Выполнение бетонных работ в экстремальных климатических условиях в Черногории

Автор: Вукчэвич Ивана

Журнал: Строительство уникальных зданий и сооружений @unistroy

Рубрика: Технология и организация строительства: зарубежный опыт

Статья в выпуске: 1 (28), 2015 года.

Бесплатный доступ

В статье "Выполнение бетонных работ в экстремальных климатических условиях в Черногории" описываются возможные трудности в выполнении строительно-монтажных работ в зимний и летний периоды, даются рекомендации для успешного проведения бетонных работ в этих условиях. Рассматриваются климатических особенностей отдельных городов Черногории (Подгорица и Плевле) и условия бетонирования в этих областях. Приводится описание лабораторных испытаний, делается сравнительный анализ результатов испытания образца, который затвердевает при моделируемых экстремальных климатических условиях и при нормальных условиях окружающей среды.

Бетонные работы, лабораторные испытания, экстремальные климатические условия, черногория, технология производства работ, образцы бетона

Короткий адрес: https://sciup.org/14322179

IDR: 14322179 | УДК: 69

Текст научной статьи Выполнение бетонных работ в экстремальных климатических условиях в Черногории

Concrete, as a construction material, for years retains primacy in construction of objects: the building constructions, hydro constructions, road constructions. This material is made of mixture of aggregates, cement and water (with additives), and is often a subject of different examinations, by which is tried to improve its characteristics and add to its improvement in usage in spheres of work where it had limited access. The most prolonged problems, while working with concrete, are negative influences of climate in the construction area which are common for summer and winter periods of the year. Under these conditions are usually considered temperatures under plus 5 degrees and above 30 degrees Celsius, as expected representative temperatures in winter and summer months. But besides temperature, there are influences that with or without mutual combinations, can leave drastic consequences to the concrete (destruction of the same). Among these influence parameters, are mainly perceived: relative moisture, concrete temperature, area temperature, wind velocity, exposure to the sun rays and rainfalls. In this paper work, it will be presented laboratory examinations where the concrete exposed to the simulated extreme climate conditions, which are possible to expect in certain areas in Montenegro [1-20].

Climate characteristics and terms of concreting in Montenegro

Climate in Montenegro is very complex, which is due to: geographical width, elevation, nearness of the sea (water surfaces), relief, direction and position of mountain hinterlands close to the shore, as well as mountain massifs in other areas. According to the climate specifics through current drafts of Eurocodes the two main zones stand out in Montenegro: North and South, which in this work are represented by Municipalities and cities of Podgorica and Pljevlja [1, 3].

The area of the southern zone (region) is characterized by long, hot and dry summers with relatively mild (less colder) and rainy winters. In the valley of the river Moraca is situated Podgorica, the city with the highest average monthly temperature in summer and the highest average number of tropical days. The maximum air temperature in summer can exceed +40 º C, so these are considered as extreme temperature. Number of tropical days where air temperatures exceed +30 º C, in the 2012 were about 82. Average temperatures in the winter are + 7.3ºC, and in the summer over + 30 ° C. The highest mean annual rate has a northeast wind (6.2 m / s), with the highest value recorded during winter (average 8.9 m / s). Relative humidity, on an annual basis, the average is 59.6%. The amount of rainfall measured in 2012, in Podgorica, amounted to 1772 l / m2 and decreasing on average by 118 days (mostly in winter). Most a few days are snowy (3 days) and with frost (34 days).

In mountainous areas in the north of the state summers are relatively cool and winters are long and harsh, with the presence of extremely low temperatures and frequent frosts. The most northern municipality - Pljevlja is one of the coldest Municipalities in Montenegro. In January as the coldest month of the year, the minimum temperature is about -8.7 ° C and maximum +0.3 º C. However, in the winter, you can expect even lower amplitude of the temperature of the air in the mentioned municipality. The average minimum temperature in July is + 10.7ºC, while the average maximum temperature recorded in the same month, amounts to + 24.7ºC. Exactly due to its position valley of Pljevlja, shackled with high mountain ranges, almost 70% of the days in a year is without wind, and about 200 days with the fog. The average monthly value of humidity is lowest in May (70%), and highest in December (83.7%). The higher altitudes (in the mountains), in winter, increased tendency of development of frost. Pljevlja was town with the highest cloudiness in Montenegro, where the mean annual rainfalls is 797.5 mm.

