Ultrasound treatment: effect on germinating barley

Автор: Kretova Yu.I., Avdeeva L.A., Annapure U.Sh.

Рубрика: Пищевые ингредиенты, сырье и материалы

Статья в выпуске: 2 т.11, 2023 года.

Бесплатный доступ

We investigated the way ultrasound exposure enhances the germinating of barley for brewing as germination is a major issue for the brewing industry. The rate of germinating of ultrasound-exposed grains were compared to those of non-exposed ones that germinated under normal conditions. Optimum parameters of treatment were obtained by two-factor analysis, with regard to post-storage initial state of the grains. Power and duration of ultrasonic exposure varied between 360 and 630 W, 1 and 5 minutes, respectively. The research found 9-10 % increase in germinating capacity of the treated grains versus germinating capacity of the non-treated ones. Heating power of 360 W and treatment duration of 5 minutes proved to have the strongest effect on the increase of the germinative ability. The aim of the study was to find the optimum non-conditions of ultrasound treatment to enhance the germination of conditioned barley for brewing. The method offers an opportunity to monitor the process the process and control the nature of metabolic processes in germinating grains.

Ultrasonic exposure, barley, malt, rate of germinating, germinative ability

Короткий адрес: https://sciup.org/147240827

IDR: 147240827 | УДК: 663.421 | DOI: 10.14529/food230203

Текст научной статьи Ultrasound treatment: effect on germinating barley

Barley is one of the world’s most important cereal crops. Barley grains occupy 90 % of raw components in brewing, with just 10 % left for other cereals: rice, corn, wheat, sorghum, oats, rye etc. However, poor quality of barley grown in Russia makes its most part (50–70 %) a cattle fodder, and only 30 % is good enough for brewing [5, 13]. In terms of quality, the barley acceptable for malting must have high germinative ability (more than 90–95 %).

Quality divides barley into two groups: conditioned and non-conditioned one. Conditioned barley used for brewing is then divided into classes (depending on its germinative ability):

-

- class 1 (germinative ability ≥ 95 %);

-

- class 2 (germinative ability 90 to 94 %).

However, leaders of malting both in Russia and in other countries struggle to obtain the required amount of the conditioned barley. One of the main reasons is a weak rate of germinating due to poor physiological quality caused by unfavourable weather conditions [9]. E.g. in 2007, in Australia continuous drought reduced production volume of conditioned barley [1]; that same year, in Europe, low temperatures in winter and hot and dry summer exceeded humidity of corn, as grains had been damaged before germination [10]. In 2018, Russia increased its barley-planted areas by 3.5 % (vs. 2017), yet its crop yield dropped by 18 % because of abnormal heat that set at the most part of the European continent, too [9].

This explains why only half of the barley grown had high germinative ability (more than 90 %) and was good for brewing, whereas the other half could only be used as food (25 %) and/or fodder (25 %).

The problem of timely, sustainable and sufficient supplies of conditioned barley to the maltmakers may find its solution through rise of nonconditioned raw material quality.

To overcome this difficulty, malt-makers and suppliers should purposely turn to innovative technologies of grains treatment, as traditional methods require too much labor, expensive equipment and do not always give desired result [6, 15].

One of the most promising methods that solves this problem seems to be a resource-saving technology of treating the grains with ultrasound (US) [3, 5, 12].

Ultrasound is a proven stimulator of vital forces naturally available in every agricultural plant, which is why it is widely used for preplanting treatment of grains [11, 16, 17].

Russian and foreign researchers found that ultrasound oscillations contribute to greater germinating and growing power, thus having a positive effect on germinating of grains and further development of plants [11, 16, 17].

When exposed to ultrasound, the surface of dry grains forms microcracks [8] of typical size (10–5–10–6 m), that weaken mechanical strength of cover and make gas and moisture exchange easier. As a result, grains swell faster and germinate sooner than usual, plants develop better and produce higher crop of grains and herbage. E.g grains treated with ultrasound spring 2–3 days earlier than non-treated ones, with 30 % increase in spike length and number of its grains.

Germination of grain is the most important process of malting. In the process, the grain undergoes biochemical and physiological changes similar to those of natural growing in the soil. This is why US treatment may produce the same effect, if the grain of barley to be used for malting will be used as an object of action.

