Application of drying acceleration to study the forms of moisture bond in currant fruits

Автор: Antipov S.T., Emelyanov A.B., Baturina E.V., Kazartsev D.A., Babenko D.S., Posnova G.V.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Процессы и аппараты пищевых производств

Статья в выпуске: 1 (95) т.85, 2023 года.

Бесплатный доступ

The article discusses issues related to the study of the forms of connection of moisture removed during the drying process in black currant fruits. A study was carried out to determine the quantitative moisture content of various forms of communication by two methods and a comparative analysis was carried out. It is shown that the existing methods for studying the forms of moisture-material bonding have significant drawbacks and generally give a qualitative assessment of the state of moisture in the material or are very laborious and require long-term laboratory studies. The efficiency of the approach to determining the forms of moisture connection in black currant fruits is shown on the basis of graphical-analytical analysis of the drying kinetics, which allows qualitatively and quantitatively assessing the state of moisture in the fruits. With the help of a graphical editor, the curves of the drying kinetics of black currant fruits were processed and the dependences of the quantity called "drying acceleration" characterizing the rapidity of the change in the drying rate of currant fruits on the moisture content of the product were obtained. The analysis of the obtained curves is carried out, indicating the presence of extrema and points of inflection to the corresponding critical moisture content, as well as the presence of areas with a slowdown or acceleration of the drying rate change, allowing to establish the intervals of moisture removal with different binding energies. The approach under consideration makes it possible to give a quantitative and qualitative assessment of the physical state of moisture not only in currant fruits, but also in other food products, as well as reduce the time for analysis and improve the accuracy of the results.

Currant fruits, drying acceleration, moisture content, drying

Короткий адрес: https://sciup.org/140301804

IDR: 140301804 | УДК: 640 | DOI: 10.20914/2310-1202-2023-1-17-23

Текст научной статьи Application of drying acceleration to study the forms of moisture bond in currant fruits

In the study and optimization of the parameters of the drying process of currant fruits, the study of the forms of moisture connection is of great theoretical and practical importance. In the process of drying, currant fruits under the influence of heat and moisture significantly change their size and physical properties. These changes are due to the molecular nature of the connection between moisture and the dry skeleton of the substance. The process of removing moisture from currant fruits, which are a colloidal capillary-porous body, depends on the nature of the molecular bond of the liquid contained in the fruit and is accompanied by a violation of its connection with the dry skeleton of the substance, which requires a certain amount of energy [1–3].

According to P A Rebinder, each form of connection between moisture and matter has its own energy [2]. Currant fruits contain capillary, osmotically bound, adsorptively bound moisture of polymolecular and monomolecular layers. In order

to remove moisture of one form or another from the fruit, you need to spend a certain amount of energy, depending on the binding energy of moisture and the amount of moisture of this form in the product.

To optimize energy consumption for the drying process, temperature regimes and the development of methods for controlling the drying process, reliable mathematical models are needed, which should form the basis of modern automation tools. It should be noted that the development of reliable mathematical models is impossible without knowledge of the state of moisture in the product being dried: bond forms, ratios of different forms, bond energies, etc [4, 5]. The complexity of the problem lies in the fact that in the fruits of currants of various varieties, as well as those grown in different climatic conditions, the moisture ratio of different forms of connection will not be the same. Factors of the production stages preceding drying, for example, blanching, long-term storage, etc., can also affect the relationship between moisture in currant fruits.

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International License

Therefore, the study of the forms of moisture connection in currant fruits and the development of accurate and accelerated methods for determining the physical state and properties of water in them is of great theoretical and practical importance and is relevant.

The existing methods for studying the forms of the connection between moisture and material have significant drawbacks and generally provide a qualitative assessment of the state of moisture in the material or are very laborious and require long-term laboratory studies.

In this regard, the purpose of this work is to determine the qualitative and quantitative assessment of the forms of moisture connection in black currant fruits based on graphic processing of the drying kinetics.

The object of the study was the kinetics of the drying process of black currant fruits: the dependence of the change in moisture content on the drying time and curves of the drying rate of currant fruits, as well as the results of thermal analysis of currant fruits. The subject of research is the forms of moisture connection in currant fruits removed during drying.

Materials and methods

The kinetics of drying black currant fruit was investigated in a vacuum dryer with a microwave energy supply [6]. The installation consists of a sealed vacuum chamber with a cover equipped with a viewing window, a control panel, a microwave energy supply device and a system for evacuating and removing vapors. The working vacuum was created by a rotary oil pump.

For the experiment, the fruits of the black currant variety "Izyumnaya" were used. Fruit for drying was used as a whole without peeling and cutting.

Studies of the kinetics of black currant fruit were carried out in a stationary mode with constant process parameters in a given range of values. For the experiment, the process parameters were kept constant in the range of values: product layer height from 0.005 to 0.025 m; Microwave power from 160 to 750 W; the pressure in the drying chamber is from 50 to 100 kPa. Sampling was carried out at intervals of 5 minutes. The moisture content of currant fruits was determined by drying to constant weight on a moisture meter at a temperature of 378 K.

The processing of experimental data on the kinetics of drying, the construction and approximation of the dependences of moisture content on time, and carrying out were carried out using the Mathcad program.

The curves of the drying rate of currant fruits were plotted by graphical differentiation of the drying curves in the KOMPAS-Graph program.

The study of the physical state and properties of water in currant fruits was also carried out on a device for simultaneous thermal analysis, model STA 449 F3 Jupiter with a sample holder (DSC/TG) type S in an aluminum crucible with a punctured lid (an empty aluminum crucible with a punctured lid was used as a reference), measurements were carried out in a nitrogen environment of class 5.0.