Under hot weather or extreme summer conditions, it is possible to expect a combination of phenomena: high air temperatures (high ambient temperature - over + 30 ° C); high temperature of concrete; the small relative humidity; high wind speed; direct exposure to solar radiation concrete. This unfavorable parameters and conditions for work are typical of the city of Podgorica, during the summer period. Joint or individual effects, of these phenomena, will influence the decrease the quality of fresh or hardened concrete mixtures, through accelerating rates of loss and reduction of cement hydration. The concrete element exposed to the sun (higher temperatures) and the wind has a more pronounced degree of evaporation of moisture from the concrete, which is a favorable condition for the development of cracks in such elements. Potential problems, common in warmweather working with fresh concrete mix, have an increased need for water; increase in the rate of loss of consistency (loss of subsidence and increase the tendency for water on site, less spread); short curing time, which creates difficulties in handling, installation and finishing of concrete (risk of cold joints); increased tendency to cracking due to plastic shrinkage; increased difficulty in controlling entrained air content with aerated concrete. Expected effects that extreme summer conditions may have on the hardened concrete are: lower 28-day and subsequent strength; increasing shrinkage due to drying, resulting from the thermal cooling of the overall structure; reduced resistance to aggressive action and therefore reduced life; higher permeability (permeability), 100

as a result of the high content of water, inadequate cure and other adverse effects; increase the risk of possible corrosion of reinforcement due to poor structure (higher porosity) of concrete cover.

Cold-weather period, dominant during the winter months (occurs later in the fall and early spring), is considered as an extreme, if more than three consecutive days: the average daily air temperature is less than + 5 ° C when the air temperature does not exceed + 10 ° C, for more than half of a 24-h. Water, which in concrete may be present due to the increased w / c ratio or increased humidity environment (pronounced precipitation) and low ambient temperature in winter conditions, it can be destructive of concrete. Low ambient temperature, expected in the municipality of Pljevlja, are in the particular correlated with the temperature of the concrete. In these circumstances, there is a rapid cooling "fresh concrete" and slowing down the hydration process (at a temperature of -10 ° C up to its complete disruption), thereby endangering the key step for the maturation of the material and the acquisition of the expected mechanical properties. Note here mainly refers to the temperature below 0 ° C, which proved to be the cause of the formation of the so-called "Frozen concrete."The process that contribute to the creation this effect is taking place in capillary pores (with a diameter of about 10-7 mm), where they often contain water, which under these temperatures, have a tendency to transfer to the ice (ice volume increases by 9% as compared to water). The expansion of the ice toward the interior of the concrete is being developed pressures in the capillaries, potentially damaging to the structure of concrete (cement stone). Under these conditions it is expected that increasing porosity of the concrete, which leads to a reducing the possibility of obtaining the expected mechanical properties of concrete. If in time does not provide adequate protection in concrete can occur: a crack, as well as the appearance of flaking, separating the pieces and other.

The effects of extreme climatic characteristics (most environmental temperature) on concrete, in

Montenegro, are considered in the laboratory test which is made in Facylty of Civil Engineering in Podgorica.

Experimental testing

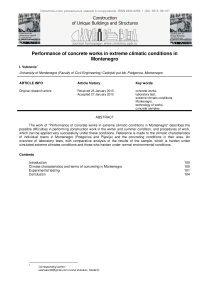

Conducted laboratory testing, where the 6 concrete cubes, mold dimensions 10x10x10 cm and 20x20x20 cm, exposed to simulated temperatures expected in extreme weather conditions (hot and cold period). The samples were, in this experiment , exposed to air temperatures of +60 ° C ( in the oven ) and -20 ° C ( in the freezer), as well as representatives of different temperature regimes that can be expected on place of fresh concrete. Three etalons, measuring 15x15x15 cm, obtained from the same concrete mixture, were hardened under normal conditions of curing at a temperature of +20 ° C and at relative humidity of about 80 % , over the same time [2].

The concrete mix is prepared in the laboratory, where they were to the mixer add the constituent components and Chemical admixture – Super plasticizer Kemament L20, according to the recipe shown in Table 1. At the time of making, super plasticizer previously mixed with water and as such is subsequently added to the mix. Supplement Kemament L20, included at 0.80% by weight of cement, reducing to 20% of the required amount of water to prepare concrete.

