Woven, knitted, and wattled 17th–18th century textiles from Tara fortress, Western Siberia

Автор: Glushkova T.N., Senyurina Y.A., Tataurov S.F., Tikhonov S.S.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.44, 2016 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145277

IDR: 145145277 | DOI: 10.17746/1563-0102.2016.44.3.093-100

Текст обзорной статьи Woven, knitted, and wattled 17th–18th century textiles from Tara fortress, Western Siberia

Analytical studies of clothing and textiles based on available archaeological and ethnological materials represent one of the directions of human cultural research. Specialists in this field have established the North European Symposium for Archaeological Textiles (NESAT). Twelve NESAT forums were held in the period between 1981 and 2014. The latest symposium was held in Austria in 2014. The University of Copenhagen issues an annual scientific journal, Archaeological Textiles Review . In total, 57 issues had been released by 2015. In Russia, studies of archaeological textiles are not so popular.

However, two noteworthy examples are a special section, “Problems of Study and Reconstruction of Traditional Cultures’ Costume”, that was arranged at the Symposium “Integration of Archaeological and Ethnographic Studies” held in Kazan in 2010 (Integratsiya…, 2010: 253–462); and also T.N. Glushkova’s doctoral thesis (2004). Study of this topic provides information on the social status of the person who used particular textiles, technologies of fabric manufacture, regional features, possible trade links, and many other matters.

Unfortunately, textiles are not often recovered from archaeological sites. However, excavations at the Tara Fortress have yielded numerous remains of woven, knitted and wattled textiles produced from vegetable fibers and horse-hair. The samples were comparatively well preserved, which allowed their analysis.

Tara Fortress in archaeological studies

Since 2005, the Omsk Division of the Institute of Archaeology and Ethnography SB RAS has carried out archaeological excavations of the Tara Fortress (founded in 1594). The Knyazhya Tower of the fortress (17th– early 19th century), a portion of a mansion in a fortified town (mid-18th–early 19th century), and a side-chapel in St. Nicholas Cathedral (consecrated in 1774) have been excavated. Studies of a mansion belonging to a rich citizen (early–mid-17th century) have been completed. The cultural layer at Tara is up to 4 m thick. During repeated sieges of the fortress by nomadic tribes, citizens had to keep their horses inside, whereby a layer of horse dung was accumulated. This facilitated the preservation of organic materials: basements of wooden dwellings and utility constructions, street flooring, fragments of fence, as well as various objects of wood, bark, leather, textile, knitted and wattled ware. The results obtained from Tara Fortress studies have been published in three monographs (Adaptatsiya…, 2014; Tara…, 2014; Khramy…, 2014).

Data from written sources

Along with archaeological materials, historical data on weaving and textile trade at Tara have been studied. The town was founded as a military and administrative center, with only minor handicraft trade; this is why no textileproduction factories existed here till the late 19th century. In 1625, there were only 10 artisans in Tara. The low number is explained by the fact that men belonged mostly to the service class. In addition, the military situation at the Tara Fortress throughout the 17th century benefited development of the crafts related to military services (arms-repair, horse-harness manufacture, construction and renovation of military defenses, etc.) (Tataurov, 2014).

In the beginning of the 18th century, tailors appeared at Tara. By 1720, there were 113 artisans here, including eight tailors and six hatters, while in 1763, there were already 49 tailors. In 1753, a hat-factory was founded by Tara merchant Vasily Medovshchikov, where hats were manufactured of lamb’s wool and woolen cloth. But in 1773, this factory was burnt down (Tara…, 2014: 101–103).

In the late 18th–19th centuries, features of agriculture were developed in the Tarsky Uyezd that were associated with the production of raw materials for weaving; and then, weaving itself was established. In nearly all villages of the region, the manufacture of linen, ropes, threads, tablecloths, and towels has been recorded. Tatars also produced these items (Ibid.: 133).

The situation with woolen knitted and felt ware was different. From the time of the town’s foundation, its citizens raised sheep; thus, there was always a good supply of wool, and the woolen clothing of people was self-made. Felt was produced by citizens of the Bukharan district (founded in the early 17th century) at Tara. The available list of goods imported from Central Asia by Bukharans does not include either felt or woolen cloth; hence, these items were likely brought to Tara as gifts, with other immigrant belongings, and were also produced in Tara.

