the Republic of Mordovia

|

Residuals |

Residue on sieves, %, with size of mesh, mm |

|||||

|

2.5 |

1.25 |

0.63 |

0.315 |

0.16 |

pallet |

|

|

Partial |

0.28 |

1.11 |

6.44 |

32.16 |

47.34 |

12.67 |

|

Total |

0.28 |

1.39 |

7.83 |

39.99 |

87.33 |

100 |

Table 8. Characteristics of the grain size distribution of quartz sand from the Khramtsovsky quarry in the Ivanovo region

|

Residuals |

Residue on sieves, %, with size of mesh, mm |

|||||

|

2.5 |

1.25 |

0.63 |

0.315 |

0.16 |

pallet |

|

|

Partial |

9.63 |

8.89 |

34.35 |

35.37 |

9.94 |

1.82 |

|

Total |

9.63 |

18.52 |

52.87 |

88.24 |

98.18 |

100 |

CONSTRUCTION MATERIAL SCIENCE

Modified compositions were obtained on the basis of composition No. 1 (Table 9), to which the following additives were added:

– composition No. T17 with the biocide “Teflex Antimold”;

– composition No. T19 with the biocide “Teflex Antimold” and the hyperplasticizer Melflux;

– compositions No. 3-B and 9-B with additives of white and black soot, respectively.

When studying impact strength, it was important to establish the influence on the properties of, in addition to the foreign superplasticizer Melflux, the domestic superplasticizers FortraceTM Strong (composition No. 7) and Hidetal 9γ (composition No. 8).

Cement paste-based samples were prepared manually. The components were weighed before mixing. The cement, superplasticizer, and modifiers were weighed using an electronic scale with an accuracy of 0.01 g. When preparing the mixtures, a solution of dry superplasticizer in water was first prepared. This solution was then added to the cement. For mixtures containing superplasticizer, the amount of water was adjusted to ensure a paste of normal consistency.

Concrete mixtures were prepared using a mixer or gravity-fed concrete mixer. Bulk concrete ingredients, specifically Portland cement, aggregates, and fillers, dosed by weight, were sequentially added to the mixer along with mixing water and a plasticizer. The mixture was thoroughly mixed until a self-compacting, homogeneous mass was obtained, poured into standard molds, and compacted on a laboratory vibrating platform.

Samples measuring 4×4×16 cm were made in metal molds, which were pre-lubricated with paraffin. The samples were cured using heat and humidity treatment after being cured for 24 hours in a bath with a water seal.

The studies of cement stone were carried out in accordance with the following GOSTs (State Standards): methods for determining normal density, setting time and uniformity of volume change of cement – according

to GOST (State Standard) 310.3–76; methods for determining the fineness of grinding by sieve residue and by specific surface – according to GOST (State Standard) 30744–2001; method for determining water separation of cement – according to GOST(State Standard) 310.6–85; method for determining the strength of cement – according to GOST (State Standard) 30744–2001.

Porosity was determined using a Micromeritics Autopore IV instrument. The internal pore surface area was determined using the Bruner-Emmett-Teller (BET) method using an ASAAP-2000 instrument from the same company. Mercury porosimetry was used. Pore volume V was determined on the basis of maximum adsorption capacity of a substance completely filling all pores, assuming the density of the substance in the pores is equal to that of a normal liquid.

The strength of cement paste and powder-activated concrete was determined by testing 4×4×16 cm specimens in accordance with GOST 10180–2012, “Concrete. Methods for Determining Strength Using Control Specimens”. The specimens were subjected to bending tests as beams on two supports, with a single force applied at midspan. Compressive strength was determined on halves of beam specimens with a cross-sectional area of 25 cm2 using a specially designed fixture that applied the load through pressure plates. To determine the splitting strength of the specimens, a fixture was used that secured them in a predetermined position and loaded their faces with prisms located on the upper and lower plates of the loading device. The average rate of load increase was 50 N/s. The deviation of the instrument in measuring the load was no more than 1 %.

Compressive strength was determined using the formula:

R = αFKw /A , (1)

where α = 0.85 – is the scale factor; Kw = 1.0 – is the correction factor; A – is the cross-sectional area, m2.

