A half of a metal bipartite mold of the Seima-Turbino period from the Upper Irtysh region

Автор: Borodovsky A.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.46, 2018 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145383

IDR: 145145383 | DOI: 10.17746/1563-0110.2018.46.3.059-065

Текст обзорной статьи A half of a metal bipartite mold of the Seima-Turbino period from the Upper Irtysh region

The material of which a mold is made determines the method of casting. There were four main methods in the Bronze Age: casting into stone; clay, or clay-earthen mold; investment casting; or permanent casting using metal molds (chill molds). Chill mold is a detachable mold of metal, which is capable of withstanding the whole number of castings (from a hundred to several thousand). First metal molds appeared already in the Middle Bronze Age. Bronze molds for making celts and axes are known from various regions of Eurasia (Grishin, 1971: 11–14; Chernetsov, Moshinskaya, Talitskaya, 1953: 123–127; Soloviev, 2003: 40, fig. 33; Wang, Ottaway, 2004: 37). Metal casting molds were also widely used in the Early Iron Age, but exclusively for casting arrowheads of the pre-Scythian and Scythian types in the 8th–4th centuries BC (Fig. 1). Such objects have been found in various regions of Eurasia, but their main number occurred on the territory of the forest-steppe Ukraine*.

A discussion on the functional purpose of metal molds still continues in archaeological literature. There are two points of view. Some scholars believe that such molds were in fact chill molds, that is, metal was directly poured into them; according to other scholars, they were used as press molds for obtaining wax castings (Wang, Ottaway, 2004: 37). In the description of the Novocherkassk hoard (the forest-steppe Ukraine) in the middle of the last century, A.A. Iessen suggested that bronze chill mold from that hoard (Fig. 1, 1 ) was intended for casting arrowheads or their wax models (1953: 50).

Fig. 1. Chill molds for casting arrowheads of the Early Iron Age from the foreststeppe Ukraine.

1 – part of chill mold from the Novocherkassk hoard; 2 – part of a composite mold from the western fortification of the Belsk fortified settlement.

Fig. 2 . Chill mold from Mosul (northern Iraq).

1 – parts of the mold; 2 – mold assembly.

In general, chill casting in Eurasia in the era of metal was discrete. After the Early Iron Age, this technology had been lost for a long time and was revived only in the 17th century (Magnitsky, Piraynen, 1996: 8).

Description of the find

Metal composition of the chill mold under discussion was determined by the method of elemental analysis using a Hitachi TM 3000 electron microscope with a Brucer Quantax 70 energy-dispersive device (operator M.M. Ignatov). Measurements were carried out on one of the lower (shortened) gates and on the inner surface of the mold (see Table , samples 1 and 2 respectively). At the area of the gate that was not covered with oxides, the copper content reached 65.47 %, and on the inner surface of the mold with abundant oxides, black spots, and impregnations of some substance, the copper content was only 42.21 %. It can be concluded from this data that the object was made primarily of copper alloy, which is still used for manufacturing chill molds (Ivanov, Karpenko, 1999: 182).

The size of the chill mold from the Upper Irtysh region is 9 × 4 × 3 cm;

After analyzing the complete mold from Mosul (northern Iraq) (Fig. 2), L. Underwood concluded that it was a press mold for making wax models of arrowheads (1958: 17–22). B.A. Shramko consistently and categorically challenged this point of view: “The assumption of L. Underwood that the good preservation of the Mosul mold resulted from its use only for obtaining intermediate wax models of arrowheads is unconvincing. Such models are not needed for manufacturing bronze arrowheads. Casting of wax models in a chill mold could not improve the manufacturing process of bronze arrowheads in this mold and make the mold’s use feasible” (2002: 165).

From the area beyond the Urals, a metal chill mold for three javelin heads, from the Upper Irtysh region (Fig. 3, 1 , 2 ), belongs to the number of these few artifacts, as do chill molds from the Itkul fortified settlement (Chelyabinsk Region, Verkhneufaleisky District, the village of Dautovo, the northern shore of Lake Itkul) (Beltikova, 1993: 54, fig. 6; 7, 1–13 ).