Table 1. Contents of concrete mixture

|

components |

participation (%) |

quantity (kg/m³) |

quantity for samples (kg) |

|

|

£ ел га с CD о d) о S го CD .Н га |

0-4 |

30 |

585 |

26.30 |

|

4-8 |

15 |

290 |

13.04 |

|

|

8-16 |

20 |

390 |

17.54 |

|

|

16-32 |

35 |

685 |

30.80 |

|

|

- |

Σ=100 |

Σ=1950 |

Σ=87.68 |

|

|

cement |

- |

380 |

17.09 |

|

|

water |

- |

165 |

6.60 |

|

|

W/C |

0.4 |

- |

- |

|

|

L20 |

0.8%*C |

3.04 |

0.14 |

|

The fresh mixture is placed in the corresponding metal molds, of which four sizes of the mold 10x10x10 cm, while the other two dimensions of the mold 20x20x20 cm. Concrete experimental samples were treated in the same way as for incorporation into the design, so after inserting concrete into metal formwork accessed compaction, using the pervibrators. After this, the samples are exposed to indicate temperatures. Three samples, two dimensions of 10x10x10 cm and one dimension 20x20x20 cm, are inserted into the furnace in which it will be exposed to temperatures of + 60 ° C. This temperature is adopted as a reference to the approximate simulation conditions similar to those expected in hot weather. The remaining samples made of concrete, of the same 101

dimensions, were placed in a freezer, where the temperature is about -20 ° C. The same concrete mix made three more concrete sample-standards, measuring 15x15x15 cm, which are maintained under normal laboratory thermo-hydrometric conditions. All samples were maintained under the above temperature regimes over a period of 7 days.

Figure 1. Samples exposed to high temperatures in the furnace ( +60°C) (a) and low temperatures in the freezer (-20°C) (b)

Two cubes, measuring 10x10x10 cm, immediately, by making the seven-day attention and exposure to extreme high and low temperatures ( in the oven and freezer), subjected to tests as are necessary to establish their compressive strength. At the same time, established the compressive strength of concrete in another cube, measuring 15x15x15 cm, after its controlled attention of 7 days in a normal environment. In accordance with that, the samples are removed from the molds and measures, which would provide information about there volumetric mass. Exposure to pressure force, using the hydraulic presses, are obtained the values of the strength of individual samples through a simple form:

Pl

о =

A where is the: Pl- breaking force expressed in kN, A- cross-sectional area of concrete samples, expressed in cm² , σ- compressive strength of concrete is expressed in MPa.

Other untested concrete samples (six cubes , where the two cubes measuring 10x10x10 cm, 20x20x20 cm and 15x15x15 cm) are left to the fourteenth day of caring in normal environmental conditions, with three stamps that already cured under such a regime. After completion of the prescribed period of care is carried out the same test procedure, which establish the compressive strength of concrete cubes of different sizes.

Figure 2. Strength tests on the concrete sample, after a period of care

Results obtained of concrete cubes that were left in the furnace, in the period mentioned above, have shown significant strength in comparison to those cubes that were under the influence of low temperature in the freezer, but also those who are hardened in normal environmental conditions (Tab. 2 and 3 ).

It is assumed that the reason for this result is the creation of such conditions (inside the furnace), where the concrete hardening process takes place in a humid environment, or the environment in which it is prevented from undue loss of moisture from the concrete as a result of his warming. This process, known under the name steaming concrete, is given the option to enable free hydration, along with eliminating the negative effects of shrinkage of concrete inside molds.

It can be seen that the samples, which are hardened under simulated winter temperatures, after a period of 7 days and 14 days, have drastically reduced strength. These values strength of concrete up to 50% lower than those achieved with simulated high temperatures. It was confirmed that the low temperature, which are concrete cubes were exposed, operated at slowing the hydration process and its complete termination, after a certain period. However, mention impacts are enabled to reach the specified minimum concrete strength, which is presented as a result of the heat of hydration reached before the start of the procedure of freezing samples (Tab. 2). During testing it was observed that the concrete mixture samples insufficiently hardened, as might be expected in the circumstances the environment.

