Tools used in Tagar rock art: findings of an experimental traceological study

Автор: Zotkina L.V., Davydov R.V.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.50, 2022 года.

Бесплатный доступ

We describe the findings of traceological analysis and experiments with bronze and iron tools used by Tagar and Tes artists. The pecking traces these tools leave on the red Devonian sandstone were examined to assess which of them could have been used in rock art production. At the first stage, a preliminary analysis of Tagar petroglyphs was carried out, and metal tools and weapons from the Martyanov Museum of Local History in Minusinsk were examined. Morphologically suitable ones were selected, and experimental tools were made of stone, copper alloys, and low-carbon steel. Experiments were conducted and samples of pecking traces were produced. The final stage of the work consisted of comparing these samples with actual petroglyphs, and use-wear traces on the experimental tools with those on the actual tools. This approach made a direct comparison possible. Among the Tagar and Tes metal tools, those that had likely been used in rock art production were detected. The conclusion was made that no specialized tools designated for that purpose existed at that time in the Minusinsk Basin. Rather, multifunctional tools were used. These were made of tin bronze and low-carbon steel with thermal processing. Such tools first appeared in the region in the Early Iron Age.

Rock art, petroglyphs, Tagar culture, Minusinsk Basin, use-wear analysis, experiment, traceology

Короткий адрес: https://sciup.org/145146802

IDR: 145146802 | DOI: 10.17746/1563-0110.2022.50.3.060-071

Текст научной статьи Tools used in Tagar rock art: findings of an experimental traceological study

Correlating petroglyphs with specific forms of tools used for their creation has always been crucial for the study of techniques applied to petroglyph making. This becomes particularly acute when petroglyphs do not have a clear cultural or chronological attribution (for example, the earliest rock art) (Molodin et al., 2019; Miklashevich, 2020; Zotkina et al., 2020; Zotkina et al., in press), but is also relevant for imagery that is reliably associated with a particular archaeological culture. The problem primarily results from the scarcity of finds, which may be linked to the process of creating rock art (Zotkina, Bocharova, 2017: 28). Even if artifacts that, according to their morphological features, might have served as tools for creating rock art were found directly under the panel with petroglyphs, the fact of their use in this capacity needs to be proven.

The experimental traceological approach is usually applied to the study of techniques in rock art (Beaune, de, Pinçon, 2001; d’Errico, Sacchi, Vanhaeren, 2002; Girya, Devlet E.G., 2010; Aubry, Sampaio, Luis, 2011; Miklashevich, 2012; Bradfield, Thackeray, Morris, 2014; Zotkina et al., 2014; Santos Da Rosa et al., 2014; Zotkina, 2019; Fedorova, 2019; Zotkina, Kovalev, 2019; Zotkina et al., 2020; Molodin et al., 2020). Several studies are known that have successfully correlated rock carvings with the archaeological tools used for their creation (Alvarez et al., 2001; Plisson, 2007; 2009: 442–443; Gueret, Benard, 2017: 105–111; Lopèz-Tascon et al., 2020).

The tools for experimental reproduction of rock images are usually chosen using one of two approaches. The first approach is to examine the most diverse toolkit. This is optimal if there are no data on the period when the petroglyphs were created and there is a lack of tool finds potentially suitable for making these images. In this case, one needs to test all acceptable options, for which a fairly representative series of tools made of various lithic raw materials and metal alloys is assembled. It is advisable to select the tools with active parts of various shapes, different weights, etc. (see, e.g., (d’Errico, Sacchi, Vanhaeren, 2002)). The second approach implies a larger amount of initial data available. If cultural and chronological attribution of petroglyphs is reliably established, it is advisable to turn to the archaeological evidence and to make a selection of tools with morphological features suitable for making rock images (see, e.g., (Zotkina, 2016: 311, fig. 7)). Then, after the analysis of archaeological collections, a reference base is formed, which should be as close as possible to the technological conditions relevant for the archaeological culture under consideration. This approach was followed while studying the technological features of rock art of the Tagar and Tes period and of the toolkit available to ancient artists at this time.

Scholars associate the rock art of the Scythian period in the Minusinsk Basin with the Tagar culture (8th– 3rd centuries BC) and with the Tes transitional stage (late 3rd century BC to early 1st century AD) (Savinov, 1994: 124; Kuzmin, 2008: 187). It is considered “a separate trend of the Scythian Siberian style” (Sovetova, 2005: 4). Notably, the style in rock art of that period evolved according to its own laws and did not always fully correspond to internal stages in the development of the Tagar culture and its Tes stage (Vadetskaya, 1986: 77– 129; Kuzmin, 2008; Chlenova, 1992). Therefore, the rock art style development does not always correspond to periodization of the material culture (Sovetova, 2005: 15). Scholars often call the Tes rock art of the Minusinsk Basin “the transitional Tagar-Tashtyk” style (Ibid.; Devlet M.A., 1976; Baiberdina (Talyagina), 2019), taking into account the gradual emergence and consolidation of the figurative tradition in connection with the arrival of a new population and recognizable artifacts typical of the Tes stage.

The tools of the Tagar and Tes period are heterogeneous in composition and mechanical properties, since metalworking in the Minusinsk Basin at that period underwent significant changes. Scholars describe the period from the 8th to the 4th century BC as technologically unstable, with preservation of the remnants of the pre-Tagar period. By the 5th–3rd centuries BC, tin bronze became the main material, with a standardization of technology (Naumov, 1963: 189–190; Khavrin, 2000). At the later stages of the Tagar culture, in Southern Siberia there appeared iron items; however, scholars identify them as imported products (Zavyalov, Terekhova, 2014: 111). The increase in the number of iron items at the Tes stage, including artisan tools, can be associated with the emergence of local metallurgy, yet the first known centers for manufacturing ferrous metal items go back to the period corresponding to the Tashtyk culture (Sunchugashev, 1979: 28). These data determined the choice of archaeological evidence whose features became the basis for manufacturing bronze and iron experimental tools used in the technological study of rock art of the Tagar culture and Tes stage.

This study was intended to establish the technological capacities of the Tagar and Tes metal tools as implements for creating petroglyphs by pecking, and to identify the artifacts that could have been used for this purpose.

