The supramolecular impact mechanism of polycarboxylate superplasticizers on controlled hardening construction of nanocomposites

Автор: Khalikov R.M., Ivanova O.V., Korotkova L.N., Sinitsin D.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: System resolutions to technological problems

Статья в выпуске: 5 Vol.12, 2020 года.

Бесплатный доступ

Introduction. The use of modifying nano-additives in the production of binding building materials is one of the most effective ways to control the technological parameters of concrete by conducting good control of the rheological characteristics reliability. Plasticizing additives increase the water-holding capacity of building compositions, which leads to the dispersed nanosystems stability. This article is focused on examining the physical and chemical mechanisms of the supramolecular effects of polycarboxylate ethers on technological and rheological characteristics of cement nanobinders. Methods and materials. This study describes controlled hardening processes of concrete nanocompositions with demanded technological characteristics in the presence of highly effective plasticizers. Moreover, this paper carries out the analysis of the innovative trends in regulating the consistency of building nanocomposites with the use of new comb-like polycarboxylate esters, which as superplasticizers allow to purposefully influence the kinetics of structure formation of cement nanocomposites. Results. Electrostatic and steric repulsion mechanisms, as well as the dispersing effects of innovative and traditional plasticizing nanoparticles, affect the adsorption and diffusion layers of the hydrated cement nanobinders ultrastructure. The most effective plasticizing properties are shown by comb-like polycarboxylate esters (CPE) with a linear chain molecular weight of ≈12000 g/mol and a length of side branches which correspond to a molecular weight of ≈750 g/mol. The supramolecular mechanism of nanosteric van der Waals repulsive forces begins to be detected at a distance of ≈11 nm, and the elasticity of the lateral branches of innovative CPE is ≈ 5 nm. Individual segments of CPE macromolecules enter the diffuse layer of dispersed nanosystems due to lateral interactions of anions of functional groups, hydrophobic fragments, etc.; they enhance the plasticizing effect of cement binders in concrete nanocompositions. Discussion. When using superplasticizing CPE, the density of concrete nanocomposites can be increased by reducing the amount of water mass to the cement mass ratio to the optimal 0.3; at the same time, technological pumpability and reliability control of the joint hardening kinetics with fillers are preserved within the framework of the technological problems system solutionsconcept. Supramolecular interaction of «anchoring» functional groups of polyacrylic acid containing solid phase cations of cement microparticles, fractal clusters of calcium hydrosilicates and simultaneous steric stabilization of polyethylene glycol radicals give the necessary rheological characteristics to construction nanocompositions and allow the construction of high-strength 55÷80 MPa building materials. Conclusions. The branched comb-like nanostructure of polycarboxylate esters exhibits effective technological characteristics of superplasticizers for concrete, building mortars and dry building mixes.

Cement nanobinders, superplasticizers, polycarboxylates, reliability management, concrete structure formation

Короткий адрес: https://sciup.org/142226956

IDR: 142226956 | DOI: 10.15828/2075-8545-2020-12-5-250-255

Текст научной статьи The supramolecular impact mechanism of polycarboxylate superplasticizers on controlled hardening construction of nanocomposites

The use of modifying nano-additives in the production of binding building materials is one of the most effective ways to control the technological parameters of concrete by conducting good control of the rheo- logical characteristics reability. Plasticizing additives increase the water-holding capacity of building compositions, which leads to the dispersed nanosystems stability. In the production of self-compacting concrete, high-performance superplasticizers are used, which are based on comb-like polycarboxylate ethers (CPE) system

SYSTEM RESOLUTIONS TO TECHNOLOGICAL PROBLEMS hardening that can significantly increase the technological saving time of concrete nanocomposites and strength of building structures by 1,5–2 times [1, 2].

This article is focused on examining the physical and chemical mechanisms of the supramolecular effects of polycarboxylate ethers on technological and rheological characteristics of cement nanobinders.

METHODS AND MATERIALS

Currently, traditional plasticizers based on lignosulfonates and sulfated melamine and naphthalene formaldehyde polymers are used to reduce energy consumption and labor intensity in the production of concrete mixtures. The inclusion of conventional plasticizers in the concrete mix allows toincrease mobility and workability while maintaining the necessary rheological characteristics, i.e., to reduce the consumption volume of the mixing water. Electrostatic and steric mechanisms of repulsion, as well as dispersing effects (water reduction, reduction of hydration time, etc.) of nanoplasticizing additives affect the adsorption and diffusion layers of cement nanobinders. However, the plasticizing effect of using traditional nano-additives is limited in time due to rapid adsorption of cement microparticles, surface screening and reduced hydration processes, and as a result, their dispersing efficiency decreases.

