Trends in the development of industrial robotic manipulators

Автор: Lukyanov V.V., Votintsev V.V., Ilyina V.N., Akhmadullina A.F.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 6 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Industrial robotic manipulators are becoming an integral part of modern enterprises due to their versatility and ability to perform complex operations with high precision and speed, including in extreme conditions. Effective implementation and operation of robotic manipulators requires an understanding of their design features, control methods, and manufacturing technologies. Main part. This review presents a classification of robotic manipulators based on their design features, number of degrees of freedom, and drive types. Their application areas and market trends are analyzed. This review points to the steady growth of the industrial robotic manipulator market, driven by the transformation of production processes in line with the concept of Industry 4.0. This article examines the structural components of robotic manipulators: the mechanical part, the drive, and the control system. It also presents an overview of modern materials used in the production of manipulators. A method for enhancing the performance properties of structural components through the use of materials with a nanocrystalline structure is proposed. Current development trends in industrial robotics are identified. It is noted that the integration of machine vision and artificial intelligence into manipulator control systems is becoming a key trend in robotics. Such solutions enable rapid response to changing operating conditions and the prevention of potential accidents. Conclusion. Industrial robotic manipulators continue to evolve, opening up new opportunities for automation and increased efficiency in production processes. Their further improvement requires an interdisciplinary approach combining engineering, software, and technological solutions. The results of this review can be used for selecting, designing, and implementing industrial robotic manipulators in enterprises, as well as for further scientific research in the field of robotics.

Robotic manipulators, robotic manipulator control, drive, gearbox, low-alloy steels, nanomaterials

Короткий адрес: https://sciup.org/142246528

IDR: 142246528 | DOI: 10.15828/2075-8545-2025-17-6-733-743

Текст научной статьи Trends in the development of industrial robotic manipulators

Review article

Лукьянов В.В., Вотинцев В.В., Ильина В.Н., Ахмадуллина А.Ф. Тенденции развития промышленных роботов-манипуляторов. Нанотехнологии в строительстве. 2025; 17(6):733–743. – EDN: QKRTOV.

With the digitalization and automation of production processes, industrial robotic manipulators are becoming an integral part of modern enterprises, including those in the oil and gas industries. Their use significantly improves the efficiency, precision, and safety of operations during production, maintenance and repair, and technological processes in extreme and hazardous conditions.

According to GOST 25686-85, an industrial robot (robot-manipulator) is an automatic machine, stationary or mobile, consisting of an actuator in the form of a manipulator with several degrees of mobility, and a reprogrammable software control device for performing motor and control functions in the production process.

In modern robotics, manipulators occupy a key place due to their versatility and ability to perform complex operations with high precision and speed. Effective implementation and operation of robotic manipulators requires a thorough understanding of their design features, control methods, and manufacturing technologies.

Types of robotic manipulators and their characteristics

According to their design, manipulation mechanisms are divided into manipulators of sequential [1] and parallel [2] structures. Recently, manipulators of parallel-sequential structure (hybrid), which combine the advantages of both design schemes, have become widespread.

The key performance characteristics of robotic manipulators include [3]:

– workspace – the area within which the robot can perform tasks;

– load capacity – the maximum mass the manipulator can move;

– accuracy and repeatability – the ability to achieve and repeat specified positions with minimal error;

– speed and acceleration;

– rigidity and stability of the structure, ensuring reliability and stability during operations.

Market analysis

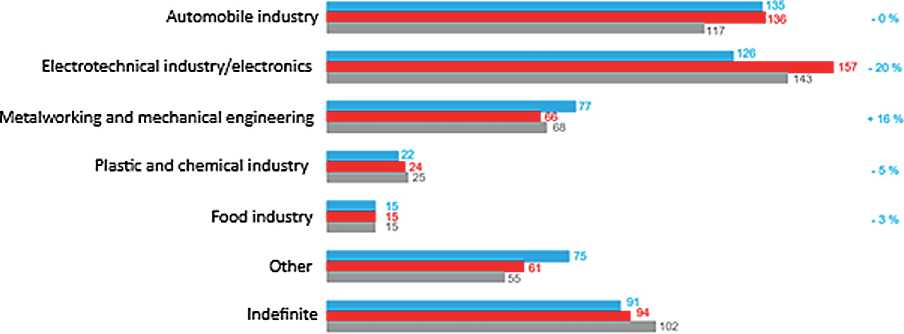

The choice of a specific robotic manipulator design is determined by the industry of use. Industrial robotics has evolved significantly in recent years due to the demand for intelligent, flexible, and autonomous automation solutions. Figure 1 shows the trend in robotic manipulators usage across various industries from 2021 to 2023 [4].