Initially (approximately until the 1740s), the Tara service class did not have any uniform; hence, there are no grounds by which to identify the fabrics that might have been used for uniform manufacture. Unmounted Cossacks and riflemen wore their own clothes. No state supply of fabrics and clothing to Tara existed. The Tara military post began to wear uniforms only in the mid-18th century.

Clothes and shrouds were provided in Tara by the state only for clergy. Thus, after the fire in the Pyatnitsky church in 1631 (Strogova, Tataurov, 2012), the following things were delivered: “rich phelonia, green shoulder coverings, ciselé velvet on red base, black silk, an epitrachelion and epimanikia made of the same velvet, silver buttons, two phelonia of cotton fabric, shoulder coverings of colored velvet, two epitrachelia and two epimanikia of the same velvet, a sticharion under phelonion of cotton fabric, colored velvet shoulder covering, two sticharia under phelonion of plain cloth, shoulder covering of cotton velvet, and three woven belts decorated with red and green silk with tassels, two woven belts of knitted cotton… with tassels, as well as veils and aers on three holy vessels, and in their middle there is Qizilbash damask, and near that they bear the decoration of blue Qizilbash damask; and two veils and aers of Qizilbash damask, and thirty three arshins of linen for three altar strachitsas, and over ten arshins of colored velvet for three inditias, and twenty six arshins of blue colored homespun cloth, and almost four arshins of cotton fabric for the crosses on three eiletons and inditions” (RGADA. F. 214, Inv. 1, D. 31, fol. 181).

Tara was a large transit-center in the trade routes to China and Central Asian states. Merchants brought here various fabrics, including Chinese and Central Asian silk, which was in constant demand. Such textiles have represented typical finds during excavations of Tatar burial grounds of the 17th–18th centuries (Tataurov, Tikhonov, 1996). By the middle of the 17th century, Tara market had become oriented towards ready-made goods: gunpowder, broadcloth, paper, copper wire, axes, sickles, needles, mirrors, etc. The Russian product-list included various sorts of fabrics, clothes, household items, and other things. The majority of these goods were industrially manufactured (Bashkatova, 1994).

On the basis of available written records, the textile’s remains, which were discovered in archaeological layers dating to the 16th–18th centuries, can be subdivided into two main categories: imported and home-made.

The Tara collection of woven, knitted, wattled, and twisted goods

The samples were recovered during the study of a rich citizen’s mansion. The finds were located in the space between the dwellings, at a depth of about 3 m from the daylight surface (construction horizons 4 and 5 dating to not later than early 18th century). All building structures of the mansion were damaged by fires, and goods made of organic materials have not survived. But the areas between structures, especially if the roads passed there, were mostly wet and dirty at the time of their use. Therefore, goods made of organic materials were mostly preserved outside the dwelling structures. All these items were thrown away as garbage. However, they can be used as samples for the analysis and description of textiles. In total, 68 pieces were studied: 31 woven, 7 knitted, and 30 wattled and twisted pieces. Technological study of textile fragments (including visual inspection, materials and structural analysis of samples, search for technological parallels, and reconstruction of textile manufacture techniques) was performed according to the developed methodology in the Laboratory for Historical Studies of the Surgut State Pedagogical University (Metodika…, 2011). Available textile samples were classified into four main categories.