Table 2. Characteristics of concrete in the winter and summer and normal operating conditions

|

Winter conditions (-20 °C) |

Summer conditions (+60 ° C) |

||||||||||||

|

concrete cubes (cm) |

m (g) |

Pl (kN) |

γ (kg/m3) |

σ (MPa) |

m (g) |

Pl (kN) |

γ (kg/m3) |

σ (MPa) |

age (days) |

||||

|

a=10 |

2546 |

182.5 |

2546 |

16.43 |

2457 |

400 |

2457 |

36.00 |

7 |

||||

|

a=10 |

2503 |

197.5 |

2503 |

17.78 |

2449 |

410 |

2449 |

36.90 |

14 |

||||

|

a=20 |

19610 |

700 |

2451 |

17.50 |

18663 |

1455 |

2333 |

36.38 |

14 |

||||

|

σsr=17 .64 |

σsr=36. 64 |

||||||||||||

|

Normal conditions (+20°C) |

|||||||||||||

|

cubes (cm) |

m(g) |

Pl(kn) |

γ (kg/m3) |

σ (Mpa) |

age (days) |

||||||||

|

a=15 |

8460 |

670 |

2507 |

28.29 |

7 |

||||||||

|

a=15 |

8520 |

890 |

2524 |

37.58 |

14 |

||||||||

|

a=15 |

8480 |

930 |

2513 |

39.27 |

14 |

||||||||

|

σsr=38.43 |

|||||||||||||

For all samples, which has been extended period of solidification under normal temperatures and commonly humid environment (in normal conditions the curing up to 14 days), as well as those who are hardened under such conditions in the entire period of care, there is a progress in structural strength. Concrete samples, which are in the first 7 days of care were exposed to supplementary effect of "steaming" and "ice environment" after the expiry of the period of care of 14 days was noticed smaller increase strength, as a result unusually the slower later hydration of cement and water. Degree of deceleration hydration is in a function of the dimension of the concrete cubes, and this effect was more pronounced in cube of 20cm.

The most significant increase in strength was noted for samples dimensions 15x15x15 cm, which hardened under the normal environment of 14 days. Designed mechanical strength achieved by its gradual increments during the mentioned time range, with lower early-initial strength concrete, but high final strength (table 2).

Conclusion

According to the previously described potential threats to the properties of fresh and hardened concrete in the circumstances, it is necessary to implement adequate procedures of work. Requirements when working with concrete at very low temperatures necessitate the use of: cements with rapid weight gain early strength - higher heat of hydration (more classes such as cement 42.5r and 52.5r), additive types of accelerators, which would pump in a shorter time period to achieve a certain level of strength, larger amounts of cement, the amount of which is determined by the fact that, a usual dosage of the cement mixer is increased by 60 kg / m³, a lower water-cement ratio, which is reduced by means of additives (plasticizers and super - plasticizers Kemament L20); special additives in concrete in winter concreting - antifreeze, which works by lowering the freezing point of the liquid phase present in the concrete (also serves to reduce the destructive phenomenon) , extras - air-entraining agent , intentionally pulling air pores break the capillaries ( potentially dangerous the development of ice in the concrete), seal - on that react with clinker minerals form compounds that are sealed capillary pores in the cement stone , which allows the reduction of capillary absorption of water in hardened concrete (like aerates) of certain funds for the care and protection of concrete , with the formation of specific thermal conditions during his hygrometry (heating concrete). Attention must also be focused on warm -weather protection, when prolong use: CEM II, the recommendations specifically related to the type of cement with addition of fly ash, the percentage to 35 %, labeled N, less quantity of cement beyond normal working, which will develop a lower heat of hydration in concrete; additives - retarder, stackers start time bonding with the prolonged consistency of concrete, super plasticizer (eg. Kemament L20), while decreasing the w / c factor, methods of care and protection, which maintains the moisture in the concrete (and optionally cooled mixer). Note the type of cement with addition of fly ash is recommended because of the exceptional properties of fly ash can have on: fresh concrete (improves workability , reduces segregation and separation of the water , extending the time of placing concrete, reduces the development of heat, reduces the early strength of concrete and increases the late strength, improves consolidation) and hardened concrete (improves strength and durability , reduced permeability, reduce aggregate expansion (necessary to establish the lab examination), reduces shrinkage due to drying , etc.), as well as because of its unused resources at the disposal of Montenegro , and the municipality of Pljevlja. [4]

However, it is noted that the construction work on concreting in winter and summer conditions, unless otherwise assessed, should be postponed until some favorable climate regime. Normal thermal hygrometry conditions give more options for achieving the projected strength in relation to these.