The purposes of barley germination on malt are:

-

1) grain accumulates maximum amount of active ferments to biologically convert amylum into soluble carbohydrates that can be fermented with yeast;

-

2) preparedness of reserve products to ferment exposure.

Activity of ferments is essential, as it ‘sets pace’ for all physiological processes the grain undergoes during germination on malt.

Activation and work of ferments in the germinating grain launch the following necessary processes:

-

1) biological – germination of germ, formation of new substances, breathing and morphological changes of the grain (development of organs and of the kernel itself);

-

2) biochemical – hydrolysis of endosperm reserve products;

-

3) chemical – interaction of solved substances obtained by hydrolysis and formation of aromatic and taste substances;

-

4) physical – transportation of solved reserve products from endosperm to germ and back.

These processes contribute to greater activity of ferments and formation of new substances as the grain germinates. These substances catalyze conversion of highly-molecular reserve products of grain endosperm (amylum, albuminous substances, oils etc.) into simpler ones, easy to solve and transportable to germ, necessary both for feeding and developing of germ and, in future, for obtaining desired quality of the brewing syrup.

In addition, ultrasound increases penetrability of biological membranes [8] and activates activity of ferments that, in its turn, accelerates metabolism extremely important for barley germination on malt, because a sprouted grain (malt) is the richest source of ferments.

However, only several regimes of ultrasonic exposure have a positive effect. Biological influence the ultrasound has on cells and tissues relies mostly on intensity of ultrasound and duration of exposure [2, 18].

Scientific research performed in many countries agree that different parameters of US-exposure cause different biological effects. E.g., positive effect is possible at low intensities of ultrasound (up to 1–2 Wt/cm2) when mechanical oscillations of particles work as micromassage of tissues that improves metabolism and supplies tissues with blood and lymph. At medium intensity (2 to 10 Wt/cm2), variable ultrasonic pressure can destroy, conver and/or damage biomacromolecules.

Negative biological effect occurs at continuous exposure and intensity of more than 10 Wt/cm2. This regime causes undesirable morphological and functional changes accompanied with irreversible damages, beginning with the cell nucleus, and are expressed in pathological deformations, destruction of cells and homogenization of tissue. In addition, ultrasound can inactivate ferments, and results of many researches prove this [2, 17].

Thus, the nature of metabolic processes in a germinating grain may be affected by various parameters of ultrasonic exposure. The mechanism of the effect ultrasound has on the grain during barley germination on malt is not yet known completely, which is why the study of this issue makes a scientific interest.

The aim of the study was to find the optimum conditions of ultrasound treatment to enhance the germination of conditioned barley for brewing. The method offers an opportunity to monitor the process the process and control the nature of metabolic processes in germinating grains.

Materials and methods

Sample collection and preparation

Samples of barley were grown in Russia, in different areas of Kurgan, Sverdlovsk, Tyumen and Chelyabinsk regions (lots 1, 2, 3, 4, respectively). 100 grains from each lot were selected for quality assessment; experiments were repeated at least 15 times. 100 g of weighted grains were selected as model samples for US treatment. Version of treatment depended on the regime of ultrasound exposure (Tabl. 1).

Table 1

Regimes of grain treatment

|

Treatment parameters |

No. of version |

||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

Duration of treatment, min |

5 |

1 |

5 |

1 |

5 |

1 |

3 |

3 |

3 |

|

Power of exposure, Wt |

630 |

630 |

360 |

360 |

495 |

495 |

630 |

360 |

495 |

Regimes of ultrasonic treatment for grain mass accounted for variations of power (360, 495 and 630 Wt) and duration of treatment (1, 3 and 5 minutes). To process the studied samples based on ultrasonic exposure, Volna-M ultrasonic technological device (model UZTA-04/22-OM) with the following characteristics was used: frequency of mechanical oscillations – (22 ± 1.65) kHz; power – 400 VА; ultrasonic exposure intensity, no less than 10 W cm–2; radiating surface diameter – 25 mm.

The ultrasonic oscillatory system is built on piezoelectric ring elements and is made of VT5 titanium alloy. The engineering solutions used are protected by the RF patent No. 2141386.