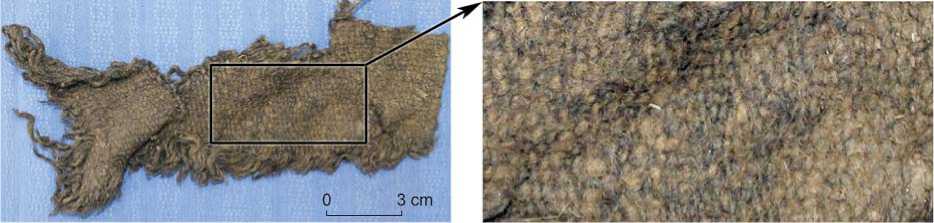

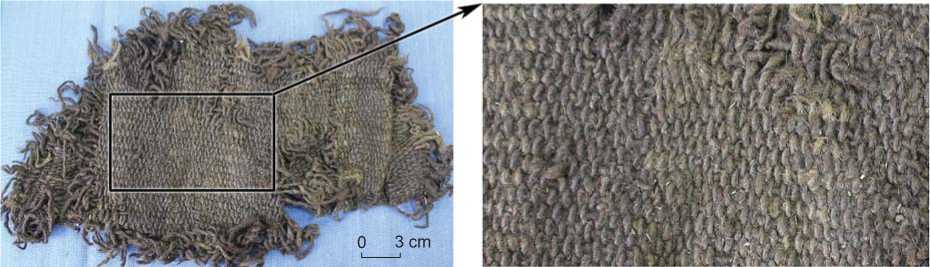

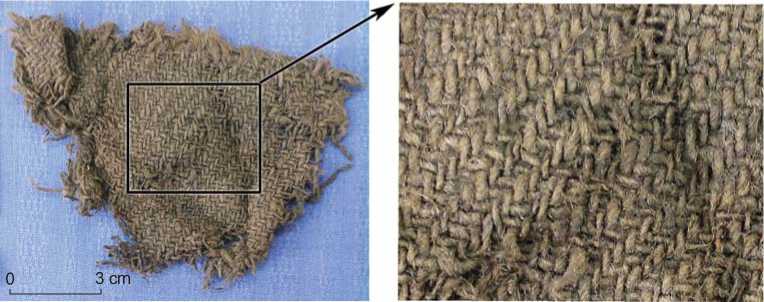

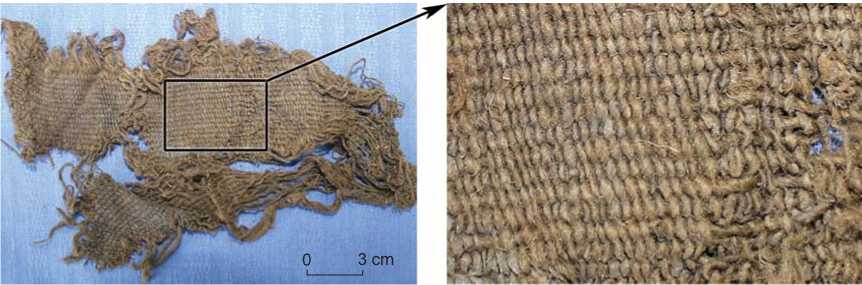

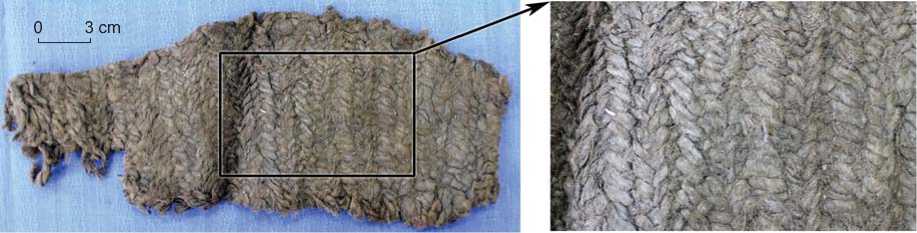

Woven materials. There are woolen fabrics of linen (Fig. 1, 2) and twill (Fig. 3) weave. The majority of samples demonstrate twill weaving. All samples of twill fabrics (even-sided twill 2/2) were woven of similar

Fig. 1. Coarse woolen linen weave fabric.

Fig. 2. Striped coarse woolen linen weave fabric.

Fig. 3. Twill weave fabric (twill 2/2).

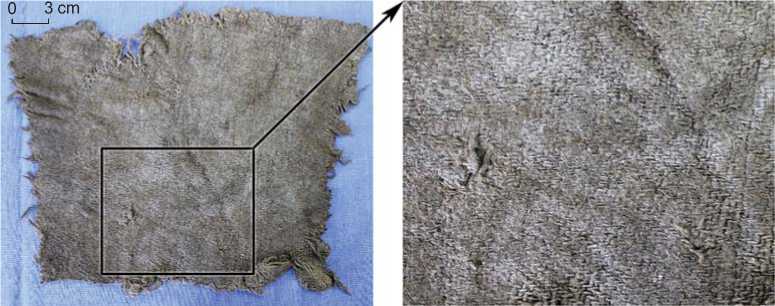

Fig. 4. Broadcloth showing nap damage.

Fig. 5. Woolen linen weave fabric with rep effect.

Fig. 6. Woolen stocking knitted with one needle.

Z-spin warp and weft threads 0.8 to 1.0 mm thick, and have regular density from 7–8 to 10–11 threads in 1 cm. These fabrics were manufactured of wool of natural color.