Список литературы Выполнение бетонных работ в экстремальных климатических условиях в Черногории

- Godišnji klimatski izvještaj za ljeto, proljeće, jesen i zimu Hidrometeorološki zavod Crne Gore, 2012/2013. godine.

- Prilozi sa podacima o izvršenim laboratorijskim ispitivanjima za potrebe specijalističkog rada, u laboratoriji Građevinskog fakulteta Podgorica, (2013), 156 p.

- Grdić, Z. Tehnologija betona University of Nis, Niš, (2011), pp. 319-343.

- ACI Cementitious materials for concrete, Developed by Committee E-701 Materials for Concrete Construction, Education bulleting E3-01, (2001), 385 p.

- Shishkin, A., Shishkina, A., Vatin, N. Low-shrinkage alcohol cement concrete (2014) Applied Mechanics and Materials, 633-634, pp. 917-921.

- Garanzha, I., Vatin, N. Analytical methods for determination a load capacity of concrete-filled tubes under axial compression (2014) Applied Mechanics and Materials, 633-634, pp. 965-971.

- Shishkin, A., Shishkina, A., Vatin, N. Low-shrinkage alcohol cement concrete (2014) Applied Mechanics and Materials, 633-634, pp. 917-921.

- Grinfeldi, G.I., Gorshkov, A.S., Vatin, N.I.Tests results strength and thermophysical properties of aerated concrete block wall samples with the use of polyurethane adhesive (2014) Advanced Materials Research, 941-944, pp. 786-799.

- Ponomarev, A., Knezević, M., Vatin, N., Kiski, S., Ageev, I.Nanosize scale additives mix influence on the properties of the high performance concretes (2014) Journal of Applied Engineering Science, 12 (3), pp. 227-231.

- Akimov L., Ilenko N., Mizharev R., Cherkashin A., Vatin N., Chumadova L. Influence of Plasticizing and Siliceous Additives on the Strength Characteristics of Concrete, (2015) Applied Mechanics and Materials, Vols. 725-726, pp. 461-468

- Ortiz J., Aguado A., Agulló L., García T. Influence of environmental temperatures on the concrete compressive strength: Simulation of hot and cold weather conditions (2005) Cement and Concrete Research, Vol. 35(10), pp. 1970-1979.

- Fedorova, G., Mestnikov, V., Matveeva, O. Evgenye Nikolayev. Features of High-Strength Concrete Creation for Concreting of Monolithic Constructions in the Far North Conditions (2013) Procedia Engineering, Vol. 57, pp. 264-269.

- Saha, M., Eckelman, M. J. Urban scale mapping of concrete degradation from projected climate change (2014) Urban Climate, Vol. 9, pp. 101-114.

- Yuan, Y., Jiang, J. Climate load model -Climate action spectrum for predicting durability of concrete structure (2012) Construction and Building Materials, Vol. 29, pp. 291-298.

- Baharom, S., Hamid, R., Hamzah, N. Development of a Problem based Learning in Concrete Technology Laboratory Work (2012) Procedia -Social and Behavioral Sciences, Vol. 60(17) pp. 8-13.

- Proske, T., Hainer, S., Rezvani, M., Graubner, K.A. Eco-friendly concretes with reduced water and cement contents -Mix design principles and laboratory tests (2013) Cement and Concrete Research, Vol. 51, pp. 38-46.

- Власов В.М., Донов А.В., Кондаков В.Е., Бакановичус Н.С. Применение неразрушающих методов контроля при оценке качества бетона по испытаниям кернов. Гидротехническое строительство. 2007. № 2. С. 11-22.

- Дикун А.Д., Фишман В.Я., Нагорняк И.Н., Тюрина Т.Е. Прогнозирование морозостойкости бетона. Строительные материалы. 2003. № 11. С. 28-31.

- Перфилов В.А. Влияние высоких температур на прочность и трещиностойкость жаростойких бетонов. Технологии бетонов. 2012. № 1-2 (66-67). С. 36-37.

- Семенюк С.Д., Фролков И.С., Мамочкина М.Г., Дивакова Г.А. Прочность и деформативность бетона средних классов по результатам испытаний. Вестник Белорусско-Российского университета. 2013. № 3 (40). С. 92-100.