The effect of ultrasonic exposure to rate of germinating of barley grains was monitored throughout the germination period, as well as 120 hours after the barley had been put for germination.

The following control parameters prove positive direction of the germination process:

-

1) ‘eyes’ after 24 hours;

-

2) roots (sprouts) after 72 hours;

-

3) number of grains germinated in 120 hours (% of the whole number of the grains analyzed) since the moment grains were put for germination.

Indicators were assessed with regard to conditions of barley grain growing. Variation coefficient ( ν в, %) was calculated with methods of mathematical statistics.

Design of the experiment

The first step focused on the quality of barley grown in Russia, in different areas of Kurgan, Sverdlovsk, Tyumen and Chelyabinsk regions.

Then, one part of dry barley was treated with ultrasound (model samples), and other part was not (control samples).

Barley grains were placed in a glass tumbler and exposed to ultrasound (Fig. 1).

The second step studied how ultrasonic exposure effected barley grains rate of germinating during germination.

Rate of germinating of barley treated and not treated with ultrasound was found when wet grains were being germinated at constant temperature (20 °С). Average samples (50 g) of grain were taken from every lot; then two analytical samples of 500 grains each were formed.

Rate of germinating was estimated visually, after 120 hours.

Barley is thought to have germinating power when it produces so called ‘eyes’ (the first indication of rootlet) in 24 hours since the moment of germination, and, after 72 hours of germination has well-developed white firm branched rootlets (sprouts) of the length equal to caryopsis or 1.5–2 times longer. 90 % and/or more grains must germinate in 120 hours (% of total amount of the grains analyzed).

Fig. 1. Grains being exposed to ultrasound

Statistical data analysis

The experimental data was processed using traditional variation statistics methods and expressed as an arithmetic mean (m) and a standard error (m). Statistically significant differences between the test and control groups were determined through the use of Maneesn-Whitney test (U). Results were expressed as an arithmetic mean and its standard deviation. The differences were considered significant at p < 0.05. Statistical interrelations were studied using the nonparametric correlation analysis by calculating the Spearman correlation coefficients (PC).

Results

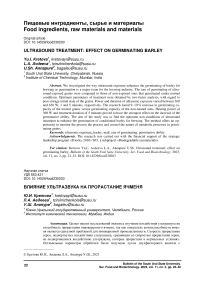

Analysis of barley quality control results shown in Fig. 2 found a significant percentage (37–58 %) of non-conditioned grains inappropriate for brewing.

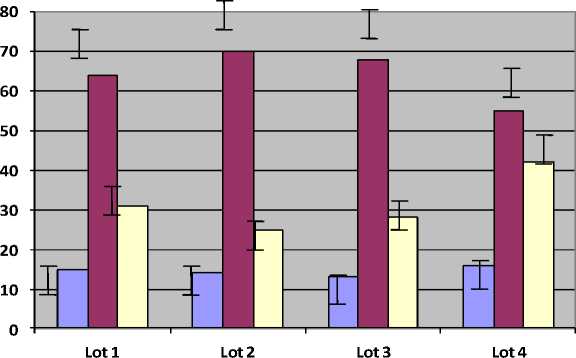

Amount of noconditioned barley increases annually, as data in Fig. 3 show.