Material and methods

Following the classic experimental traceological approach (Semenov, 1957: 6–7, 9, 11), the study of archaeological artifacts involves:

analyzing the archaeological evidence;

proposing a working hypothesis based on the data obtained, preparing experimental tools, and conducting a series of experiments;

comparing the results of experiments with the initial data—traces on the experimental tools vs. original artifacts; making a conclusion that confirms or rejects the working hypothesis.

The experimental traceological study involved both reconstructing the technological process of pecking the Tagar petroglyphs and identifying specific use-wear traces that appeared on Tagar metal tools in the course of their use in making rock carvings. Thus, the research algorithm was as follows:

creating replicas of bronze tools (experimental tools) based on the analysis of collections of Tagar metal artifacts;

performing various types of pecking (direct and indirect, sparse and dense, with and without removal of the active part of the tool from the surface) on the panel of the experimental site, using the replicas of Tagar and Tes metal tools;

carrying out traceological analysis on experimental samples of the pecked surface;

studying use-wear traces on the active parts of the replicas of the Tagar and Tes metal tools;

comparing the traceological features of the pecking samples and use-wear traces on the experimental tools with their archaeological originals.

Thus, the study implied a comprehensive analysis of the chaîne opératoire * of creating petroglyphs in the Tagar period.

Documenting the process and results of the experimental traceological study involved recording each stage of the experiment in accordance with the description protocol (taking into account the time of pecking, the number of impacts, various methods of pecking, position of the tool on the panel, features of tool use-wear, and characteristics of the resulting modification of the rock surface). The experiments were recorded using a GoPro Hero 5 Action Camera (video recording 120 fps). The 3D-models rendering the details of all the samples of pecking were made using the cloud photogrammetry technique (the frames were put together using the Agisoft Metashape Pro software). A Nikon D750 full-matrix camera with an AF-S MICRO Nikkor 60 mm macro lens and Nikon Speedlight Kit R1C1 Macro ring flash, which makes it possible to produce shots uniformly illuminated in all areas, was used for obtaining high-precision models (over one million points over the area of 3–5 cm2) and further studying the traces in detail both in plan and in side view.

Specific features revealed by pecking in plan view were analyzed using a portable microscope with ×20 magnification (Nikon 11470 NS). For obtaining the data on the features of pecking in side view, 3D-models of experimental tools and traceologically significant areas of petroglyphs were analyzed. The MeshLab, Blender, and Geomagic Studio software was used for analyzing the metric parameters of indentations in plan and side view, as well as the morphological features of pecking marks (based on 3D-models).

Rock images at various scales (from a general view of the panel to details of petroglyphs with areas of 1 cm2 or less) were photographed using a Nikon D750 camera with different lenses (AF-S Nikkor 14–24 mm, AF-S MICRO

Nikkor 105 mm, AF-S MICRO Nikkor 60 mm). Macrophotography captured use-wear traces on archaeological artifacts and experimental tools using the stacking technique with a Nikon D 3200 camera which had an AF-S MICRO Nikkor 60 mm lens. The Helicon Focus software was applied for obtaining sharp photographs based on the frames with focus on different areas. Documentation of usewear traces on the active part of the experimental tools was made after each series of pecking, before rejuvenation, or after the tool became unusable.

Results

Experiments on the production of metal tools

Experimental replicas of tools and weapons of the Tagar culture, which could have been used for creating petroglyphs, were made for identifying potential bronze tools. Various artifacts of the Tagar culture of the 5th– 3rd centuries BC from the collection of the Martyanov Museum of Local History in Minusinsk were examined. Individual iron items of the Tes period were also studied. Pointed and chisel-shaped tools, chisels, spear-shaped chisels, and battle axes were chosen as samples for experimental tools made of copper and bronze. Iron experimental tools included pointed tools.

Replicas made of non-ferrous metals were cast in clay two-partite casting molds using wooden experimental tools. The metal was smelted in ceramic crucibles in a coal hearth, using manual air injection with two-chamber bellows. Since mechanical properties of copper-based alloys significantly differ depending on the tin content, which, among other things, affects the nature of use-wear traces, the published results of analyzing the elemental composition of the Tagar metal items were used. Seventy six samples were taken into account (counter-weights, chisels, celts, spearheads, sickles, battle axes, axes, and items of unknown purpose). It has been established that most of the items were made of copper and bronze with a tin content reaching 12 % (Savelieva, 2015, 2016; Khavrin, 2000: Pl. 1; 2007: Pl. 1). Considering these data, copper and 5 % and 10 % tin bronze were chosen as materials for casting experimental tools. After smelting, the experimental tools were studied by scanning electron microscopy and energy-dispersive X-ray spectroscopy (SEM-EDX) using a Hitachi TM3000 desktop microscope and Bruker Quantax 70 elemental analyzer at the Center for Collective Use, “The Geochronology of the Cenozoic”, at the Institute of Archeology and Ethnography SB RAS. It was established that the content of tin in the resulting bronzes was 4–5 and 7–8 %.

Subsequently, the castings were subjected to forging and metalworking using stone and metal tools with parallels from a wide geographical and chronological range, which included hammers made of pebbles, copper, and bronze, anvils made of large pebbles, and abrasives of sandstone (Golubeva, 2016; Gorashchuk, Semin, 2018; Knyazeva, 2011; Fregni, 2014). Casting defects were removed. The functional elements of the tools were subjected to hard forging (cold hardening).