Therefore, the component composition of lignosulfonate, synthetic melamine- and naphthalene-formal-dehyde macromolecular traditional plasticizers are mixed with regulators of technological parameters: setting inhibitors, in particular, to preserve the rheology (viscosity, thixotropy) of modified concrete mixtures. This process leads to some difficulties: the use of complex plasticizers based on sulfated melamine and naphthalene formaldehyde macromolecules with setting inhibitors slows down the kinetics of concrete strength gain, increases the period of formwork turnover, etc. [3–7].

Plasticizing compositions based on innovative CPE are supramolecular complexes made of a macromolecular matrix and various nano-additives that correct the setting and hardening time of calcium hydrosilicates, enhance the speed of strength gain and the ability to conduct concrete work at low sub-zero temperatures [8]. Linear polycarboxylate macromolecules are synthesized by radical polymerization of acrylic acid in an aqueous solution, with comb-like analogues of polycarboxylate esters being technologically obtained by esterification with methoxy-lated polyethylene glycol of various molecular weights (350–1000 g/mol).

Along with the size of the main chain of the CPE macromolecule, the length of the side chains (ridges) and their frequency play an important role as a superplasticizer (hyperplasticizer) [9, 10]. The most effective plasticizing properties are shown by CPE with the molecular weight of the linear part of ≈ 12000 g/mol and the length of side chains corresponding to the molecular weight of ≈ 750 g/mol. The van der Waals forces of nanosteric repulsion begin to manifest at a distance of ≈ 11 nm, and the elasticity of the side branches of the CPE is ≈ 5 nm.

RESULTS

Due to the interaction of delocalized negative charges of carboxyl groups of CPE macromolecules with immobilized and partially neutralized calcium cations of cement nanobinders, surface adsorption of the hyperplasticizer is carried out at the initial stage of interaction. As a result, after adsorption of CPE on the surface of hydrated cement microgranules (with size of ≈ 20–30 microns), microparticles of calcium hydrosilicates begin to repel each other and disperse more strongly. The supramolecular mechanism of action of CPE is based on the physical and chemical “pushing” of a part of water molecules from the adsorption layer on the surface of cement nanobinders to the diffuse layer, which in turn increases the mobility of concrete building material.

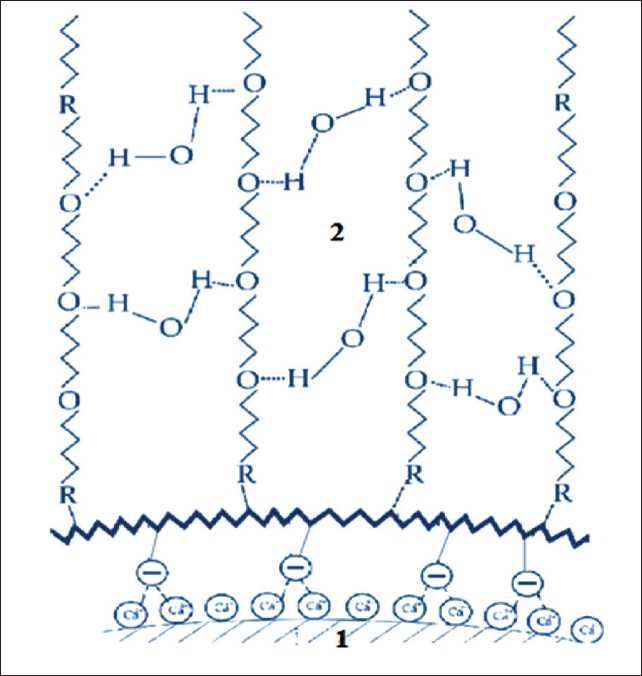

Individual segments of CPE macromolecules “come out” and a diffuse layer of dispersed nanosystems enhances the plasticizing effect of cement nanobinders due to lateral interactions (anions of functional groups, hydrophobic fragments, etc.) (Fig. 1). A structured hydrate nanolayer (size ≈ 70 nm) is formed on the calcium hydrosilicates fractal clusters surface (aquacomplexes of tetrahedral polysilicates) of cement microparticles, and the range of mobility retention of concrete building materials increases to 4–5 hours.