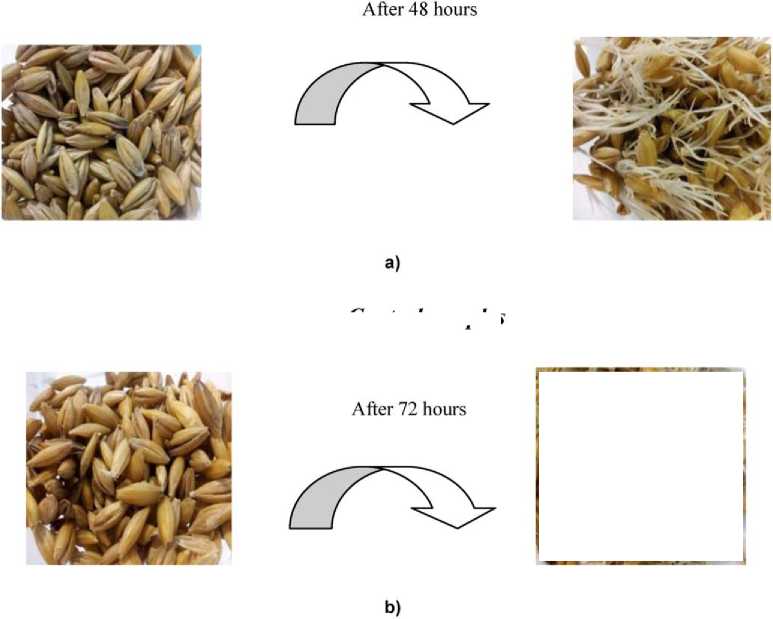

Control sample of barley failed to produce ‘eyes’ after 24 hours (Fig. 4,а). In 72 hours since the moment of germination, only some grains of barley developed branched rootlets, as long as caryopsis or even longer (Fig. 4,b). After 120 hours, the analysis of germination found (83 ± 2) % germinated grains, 7 % below the threshold value (Fig. 4,c).

□ Conditioned barley (class 1)

□ Conditioned barley (class 2)

□ Non-conditioned barley

Fig. 2. Percentage of conditioned/non-conditioned barley in total amount of grains in sample lots from different areas of Russia: Kurgan, Sverdlovsk, Tyumen and Chelyabinsk regions (lots 1, 2, 3, 4, respectively)

Fig. 3. Percentage of non-conditioned barley vs. total amount of grains in sample lots of barley from different areas of Russia in the period between years 2015 and 2018

a) b)

c)

Fig. 4. Control sample of grain after 24 (a), 72 (b) and 120 (c) hours of germination (photo)

The second step of the experiment researched how ultrasonic exposure affects the rate of germinating of non-conditioned barley.

Steady germinative ability [14] is known to be important in assessment of barley acceptability for malting, this was why we watched if the treated barley produced ‘eyes’ in 24 hours since the start of germination.

The results are presented in the Tabl. 2.

Passing of rootlet through the shells of the grain gives the external indication the germination has started. However, regimes of US exposure have different effect on the rate and nature of exchange processes in the germinating grains. Specifically, some regimes of treatment (No. 2, No. 3 and No. 5) contribute to appearance of numerous ‘eyes’ as early as one day since start, while other regimes deter germination (No. 1, No. 4, No. 6–9).

Different reaction of barley grains to 1–5 minutes exposure to ultrasound of 22 kHz, 360– 630 Wt gives an insight into the mechanism of action, that in many ways depend on the parameters of exposure (power and duration).