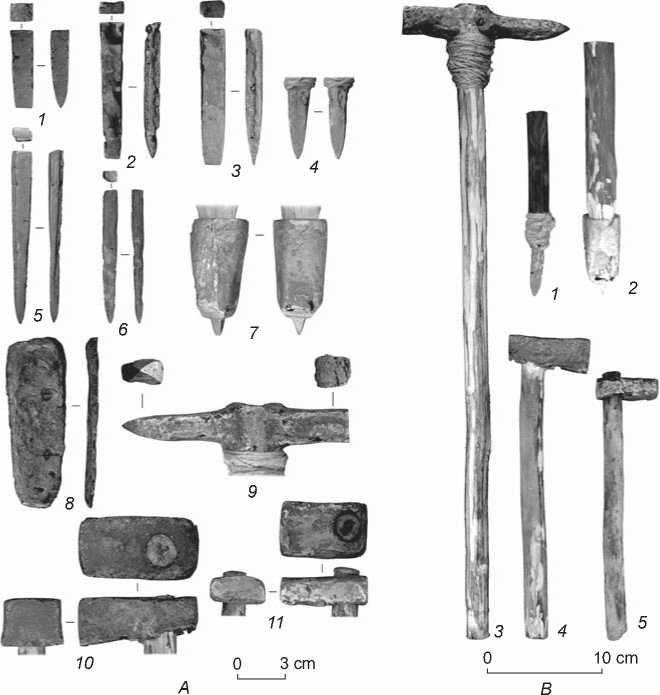

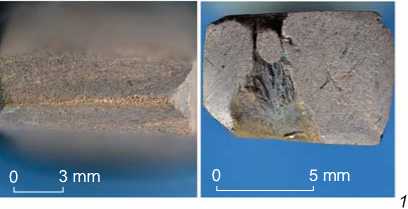

As a result, the reference collection of metal experimental tools (11 items in total) included (Fig. 1): copper chisels, 4–5 % and 7–8 % bronze; pointed tools made of copper, 4–5 % and 7–8 % bronze; a chisel-like tool made of 7–8 % bronze; spear-shaped chisel made of 4–5 % bronze; battle axes made of 7–8 % bronze, and hammers made of copper and 4–5 % bronze.

Iron experimental tools (pointed and chisel-shaped) were forged of low-carbon steel of two grades (CT1 with a carbon content of 0.06–0.12 % and CT3 with a carbon content of 0.14–0.22 %). Half of the experimental tools were hardened in cold water. As a result, eight experimental tools were obtained: pointed tools made of CT1 and CT3 steel, unhardened and hardened, and chisel-shaped tools made of CT1 and CT3 steel, unhardened and hardened.

Pecking experiments

After the set of reference metal tools was prepared, experiments were carried out to perform pecking on the rock surface (Fig. 2). Each tool was used until the final stage of wear—the state of the active part when the tool becomes unsuitable for pecking. In most cases, the experimental tools, despite intensive wear, were rejuvenated after each use. Typically, each experimental tool served to perform three or four pecking samples.

In the course of the experiments, attention was paid to the effectiveness of the tools and correspondence of the resulting indentations to traces of pecking among the petroglyphs of the Tagar and Tes period or other chronological periods. If after applying a

Fig. 1 . Experimental metal tools.

A – copper ( 1 , 4 , 10 ) and bronze ( 2 , 3 , 5–9, 11 ) tools: 1–3 – chisels; 4–6 – pointed tools; 7 – spear-shaped chisel; 8 – chisel-like tool; 9 – battle axe; 10 , 11 – hammers. B – tools with wooden handles: 1 – pointed tool; 2 – spear-shaped chisel; 3 – battle axe; 4 , 5 – hammers. C – iron tools ( 1 , 3 , 5 , 7 – СТ1 steel; 2 , 4 , 6 , 8 – СТ3 steel; 1 , 2 , 5 , 6 – non-hardened; 3 , 4 , 7 , 8 – hardened in cold water): 1–4 – pointed rod-shaped; 5–8 – chisel-shaped.

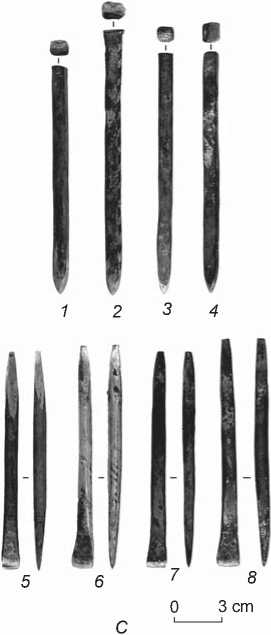

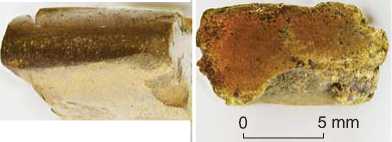

Fig. 2 . Pecking made by experimental tools, using the direct dense pecking technique and indirect technique with separation (3D-models).

1 , 2 – traces of sparse indirect pecking with chisel made of 5 % tin bronze; 3 , 4 – traces of dense direct pecking with chisel made of 5 % tin bronze; 5 , 6 – traces of sparse indirect pecking with rod made of hardened steel.

minimum number (about five) of impacts, the active part became unusable, and the resulting traces did not have a pronounced relief, were superficial, and did not correspond to the characteristics of the pecked indentations typical of the rock art of the region, such a tool was recognized as inapplicable for creating rock carvings in the pecking technique. The following conclusions were made based on the observations of pecking with metal tools.

Copper tools wore out very quickly; the active edge became deformed from only several impacts. The resulting indentations were few and superficial; the relief of the rock changed only slightly. The first rejuvenations with the help of an abrasive made it possible to quickly restore the effectiveness of the tools, since copper is a relatively soft metal. However, retouching of the working edge was required every 2–3 minutes; therefore, copper tools can hardly be considered suitable for creating petroglyphs in the pecking technique on red Devonian sandstone.

Bronze tools with a tin content of 4–5 % and 7–8 % respectively demonstrated similar capacities for creating rock carvings. On average, without rejuvenation, the effective pecking with rods made of such alloys lasted from 5 to 7 minutes. In the technique of direct pecking, about seven hundred impacts could be made during that time, which usually corresponds to the same number of marks (Fig. 2, 3 , 4 ). As a result of impacts in the indirect technique with detachment of the tool from the processed surface, about sixty indentations were made (Fig. 2, 1 , 2 ). Thus, using tools made of 4–5 % and 7–8 % tin bronze, without any or with only slight rejuvenations, one small image covering an area of 10 to 15 cm2 (depending on the pecking density and chosen approach) could have been created in this technique. Traces obtained during experiments have a fairly pronounced relief; dependence of shape in the pecked indentations on the morphological features of the active part of the tool can be clearly observed. The most expressive traces remained after impacts with various chisel-shaped and rod-shaped tools

(Fig. 2). The experimentally obtained indentations were similar to those of the petroglyphs of the Minusinsk Basin (Fig. 3). It was suggested above that weapons might have been used as tools for creating petroglyphs (Zotkina et al., 2014: 57). However, during experiments, the inefficiency of the bronze battle axe as a tool for pecking was established. Since the wooden handle dampened and buffered the momentum of impacts, the marks were superficial and inexpressive.