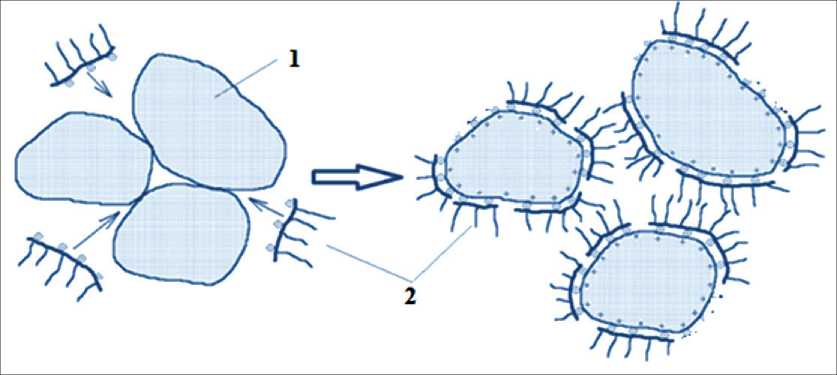

The mechanism of plasticizing supramolecular nano-additives CPE action is based on the chemisorption of macromolecules on the surface of cement clinker microparticles and strengthening of electrostatic repulsion. In this case, a double electric layer is formed, which leads to a shift of the ζ-potential values to a more electronegative region, and it contributes to the dispersion of nanobinders due to spatial repulsion [11]. Supramolecular interaction of the CPE “anchor” functional groups with cations of the cement microparticles solid phase and simultaneous steric stabilization by polyethylene glycol radicals gives the necessary rheological characteristics to construction nanocompositions. Voluminous CPE macromolecules are adsorbed on the surface of cement microparticles and enhance dispersion due to steric repulsion (Fig. 2).

Depending on the synthesis conditions, it is possible to obtain CPE macromolecules of different structures of the main and side polyester chains, and this allows us to design effective superplasticizers with a different ratio of the steric factor and the density of the anion charge in the macromolecule, taking into account the composition of the nano-binding building material. The presence

SYSTEM RESOLUTIONS TO TECHNOLOGICAL PROBLEMS

Fig. 1. Scheme of formation of microparticles of calcium hydrosilicates (1) on the surface of fractal clusters of cement binders of a comb-like polycarboxylate esters adsorption nanolayer (2)

Fig. 2. Supramolecular mechanism of action on cement nanobinders (1) macromolecules of comb-like polycarboxylate esters (2)

of ion charges of the main chain of CPE macromolecules provides the formation of an electrostatic effect, while the side ridges cause spatial repulsion, which increases the dispersing effect of the supramolecular mechanism: the interphase energy of adhesion of cement nanobinders decreases, the degree of disaggregation increases.

SYSTEM RESOLUTIONS TO TECHNOLOGICAL PROBLEMS

DISCUSSION

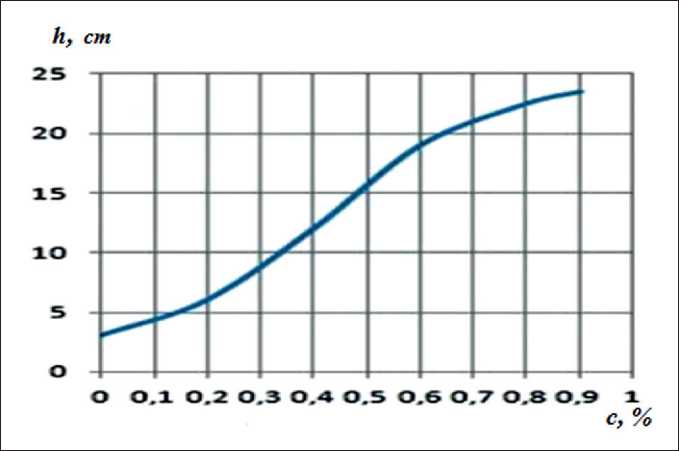

The economic use of plasticizing nano-additives in concrete production is technologically feasible, since it allows managing the reliability of the strength set of construction nanocomposites based on fractal clusters of calcium hydrosilicates of cement binders. Using superplasticizing CPE, it is possible to increase the density of concrete nanocomposites by reducing the amount of water mass to the cement mass ratio (water/Portland cement) to an optimal 0.3, while maintaining good pumpability and managing the reliability of uniformity. A comparative study of the effect of innovative compatible CPE in the amount of 0.1 to 0.9% on the mobility of the concrete composition, which was determined by measuring the cone sediment (Fig. 3) on the physical and chemical kinetics of hardening of cement nanobinders showed that they are superior in technological parameters to traditional lignosulfonate, melamine and naphthalene formaldehyde polymers.