In terms of application industries, the largest consumer of industrial manipulators remains the automotive industry, accounting for approximately 40% of all deliveries. Logistics and warehouse automation, particularly in the context of growing e-commerce, account for approximately 20%, and the remaining 10% is accounted for by the food, pharmaceutical, and electronics industries [5].

The manufacturing sector, including metalworking, assembly, and packaging, uses approximately 30% of the total number of manipulators [6]. The use of cobots in the automotive industry allows for a reduction in assembly

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

The number of industrial robots installed by customers from various industrial sectors, 1СОЭ units

Fig. 1. Trends in the use of robotic manipulators in various industries from 2021 to 2023

cycle time by 30% and an increase in product quality by 15% [7].

In logistics, autonomous mobile robots (AMRs), which combine robotic manipulators, cameras, and adaptive endpoints to handle a variety of products, reduce warehousing costs by 25% [8]. Unlike traditional automated guided vehicles (AGVs), which use fixed routes, AMRs’ AI-powered navigation optimizes routes. This has resulted in Amazon seeing a 40% increase in order fulfillment speed, while Ocado has seen a 99.8% increase in accuracy [9]. However, the high cost of AMRs compared to traditional AGVs requires an analysis of their economic feasibility.

In healthcare, robotics improves the precision and quality of patient care, as exemplified by soft robotic gloves and minimally invasive surgery (MIS) systems such as the Da Vinci [10]. Pneumatically powered gloves improve dexterity during rehabilitation, while MIS reduces complications by 30% and increases the precision of neurosurgical procedures by 50% [23]. Modern robotic manipulators are finding application in areas of medicine that require high-precision surgical interventions [11]. However, the long payback period of five to seven years limits their availability.

Agriculture is demonstrating the potential of robotics to address labor shortages and promote sustainability: systems such as the flexible parallel tomato packing robot reduce labor time by 31% and minimize fruit damage through optimized path planning [12]. AI-powered drones optimize crop monitoring, reducing losses by 20% and water consumption by 30% through multispectral imaging [13]. In the UK, robots such as Dick are used for targeted weed control without chemicals, promoting sustainable agriculture [14].

Manipulators are particularly important in environments inaccessible to humans. In the space industry, they are used to service satellites and conduct operations in orbit. The International Space Station uses the Mobile Servicing System, including Canadarm2 and Dextre, to install and repair equipment in outer space [15]. Similarly, underwater manipulators such as Sea Dragon III are used for seafloor exploration, deep-sea servicing, and rescue operations.

The service industry also actively uses robotic manipulators, which provide services to people in homes, hotels, shopping centers, and medical facilities. Modern developments in human-machine interaction make such systems convenient and intuitive for users. Robotic manipulators are increasingly used for educational purposes [16].

In the oil and gas industries, robots are used both in production and in subsequent technological processes [17]. The Norwegian company Robotic Drilling Systems is developing intelligent drilling technology in collaboration with NASA [18]. ABB has developed an integrated remote monitoring system for tracking all critical plant parameters from a single platform [19]. At the end of 2021, Nabors Industries, in collaboration with ExxonMobil, tested the world’s first fully automated land drilling rig, the PaceR801. This innovative rig is equipped with a specialized robot capable of automatically lifting drill pipe segments and securely attaching them to the drill string. This technological solution accelerates the process of connecting pipes and, accordingly, increases the drilling speed [20]. Highly maneuverable underwater robots, controlled by an operator on board a surface vessel, are used for internal and external inspection, as well as repair of underwater pipelines [21]. A six-axis robot is used at the Daewoo shipbuilding company for welding

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES tanker walls [22]. In Russia, the national project “Means of Production and Automation” creates the conditions for the confident development of robotics in the oil and gas sector [23]. The main types of robots used in the fuel and energy complex (FEC) are manipulators, warehouse robotic systems, flaw detectors and welding devices. At the “Oil and Gas 2025” exhibition, it was noted that, according to the instructions of the President of the Russian Federation, by 2030 there should be 230 robots per 10,000 workers in the FEC [24].