Table 9. Basic compounds of the compositions for the preparation of samples

|

Components |

Content of components, mass. h, for the composition |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

Ulyanovsk cement PC 500 D0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Water |

0.267 |

0.35 |

0.171 |

0.6 |

0.475 |

0.525 |

|

GP «Melflux 1641F» |

– |

– |

0.009 |

0.009 |

0.009 |

0.009 |

|

Lipetsk microsilica |

– |

– |

– |

– |

0.1 |

– |

|

Microquartz |

– |

– |

– |

1.1 |

0.75 |

– |

|

Quartz sand fraction 0–0.63 mm |

– |

– |

– |

2.753 |

1.775 |

2.065 |

|

Quartz sand of fraction 0.63–2.5 mm |

– |

– |

– |

2.347 |

1.975 |

1.76 |

CONSTRUCTION MATERIAL SCIENCE

The calculation of the bending strength was carried out and based on the results of testing at least five parallel samples and was calculated using the formula

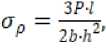

where P – is the bending load, N; b – is the specimen width, mm; h – is the specimen height, mm; l is the base, mm.

The splitting tensile strength was calculated using the formula

a uniform impact energy (normalized by specimen thickness). The impact tester was equipped with the necessary instrumentation to record the force and energy versus time and displacement during impact with the specimen, either continuously or at specified intervals. A minimum of 100 points were used for each test.

The following were recorded in the test protocol: indentation depth, damage zone dimensions and area, F1, F max , E 1 , E max .

Impact energy Ei , J, was calculated using the formula

Е.: = CE-h,

R рр = γ2 FKw /(π А ),

where γ and Kw – are the scale factors adopted in accordance with GOST (State Standart) 10180‒2012 in this study as 0,85 and 1,0, respectively; F is the breaking force, N.

The modulus of elasticity was calculated using the formula

where P – is the destructive load, N; l0 – is the initial length of the sample, mm; ∆l – is the value of absolute longitudinal deformation.

Drop-weight impact tests were conducted on specimens to determine their resistance to damage. The dropweight impact tests were performed using Method A, based on ASTMD7136 (Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event). This method involves subjecting specimens to

where CE = 6.7 – is the coefficient of normalization of the impact energy by the thickness of the sample, J/mm; h – is the thickness of the sample, mm.

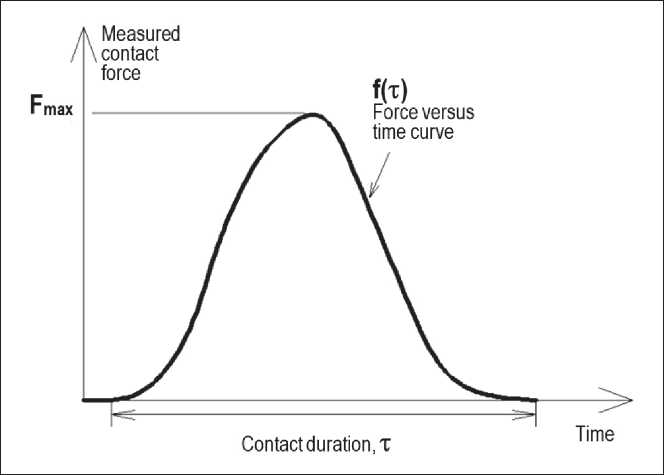

A typical curve of contact force – time dependency is shown in Figure 5.

From the contact force – time dependency, force F1 and maximum force Fmax were determined. From the energy – time dependency curve, energy E1 (at force F1) and absorbed energy Emax (at force Fmax) were determined.

The duration of contact tт is determined using any of the relationships. The integral sum of the changing magnitude of the impactor force over the contact time with the specimens is a characteristic of the impactor impulse.

EXPERIMENTAL RESULTS AND THEIR ANALYSIS

This section presents the results of a study of the porosity, static, and impact strength of cement paste and powder-activated concrete samples.

Fig. 5. Typical curve of the striker force – time dependency

CONSTRUCTION MATERIAL SCIENCE

Porosity and pore surface area were determined using the Bruner-Emmett-Teller (BET) method using the ASAAP 2000 system from Micromeritics. The method is described above. The studied compositions (see their formulas in Table 9) and the results of the studies are presented in Table 10.