Tools of hardened and unhardened low-carbon steel were also used during the experiments. Tools made of unhardened CT1 steel, just like copper rods, were found unsuitable for pecking. Experimental tools made of hardened steel CT1 and non-hardened steel CT3 were approximately comparable to the bronze tools mentioned above in terms of wear resistance and efficiency. However, owing to the greater hardness of the metal, the process of their rejuvenation required more effort and time. Traces of pecking left by steel and bronze tools also show similarities. Specific traces were left only by a pointed rod made of hardened steel CT3. The active part of the tool underwent minimal damage from pecking. Capable of leaving relatively expressive deep marks, it could be used for quite a long time without rejuvenation (see Fig. 2, 5, 6). The resulting indentations showed similarities to those appearing on the petroglyphs of the Minusinsk Basin (see Fig. 3, 3, 4). Rejuvenation of hardened steel tools required the greatest energy and time.

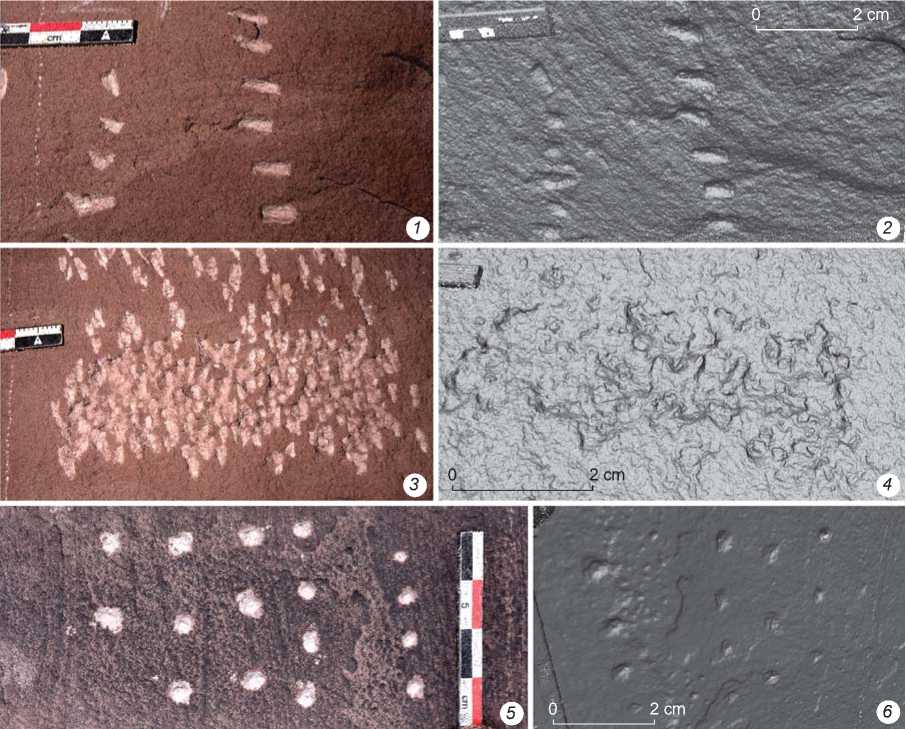

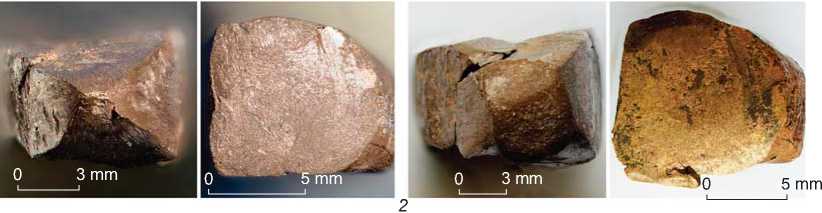

Fig. 3 . Petroglyphs of the Tagar and Tes period and fragments of the rock surface with distinctive traces of pecking with metal tools.

1 – image of a deer in the Scythian-Siberian style ( a , b – traceologically significant fragments (3D-models)), Sorok Zubiev, Oglakhty, Republic of Khakassia; 2 – image of a Tagar warrior with a battle axe in his hand ( a–c – traceologically significant fragments (3D-models)), Shalabolinskaya Pisanitsa, Krasnoyarsk Territory; 3 – zoomorphic figure showing the posture of a sudden stop ( a , b – traceologically significant fragments (3D-models)), Shalabolinskaya Pisanitsa, Krasnoyarsk Territory; 4 – image of a cauldron of the Tes period (3D-models with and without texture) ( b–c with the traceologically significant fragments), Malaya Boyarskaya Pisanitsa, Republic of Khakassia.

Results of the comparative analysis between pecking experimental samples and the Tagar and Tes petroglyphs

The most typical signs of using metal tools are even contours of indentations and the stably repeating shape of traces. It is often close to being round, which indicates the use of a non-sharp point as an active part. Less often, this shape can be oblong or subtriangular, possibly resulting from the use of the main and sharp lateral parts of a chisel (Ibid.: 57, fig. 2). In the course of experiments, the tools that showed the greatest efficiency made it possible to produce indentations with features resulting from the use of metal tools (see Fig. 2). Moreover, samples of indentations created by these tools showed great similarity to indentations on late petroglyphs, including those attributed to the Tagar and Tes period (see Fig. 3). A comparative analysis makes it possible to apply the data obtained experimentally to the evidence of rock art and to draw the preliminary conclusion that the Tagar and Tes metal tools chosen as prototypes for the experimental tools could have been used for creating the petroglyphs of that period.