The industrial robotic manipulator market is currently demonstrating steady growth, driven by the accelerated implementation of automation in production processes and logistics. According to a study by Verified Market Reports, the global robotic manipulator market size was USD 398.87 million in 2023 and is projected to reach USD 505.6 million by 2028. The compound annual growth rate is estimated at 4.3% [25]. The main reasons for this growth are the implementation of robotics in the automotive industry, manufacturing, and logistics, as well as the spread of the Industry 4.0 concept, based on the integration of cyber-physical systems, the Internet of Things, and artificial intelligence [26].

As of 2023, Russia ranked 27th in terms of robot sales [27]. The AMO Steel Plant in Miass is developing the production of two-axis linear robotic manipulators, the cost of which is half that of imported analogues [28]. Russian Robot LLC has launched serial production of planetary gearboxes for industrial manipulators, adapted to Russian climatic conditions [29]. The С4-260St gearboxes from the REDUKTOR Scientific and Technical Center replace similar ones from Harmonic Drive (Japan) while maintaining accuracy [30].

Despite the positive dynamics, the market faces a number of challenges. First and foremost, high initial investments for acquisition, integration, and personnel training limit the implementation of robotic systems in small and medium-sized enterprises. There is also a shortage of specialists capable of not only operating but also servicing complex manipulation systems [31]. Compatibility of new equipment with existing production lines is an issue, requiring additional adaptation costs. Furthermore, strict regulatory standards and safety requirements complicate the implementation of new types of manipulators.

Industrial robots are capable of quickly moving heavy objects and using dangerous and sharp tools, posing a potential hazard to humans working in the same workspace [32]. Planning safe and collaborative workspaces for humans and robots is a key challenge in implementing robots in manufacturing. An algorithm for controlling all robot parameters in real time is proposed in [33]. The proposed tool, combined with an intelligent manufacturing core, integrates data from robotic manipulators into industrial big data for enterprise management. This solution opens up opportunities for the development of smart factories.

In the future, the market will be supported by scalable, modular, and intelligent solutions. A particularly promising direction is the development of cable, hybrid, and mobile manipulators, which feature reduced weight, increased working volume, and the ability to move between different production areas [34].

Mechanical part of a manipulator

A manipulator’s design is traditionally divided into three main subsystems: the mechanical part, the drive, and the control system.

The mechanical part of a manipulator forms its skeleton and ensures interaction with the external environment. Its main elements are axes and drives. Axes are rigid elements connected to each other by movable or fixed joints – drives. Drives provide rotational (revolving) or linear motion.

Robotic manipulators can have from three to seven or more degrees of freedom. Manipulators with three to five degrees of freedom are used to perform simple operations, such as grasping and moving objects. Robots with six degrees of freedom provide complete control of the position and orientation of the end-effector, which is necessary for complex operations. Manipulators with seven or more degrees of freedom are highly flexible and adaptable, which expands their application range [35].

To reduce weight and increase rigidity, additive manufacturing technologies and modern materials are used: aluminum and titanium alloys, carbon composites. The use of composites allows for a significant reduction in inertial loads and an increase in dynamic response [36].

Bearing assemblies are crucial elements, ensuring minimal play and friction during link rotation. Modern developments include the use of hydrodynamic and magnetic bearings [37].

The final element of the manipulator – the gripper – is designed to interact with the object. It can be mechanical, vacuum, magnetic, or adaptive, capable of changing shape to suit a specific object [38]. Modern grippers are equipped with pressure sensors and tactile sensors for more precise control.