A comparison of porosity values for various cementitious composite compositions demonstrates the following. For compositions No. 1–No. 3, which differ in the amount of mixing water and the presence of superplasticizer, this confirms the well-known principle that increasing the water content in mixtures increases porosity, while adding a plasticizer decreases it. Furthermore, the internal pore surface area changes according to a similar relationship. Thus, a 31% increase in the W/C ratio compared to a normal-consistency paste increases the porosity of the cement stone by 15%, while bringing the cement paste to normal consistency (with a superplasticizer content of 0.09%) with a W/C ratio of 0.171 decreases it by 25.8%.

Changing the amount of fine filler in sand mixtures also significantly affects porosity. For example, a comparison of compositions No. 4 and No. 5 shows that the porosity of the highly filled material decreases by 20.1%, but the internal pore surface area is lower in composition No. 4.

The addition of microquartz increases the porosity of cementitious composites. This is evident when comparing compositions No. 4 and No. 6. While the porosity of No. 4 is 11.2362%, that of No. 6 is 9.7886%. The internal pore surface area is also slightly higher in the sample of composition No. 4. The combined addition of microquartz and microsilica helps to reduce porosity.

The addition of the Teflex Anti-Mold additive also helps to reduce porosity. A comparison of formulations No. 1 and No. T17 shows that the porosity of the cement stone with the biocidal additive is lower. Increasing the

water content in the formulations with the biocidal additive increased both porosity and the internal pore surface area. The Melflux polycarboxylate superplasticizer also works effectively with the Teflex Anti-Mold biocidal additive. Their combined use further reduced porosity (formulation No. T19). The internal pore surface area is larger in all cases than in the control.

The addition of micrometer-sized filler leads to significant porosity in cement stone. For example, the inclusion of white and black carbon in equal quantities (30 parts by weight per 100 parts by weight of Portland cement) increased this figure to 39.5702% and 37.4560%, respectively. The water-cement ratio of the mixtures reached 1.21 and 1.17. The control mixture (paste with normal consistency) had a water-cement ratio of 0.25.

Tables 11 and 12 present the results of studies to determine the influence of the water-cement ratio and superplasticizer on the strength of cement stone, as well as the water-cement ratio, superplasticizer and fine fillers on the strength of powder-activated concrete.

Two types of cement stone were studied, the compositions of which differed in water-cement ratio: composition No. 1 with W/C of 0.267 and composition No. 2 with W/C of 0.350.

As can be seen from the data in Table 11, an increase in the water-cement ratio resulted in a decrease in compressive strength by 30%, tensile strength by 22%, and flexural strength by 58%. A significant change in flexural strength compared to other characteristics occurs due to the testing of specimens with induced cracks, which explains the increased sensitivity of cement stone to changes in the water-cement ratio.

Next, the effect of the Melflux 1641F superplasticizer (consumption of 0.009 of the cement mass) on the physical and mechanical properties of cement stone made from self-compacting cement slurry at a reduced water-cement

Table 10. Research results [62]

|

Composition number |

Inner pore surface, m 2 /g |

Porosity, % |

|

1 |

5.0298 |

16.710 0 |

|

2 |

11.3416 |

19.1841 |

|

3 |

2.9122 |

12.5173 |

|

4 |

3.6008 |

11.2362 |

|

5 |

5.9816 |

8.9887 |

|

6 |

3.5615 |

9.7886 |

|

T9 |

6.4964 |

10.7968 |

|

T17 |

5.1297 |

12.2809 |

|

T19 |

6.8942 |

12.0931 |

|

3B |

32.1824 |

39.5702 |

|

9B |

25.9365 |

40.5065 |

CONSTRUCTION MATERIAL SCIENCE ratio of 0.171 (composition No. 3) was assessed. Comparative results of the strength tests of the cement stone are presented in Table 12, from which it follows that the use of the superplasticizer led to a significant decrease in the water-cement ratio – by 1.56 times compared to composition No. 1 and by 2.04 times compared to composition No. 2, as well as a corresponding increase in strength properties: compressive strength – by 1.20 and 1.72 times and tensile strength during splitting – by 1.66 and 2.13 times. A more significant change is observed for the flexural strength, which increases by 2.91 times compared to composition No. 2, which correlates with the previously established effect of the water-cement ratio.

