A method for producing an anticorrosive paint based on nanostructured polyvinyl varnish

Автор: Boev E.V., Islamutdinova A.A., Kasyanova L.Z., Aminova E.K.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 3 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Most of the paint and varnish materials are produced from imported raw materials using foreign technologies. Due to the growth of the construction industry, demand for varnishes and paints has significantly increased. Varnishes and paints provide a protective coating for buildings and structures. Therefore, the need for paint and varnish products made from locally sourced materials is relevant not only in terms of import substitution, but also in terms of economics. The materials used as lacquers are composite compositions. They are made by applying them to a selected surface, resulting in a solid polymer film with appropriate properties. This type of materials is used to coat and protect structural building materials from external influences, and gives them the necessary color and texture. The production of nanostructured anticorrosive paints based on PVC has such advantages as environmental friendliness, high adhesion, high dispersion, low opacity, low viscosity, and environmental resistance. Methods and materials. The scientific research is aimed at obtaining nanostructured lacquer paint by modifying PVC with organic solvents and montmorillonite, a clay mineral of various extraction depths from the Talalaevsky deposit located 20 km from Sterlitamak, Republic of Bashkortostan. The purpose of the scientific work is to use clay minerals consisting of oxides and silicates of aluminum and magnesium with a small content of sodium and calcium salts, which act as nanostructuring binders. The performance characteristics of the obtained nanostructured paint samples were tested for adhesion, opacity, drying rate, and elasticity. Results. The research results have shown that the use of clay as a nanostructuring modifier of PVC paint makes it possible to obtain a product with characteristics corresponding to regulatory documents. Conclusion. This study aims to develop a nano-lacquer paint made from locally available raw materials that can be used to coat building facades and other construction surfaces.

PVC, clay, nanostructuring montmorillonite, lacquer paint

Короткий адрес: https://sciup.org/142244836

IDR: 142244836 | DOI: 10.15828/2075-8545-2025-17-3-331-338

Текст научной статьи A method for producing an anticorrosive paint based on nanostructured polyvinyl varnish

Original article

Боев Е.В., Исламутдинова А.А., Касьянова Л.З., Аминова Э.К. Способ получения красок на основе наноструктурированного поливинилового лака. Нанотехнологии в строительстве. 2025;17(3):331–338. –338. – EDN: ZEBVIG.

Due to their nanostructured composition, paint and varnish materials better protect and cover building structures made of various materials, allowing them to give a consumer decorative appearance. Nanostructuring additives are widely used in the construction industry to improve operational characteristics [1–3].

The application of paint and varnish coatings leads to the formation of a thin nanostructured protective layer on its surface.

The preparation of such paint and varnish materials is carried out using a fairly simple technology. The main components included in the composition of lacquer paints are pigments, various fillers and binders. Pigments are used to give the paint certain shades of colors. The compositions of the pigments and their properties are also selected in accordance with the material of the building structures and taking into account the effects of external factors. Depending on the concentration, the pigment can affect the color saturation of the lacquer paint, it has been found that, as a rule, high concentrations give a dull color, and low concentrations, on the contrary, give brightness [4–10].

The bonding property of lacquer paints is one of the most important characteristics affected by the binder additive. The function of the binder additive is to glue small

pigment particles into a single integral film formed during drying. Fillers give the varnish-paint smoothness and stickiness. When applying varnish-paint to the surface of building structures, such a filler evaporates. Paint and varnish materials made on the basis of PVC resin provide a richer color range and retain their decorative function for up to four years. PVC paint and varnish compositions are widely used in the construction industry, they cover not only metal and wooden structures, but also concrete, brick and plastered surfaces. Such coatings retain high activity against the effects of strong acids such as sulfuric and nitric acids, concentrated solutions of mineral salts, organic compounds and oils. It is necessary to note the high adhesive properties that protect building structures from moisture penetration. Also, the paint composition is ready for use and does not require dilution with solvents [11–16].

METHODS AND MATERIALS

The paper develops a formulation for the production of nanostructured lacquer paint based on polyvinyl chloride and clay from a local deposit containing aluminum and silicon as nanoparticles.