Woolen fabrics of linen weave include textiles with thin and homogeneous threads representing the structure associated with broadcloth production technologies (Fig. 4), where the warp and weft threads are spun in opposite directions (Z/S). Some samples with this structure were made of thick and rough home-made threads. However, there are also very simple textiles with similar warp and weft threads of Z-spin. One sample shows weaving of thin even threads of S-spin, forming a dense and thin cloth. Another sample demonstrates a linen-weaving pattern with rep effect (Fig. 5): the warp and weft threads are uniform, but the density varies depending on the thread direction.

Knitted materials. All items of this type are similar. They are knitted with one needle of double twisted threads with the complicated Z2S structure. The samples show missing parts, ruptures and cut marks that make it possible to identify the knitting techniques and the cloth production features. Well-preserved sections allow technological features to be identified. The collection of knitted pieces includes woolen stockings (Fig. 6), and a fragment of a cut knitted cloth in the form of a shoe’s insole (Fig. 7) (secondary use of textile).

Fig. 7. Insole made of a woolen item knitted with one needle.

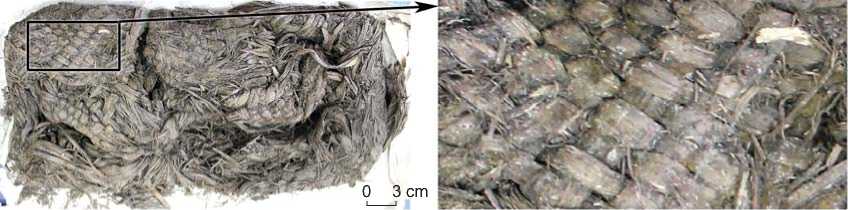

Fig. 8. Container wattled of bast fibers.

3 cm

Fig. 9. Rope plaited of vegetable fibers.

Fig. 10. Rope with a complicated twisting pattern.

Wattled materials. These include a container wattled of vegetable fibers of the bast type 5 to 7 mm wide (Fig. 8) and a four-edged braided cord of horse-hair, which was made on five fingers using a “pulling” technique.

Twisted materials: cords and ropes. These items were produced with a simple technique of twisting with two “threads” (Fig. 9) or twisting of several strands in opposing directions (Z2S, Z3S, Z4S) (Fig. 10). Cords and ropes were mostly made of vegetable fibers, yet some specimens were manufactured of woolen threads and horse-hair.

Discussion

The described materials represent a variety of textile technologies.

The first textile tradition is a technology of broadcloth fabric manufacture, which has been used in Russia since the 16th century (Nakhlik, 1963). The technology is based on the use of threads spun in opposite directions (Z/S) in warp and weft structures of linen weave, with equal density of threads in both structures. Fulling of cloth through such technique makes it possible to produce a dense and even nap on both sides of the textile fabric, which is an essential condition in producing warm and wind-proof clothes. Broadcloth meets this requirement in the best way. In addition, it does not let the moisture go through even when the cloth gets wet. Thus it is not surprising that broadcloth was a popular fabric in Siberia. The following equipment and materials are necessary for manufacture of broadcloth: a horizontal weaving loom that ensures even cloth density; threads specially prepared to be used as warp and weft threads; and appliances for fulling (special room or basin and hot water). But most important are good production skills. In order to produce thin (and often dyed) broadcloth fabric with even and regularly spun threads and even density without weaving errors, a certain specialization was needed, which apparently was initially absent in Tara. Hence, it is generally believed that such a textile tradition did not exist in Siberia in the 17th–18th century, and the great bulk of such textiles was imported from the European part of Russia (Bakhrushin, 1952: 91–92). The technology of production of low-quality coarse heavy cloth was widespread in Western Siberia as early as in the late 17th century (Vilkov, 1967: 85); so, from that time forward, it could have been manufactured locally. It was unreasonable to import the low-quality textile for trade, given the high costs and low profit.

The second textile tradition represents the technology of manufacturing fabric of linen-weaving pattern, with the warp and weft threads belonging to a similar spinning type. The tradition can be subdivided into several variants.

Variant 1 implies ordinary woolen fabrics of linen weave with Z-spin threads. This is usually the comparatively coarse textile manufactured of home-made threads. Such fabric can represent, for example, a piece of cloth resembling footwraps. Variant 2 differs from Variant 1 by its rep effect: the density of either warp or weft threads is at least twice as high as in the other structure. Variant 3 includes high-quality fabrics made of thin and even warp and weft threads of a single spin, with the density equal and comparatively high in both directions. Fabrics of this type were most likely produced in textile mills or in handicraft centers.