Results of analyzing use-wear traces on the experimental tools

The experimental tools were used for producing 76 pecking patterns. Examination of the copper and bronze tools

Platforms/striking edges

Blades/points

Platforms/striking edges

Blades/points

0 3 mm

5 mm

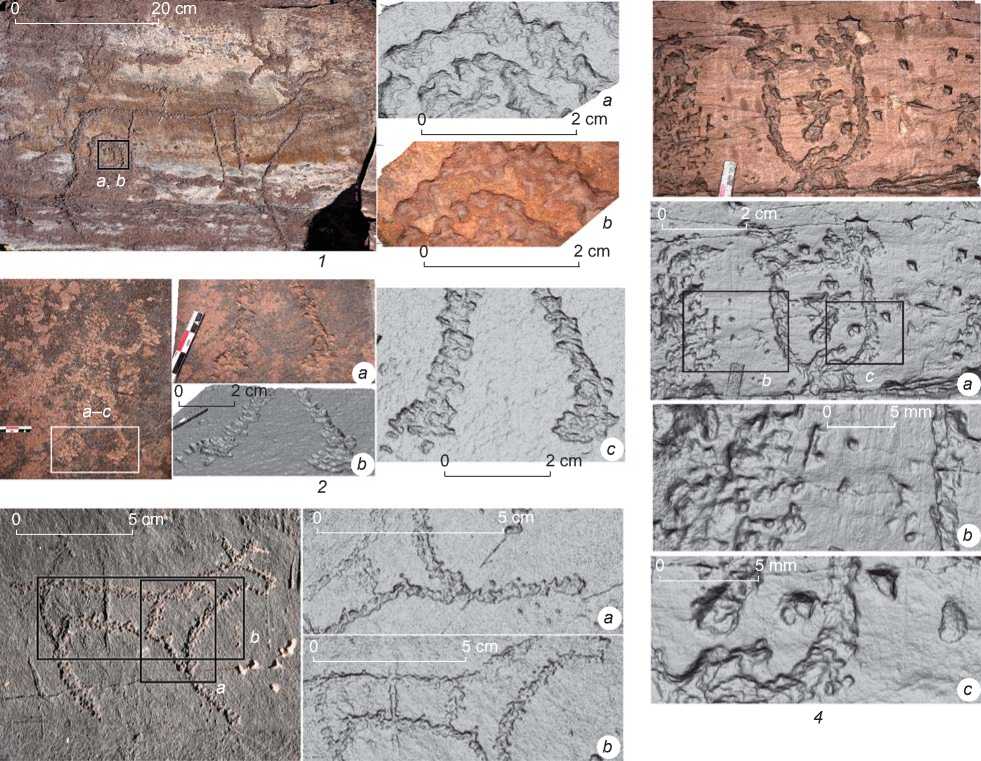

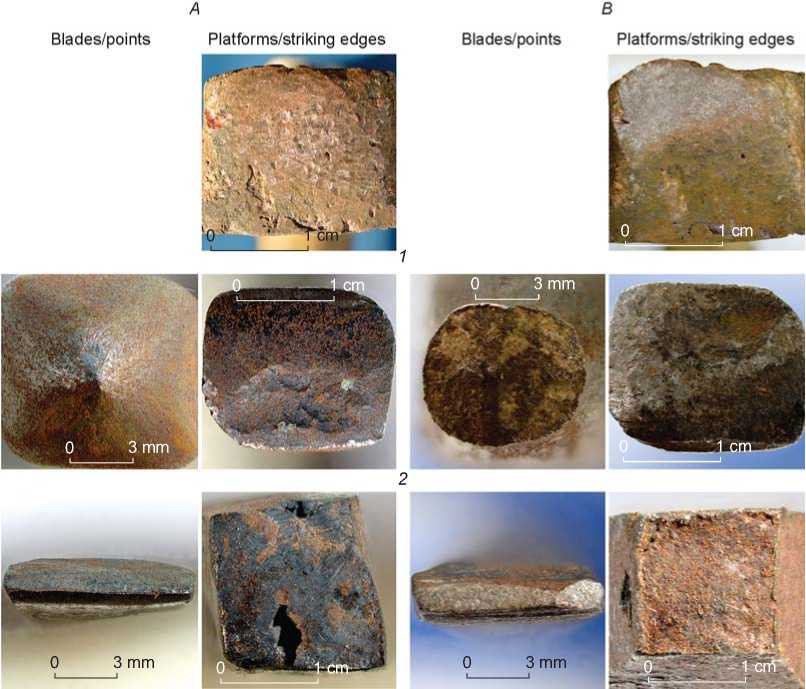

Fig. 4 . Active parts of experimental bronze tools after manufacture ( A ) and after use ( B ).

1 , 3 , 4 – 7–8 % tin bronze; 2 – 4–5 % tin bronze. 1 – chisel; 2 – pointed tool; 3 – spear-shaped chisel; 4 – battle axe.

revealed specific use-wear traces resulting from making petroglyphs in the pecking technique (see Fig. 1, 2).

The blades of chisels were distinctively flattened, and the microrelief of the rock surface was imprinted on the entire surface (Fig. 4). Metal protrusions directed to the side and individual groups of parallel scratches from tangential impacts were observed (Fig. 4, 1 ). In the side view, thin items became deformed from strong impact.

The points had rounded flattenings with rock surface microrelief and metal protrusions, which were bent sideways and backwards (Fig. 4, 2–4 ). Parallel scratches resulting from tangential impacts were visible along the edges (Fig. 4, 3 ).

The striking edges and platforms were flattened and became rounded in the process of indirect pecking (Fig. 4, 1 , 2 , 4 ). Their relief leveled out; delaminations appeared from strain hardening. There were imprints of a stone percussion tool with uneven microrelief in the location of impacts (Fig. 4, 1 ; 5, 1 ). Separate scratches along the edges are associated with tangential impacts (see Fig. 4, 1 ).

Thin bronze items were often bent. The deformation degree of platforms in copper tools was much greater than that of bronze tools (2–7 and 1–2 mm, respectively).

The same traces are observed on the steel experimental tools. The points are flattened; they are imprinted with microrelief of the rock surface. The blades are crushed; distinctive depressions and protrusions of sandstone are observed on them. The striking platforms have metal cornices along the edges, linear tangential traces of impacts, and imprints of stone percussion tools (see Fig. 5, 2 , 3 ).