All the main characteristics of paint and varnish materials describing their quality can be found in the passport for products provided to consumers.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

The samples obtained in the laboratory were tested according to the methods and relevant regulatory documents:

The degree of grinding. This indicator is based on measuring the size of solid paint micro-components. The quality of the paint composition depends on their quantity, and as they increase, the quality decreases. The method for determining the degree of grinding of paint and varnish materials was calculated in accordance with GOST R 52753-2007. “Paint and varnish materials. The method of determining the degree of grinding”.

Testing was carried out at a temperature of 23–25 ° C. The device was installed on a horizontal surface. The analyzed paint and varnish samples were placed in the farthest deep end of the groove, thus preventing air bubbles from entering. The scraper was installed perpendicular to the far end of the groove, with the condition that the length of the scraper was parallel to the width of the device itself. The scraper with gentle pressure is positioned strictly vertically on the measuring surface. So that the scraper completely removes the excess applied at the beginning and the paintwork is completely evenly distributed. Then, for 5–6 seconds, it is necessary to examine the analyzed material in the light. The viewing direction is perpendicular to the length of the groove, at an angle of no more than 30° and no less than 20°, and the determination of the location of the particles in the groove, where they become visible, begins.

Viscosity. This indicator is analyzed by the expiration time of the required amount of paint and varnish material through a calibrated hole, characterizing the painting properties. The viscosity index determines the method of applying the paint coating to the cleaned surface. The coating can be applied with a brush, roller and spray gun.

The viscosity of the paint can be measured on a viscometer, the analysis is carried out at a pressure of 0.1 Mpa and a temperature of 21–25 °C. The viscometer consists of a funnel and a nozzle of a certain size. A viscometer of the VZ–246 brand was used in the work, which shows the conditional (Newtonian) viscosity – the time of transition of the studied paint composition through the calibrated nozzle hole, while the paintwork is not affected by any forces other than gravity.

The opacity index shows how much paint is needed to paint 1 m2 of the surface. This method allows you to determine the consumption of the studied material, the less it is, the better the economic component. Thus, the discontinuity of paints, enamels, and varnishes is understood as their ability to apply evenly on a plain, flat surface. For varnishes, an important characteristic is its ability to give invisible color or, when painting a black-and-white substrate, reduce the contrast between black and white until the difference between them disappears. A visual assessment method is usually used when conducting opacity tests. A black and white chessboard is

used for this purpose. The essence of the opacity assessment is to apply layers of paint and varnish composition to the glass surface until the black and white squares of the checkerboard located under the glass plate disappear. As a rule, glass plates of 90×120 mm and 1.2–1.8 mm thick are used.

The determination of the drying time corresponds to the curing time of the paintwork, which allows you to determine the time of application of subsequent layers and assess the readiness of the analyzed coating for continuous use. The degree of drying determines the condition of the applied coating applied to the plate depending on the drying time under certain conditions. That is, the drying time of the paint is called a certain period of time at which the required degree of drying of the paint composition layer with a given coating thickness is achieved under certain drying conditions.

Adhesion is the properties of the paint and varnish material that make it possible to assess the adhesion strength of the paint and varnish coating to the painted surface. The higher this indicator is, the better. The adhesion of the paint and varnish material is determined in accordance with GOST 15140-78 “Paint and varnish materials. The method of determining adhesion”. The basis for determining the adhesion of a paint coating is the determination of the peeling of a flexible plate from a fiberglass-reinforced surface and the measurement of the force applied for this purpose.

The analysis of adhesive properties is carried out at a temperature range of 18–22 °C with a relative humidity of 60–70%. The study is carried out with two samples on at least three sections of the treated surface. At least six incisions are made in each of the test areas and the condition is met at a distance of at least 10 mm from the edge of the treated surface. The cutting tool is positioned perpendicular to the surface. Perpendicular incisions are made in the same way. Thus, a grid with squares of the same size is formed on each analyzed sample. The gratings should be located at least 2 cm apart from each other. Adhesion is determined according to the requirements in GOST 15140-78 [17].

I evaluate the water resistance based on the resistance of the paint and varnish material to the effects of fresh or sea water. When determining the water resistance, the paint and varnish coating is applied to two identical metal plates each measuring 70×150 mm in accordance with the standard. After drying, the plates are vertically suspended and immersed in distilled water. It is necessary to cover the edges with Mendeleev putty before immersion in water to prevent moisture from entering the coating. After the plates dry for 1–2 hours, the appearance and color of the coating are evaluated. The presence of white matte spots, rashes, blisters and other types of destruction is not allowed. The resistance of the paintwork to alkalis and acids is checked in the same way.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Weather resistance. This property of the paint and varnish material characterizes its ability to preserve its protective and decorative properties for a long time in atmospheric conditions.