Manipulator drive

A manipulator requires a drive to convert control signals into mechanical movement of the manipulator’s axes. There are three main types of drives:

– electric drives are the most common due to their high precision, ease of control, and compactness [39]. Servo motors with integrated encoders for feedback are often used;

– mechanical gearboxes (planetary, worm, harmonic), which are used to increase torque and reduce speed.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Modern gearboxes are designed to minimize backlash and energy loss;

– hydraulic and pneumatic drives are used where high force or rapid response is required. Modern hydraulic drive systems incorporate intelligent flow control and energy recovery [40, 60], which improves efficiency and reduces operating costs;

– hybrid and innovative drives combine the advantages of different drive types; for example, electromechanical drives with hydraulic elements are used to achieve maximum performance [41].

Modern drive design is based on a comprehensive assessment of parameters such as torque, speed, positioning accuracy, and energy efficiency. In recent years, an important trend has been the creation of modular designs that allow individual components to be replaced and upgraded to increase versatility and reduce operating costs [42].

Of particular interest is the integration of electromechanical drives with control systems based on PID controllers, state observers, and adaptive algorithms [43]. Harmonic or cycloidal gearboxes, which provide high gear ratios with compact dimensions, are increasingly being used in the design of drives for manipulators. Their modeling requires consideration of deformations and return backlash, especially in tasks involving precise positioning. The development of CAD/CAE technologies has made it possible to significantly simplify this process [44].

In addition to electromechanical solutions, hydraulic and pneumatic drives are being actively researched and applied, particularly in applications requiring high power density [45]. Their modeling is carried out using specialized libraries in Simulink and Modelica, which allows for the consideration of nonlinear flow characteristics, throttling, and fluid dynamics [46].

The patent [47] describes proposed solutions aimed at increasing the accuracy, reliability and efficiency of drives of industrial robotic manipulators.

Gearboxes are a critical component in the design of manipulators, providing torque transmission with high gear ratios, precision, and reliability. Modern gearbox manufacturing methods focus on high precision, minimizing backlash, and increasing service life [48]. Gearbox components (gears, shafts) are selected with a tolerance of ±2 µm to minimize backlash [49].

The selection of materials for industrial manipulator gearboxes plays a key role in ensuring the reliability, durability, and efficiency of the entire system. Key material requirements include high strength, wear resistance, thermal stability, and resistance to fatigue loads [50]. The most common materials remain alloyed structural steels used for gears and shafts [51].

Heat treatment technologies for surfaces play an important role, especially for gear pairs operating under high loads. The use of induction and laser hardening allows for increased surface wear resistance while maintaining the ductility of the material core. To increase the service life of gears operating under high cyclic loads, heat-hardened steels with case hardening and quenching, as well as nitrocarburized materials, are widely used [52].

To test the theoretical assumptions a study of the structural composition of the metal of the gearbox of the 5th axis of the 6th axis robotic manipulator of one of the world’s leading manufacturers of industrial manipulators from Japan was conducted.

This robotic manipulator manufacturer implements torque transmission along the robot’s 4th axis using a mechanical transmission. The tested hypoid transmission samples had a strength exceeding 56 HRC. This confirms the need for thermal and thermochemical treatments to increase the mechanical hardness and wear resistance of mating pairs of mechanical contacts.

A spectral analysis of the gearbox wheel material revealed that the hypoid gear material composition of the fifth axle is close to that of AISI-grade stainless steel. This stainless steel standard was developed by the American Institute. Among the AISI-grade steels, the grade AISI4140 is noted.

AISI4140 is a low-alloy steel containing chromium, molybdenum, and manganese. It exhibits high fatigue strength, abrasion and impact resistance, and excellent impact toughness, strength, and ductility. In the annealed condition, the steel exhibits good machinability and can be formed using traditional methods.

Hardening heat treatment involves heating to 845 °C followed by oil quenching. Prior to hardening, normalization can be performed by prolonged heating at 913 °C followed by air cooling. Tempering is performed at temperatures ranging from 205 °C to 649 °C, depending on the desired hardness. Hardness can be increased by lowering the tempering temperature.