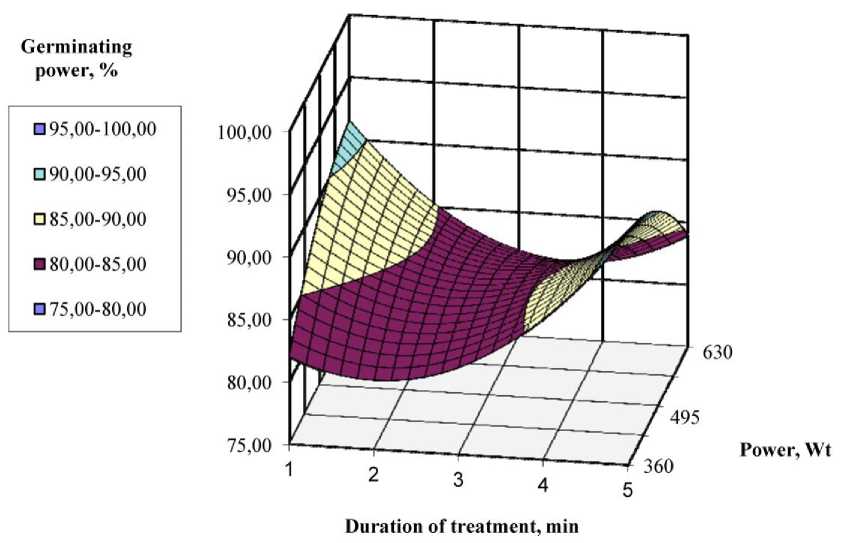

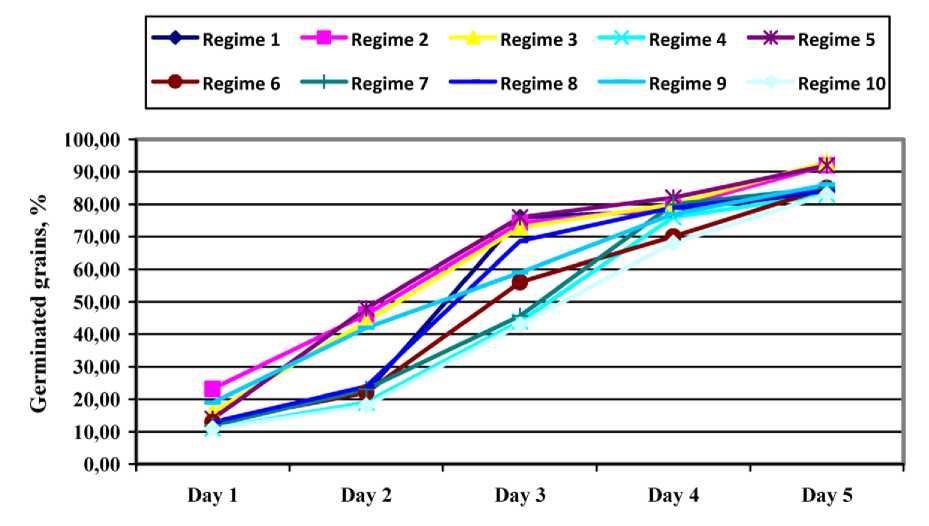

The effect of US exposure was assessed through the number of grains that germinated after 120 hours. Fig. 5 shows how US exposure affected rate of germinating of the barley grains.

Specifically, regimes No. 2, 3 and 5 demonstrated the strongest ‘germinating’ effect. As early as on the second day (after 48 hours) we could see well-developed, white, firm, fresh young rootlets (sprouts, Fig. 7, a), whereas control barley demonstrated well-developed rootlets only after 72 hours (Fig. 7, b). This is how barley germination on malt can be intensified.

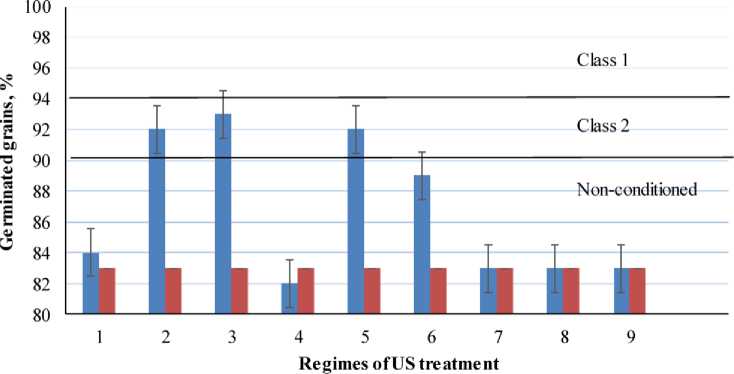

They offer maximum increase in germinative ability, 9–10 % vs. control samples, and increase its quality. After the US treatment, germinative ability of non-conditioned barley reached 92– 93 % (see Fig. 8), that agrees with ‘conditioned barley’ quality category (Class 2).

Discussion

The result of biochemical processes during barley germination depends on the quality of the raw grain being processed. Low qualitative indicators were the main reason why brewing barley was transferred to non-conditioned category. In particular, control samples of barley grains had low germinating power (83 ± 2 %). This barley cannot be used for malting, as, for normally ripen grains, the energy of germinating exceeds 95 % of germinated grains with well-developed rootlets, and germinative ability does not fall below 95 % (for class 1 barley) and 90 % (for class 2 barley).

Tablе 2

Typical examples of US-treatment effect on the grain germinating power (in 24 hours)

Regimes of US exposure

No. 2 No. 5

No. 3

No. 4

No. 6

No. 8

No. 1

No. 7

No. 9

Results of research presented in Fig. 6 prove positive effect US exposure has on barley germinating power that increases by 1–10 % vs. the control sample.

Germinating power of model samples varied between 84 and 93 % depending on power and duration of exposure (Fig. 8).

Analysis of data presented in Fig. 8 highlights the most effective parameters of treatment.