Discussion

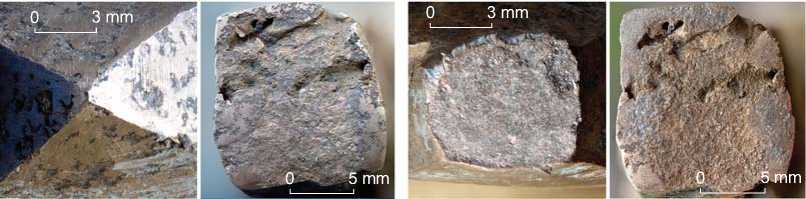

Four items with use-wear traces similar to those identified during the experiments have been found in the collection of the Martyanov Museum of Local History in Minusinsk. Bronze items include a rod-shaped tool rectangular in cross-section (MM A9335), a spear-shaped chisel (MM A499), and a chisel-shaped tool (MM A9734); the fourth item is a pointed tool made of iron (VF681-44) (Fig. 6).

The rod-shaped tool (MM A9335) has a striking part with plastic deformation from impacts and flattening showing stone tool microrelief (Fig. 6, 1 ). Scratches from tangential impacts are visible along the edges. The tip

Fig. 5 . Active parts of experimental copper and steel tools after manufacture ( A ) and after use ( B ).

1 – copper; 2 – non-hardened steel; 3 – hardened steel. 1 – hammer; 2 – pointed tool; 3 – chisel.

is rounded from impacts at different angles. Distinctive flattening with clear microrelief of the rock surface is visible. The tool became bent from multiple impacts.

The spear-shaped chisel (MM A499) (Fig. 6, 2 ) is a socketed tool; its blade is evenly flattened and clearly shows the microrelief of the rock surface over its entire area.

The chisel-like item (MM A9734) has a flattened striking platform with traces of a stone tool and scratches from tangential impacts (Fig. 6, 3 ). Its blade, bearing the imprints of relief of rock surface, is crushed.

Thus, bronze tools for drawing petroglyphs of the Tagar culture were identified among the universal tools of various forms.

The pointed iron tool (VF681-44) of the Tes stage is distinguished by a flattened striking platform with metal protrusions along the edges and linear marks from tangential impacts (Fig. 6, 4). Although its tip is flattened, imprints of the microrelief of the rock surface, which do not expand to the sides, are preserved. Regular linear traces indicating rejuvenation of the tool appear on the sides.

The iron item is of very simple shape. The manufacturing and use of such tools made of metal with low carbon content occurred at the initial phase of the development of local metallurgy at the transitional Tes stage. The steel of the experimental samples was similar in carbon content to raw steel, which was obtained without special carbonization (Zavyalov, Rozanova, Terekhova, 2012: 31). Hardening in cold water was the simplest heat treatment technique used in Southern Siberia in the Xiongnu-Sarmatian period, as evidenced, for example, by locally produced iron files (Soenov, Konstantinova, 2015: Fig. 8). The tool from

0 2 mm

0 2 mm

0 2 mm

0 2 mm

0 2 mm

0 2 mm

0 2 mm

0 2 mm

Fig. 6 . Tools with traces of working on a rock surface from the collection of the Martyanov Museum of Local History in Minusinsk.

1 – rod-shaped tool (MM A9335); 2 – spear-shaped chisel (MM A499); 3 – chisel-like tool (MM A9734); 4 – pointed tool (VF681-44).

the Martyanov Museum of Local History is interesting in the presence of a socket that was not used for its intended purpose. This is indicated by deformation of the striking platform and too small size of the hole. This socketed tool can be considered to be an example of copying bronze socketed varieties at an early stage of technological adaptation to new raw materials.

Unfortunately, there is no information on the context of discovering the metal items under discussion. These artifacts were surface finds; they entered the museum in the late 19th century. Nevertheless, the wear on these items provides very important information on the categories of tools that could have been used for creating rock images in the Scythian period.

Earlier experiments, aimed at reproducing pecking with stone tools made of pebble raw materials that were local to the Minusinsk Basin, showed very high efficiency and wear resistance of such tools. The possibility of using knapped pebbles as tools for making petroglyphs in the Tagar period cannot be ruled out, since they were more efficient than metal tools, and labor costs for their manufacturing in that period were much lower than those needed for manufacturing metal tools.

Conclusions

The experiments on reconstructing the technological process of creating petroglyphs by pecking has shown that rod-shaped and chisel-shaped tools made of 4–5 % and 7–8 % tin bronze typical of the 5th–3rd centuries BC, associated with the advanced stages of the Tagar non-ferrous metallurgy, as well as rod-shaped tools made of hardened low-carbon steel, could have been used to create the Tagar petroglyphs. Furthermore, a comparative study of traces on archaeological originals and experimental samples makes it possible to establish which petroglyphs were made with tools having the features discussed above (see Figs. 4, 5), and which metal tools were used to create the rock images (see Fig. 6). Thus, a comparative analysis of pecking traces on rock surfaces and use-wear traces on metal tools makes it possible to apply the experimental data to the archaeological evidence under study.

As a result of comprehensive technological study of the process and experiments on creating pecking with metal tools, a preliminary conclusion as to the absence of specialized tools for these tasks in the Tagar and Tes period can be drawn. The data obtained on the morphological features of the tools and on the nature of alloys of which the most effective tools for creating rock images in the pecking technique were made will be useful for subsequent research on the technological aspects of rock art in the Minusinsk Basin and Southern Siberia.

Acknowledgments

This study was supported by the grant from the President of the Russian Federation, No. MK-2273.2020.6.

The authors express their gratitude to the staff of the Martyanov Regional Museum of Local History in Minusinsk for their help in organizing the work with the collections.

Список литературы Tools used in Tagar rock art: findings of an experimental traceological study

- Alvarez M., Fiore D., Favrey E., Guerra R.C. 2001 The use of lithic artifacts for making rock art engravings: Observation and analysis of use-wear traces in experimental tools through optical microscopy and SEM. Journal of Archaeological Science, No. 28: 457-464.