Results of energy-dispersive analysis of metal composition

|

Chemical element |

Sample 1 |

Sample 2 |

|

Cu |

65.47 |

42.21 |

|

C |

5.53 |

24.18 |

|

O |

6.44 |

21.06 |

|

Si |

0 |

4.4 |

|

S |

1.5 |

2.6 |

|

Sn |

6.96 |

2.16 |

|

Ca |

0 |

1.36 |

|

Al |

0 |

0.74 |

|

Fe |

0 |

0.37 |

|

Cl |

14.09 |

0.36 |

|

Ph |

0 |

0.33 |

|

Mg |

0 |

0.24 |

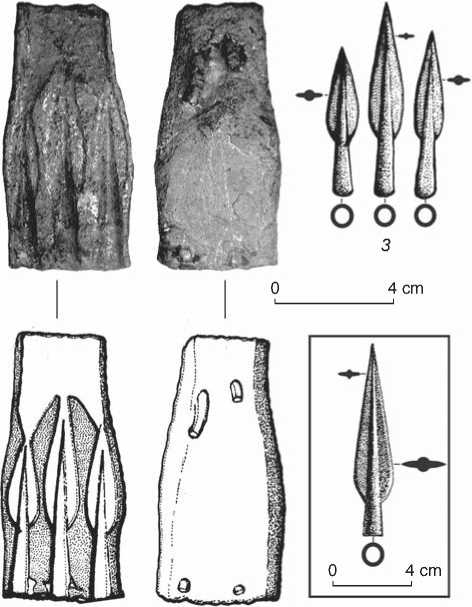

Fig. 3 . Part of metal chill mold from the Upper Irtysh region ( 1 , 2 ), drawings of the impressions of the arrowheads made using this mold ( 3 ), and bronze point from Sopka-2 site in the Baraba forest-steppe region ( 4 ) (Molodin, 1985: 59, fig. 28, 1 ).

the thickness of the walls varies from 2 to 4 mm, and the weight is 119.5 g. Accordingly, the weight of the complete set of the casting piece must have been 239 g. The traces of its own casting (four gates on the outer side) have been preserved on the chill mold. Judging by their location, during manufacture of the chill mold, metal was poured from the opposite side relative to its mouth, which was subsequently used for casting a number of javelin heads. The gates at the bottom of the chill mold were cut down almost completely, and have been partially preserved at the top (Fig. 3, 2 ). The location of these remains of the gates makes it possible to determine the type of the gate system in the metal mold from the Upper Irtysh region. Such molds were typically used for pouring metal in several (four) independent gates (Magnitsky, Piraynen, 1996: 109, fig. 4, 12 , f ).

Since there are no special pins and the corresponding grooves on the working surface of the mold, which are necessary for accurate alignment of the parts while pouring metal into the chill mold, their function was possibly performed by four outwardly projecting rod-like gates remaining from the previous technological operation (mold casting). The presence of these details on the outer surface of the chill mold did not imply a special clamping holder for tightening the mold, which is present in the casting set from Mosul (see Fig. 2).

The gating system of the half of the bipartite mold from the Upper Irtysh region is represented by the pouring basin measuring 2.7 × 2.5 × 0.8 cm with three gates for distributing metal to each of the three mold cavities (see Fig. 3, 1 ). The casting cores for production of socketed bases for javelin heads were located in the lower part of the chill mold. They must have been immovably fixed in a special tray, as is the case with the mold from Mosul (see Fig. 2). The size of the casting cores of the Upper Irtysh chill mold for casting javelin heads of various sizes must have ranged from 5.0 to 5.5 cm.

In terms of its structural features, the chill mold from the Upper Irtysh region shows certain similarities to the Early Scythian metal molds for casting arrowheads from the Novocherkassk hoard and Mosul, dated to not later than the first third of the first millennium BC.

Discussion

The chill mold usually consists of two halves, which are fixed with locking pins (see Fig. 1), and are locked

0 4 cm

4 cm before pouring metal. These implements are absent from the half of the metal mold from the Upper Irtysh region probably because of its archaism (see Fig. 3, 1). The later (Early Scythian and Scythian) chill molds known from the northern Balkans, Greece, northern Black Sea region, forest-steppe Ukraine, northern Iraq, and southern Urals already have such a detail needed for their rigid fixation (Woolley, 1921: 89; Iessen, 1953: 50, fig. 1, 7; Zelenin, 2011: 231–232; Shramko, 2002: 163, fig. 1, 2; Shtitelman, 1947: 161, fig. 1, 4; Furmanska, 1958: 42, pl. 1, 6; Robinson, 1941: 410–411, tab. CXXVI, 2139; Romsauer, 2004: 401, tab. I, 1).