Regimes most favourable for US treatment of barley are:

-

- No. 2 (duration 1 minute, power 630 Wt),

-

- No. 3 (duration 5 minutes, power 360 Wt),

-

- No. 5 (duration 5 minutes, power 495 Wt).

Fig. 5. Grain germinating power affected by US exposure

Fig. 6. Dynamics of brewing barley germination after US exposure (germinated grains), %

Model samples

Fig. 7. Germinating power of model (a) and control (b) grain samples after 24, 48 and 72 hours

Control samples

Model sample

Control sample

Fig. 8. Grains germinated after 120 hours (percentage of germinated grains), %

US treatment stimulates biological activity of the barley grain; the effect of the exposure is different and depends on the parameters of regime. Some regimes of exposure activate grains (accel- erate germination, increase growing of roots), while others inhibit them. Change of water absorption dynamics can be an important result of such exposures [7]. Thus, at certain parameters of exposure some heterogenous parts of caryopsis vibrate and make microstructure of natural channels in the grain appropriate for transporting of water and nutrients. Water absorption can accelerate denaturation and unwinding of polypeptide chains in the germ and endosperm and forms cavities where additional osmotic water rushes.

This creates good conditions for activity of the germ, release and transportation of ferments into the cells of aleurone level, synthesis of ferments important for amylolysis in the endosperm cells and germ feeding during germination.

Thus, certain regimes of US exposure and variation of US treatment parameters (power and duration) can manage barley germination on malt, influence germination rate and degree of barley swelling.

Variation of germination rate and degree of swelling result from structural changes in the caryopsis and offer a mechanism for US exposure to increase the activity of the main groups of hydrolytic ferments that, in its turn, improves the quality of the end malt.

The main goal of barley germination on malt is the synthesis and activation of enzymes, which is achieved by dissolving the mealy body of the grain. In this case, the grain structure changes, important biochemical changes occur: some enzymes pass from the inactive state to the active state, others are formed as a result of synthesis. The activity of enzymes changes the structure of endosperm cells, as a result of which the cell walls soften. Changes in the grain structure determine the degree of loosening of the grain endosperm an important technological factor of malting. This factor is due to the action of a complex of cytolytic and proteolytic enzymes, the rate of accumulation of which determines the quality of preparation of malt. These data are consistent with those of other scientists [16].

The nature of metabolic processes in germinating grains can be influenced by the use of various physical factors of influence [16]. In particular, US treatment can increase the activity of hydrolytic enzymes during the germination of barley in malt. US treatment has proved to be effective for increasing of the barley quality.

Conclusion

Ultrasonic exposure was used as a stimulating factor that increased activity of ferments.

Certain regimes of barley US treatment increased its rate of germinating by 9–10 % against the control sample, thus raising its quality to Class 2, that agrees with ‘conditioned barley’ quality category. Heating power of 360 Wt and treatment duration of 5 minutes brought the strongest effect in increasing of rate of germinating.

The research has found US treatment reduces time required for the cycle of barley germination on malt that, in its turn, intensifies technological process of grain treatment during germination on malt and reduces risk of defects.

Список литературы Ultrasound treatment: effect on germinating barley

- Bennell M.R., Verbyla A.P. Quantifying the response of crops to shelter in the agricultural regions of South Australia. Australian Journal of Agricultural Research, 2008, vol. 59, pp. 950-957. DOI: 10.1071/AR08188

- Carstensen E.L. Biological effects of low-temporal, average-intensity, pulsed ultrasound. Bioelectromagnetics, 1982, vol. 3, pp. 147-156. DOI: 10.1002/bem.2250030118

- Chandrapala J., Oliver C., Kentish S., Ashokkumar M. Ultrasonics in food processing. Ultrasonics Sonochemistry, 2012. vol. 19, pp. 975-983. DOI: 10.1016/j.tifs.2012.01.010

- Kastal'eva T.B., Bogoutdinov D.Z., Bottner-Parker K.D., Girsova N.V., Lee I.M. Diverse phytoplasmas associated with diseases in various crops in Russia - Pathogens and vectors. Sel'skokhozyaistvennayaBiologiya, 2016. vol. 51, pp. 367-375. DOI: 10.15389/agrobiology.2016.3.367eng