The effect of finely dispersed quartz – microquartz (composition No. 4) or a mixture of microquartz and microsilica (composition No. 5) – on the properties of sand concrete was studied by comparison with control composition No. 6, which did not contain finely dispersed quartz. All tested compositions, in addition to cement and water, used Melflux 1641F superplasticizer and two-fraction quartz sand. To ensure uniform flow of the cement-sand mortar, the water-cement ratio of the control composition was 14% lower than that of composition No. 4 based on microquartz and 9.5% higher than that of composition No. 5 based on a mixture of microquartz and microsilica. The latter is explained by the plasticizing effect of microquartz. From the data in Table 12, it follows that the use of finely dispersed quartz in sand concrete compositions leads to an increase in strength properties from 1.62 to 2.55 times, which is explained by an increase in the packing density of the quartz

filler and is confirmed by a 9.5% increase in the density of such samples. At the same time, a 1.3% decrease in the density of composition No. 5 relative to composition No. 4 not only did not reduce the strength properties, but also led to their increase: compressive strength – by 9.1%, flexural strength – by 20.6%, and tensile strength when splitting – even by 57.7%. This is explained by the use of quartz filler – microsilica with a more active surface than microquartz, which, as is known, affects an increase in Rtb and especially Rbb .

Impact resistance testing of composites was performed using a drop weight tester according to ASTMD7136 using a Coesfeld vertical impact tester. The test procedure is described above. According to this procedure, the onset of impact contact between the impactor and the specimen is determined when the contact force deviates from zero. As soon as the impactor touches the specimen’s surface, it bends it, causing a localized indentation, resulting in an increase in the contact force. Sharp jumps in contact force are explained by fracture processes that lead to a sudden loss of specimen rigidity in the contact zone. The maximum force, Fmax , is determined from the time dependence of the contact force, which is used to determine the contact duration, τ .

The physical and mechanical properties obtained from impact resistance testing of building materials made it possible to determine the qualitative characteristics of the elastic-viscoplastic state of composite materials, changing over a short period of time [62]. The stress-strain state of the materials during testing in this case was estimated by the maximum contact force as the value of the ultimate

Table 11. Effect of superplasticizer “Melflux 1641F” on the strength of cement stone

|

Composition number |

Tensile strength |

|||||

|

compressive |

flexural |

tensile strength when splitting |

||||

|

R , MPa |

Rel. unit |

Rtb , MPa |

Rel. unit |

R , MPa bb |

Rel. unit |

|

|

1 |

56.4 |

1.00 |

8.70 |

100 |

3.26 |

100 |

|

2 |

39.2 |

0.70 |

3.68 |

42 |

2.55 |

78 |

|

3 |

67.5 |

1.20/1.72 |

10.71 |

1.23/2.91 |

5.42 |

1.66/2.13 |

Note: above the line – indicators relative to composition No. 1, below the line – composition No. 2

Table 12. Effect of finely dispersed quartz on the strength of sand concrete samples

|

Composition number |

r |

Tensile strength |

|||||

|

compressive |

flexural |

tensile strength when splitting |

|||||

|

R , MPa |

Rel. unit |

Rtb , MPa |

Rel. unit |

R , MPa bb |

Rel. unit |

||

|

4 |

2300 |

103 |

2.06 |

9.84 |

1.63 |

4.33 |

1.62 |

|

5 |

2270 |

110.5 |

2.25 |

11.87 |

1.97 |

6.83 |

2.55 |

|

6 |

2100 |

50 |

1.00 |

6.02 |

1.00 |

2.68 |

1.00 |

CONSTRUCTION MATERIAL SCIENCE stress state at failure of the composites. The duration of contact between the striker and the specimens was related to the elastic-viscoplastic state of the material. The integral total amount of the changing magnitude of the striker force from the time of contact with the specimens, which depends on the structural characteristics of the material during testing (dissipation, relaxation, deformation), is a characteristic of the striker impulse. The calculated value of the force impulse correlates with the impact strength indicator, which is estimated by the impact energy. The test results are shown in Figs. 6–8 [62].