- Aubry T., Sampaio J., Luís L. 2011 Approche expérimentale appliquée à l’étude des vestiges du Paléolithique supérieur de la Vallée du Côa (Portugal). In La Investigación Experimental Aplicada a la Arqueologia. Vol. 1: Tecnologia y Traceologia Litica Prehistorica y su Experimentacion. Granada: Universidad de Granada, pp. 87-96.

- Baiberdina (Talyagina) M.A. 2019 Izobrazheniya tesinskogo vremeni v Minusinskoy kotlovine v kontekste arkheologicheskogo materiala. Teoriya i praktika arkheologicheskikh issledovaniy, No. 3 (27): 20-34.

- Beaune S.A., de, Pinçon G. 2001 Approche expérimentale des techniques magdaléniennes de sculpture pariétale: Le cas d’Angles-sur-Anglin (Vienne). In Préhistoire et approche expérimentale. Montignac: Edition Monique Mergoil, pp. 67-75.

- Bradfield J., Thackeray J.F., Morris D. 2014 An experimental investigation into the origin of incised lines on a 4000-year-old engraving from Wonderwerk Cave, Northern Cape Province. South African Archaeological Bulletin, No. 69 (199): 72-79.

- Chlenova N.L. 1992 Tagarskaya kultura. In Stepnaya polosa Aziatskoy chasti SSSR v skifo-sarmatskoye vremya. Moscow: Nauka, pp. 206-223.

- D’Errico F., Sacchi D., Vanhaeren M. 2002 L’analyse technique de l’art gravé de Fornols-Haut, Campôme, France. Implications dans la datation des représentations de style paléolithique à l’air libre. In L’art paléolithique à l’air libre: Le paysage modifi é par l’image, Tautavel-Campôme, 7-9 octobre 1999. Carcassonne: Gaep, Géopré, pp. 75-86.

- Devlet M.A. 1976 Bolshaya Boyarskaya pisanitsa. Moscow: Nauka.

- Fedorova D.N. 2019 Primeneniye sovremennykh tekhnologiy dlya izucheniya petroglifov Russkogo Severa. Zapiski IIMK RAN, No. 20: 104-111.

- Fregni E.G. 2014 The Compleat Metalsmith: Craft and Technology in the British Bronze Age. Sheffield: Univ. of Sheffield, Dep. of Archaeology.

- Girya E.Y., Devlet E.G. 2010 Nekotoriye rezultaty razrabotki metodiki izucheniya tekhniki vypolneniya petroglifov piketazhem. Uralskiy istoricheskiy vestnik, No. 1 (26): 107-118.

- Golubeva E.V. 2016 Teoriya i praktika eksperimentalno-trasologicheskikh issledovaniy nemetallicheskogo instrumentariya rannego zheleznogo veka - Srednevekovya (na materialakh yuzhnotayozhnoy zony Sredney Sibiri). Krasnoyarsk: Sib. Federal. Univ.

- Gorashchuk I.V., Semin D.V. 2018 Metallurgicheskiy i metalloobrabatyvayushchiy kompleks kamennykh orudiy truda s poseleniya Mikhailovo-Ovsyanka v Samarskoy oblasti. Vestnik Udmurtskogo gosudarstvennogo universiteta. Ser.: Istoriya i fi lologiya, No. 4 (28): 599-606.

- Gueret C., Benard A. 2017 “Fontainebleau rock art” (Ile-de-France, France), an exceptional rock art group dated to the Mesolithic? Critical return on the lithic material discovered in three decorated rock shelters. Journal of Archaeological Science: Reports, No. 1: 99-120.

- Khavrin S.V. 2000 Tagarskiye bronzy. In Mirovozzreniye. Arkheologiya. Ritual. Kultura: Sbornik statey k 60-letiyu M.L. Podolskogo. St. Petersburg: Mir knigi, pp. 183-193.

- Khavrin S.V. 2007 Tagarskiye bronzy Shirinskogo rayona Khakasii. In Sbornik nauchnykh trudov v chest 60-letiya A.V. Vinogradova. St. Petersburg: Kult-Inform-Press, pp. 115-122.

- Knyazeva E.V. 2011 Tekhnologiya metallurgii i metalloobrabotki na territorii Nizhnego Priangarya v sredniye veka: Opyt eksperimentalnotrasologicheskikh issledovaniy. Vestnik Novosibirskogo gosudarstvennogo universiteta. Ser.: Istoriya, fi lologiya. No. 5: Arkheologiya i etnografi ya: 108-116.

- Kuzmin N.Y. 2008 Etapy slozheniya i razvitiya tesinskoy kultury (po pogrebalnym pamyatnikam stepey Minusinskoy kotloviny). In Nomady kazakhskikh stepey: Etnosotsiokulturniye protsessy i kontakty v Yevrazii skifo-sakskoy epokhi. Astana: Prezidentskiy tsentr kultury Respubliki Kazakhstan, pp. 187-204.

- Leroi-Gourhan A. 1964 Le Geste et La Parole. Vol. 1: Technique et langage. Paris: Albin Michel.

- Lopèz-Tascon C., Pedergnana A., Ollé A., de la Rasilla M., Mazo C. 2020 Characterization of the use-wear and residues resulting from limestone working. Experimental approach to the parietal art of La Viña rock shelter (La Manzaneda, Asturias, Spain). Quaternary International, vol. 569-570: 212-227.

- Miklashevich E.A. 2012 Tekhnika gravirovki v naskalnom iskusstve skifskogo vremeni. In Izobrazitelniye i tekhnologicheskiye traditsii v iskusstve Severnoy i Tsentralnoy Azii. Kemerovo: Kuzbassvuzizdat, pp. 157-202. (Trudy Sibirskoy assotsiatsii issledovateley pervobytnogo iskusstva).

- Miklashevich E.A. 2020 O skhodstve drevneishikh naskalnykh izobrazheniy Yuzhnoy Sibiri i Tsentralnoy Azii i probleme ikh atributsii. KSIA, No. 261: 82-98.

- Molodin V.I., Geneste Z.-M., Zotkina L.V., Cheremisin D.V., Cretin C. 2019 The “Kalgutinsky” style in the rock art of Central Asia. Archaeology, Ethnology and Anthropology of Eurasia, vol. 47 (3): 12-26.