The weather resistance of paint and varnish coating materials was studied in accordance with GOST 6992-68 on an outdoor area. The painted samples are placed on inclined stands at an angle of 45° to the horizontal surface, facing south. The analyzed samples are examined at regular intervals, according to established standards. Upon inspection, an analysis of the degree of destruction is carried out, which is characterized by loss of gloss material, discoloration, dirt retention, weathering, cracking, delamination, the presence of bubbles and corrosion as a percentage of the total area of the sample coated with paint and varnish material. The weather resistance of the coating with the applied paint and varnish material is analyzed on a five-point scale of their decorative appearance and on an eight-point scale of their protective properties. Property assessment scales are presented in the standard.

For an accelerated method of determining the weather resistance of paint coatings in the laboratory, it can be determined on a visirometer device. This device allows you to analyze samples by alternating exposure to heat and cold, moisture and dry air, as well as ultraviolet rays. The duration of the analysis is from 150 to 200 hours.

The work used suspension polyvinyl chloride of the following grades C-6669PZH, C-6069ZH, C-6369ZH, 5868PZH, the physico-chemical parameters of which are presented in Table 1.

The method of preparation of anticorrosive varnish. Anticorrosive varnish – a solution of PVC resin in a mixture of acetone, toluene (solvent), butyl acetate (ethyl acetate) – is prepared in a 3-liter container equipped with a stirrer and a refrigerator. The volume of the reaction mixture is 1000 g = 1 kg.

The solvents are loaded into the flask periodically in the following sequence: 577 ml of toluene, 303 ml of acetone, 13 ml of butyl acetate. A refrigerator is used to prevent acetone vapors from escaping. At the end of the solvent loading, the reactor agitator is switched on and 120 g of PVC resin is filled in.

The dissolution of PVC resin is carried out at ambient temperature. The completeness of resin dissolution is determined visually by sampling. The first sample is taken 2 hours after the start of dissolution.

If the solution is transparent, does not contain particles of insoluble resin, and the viscosity of the solution is within (20 to 35) seconds, the dissolution of the resin is considered complete. Then add 41 ml of plasticizer (DOF).

The reaction mixture in the flask is mixed for another 0.5 hours after loading the plasticizer, after which the quality of the varnish is determined in accordance with TU 2313-84-0203312-96.

If the quality indicators of the varnish do not match, it is set to “type” (standardization). At the same time, certain components provided by the recipe are added. The varnish is diluted with toluene (solvent) to a nominal viscosity (20–35) seconds. At a nominal viscosity of

Table 1. Physico-chemical parameters of PVC resins 6669 PP, 5868 W

|

Naming of the indicator |

Brand |

|||

|

C-6669PZH |

C-6069ZH |

С-6369ZH |

C-5868PZH |

|

|

Pollutants, pcs., not higher |

6 |

5 |

6 |

9 |

|

Transparent dots with a diameter of 0.1 cm3, pcs., not higher |

– |

– |

– |

4 |

|

The value of the Fikentcher constant |

66–67 |

60–63 |

62–64 |

57–59 |

|

Bulk density, g/cm3 |

0.53±0.02 |

0.55–0.61 |

0.52–0.62 |

0.52–0.62 |

|

Residue after sieving on a sieve with a grid: № 0315, %, not higher |

отсутствует |

отсутствует |

отсутствует |

отсутствует |

|

№. 0063, %, not less |

97 |

94 |

94 |

91 |

|

Flow rate, per second, not higher |

– |

11 |

12 |

13 |

|

The mass of the absorbed plasticizer, in grams per 100g of PVC, is not less |

21 |

15 |

– |

16 |

|

Percentage of moisture and volatile substances, in %, not higher |

0.2 |

0.2 |

0.2 |

0.2 |

|

Electrical resistivity, Om * cm, not less |

5.2 * 1013 |

5.2 * 1013 |

5* 1013 |

5* 1013 |

|

The percentage of vinyl chloride, in ppm, is not higher |

1 |

1 |

1 |

1 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION less than 20 seconds, PVC resin is loaded into the flask. These operations are carried out until the varnish meets the requirements of TU 2313-84-00203312-96.