The casting core had to be placed into the chill mold while casting socketed points. A number of metal cores for point-casting are known from the Scythian period (second third of the first millennium BC) in the northern Black Sea region, forest-steppe Ukraine, and southern Urals (Shtitelman, 1947: 161, fig. 1, 1; Murzin et al., 1997: 11, fig. 11, 1, 8; Olgovsky, 2011: 137, fig. 54, 4, 149, fig. 62; Furmanska, 1958: 43, pl. I, 5; Krutilov, 2006). In that regard, it should be emphasized that the materials from the Early Iron Age contain only individual molds with a single casting core, while several cores rigidly fixed on a special pallet-tray occurred in the Middle Bronze Age (for example, in the chill mold from the Upper Irtysh region). Later, such a detail appeared in metal molds of the Early Scythian time in the Novocherkassk hoard and Mosul (see Fig. 1, 1; 2). Notably, this structural feature of the chill mold is its distinguishing mark as compared to metal molds for casting arrowheads after wax models in the Scythian period. It should also be noted that metal (copper) casting cores were also used in stone molds as, for example, is the case in the Itkul fortified settlement in the southern Urals (Beltikova, 1993: 54). The location of a series of casting cores at the bottom of the chill molds from the Upper Irtysh region and Mosul is the evidence of pouring metal into the mold under gravity. At present, while casting into chill mold under pressure, the core is located in the upper part of the mold.

Another evidence for the use of metal molds as chill molds is the presence of non-stick coating on the internal surfaces, which protected the mold from sharp thermal shock while pouring metal, and adhesion between the casting and the mold. Crystallization rate of the alloy is very high when casting into a metal (bronze or copper) mold. Soot or talc might have been used as non-stick materials. In the old times, all stone casting molds were covered with such substances. The presence of dark, possibly non-stick coating has been observed on a bronze bipartite mold for casting Scythian arrowheads from Simferopol in the Crimea (Zelenin, 2011: 231–232).

Refractory coating is necessary for protecting the chill mold from abrupt exposure to high temperatures while pouring metal. Such protective layer also makes it possible to preserve the working surface of the mold from melting and binding with metal of the casting. At present, graphite powder mixed with boiled oil or its substitutes is a part of the refractory coating intended for copper alloys (Magnitsky, Piraynen, 1996: 192). The thickness of this layer largely determines the cooling rate of the casting inside the mold. The impression made by modeling rubber from the working surface of the half of the metal casting chill found in the Upper Irtysh region made it possible to establish the presence of the blackgray powdery substance on the surface, which might have been refractory coating. Energy-dispersive analysis of this substance has shown that organogenic chemical elements of its compound included phosphorus (0.33 %). For the application of such refractory coating in modern conditions, the chill mold must be heated to 150–280 °C. Subsequently, it should be heated again to the operating temperature, which depends on the composition of the alloy to be filled, on the thickness of the walls of the casting, and on its size.

Depending on configuration of the molded products, chill molds can be integral (one-piece) and detachable. The latter are divided into the flap-type chill molds and chill molds with parallel detachment of sections. Detachable metal molds are used for casting complex objects with parts, which makes it difficult to remove the casting from the chill mold by simple shaking out (Zotov, 1988: 271, fig. 142, b ). Judging by these structural and functional principles, the chill mold from the Upper

Irtysh region is a hinged, vertically split chill mold. A sufficiently large casting container was located in the upper part of the mold. Its volume was clearly associated with the need to fill a significant amount of liquid metal intended for manufacturing several javelin heads. The shape of the chill mold from the Upper Irtysh region is also noteworthy. Chill molds for individual casting of arrowheads of the Early Scythian and Scythian periods have completely different outlines. The earliest casting molds of that time were cylindrical. Further, bottle-shaped molds started to appear along with cylindrical molds with the gradual transition to conical molds.

While casting into a chill mold, the metal cools faster than it is the case with the molds made of other materials; therefore, the chokes of its gating system have a considerably larger cross-section (Ibid.: 272). However, this feature is not typical of the chill mold from the Upper Irtysh region. Its gates, like the gates on the half of the mold from the Novocherkassk hoard, are directly combined with the sockets of future castings of points. Perhaps this morphological feature of the prominent socket, significantly protruding beyond the surface of the blade, was largely caused by the technology of casting production, and not only by considerations of the structural rigidity of the product. It should also be noted that high rate of metal cooling in the chill mold contributes to the formation of dense castings with fine-grained structure. This significantly increases the durability and ductility of the metal in the resulting products. Such mechanical qualities are extremely important for the points of projectile weapons. These technological features once again indicate their inseparable connection with typological features of the finished products.