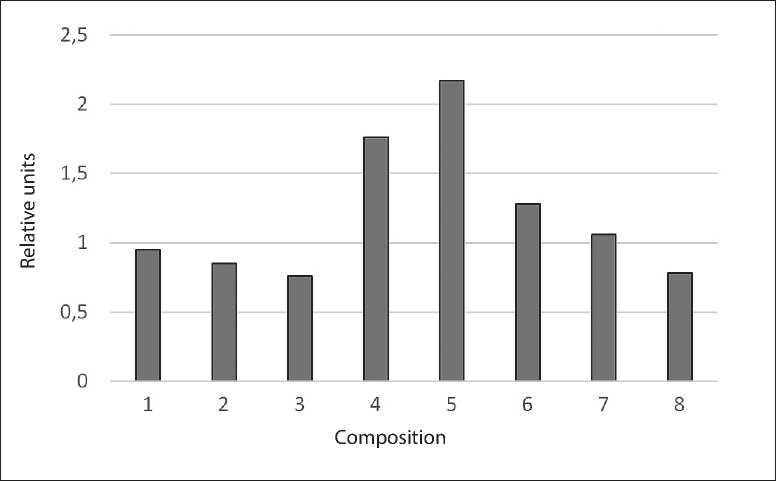

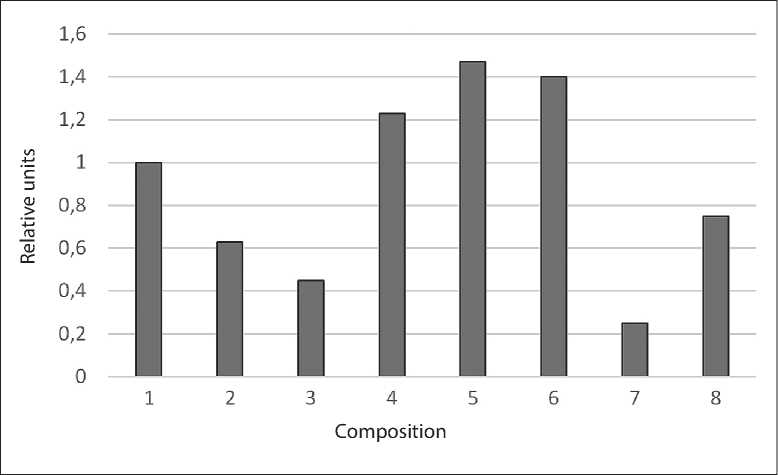

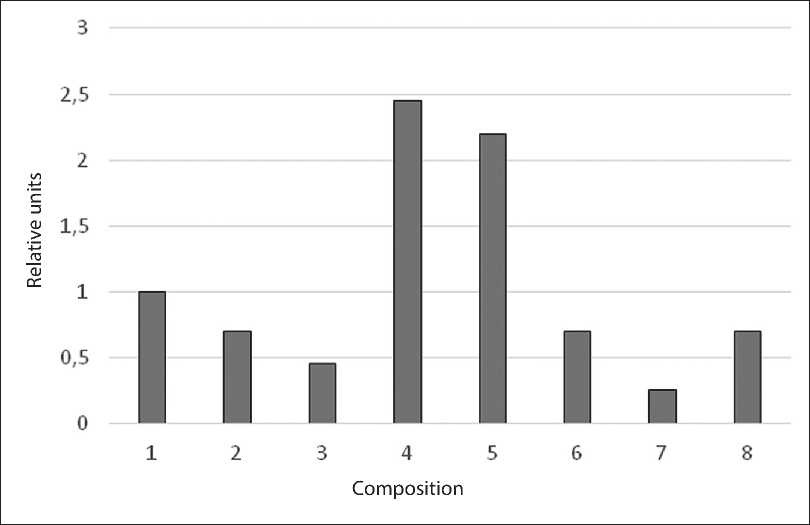

An analysis of the results of studies of samples of different groups was carried out in relative values in relation to composition No. 1. (For this composition, the maximum contact force is 1.866 N, the contact duration is 0.13 ms, and the magnitude of the force impulse is 81.1 N·ms).

A comparison of test results reveals the following. For samples made from normal-density test, the maximum contact force is lower than for samples with a higher wa-ter/cement ratio (composition No. 2) and significantly higher than for the composition with a plasticizer (com-

Fig. 6. Maximum contact force when testing cement composites

Fig. 7. Duration of contact of cement composite samples with the impactor during testing

CONSTRUCTION MATERIAL SCIENCE

Fig. 8. The magnitude of the impact impulse of cement composite samples during testing

position No. 3). It’s clear that porosity plays a role in this case. Denser materials exhibited lower contact forces. Moreover, the contact time with the impactor and the magnitude of its impulse are also higher for samples made from normal-density test than for compositions with a higher water content and with the addition of a plasticizer.