RESULTS

The resulting nanostructured lacquer paint is recommended for protecting the primed exterior surfaces of technological equipment, as well as building structures made of various materials from the effects of aggressive media at temperatures not exceeding 60 °C (1). The formulation of nanostructured lacquer paint is presented in Table 2.

The production process is carried out at room temperature and atmospheric pressure.

A comparative characteristic of the obtained sample of nanostructured lacquer paint with a similar composition

to the Krsk mark ENAMEL XB-110 (TU 6-27-7-89) was carried out. The comparative characteristics are given in Table 3 [18–19].

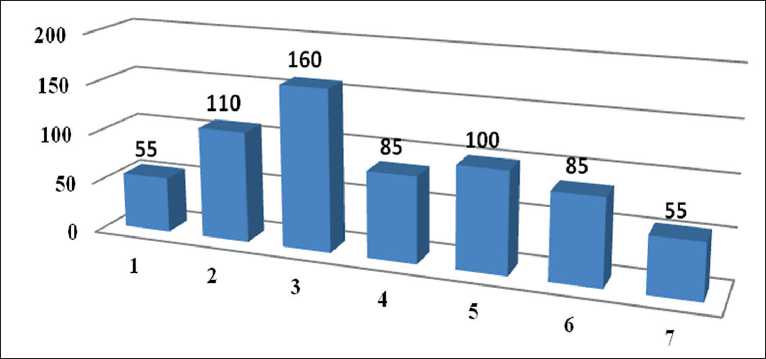

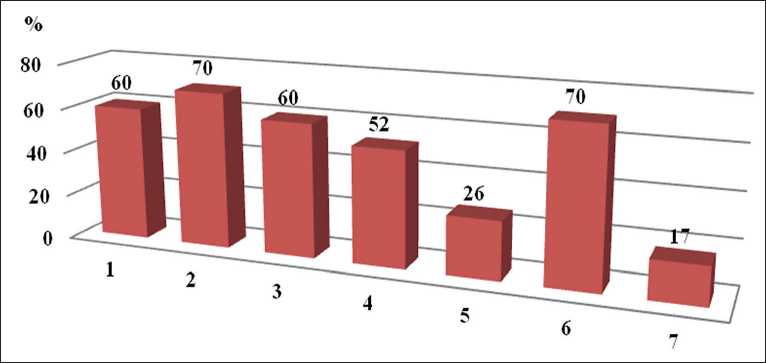

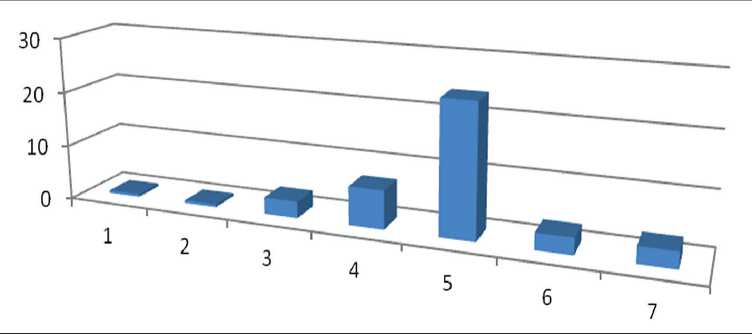

Further, Figures 1–3 show diagrams of the physical characteristics of the paints used and the sample developed by us (indicator 7) for such characteristics as relative viscosity, mass fraction of non-volatile substances and drying time.

Preferred characteristics – diagrams.

The diagram shows that of the seven samples studied, sample 3 has a high viscosity.

When analyzing non-volatile substances, two samples showed a maximum content of 70%. Drying time at temperature (20±2)°. From to the power of 4 hours, no more, is shown in Figure 3.

Sample 5 showed the longest drying time, and samples numbered 1 and 2 dried the fastest.