To date, there is no universal plasticizing nano-additive that demonstrates the same high efficiency regardless of the characteristics of the feedstock and the production technology of cement binders. The main drawback of using superplasticizers is air extraction (5% or more), and this problem is solved by adding defoamers or air-removing nano-additives. For each specific case of a cement nanobinder, it is necessary to select a superplasticizer component in accordance with the operational parameters of the technology for producing concrete composites of controlled hardening with fillers.

Supramolecular CPE with an increased electrostatic effect interact faster with hydrated cement nanowires and are able to exert an intensifying effect on the hydration processes. As a result, this leads to accelerated growth of fractal nanoparticles [12] on the surface of clinker particles and increases the strength of the concrete nanocomposite for 8–12 hours. Despite the higher price of CPE in a comprehensive assessment,which takes into account the factors of quality, technological parameters, savings of cement binders, etc., the cost of concrete nanocomposites using polycarboxylate hyperplasticizers [13, 14] is lower than using cheaper lignosulfonates based on sulfated melamine and naphthalene formaldehyde macromolecules.

At minimum dosages, compatible CPE allows ensuring the non-layability and workability [15, 16] of concrete compositions and their high performance characteristics, including increased corrosion resistance. This is important fromboththe economic point of view and from the point of view of controlled increase in the technological characteristics of concrete or other building mixes (such as gypsum [17], cement, etc.), in particular, reducing their creep and shrinkage deformations, as well as the possibility of obtaining high-strength (55÷80 MPa) building materials by controlled hardening.

New effective plasticizing nano-additives [18–22] are increasingly used in the construction industry, for example, to control the rheological behavior of dispersed systems in the process of 3D printing; in the production of self-compacting concrete nanocompositions: the du-

Fig. 3. The effect of superplasticizer concentration ( c ) on mobility (cone sediment – h ) of a concrete nanocomposition with a water / cement ratio = 0.3

SYSTEM RESOLUTIONS TO TECHNOLOGICAL PROBLEMS rability of building structures is enhanced, and the initial disadvantages of CPE, such as air entrainment, slowing down of hydration (hardening) and high cost, have now been successfully overcome. The main functional purpose of modern hyperplasticizers is to reduce the viscosity of the concrete mix to a highly mobile consistency, which ensures controlled pumpability. It should also be noted that the innovative CPE in demand is effectively used in the modern resource-saving construction industry for the disposal of man-made waste, including waste ash [23–25].

CONCLUSION

In conclusion, it should be stated that the branched comb-like nanostructure of polycarboxylate esters exhibits effective technological characteristics of superplasticizers for concrete, building mortars and dry building mixes. The use of cost-effective CPE makes it possible to purposefully regulate the processes of structure formation (control the reliability of hardening) due to electrostatic and steric mechanisms of influence and create high-quality composite building materials for various purposes.

Список литературы The supramolecular impact mechanism of polycarboxylate superplasticizers on controlled hardening construction of nanocomposites

- Chernishov E.M., Artamonova O.V., Slavcheva G.S. Nanomodification of cement-based composites in the technological life cycle. Nanotechnologies in Construction. 2020; 12 (3): 130–139. Available from: doi: 10.15828/2075-8545-2020-12-3-130-139.

- Bullard J.W., Jennings H.M., Livingston R.A. et al. Mechanisms of cement hydration.Cement and Concrete Research. 2011; 41(12): 1208–1223. Available from: doi: 10.1016/j.cemconres.2010.09.011.

- Gasiev A.A., Beppaev Z.U., Khasauov Yu.M. Research of dynamics and level of strength set of concrete laid in steel fixed formwork.Construction mechanics of engineering structures. 2015; 6: 70–76.(In Russian).

- Afanasiev G. A. Preservation of technological and rheological properties of concrete mixtures during transportation, feeding and laying in formwork systems.Technologies of concrete. 2018;5–6: 32–35.(In Russian).

- Zhuravleva M.I., Ivanova O.V., Khalikov R.M. Management of technological characteristics of binding materials with polycarboxylate superplasticizers. In: Comp. XII International Conf. “Actual problems of science and technology-2019”. Vol. 2. Ufa: Publishing house ≪USPTU≫, 2019. p. 111–113. (In Russian).

- Paul S.C., Rooyen A.S., Gideon P.A. et al. Properties of cement – based composites using nanoparticles: A comprehensive review.Construction and Building Materials. 2018; 189: 1019–1034. Available from: doi: 10.1016/j.conbuildmat.2018.09.062.

- Alenichev M.K., Drozhzhennikova E.B., Levin A.D., Nagaev A.I. Patent 2714751 RU IPC C1. Method for evaluating the aggregation of nanoparticles in colloidal solutions. 2020. No. 5.(In Russian).