A highly filled composition containing the Melflux 1641F plasticizer demonstrated superior performance compared to a composite plasticized with the Hidetal 9γ additive (compositions No. 4 and No. 8). Meanwhile, when testing cement stone, superior results were obtained for composites containing the Fortrace™ Strong plasticizer (compositions No. 4 and No. 7).

The introduction of sand fillers into cementitious composites resulted in a 33.8% increase in maximum contact force compared to the control composition. From this perspective, compositions containing finely dispersed fillers are of particular interest. In our studies, microquartz and microsilica were used as fillers.

High values of maximum contact force, impact contact duration, and impact impulse were demonstrated by new-generation plasticized, highly filled composites No. 4 and No. 5. The composite, which includes microquartz, quartz filler, and fine aggregate, as well as the Melflux 1641F hyperplasticizer, exhibits higher maximum contact force and contact duration compared to composites No. 6 and No. 7, resulting in higher material rigidity and strength. Conversely, older-generation concretes (compositions No. 6 and No. 7) exhibit shorter contact duration and shorter impact impulses compared to new-generation and transitional-generation concretes (No. 5 and No. 4, respectively). This is due to the fact that the modification of the matrix structure of new-generation concretes by filling them with rheologically active dispersed powders and binding portlandite with microsilica ensures energy dissipation within the material due to the many times greater deformation and fracture energy compared to conventional concrete. For comparison, the maximum contact force for composition No. 4 is 3.808 N, which is 84% higher than that of cement stone made from normalthickness paste (2.073 N). Moreover, the contact duration and impact impulse values are approximately twice as high. Even better results were achieved by introducing microsilica into highly filled compositions (composition No. 5). The maximum contact force at which the samples failed was 4.530 N, more than twice as high as that of cement stone made from normal-thickness paste.

CONCLUSION

-

1. A review of scientific and technical literature by domestic and foreign authors in the field of research into the physical and mechanical properties of cement stone and powder-activated concrete has been compiled.

-

2. The influence of formulation factors (W/C ratio, modifying additive, superplasticizer, fine filler, rheological and reactive fillers) on the strength properties of cement stone and powder-activated concrete is described.

-

3. The porosity of the composites was determined. A comparison of compositions differing in the quantitative content of mixing water, the presence of superplasticizer,

-

4. It was found that increasing the water-cement ratio from 0.267 to 0.350 leads to a 22–30% decrease in compressive strength. The use of Melflux 1641F superplasticizer contributed to a significant decrease in the water-cement ratio – by 1.56 times compared to the composition based on normal-density dough and by 2.04 times compared to the composition with increased water content. This resulted in a corresponding increase in strength properties: compressive strength – by 1.20 and 1.72 times; and splitting tensile strength – by 1.66 and 2.0 times.

-

5. The introduction of finely dispersed fillers into the composition of sand concrete led to an increase in compressive strength, flexural strength, and tensile strength when splitting from 1.62 to 2.55 times, which is

-

6. The impact strength of cement composites was studied depending on the main structure-forming factors: high values of the maximum contact force, the duration of contact of the sample with the striker, and the magnitude of its impulse were demonstrated by plasticized highly filled compositions of the new generation No. 4 and No. 5. The composite containing microquartz, quartz filler, and fine aggregate, as well as the hyperplasticizer “Melflux 1641F”, demonstrated higher values of the maximum contact force – 3.808 N, compared to the composition of cement stone made from normal consistency dough – 2.073 N. Moreover, the contact duration and the magnitude of the striker impulse were approximately twice as high. The introduction of microsilica into the highly filled compositions led to even higher results. The maximum contact force at which the specimens failed was 4.530 N. This is more than twice as high as that of cement stone based on paste of normal consistency.

CONSTRUCTION MATERIAL SCIENCE and fillers shows that a 31% increase in the W/C ratio compared to a normal-thickness paste increases the porosity of the cement stone by 15%. Bringing the cement paste to a normal consistency with a W/C of 0.171 using a superplasticizer reduces its porosity by 25.8%. The addition of microquartz, microsilica, and a biocidal additive also reduces porosity, while the inclusion of white and black carbon increases it.

explained by a denser packing of the quartz filler, causing an increase in the density of such samples by 9.5%, the plasticizing effect of microquartz, and the high activity of microsilica.

To be continued.