- Molodin V.I., Zotkina L.V., Cretin C., Cheremisin D.V., Batbold N., Tseveendorj D. 2020 Palimpsest s mestonakhozhdeniya Tsagaan-Salaa IV (Mongolskiy Altai): Otnositelnaya khronologiya izobrazheniy. KSIA, No. 260: 134-150.

- Naumov D.V. 1963 Proizvodstvo i obrabotka drevnikh mednykh i bronzovykh izdeliy Minusinskoy kotloviny. In Noviye metody v arkheologicheskikh issledovaniyakh. Moscow, Leningrad: AN SSSR, pp. 159-190.

- Plisson H. 2007 La fonction des outils de silex dans les grottes ornées paléolithiques. In Congrès du Centenaire: Un siècle de construction du discours scientifique en Préhistoire. Paris: Société Préhististorique française, pp. 125-132.

- Plisson H. 2009 Analyse tracéologique de 4 pics d’Olga Grande: des outils pour les gravures de plein air? In 200 séculos da história do vale do Côa: na vida quotidiana dos caçadores-artistos do paleolithico. Lisboa: IGESPAR, pp. 436-443.

- Santos Da Rosa N., Cura S., Gersés S., Cura P. 2014 Between tools and engravings: Technology and experimental archaeology to the study of Cachao do Algarve rock art. In UISPP 2014: Technology and Experimentation in Archaeology. Oxford: pp. 87-96. (BAR Intern. Ser.; vol. 10, No. 2657).

- Savelieva A.S. 2015 Tsvetnoy metall tagarskoy kultury: Istoriya issledovaniy sostava splavov na mednoy osnove s 1860-kh po 1950-ye gg. Vestnik Tomskogo gosudarstvennogo universiteta. Istoriya, No. 4 (36): 85-95.

- Savelieva A.S. 2016 Tsvetnoy metall tagarskoy kultury: Istoriya issledovaniy sostava splavov na mednoy osnove s 1960-kh po 2000-ye gg. Vestnik Tomskogo gosudarstvennogo universiteta, No. 408: 125-133.

- Savelieva A.S., German P.V. 2015 Bronzy iz kurgannogo mogilnika tagarskoy kultury Nekrasovo II (po materialam raskopok 1970 g.) Vestnik Tomskogo gosudarstvennogo universiteta. Istoriya, No. 6 (38): 108-118.

- Savinov D.G. 1994 Razvitiye stilya izobrazheniy na plitakh kurganov tagarskoy kultury. In Problemy arkheologii, iss. 3. St. Petersburg: SPb. Gos. Univ., pp. 123-136.

- Semenov S.A. 1957 Pervobytnaya tekhnika (opyt izucheniya drevneishikh orudiy i izdeliy po sledam raboty). Moscow, Leningrad: Izd. AN SSSR. (MIA; No. 54).

- Soenov V.I., Konstantinova E.A. 2015 Remeslenniye proizvodstva naseleniya Altaya (II v. do n.e. - V v. n.e.). Gorno-Altaysk: Izd. Gorno-Alt. Gos. Univ.

- Sovetova O.S. 2005 Petroglify tagarskoy epokhi na Yeniseye (syuzhety i obrazy). Novosibirsk: Izd. IAET SO RAN.

- Sunchugashev Y.I. 1979 Drevnyaya metallurgiya Khakasii: Epokha zheleza. Novosibirsk: Nauka.

- Vadetskaya E.B. 1986 Arkheologicheskiye pamyatniki v stepyakh Srednego Yeniseya. Leningrad: Nauka.

- Zavyalov V.I., Rozanova L.S., Terekhova N.N. 2012 Traditsii i innovatsii v proizvodstvennoy kulture Severnoy Rusi. Moscow: Ankil.

- Zavyalov V.I., Terekhova N.N. 2014 K voprosu o proiskhozhdenii zheleznykh izdeliy u plemen tagarskoy kultury. KSIA, iss. 236: 109-112.

- Zotkina L.V. 2016 Le bison de La Grèze (Marquay, Dordogne, France) sous le microscope. Paléo. Revue d’Archéologie Préhistorique, No. 27: 307-320.

- Zotkina L.V. 2019 On the methodology of studying palimpsests in rock art: The case of the Shalabolino rock art site, Krasnoyarsk Territory. Archaeology, Ethnology and Anthropology of Eurasia, vol. 47 (2): 93-102.

- Zotkina L.V., Bocharova E.N. 2017 Rezultaty tekhnologo-trasologicheskogo issledovaniya kamennykh orudiy dlya vypolneniya petroglifov v tekhnike piketazha. Sibirskiye istoricheskiye issledovaniya, No. 4: 27-45.

- Zotkina L.V., Cretin C., Plisson H., Geneste J.-M., Molodin V.I. 2020 Technological parameters of rock art at the Kalgutinsky Rudnik site on the Ukok Plateau, Russian Altai region. Quaternary International, vol. 559: 188-197.

- Zotkina L.V., Kolobova K.A., Sutugin S.V. (s.a.) Technological or stylistic features: What defines the Minusinsk style in the earliest rock art from the Minusinsk Basin (Southern Siberia). In press.

- Zotkina L.V., Kovalev V.S. 2019 Lithic or metal tools: Techno-traceological and 3D analysis of rock art. Digital Applications in Archaeology and Cultural Heritage, vol. 13.

- Zotkina L.V., Solodeinikov A.K., Davydov R.V., Kurbanov R.N., Postnikov N.V., Sutugin S.V., Shevchenko T.A., Konokhov V.A., Fedorenko P.Y. 2020 Rezultaty polevykh issledovaniy pamyatnikov naskalnogo iskusstva drevneishego plasta na territorii Minusinskoy kotloviny v 2020 godu. In Problemy arkheologii, etnografi i, antropologii Sibiri i sopredelnykh territoriy, vol. XXVI. Novosibirsk: Izd. IAET SO RAN, pp. 445-452.

- Zotkina L.V., Tekhterekov A.S., Kharevich V.M., Plisson H. 2014 An experimental study of percussion technologies in the Minusinsk Basin: Percussion and tool types. Archaeology, Ethnology and Anthropology of Eurasia, No. 1: 55-65.