- Minakov Yu.A., Kononova O.V., Anisimov S.N., Gryazina M.V. Control of concrete hardening kinetics at negative temperatures. Fundamental research. 2013; 4–2: 307–311.(In Russian).

- Bogdanov R.R., Pashaev A.V., Zhuravlev M.V. Influence of plasticizing additives based on polycarboxylate ether and polyaryl on the physical and technical properties of cement compositions. Bulletin of the technological University. 2018; 21(11): 45–49.(In Russian).

- Sivtsov E.V., Gostev A.I., Rodionova V.D. et al. Synthesis and properties of superplasticizers of cement mixtures based on acrylic acid copolymers with methoxypolyethylene glycol methacrylates. Izvestia of the Saint Petersburg State technological Institute (Technical University). 2018; 47: 50–56. (In Russian).

- Yamada K. Basics of analytical methods used for the investigation of interaction mechanism between cements and superplasticizers. Cement and Concrete Research. 2011; 41: 793–798.

- Sinitsin D.A., Khalikov R.M., Bulatov B.G. et al. Technological approaches to directed structure formation of construction nanocomposites with increased corrosion resistance. Nanotechnologies in Construction. 2019; 11(2): 153–164. Available from: doi: 10.15828/2075-8545-2019-11-2-153-164.

- Dalas F., Pourchet S., Rinald D. et al. Modification of the rate of formation and surface area of ettringite by polycarboxylate ether superplasticizers during early C3A–CaSO4 hydration.Cement and Concrete Research. 2015; 69: 105–113. Available from: doi: 10.1016/j.cemconres.2014.12.007.

- Ivanov L.A., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020; 12(2): 71–76. Available from: doi: 10.15828/2075- 8545-2020-12-2-71-76.

- Skripkyunas G., Yakovlev G.I., Karpova E.A. et al. Changes in the rheological properties of nanomodified cement systems over time. Industrial and civil construction. 2017; 2: 43–50. (In Russian).

- Samchenko S.V., Zemskova O.V., Kozlova I.V. Model and mechanism of stabilization of carbon nanotubes with a polycarboxylate-based plasticizer. Vestnik MSBU. 2017; 12(7): 724–752. (In Russian).

- Khalikov R.M., Sinitsina E.A., Silantyeva E.I.et al. Modifying intensification of the hardening of extruded construction gypsum nanocomposites. Nanotechnologies in Construction. 2019; 11(5): 549–560. Available from: doi: 10.15828/2075-8545-2019-11-5-549-560.

- Mikhailova N.N., Krasko S.A., Bogomazova A.A., Shavshukova S.Yu. Basic heterocyclic and bioorganic compounds. Ufa: USPTU, 2013. 98 p. (In Russian).

- Zotkin A.G. Criteria for the effectiveness of superplasticizers in concrete. Technologies of concrete. 2017; 3–4: 31–35. (In Russian).

- Slavcheva G.S., Artamonova O.V. The rheological behavior of disperse systems for 3D printing in constrcution: the problem of control and possibility of ≪nano≫ tools application. Nanotechnologies in Construction. 2018; 10(3): 107–122. Available from: doi: 10.15828/2075-8545-2018-10-3-107-122. (In Russian).

- Ivanova O.V., Korotkova L.N., Khalikov R.M. Innovative approaches to quality management of plasticizing additives creation. Comp. 10th All-Russian Conf. “Modern innovations in science and technology”. Kursk: SWSU, 2020. p. 131–134. (In Russian).

- Sinitsin D.A., Babkov V.V., Sahibgareev R.R. et al. Application of self-compacting concrete mixes in the construction practice of the Republic of Bashkortostan. Construction Materials. 2019;12: 45–51. Available from: doi: 10.31659/0585-430X-2019-777-12-45-51. (In Russian).

- Khalikov R.M., Ivanova O.V. Technological schemes for solving environmental problems of regional production of materials. Nauka-Rastudent.ru. 2014; 3(03): 10. (In Russian).

- Chernishov E.M., Artamonova O.V., Slavcheva G.S. Nanotechnological applied tasks of the increase in the efficiency of the hardening processes of cement concrete. Nanotechnologies in Construction. 2017; 9(1): 25–41. Available from: doi: 10.15828/2075-8545-2017-9-1-25-41. (In Russian).

- Gusev B.V. Concrete with fillers of various dispersion and their nanomodification. Nanotechnologies in Construction. 2019; 11(4): 384–393. Available from: doi: 10.15828/2075-8545-2019-11-4-384-393.