For production of linen-weave fabrics, the upgraded looms were used in combination with the developed textile manufacture tradition (textile made of thin and even threads, high density of warp and weft threads, without weaving errors), and also simple appliances in the presence of certain weaving skills and the absence of specialization (fabrics with thick and unevenly spun threads, with low and uneven density of warp and weft threads, and frequent weaving errors).

The third textile tradition represents fabrics of twillweaving pattern. Some twill samples show weaving errors that suggest either low weaving skills, or the use of simple appliances. However, stable technological features of this textile-type, such as the warp and weft threads of Z-spin with similar thickness and the stable structure of even-sided twill, indicate its massproduction in the comparatively simple conditions suitable for a peasant household. The stable density of warp and weft threads (from 7 to 10–11 threads per 1 cm) attests to the use of a standard loom—most likely horizontal—while slight deviations suggest that looms with various combs of similar construction were used. Twill weave fabrics were broadly used in Russia and Siberia in the 16th–19th centuries; any chronological differences in the technological features are absent (Novgorod, Mangazeya, Tobolsk, Staroturukhansk, and the sites of Tomsk-Narym regions of the Ob) (Nakhlik, 1963; Vizgalov et al., 2006; Matveyev, Glushkova, Anoshko, 2011; Glushkova, Shulaeva, 2013). Thus, the analysis of twill weave fabrics indicates their mass production, and a stable textile tradition of manufacturing xeven-sided twill.

The items knitted with a single needle of woolen threads of various thicknesses show very similar structure. This may point to a common production-technique.

It should be noted that the amount of goods twisted of vegetable fibers is large, while fabrics made from vegetable materials are not recorded. This can be explained by the structural features of flax, hemp, nettle, and cotton fibers, which decay quickly without saturation with metal oxides, and also by the secondary use of such textile owing to its good hygroscopic properties (durable secondary use as dusters for household purposes). This leads to great wear and rapid decay in soil during the period of archaeologization.

Considering the great variety of vegetable materials, the uniformity of manufacture of twisted cords and ropes is noteworthy. The thickness and strength of these items depends on the number of single elements of the structure. The purpose of the items is also important.

A special find was the four-edged braided cord twisted of horse-hair, which should most likely be attributed to the culture of nomadic and pastoralist groups of southern regions.

Conclusions

The recovered textile objects vary in terms of threads, weaving patterns, and surface texture; but the samples do not contain the expensive imported fabrics known from historical records of the 17th century (Katalog…, 2013). The noted distinctions in textile traditions suggest that fabrics could have been produced in various manufacturing centers. Hence, the Tara textile collection includes both locally produced and imported fabrics. These are apparently textiles of higher quality of linen and twill weave.

The Tara collection includes materials that are well known in other regions of Siberia (for example, woolen even-sided twill). This probably attests to their production using the same technology in various regions populated by Russians. It can be assumed that home-made coarse heavy cloth and thick, coarse, striped fabric, resembling footwraps, were produced locally.

The archaeological materials obtained during the excavations in Tara Fortress provide the evidence that in the 17th–early 18th century, manufactured fabrics were mostly imported here from the European part of Russia. At that time, there was no regular (state) supply of uniforms or other outfits for service people. Till the mid-18th century, Tara was a military and administrative center; therefore no local weaving industry was developed here. The fabrics from local production represented homemade goods.

Tara citizens used to wear knitted woolen goods, like socks, stockings, various undergarments, etc. These items could have been knitted locally, and this tradition has survived until the present. Among the goods that were delivered to Tobolsk in the 17th century, O.N. Vilkov identified a great amount of knitted and broadcloth stockings (1967: 103), but he did not describe their types. In the 17th century, goods knitted with one needle were used in Mangazeya and Staroturukhansk. Excavations in Tobolsk revealed socks knitted with five needles (Vizgalov et al., 2006; Glushkova, Shulaeva, 2013; Matveyev, Glushkova, Anoshko, 2011). The Tara stockings are fine, carefully knitted of high-quality threads, and may have been imported.

Increasing growth of industrial crops (mostly flax) in the late 18th–19th century contributed to the development of weaving in settlements and villages of the Irtysh basin. The home-made goods were sold at local fairs, and were used by the urban population for clothing and household decoration.

Thus, the results of the study provide finer detail for the information from written sources about technological features and attribution of textiles, local textile production, and imported fabrics in Tara in the 17th–18th centuries.