- Knorr D., Zenker M., Heinz V., Lee D.U. Applications and potential of ultrasonics in food processing. Trends in Food Science and Technology, 2004. vol. 15, pp. 261-266. DOI: 10.1016/j.tifs.2003.12.001

- Los A., Akkermans S., Boehm D., Cullen P.J., Van Impe J., Bourke P. Improving microbiological safety and quality characteristics of wheat and barley by high voltage atmospheric cold plasma closed processing. Food Research International, 2018. vol. 106, pp. 509-521. DOI: 10.1016/j.foodres.2018.01.009

- Patero T., Augusto P. Ultrasound (US) enhances the hydration of sorghum (Sorghum bicolor) grains. Ultrasonics Sonochemistry, 2015. vol. 23, pp. 11-15. DOI:10.1016/j.ultsonch.2014.10.021

- Rajewska K., Mierzwa D. Influence of ultrasound on the microstructure of plant tissue. Innovative Food Science and Emerging Technologies, 2017. vol. 43, pp. 117-129. DOI: 10.1016/j.ifset.2017.07.034

- Sabagh E.A., Hossain A., Islam M.S., Barutcular C., Hussain S., Hasanuzzaman M., Akram T., Mubeen M., Nasim W., Fahad S., Kumar N., Meena R.S., Kizilge?i F., Yildirim M., Ratnasekera D., Saneoka H. Drought and salinity stresses in barley: Consequences and mitigation strategies. Australian Journal of Crop Science, 2019. vol. 13, pp. 810-820. DOI: 10.21475/ajcs.19.13.06.p1286

- Schils R., Olesen J., Kersebaum K., Rijk B. and other. Cereal yield gaps across Europe. European Journal of Agronomy, 2018. vol. 101, pp. 109-120. D0I:10.1016/j.eja.2018.09.003

- Sharififar A., Nazari M., Asghari H. Effect of ultrasonic waves on seed germination of Atriplex lentiformis, Cuminum cyminum, and Zygophyllum eurypterum. Journal of Applied Research on Medicinal and Aromatic Plants, 2015. vol. 2, pp. 102-104. DOI: 10.1016/j.jarmap.2015.05.003

- Shestakov S. New technologies for the production of high-quality foodstuffs. Ind. Bull, 2005. vol. 6, pp. 4-7 (In Russ.). URL: https://www.promved.ru/articles

- Toropova E., Kirichenko A., Stetsov G., Suhomlinov V. Soil infections of grain crops with the use of the resource-saving technologies in western Siberia. Biosciences Biotechnology Research, 2015. vol. 12, pp. 1081-1093. DOI: 10.13005/bbra/1761

- Ullrich S., Clancy J., Del Blanco I., Lee H. Jitkov V. Genetic analysis of preharvest sprouting in a six-row barley cross. Molecular Breeding, 2008. vol. 21, pp. 249-259. DOI: 10.1007/s11032-007-9125-7

- Wilson S., Atungulu G., Olatunde G. Drying and decontamination of corn using a pilot-scale continuous-flow radiant heating system. American Society of Agricultural and Biological Engineers Annual International Meeting, ASABE 201620162016 ASABE Annual International Meeting; Disney's Coronado Springs Resort Orlando; United States, 2016. 17 July 2016 - 20 July 2016. DOI: 10.13031/ aim.20162460256

- Woonton B., Jacobsen J., Sherkat F., Stuart I. Changes in germination and malting quality during storage of barley. Journal of the Institute of Brewing, 2005. vol. 111, pp. 33-41. URL: https://www.researchgate.net/publication

- Yaldagard М., Mortazavi S., Tabatabaie F. Application of ultrasonic waves as a priming technique for accelerating and enhancing the germination of barley seed: optimization of method by the Taguchi approach Journal of the Institute of Brewing, 2008. vol. 114, pp. 14-21. https://doi.org/10.3136/fstr.25.489

- Yang S., Huang Y. The activation of growth in plant roots by ultrasound exposure. Biomedical Engineering - Applications, Basis and Communications, 2000. vol. 12, pp. 148-154. https://www.research-gate.net/publication/287458553_The_activation_of__growth_in_plant_roots_by_ultrasound_exposure