Domestic equivalents include AISI4140 steel, low-alloy structural steels 40H and 20HM, and heat-resistant relaxation-resistant steels 30HMA and 30HM. Of these grades, alloy steel 40H exhibits the highest strength after hardening treatment. This increased strength is due to the presence of carbon and strong carbide-forming elements such as chromium and molybdenum. Therefore, this steel is recommended for use in the manufacture of gearbox components, specifically the hypoid gear of the fifth axle.

As is well known, steel strengthening is achieved through heat treatment, including quenching and tempering. For 40H steel, quenching is carried out from a temperature of 860 °C in oil [53]. The tempering temperature is selected depending on the required properties (Table 1).

As an alternative to heat treatment, surface layer hardening can be used. The most common technology is case hardening. Traditionally, case hardened steels, after completion of thermomechanical treatment, have high hardness and wear resistance of the surface layer, and

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES limited core hardness at the level of 25...35 HRC. Case hardening of 40H steel is carried out at a temperature of 920 °C in a charcoal carburizer with an active saturation duration of 8 or 12 hours [54]. Subsequent heat treatment consists of quenching the samples in oil at T = 860 °C and subsequent low tempering at a temperature of 200 °C for 1 hour.

Another promising method for strengthening metallic materials, including alloy steels, is severe plastic deformation (SPD), which leads to the formation of a structure in the nanoscale range [55, 56]. Equal-channel angular pressing and all-round forging are widely used to obtain bulk nanomaterials [57, 58]. Structural changes in the material after SPD lead not only to an increase in strength characteristics, but also, according to a number of studies, change the corrosion behavior. Thus, the authors of the studies note an increase in the corrosion resistance of low-alloy steels with a decrease in grain size to the nanostructured range [59, 60]. This fact may be of interest from the point of view of expanding the field of practical application of gearboxes made of low-alloy steels in a nanostructured state.

Aluminum alloys are also used to produce gearboxes, particularly in lightweight manipulators and collaborative robots. However, due to aluminum’s limited wear resistance, anodizing or hard coatings are used [61]. For example, diamond-like carbon films are used to increase surface hardness and reduce the coefficient of friction [62].

Manipulator axes, which also serve as drive gearbox housings, are made of aluminum-based alloys. This re- duces the inertia of the robotic manipulator’s axes and ensures the necessary mechanical strength of the gearbox housing.

The results of the spectral analysis of the gearbox cover are presented in Table 2. The part is made of an alumi-num-silicon alloy. The closest in composition is the AK12 alloy, which belongs to the widely used casting silumin [63]. Aluminum alloys are often used in the designs of planetary gearboxes, in drives where compactness and light weight are required. Aluminum housings are distinguished by a complex shape. Due to the fluidity of special aluminum alloys during casting, it is possible to obtain a configuration that is impossible to cast from cast iron. Aluminum – silicon casting alloys have relatively good corrosion resistance [64], which is due to the formation of a mixed oxide film on the surface, consisting of Al2O3 and SiO2. The mechanical properties of AK12 silumin are presented in Table 3. Casting silumins are characterized by low strength and poor machinability. Mechanical properties depend on the concentration of impurities, as well as the homogeneity and dispersion of the resulting cast products. Mechanical characteristics can be improved by modification with oxides of various metals (γ-Al2O3, ZrO2, Al2O3, TiO2, SrO), rare earth elements (Sr, Cr, Sm), carbides (TiCN), borides (Nb-B, Ti-B). With an increase in the amount of the introduced modifier, the strength characteristics increase [65]. A significant disadvantage of aluminum alloys is the relatively high thermal coefficient of linear expansion (1.5–2.5 times higher than that of cast iron).