The progressive nature of chill casting in the Middle Bronze Age is confirmed by a number of advantages of chill molds, known from modern practice, as compared to casting equipment made of other materials, including stone or clay (Ibid.: 27; Ivanov, Karpenko, 1999: 180, 182; Magnitsky, Piraynen, 1996: 190). First, this is greater strength of metal mold, which makes it possible to treat its working surface with greater care. Second, casting into a chill mold provides higher quality of the resulting casting. Third, it becomes possible to achieve significantly better results for traditional casting industry in terms of mass production, since owing to high thermal conductivity of the metal mold, the casting hardens faster, which increases the speed and productivity of the casting process. Fourth, chill casting requires minimal mechanical treatment of the surfaces of the finished casting. At the same time, it is necessary to mention the disadvantages of using chill molds in casting industry, which include high costs and labor intensity of manufacture, poor filling of thin-walled castings, and possibility of cracks on finished products (Zotov, 1988: 271; Ivanov, Karpenko, 1999: 180; Magnitsky, Piraynen, 1996: 191). However, for the technology and scale of casting in the Middle Bronze Age, the advantages of using chill molds for the replication of metal points were clearly more important than their disadvantages, especially since in its essence chill casting was a labor- and material-saving efficient technology. Complexity of manufacture and high cost of chill molds make this technology effective only in the mass production of castings, and the points were ideal objects for that.

The configuration of the working cavities in the chill mold from the Upper Irtysh region is quite informative for the cultural and chronological attribution of both the mold and possible castings (see Fig. 3, 3 ). The impression from the working surface of the mold half made it possible to obtain the models of three socketed points of various sizes. The length of the pieces varied from 6 to 7 cm; the width of the blades ranged from 1.0 to 1.2 cm, and the width of the sockets was 0.9 cm. The massiveness of these objects allowed their identification as javelin heads. A ceramic mold for casting a similar point (see Fig. 3, 4 ) is known from the accompanying inventory in one of the Krotovo burials (burial mound 14, grave 2) at the Sopka-2 necropolis in the forest-steppe Ob-Irtysh interfluve (Molodin, 1985: 59, fig. 28, 1 ). In terms of morphology, these objects are close to the spearheads of the Seima-Turbino appearance (Ibid.: 60). Such scaled replication of the overall shape and proportions of the latter spearheads in javelin heads can be associated with a priority of the missile weaponry over light weaponry (bow) in the Middle Bronze Age.

Structurally, all javelin heads that were cast in the mold from the Upper Irtysh region are of socketed type. In this respect, it should be noted that tanged arrowheads were widespread along with socketed arrowheads to the east of the Volga, including the forest-steppe and steppe Ob-Irtysh interfluve, in the Late Bronze Age (Ibid.: 125, fig. 63, 5 ; Borodovsky, Sofeikov, Kolontsov, 2002), whereas in the northern Black Sea region in the Early Scythian period, only socketed arrowheads were used. Obviously, this was caused by the technological factor and the structural features of the casting molds. As opposed to socketed objects, tanged objects were cast in molds without casting cores.

Noteworthy are clearly different sizes of javelin heads produced simultaneously in the chill mold from the Upper Irtysh region (see Fig. 3, 3 ), which contradicts the speculative typological theories about their possible changes over a certain period. On the one hand, the greater size of the central cavity as compared to the two lateral cavities might have well been exclusively caused by the technological features. It was located under the very center of the casting bowl and might have served as the central gate absorbing the bulk of the metal in the beginning of its pouring. On the other hand, the absence of differences in the sizes of the points cast in the chill mold from the

Novocherkassk hoard (see Fig. 1, 1 ) suggests that the Upper Irtysh casting mold was intended for manufacture of products with different features and, consequently, the synchronism of such objects’ functioning.