Table 2. Formulation of nanostructured lacquer paint

|

Naming of components |

Quantity, g |

Сomposition, % |

|

Toluene |

149.99 |

39.29 |

|

Acetone |

72.16 |

18.91 |

|

Butylacetate |

29.85 |

7.82 |

|

PVC resin |

36 |

9.43 |

|

Dioctyl phthalate (DOF) |

11.98 |

3.16 |

|

Montmorillonite |

81.67 |

21.39 |

|

Total |

381.67 |

100.00 |

Table 3. Comparative characteristics

|

№ |

Naming of the indicator |

ENAMEL XB-110, TU 6-27-7-89 |

Anticorrosive paint prepared in the IHTI of the Federal State Budgetary Educational Institution of Higher Technical Education in Sterlitamak |

|

1 |

The appearance of the paint and varnish composition |

Uniformity, matte color |

Uniformity, matte color |

|

2 |

Colour |

The main color scheme (green, black, gray, light gray, dark gray, brown, red-brown, red, yellow, blue, light blue) |

The main color is white. Standard colors are allowed. |

|

3 |

Index of conditional viscosity, not less than |

65–85 |

45–65 |

|

4 |

Percentage of non-volatile compounds, % |

30–40 |

15–20 |

|

5 |

Drying time temperature (20 ±2) °C to a degree of 4 hours, not higher |

3 |

3–4 |

|

6 |

Adhesive properties, not higher |

2 |

2 |

|

7 |

Cost, rub/kg |

170 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 1. Conditional viscosity: 1– Anticorrosive acrylic silicone “three in one”; 2 – Anticorrosive thick-layer glossy composition for ferrous metals; 3 – Unikom special enamel-rust paint 3 in 1; 4 – ML-12 enamel for metal surfaces; 5 – MA-15 oil paint; 6 – Cycrol paint; 7 – Anti-corrosion paint offered

Fig. 2. Mass fraction of non-volatile substances: 1 – Anticorrosive acrylic silicone “three in one”; 2 – Anticorrosive thick-layer glossy composition for ferrous metals; 3 – Unikom special enamel-rust paint 3 in 1; 4 – ML-12 enamel for metal surfaces; 5 – MA-15 oil paint; 6 – Cycrol paint; 7 – Anti-corrosion paint offered

Fig. 3. Drying time: 1 – Anticorrosive acrylic silicone “three in one”; 2 – Anticorrosive thick-layer glossy composition for ferrous metals; 3 – Unikom special enamel-rust paint 3 in 1; 4 – ML-12 enamel for metal surfaces; 5 – MA-15 oil paint; 6 – Cycrol paint; 7 – Anti-corrosion paint offered

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

DISCUSSION

The nanostructured sample we have obtained can be used for coating building structures. This varnish-paint nanostructured with raw materials of metal origin will make it possible to effectively protect the treated surfaces from the effects of aggressive media and the environment for a long time. Figure 4.

Also, the resulting paint and varnish composition will protect against corrosion and thermal insulation of steam pipelines and heat pipelines of heating networks. The use and operation of equipment and structures coated with such nanostructured lacquer paint can be carried out at temperatures up to +60 °C. The application of such compositions allows for staining at temperatures up to –20 °C.

Recommendations for application: the varnish can be applied by pneumatic spray, brush, roller; painting must be carried out on a dry, grease-free surface, the ambient temperature must be within the temperature range from –20 to –40 °. With and relative humidity no higher than 20%; it is necessary to treat the most vulnerable areas before painting. It is recommended to apply the strip brush application method to problem areas of building structures, such as welds, bolted joints and hard-to-reach places, before starting the painting work.

Basic safety measures: When applying the paint indoors, make sure that the work area is well ventilated.

CONCLUSION

A formulation of nanostructured polystyrene lacquer paint based on clay from the Talalaevsky deposit of various extraction depths has been developed.

The use of clay from the Talalaevsky deposit as a nano-filler as a filler in polystyrene paint is justified, which makes it possible to improve the main operational characteristics, such as opacity – an increase of 1.5 times, film hardness – an increase of 3 times, and water resis-

Fig. 4. The resulting nanostructured sample of varnish paint

tance – an increase of 2 times. Reducing the amount of solvent reduces the content of volatile compounds in the paint, which will increase the safety of their use. It has been revealed that clay affects the properties of nanostructured paint and varnish compositions based on polystyrene. Clay affects an increase in the drying time of varnish paints on a cement-sand substrate by about 25–30%. It was found that the degree of drying at subzero temperatures using these nanostructured paint coatings increases by 12.5%. In addition, the introduction of clay as a nanostructuring organomineral additive improves the strength and deformation properties of products. When clay is added to the composition of polystyrene paint, the cohesive strength increases by 2 times.