Table 1. Mechanical properties of 40H steel depending on tempering temperature

|

Tempering temperature, оС |

σВ, MPa |

σ0.2, MPa |

δ, % |

ψ, % |

KCU, J/cm2 |

HB |

|

200 |

1760 |

1560 |

8 |

35 |

29 |

552 |

|

300 |

1610 |

1390 |

8 |

35 |

20 |

498 |

|

400 |

1320 |

1180 |

9 |

40 |

49 |

417 |

|

500 |

1150 |

910 |

11 |

49 |

69 |

326 |

|

600 |

860 |

720 |

14 |

60 |

147 |

265 |

Table 2. Elemental composition of a “cover”-type part

|

Al |

Si |

Cu |

Mg |

Fe |

Zn |

Mn |

Pb |

|

|

Сurrent |

82.15 |

12.60 |

2.12 |

1.33 |

0.72 |

0.658 |

0.215 |

0.054 |

|

GOST 1583-93 |

84.3–90 |

10–13 |

up to 0.6 |

up to 0.1 |

up to 1.5 |

up to 0.3 |

up to 0.5 |

– |

Table 3. Mechanical properties of aluminum alloy AK12

|

σВ, MPa |

σ0.2, MPa |

δ, % |

|

|

Chill casting, GOST 1583-93 |

147–157 |

– |

2–3 |

|

Die casting, GOST 1583-93 |

147–157 |

– |

1–2 |

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

In [66], it is proposed to use precision grinding as the final stage of mechanical processing to ensure high quality gear engagement. In addition to traditional processing, additive technologies are being actively introduced [67]. For example, laser powder fusion and electron beam melting make it possible to manufacture gearboxes with complex geometry and high structural density. These methods are especially relevant in the production of small-scale or experimental models of gearboxes [68]. One promising direction is the use of hybrid production technologies that combine additive manufacturing of the basic shape with subsequent precision mechanical processing [69]. This reduces production costs while maintaining high performance characteristics, especially in the case of small batches.

Powder steels provide superior performance compared to traditional steels, especially when operating under conditions of limited lubrication [70]. The use of polymer composite materials for the manufacture of gearbox housings or secondary components is relevant. Materials such as glass fiber-reinforced polyamide or polyetherimide offer sufficient rigidity with lower weight, which is especially valuable in mobile manipulators [71].

Assembly of gearboxes for manipulators is a critical step, directly affecting the precision, reliability, and durability of the mechanism. Modern assembly methods are aimed at minimizing backlash, correctly positioning gears and bearings, and ensuring optimal tension and lubrication. High-precision automated assembly lines using laser positioning systems allow for assembly accuracy of a few microns [72].

One of the key areas is the use of additive technologies and 3D printing for the production of special assembly fixtures and templates, which reduces assembly time and improves its quality [73]. Such methods simplify the verification process and reduce the influence of the human factor, which is especially important for the mass production of manipulators with high repeatability of parameters [74].

Quality control at all stages of manipulator production is a key factor influencing the reliability and accuracy of the final product. At the initial stages, special attention is paid to checking the quality of raw materials and components [75], and the use of modern methods of spectral analysis and ultrasonic testing helps identify microdefects at early stages [76].

During the machining and assembly of manipulators, both traditional control methods, such as measuring geometric parameters using coordinate measuring machines, and innovative approaches, such as laser scanning and optical flaw detection, are used. These methods ensure high measurement accuracy and allow for prompt adjustments to the technological process [77]. A number of modern systems utilize intelligent sensors and feedback systems, allowing for the adaptation of assembly parameters to specific operating conditions [78].

During the final assembly and commissioning stages of gearboxes and drive systems, dynamic tests, including vibration analysis and acoustic emission testing, are particularly important. They allow for the detection of imbalances, bearing wear, and gear defects, which can significantly impact the durability of the manipulator during operation [79].

Automated quality control systems using machine vision and artificial intelligence are being implemented in modern manufacturing facilities. These systems not only detect surface defects but also assess the condition of assembly units in real time, significantly reducing production cycle times and decreasing the number of defective products [80].

CONCLUSION

Industrial robotic manipulators continue to evolve, opening up new opportunities for automation and increased efficiency in production processes across all industries, including the oil and gas sector. Their further improvement requires an interdisciplinary approach integrating engineering, software, and technology solutions. The results of this review can be used for the selection, design, and implementation of industrial manipulators in enterprises, as well as for further scientific research in the field of robotics.