Conclusions

Discovery of early metal molds (chill molds) is very important for reconstructing the process of technological development and organization of the casting industry in the Middle Bronze Age on the territory of the southwestern Siberia and adjacent regions. Primarily because the gradual emergence of the casting technology at the artisanal level started precisely in the middle of the second millennium BC (Magnitsky, Piraynen, 1996: 4). A technological mark of qualitative changes is the emergence and proliferation of specialized and more productive casting equipment, such as reusable metal molds (chill molds) (Zotov, 1988: 270). Casting into chill molds is the most efficient method. Metal casting molds certainly became a revolutionary technological innovation in the Middle Bronze Age. The emergence of chill molds for casting arrowheads fully met the need for mass production of such products in the conditions of the increasing mobility of the population and intensified conflicts between the ancient groups.

Notably, casting in metal molds has always been a special type of foundry technologies (Ibid.; Magnitsky, Piraynen, 1996: 182). Even today, it is optimal for manufacturing commonly used products. Conversely, chill casting is not only impractical (Magnitsky, Piraynen, 1996: 182), but also too advanced for art casting (Zotov, 1988: 270). Judging by the part of chill mold found in the Upper Irtysh region, this advanced technological tradition appeared in the southwestern Siberia and in a number of adjacent territories already in the Middle Bronze Age. The basic conditions for mass replication of metal products, including weaponry, and main principles of production specialization reflected in casting equipment were emerging in exactly that period.

However, such a connection is far from always being unambiguous at the archaeological level. Thus, only in Olbia, casting chill mold equipment, such as two cores from the Western temenos, was associated with production complexes. One core was found in the filling of pit 33 together with the fragments of smelting ladles, nozzles and plugs for them, pieces of bronze-casting and silicate slag, and defective products (Krutilov, 2006: 213). Fragments of foundry crucibles, 79 fragments of gates, and a large amount of bronze slag was found in botros pit 12, in addition to a casting core (Ibid.: 214). Unfortunately, a significant collection of fragments of chill molds from the extensive area (over 4875 hectares) of the Belsk fortified settlement originated from various parts of this huge site, and the real context of their discovery is unknown. Moreover, many such finds are not directly associated with settlements, as for example the parts of metal molds from the Novocherkassk hoard and the “hoard” of a caster from the vicinity of the Belsk fortified settlement (Zelenin, 2010: 207, 208).

It should be noted that the most efficient metal chill molds have not yet been found in the burials of the Middle Bronze Age in the forest-steppe Ob-Irtysh interfluve with the accompanying goods showing the signs of “production specialization” (Molodin, 1985: 58, 59). This fact can be interpreted as yet another argument in favor of the “secondary” nature of bronze casting in the southwestern Siberia in the second millennium BC as compared to more southern adjacent territories. One of such territories is the Upper Irtysh region. Obviously, this region was one of the key areas of penetrating the most advanced casting equipment to the north. This equipment was needed for mass replication of objects, which in local conditions were cast in single units, mostly in more accessible clay molds.

As far as the circumstances of discovering the chill mold from the Upper Irtysh region are concerned, it should be noted that the vast majority of all known metal molds for manufacturing Early Scythian and Scythian arrowheads from the forest-steppe Ukraine are random finds. In the southwestern Siberia, in some cases, this also applies to clay molds of the Seima-Turbino period (Umna-6) (Borodovsky, 1999).

The accidental nature of the discovery of the Upper Irtysh chill mold does not detract from the historical significance of this important object, primarily because at all times chill casting was not only an exclusively specialized casting process, but also it was quite rare in terms of territorial distribution (Zotov, 1988: 270). After it had appeared in Eurasia in the Metal Ages, it was completely lost for a long period. Thus, any facts of finding the early chill molds are extremely interesting and important for reconstructing the discreteness of development of the ancient Eurasian foundry. In addition, this is one of reliable criteria for the technological level of bronze-casting production of a specific period. Equally important is the fact that the complexity and high cost of chill molds is closely associated with production specialization and professional equipment within the framework of the transcultural Seima-Turbino phenomenon. The energy-dispersive analysis of the composition of metal of which the chill mold from the Upper Irtysh region was made, revealed the presence of tin (from 2.16 to 6.96 %), which is quite consistent with the recipes of the Samus-Seima bronze products. In general, such casting equipment was unique and quite rare for its time. This is clearly evidenced by the scarcity of such finds on the territory of Eurasia of the Bronze Age.

Acknowledgment

This study was supported by the Russian Science Foundation (Project No. 14-50-00036). We would like to thank M. Dragan, I. Tolochko, and A. Dedyulkina for the opportunity to obtain photographs of the chill mold from the Novocherkassk hoard and Belsk fortified settlement.