Results and Discussion

Using the method of planning an experiment, studies of the kinetics of microwave drying of black currant fruits in an experimental drying installation were carried out [6].

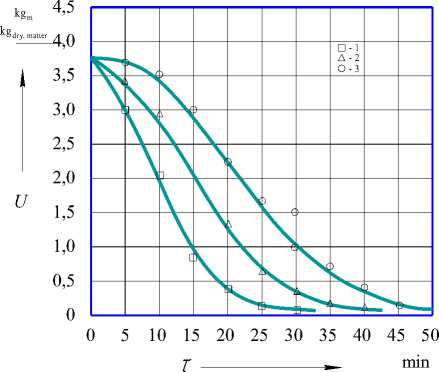

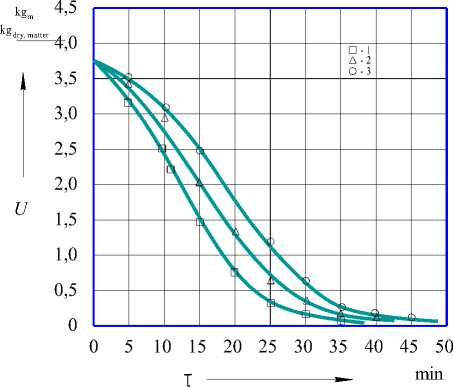

The kinetics of drying currant fruit at different values of microwave power is shown in Figure 1. The kinetics of drying currant fruit at various values of vacuum pressure is shown in Figure 2.

As is known [2, 3, 7–9], the change in the moisture content and temperature of the material during the drying process is divided into two periods: constant speed and falling speed.

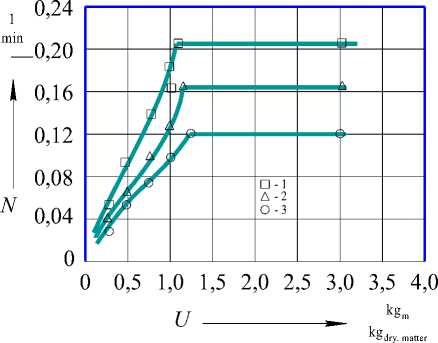

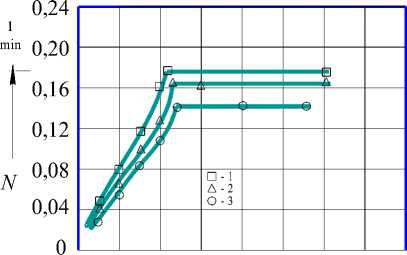

The drying rate is understood as the change in moisture content per unit time dU/d τ . Graphically differentiating the drying curves of currant fruit, curves of the drying rate of currant fruit were obtained (Figure 3, 4), showing the change in the rate of moisture removal at different moisture content of the product. The drying rate is numerically equal to the tangent of the angle of inclination of the tangent to the drying curve U = f ( τ ). When analyzing the drying speed graphs, it is necessary to read them in reverse order, since the moisture content of the material decreases during the drying process. This method allows for a qualitative analysis and determination of the critical moisture content that separates the period of constant drying rate and decreasing. Those. you can determine the quantitative and qualitative content of free moisture in the product and the quantitative of the bound moisture. In some cases, the curves of the drying rate make it possible to determine the second critical point in the form of an inflection point of the curve, which corresponds to the second critical moisture content, which is practically not visible on the curves of moisture content versus time. However, it is difficult to accurately determine the second critical point, which does not allow identifying the boundaries of polymolecularly bound moisture.

Figure 1. Drying curves of black currant fruit: 1 – h =0,015 м, p=75 кPа, P =750 W; 2 – h =0,015 м, p =75 кPа, P =455 W; 3 – h =0,015 м, p =75 кPа, P =160 W

Figure 2. Curves of the drying rate of black currant fruits: 1 – h =0,015 м, p=75 кPа, P =750 W; 2 – h =0,015 м, p =75 кPа, P =455 W; 3 – h =0,015 м, p =75 кPа, P =160 W

Figure 3. Drying curves of black currant fruit: 1 – h =0,015 м, p =50 кPа, P =455 Вт; 2 – h=0,015 м, p =75 кPа, P =455 W;

3 – h =0,015 м, p =100 кPа, P =455 W

0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

U kgm kg dry. matter

Figure 4. Curves of the drying rate of black currant fruits: 1 – h =0,015 м, p =50 кPа, P =455 W; 2 – h=0,015 м, p =75 кPа, P =455 W; 3 – h =0,015 м, p =100 кPа, P =455 W

Then, for a further and deeper analysis of the kinetics of the drying process of currant fruits, we use a value that determines the rate of change in the drying rate, that is, the first derivative of the drying rate with respect to moisture content ^ or the second derivative of moisture. The term «dry-ing acceleration» is applicable to this value [10].

To find the derivative of the drying rate in terms of moisture content ^ for currant fruits, we use graphical differentiation. The ^ value is numerically equal to the tangent of the angle of inclination of the tangent to the drying rate curve. This will allow us to determine the points of inflection and concavity of the function f ( U ), which give a more complete and accurate idea of the critical moisture content when removing physicochemi-cally bound moisture.

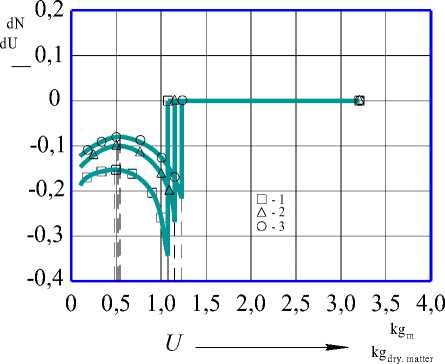

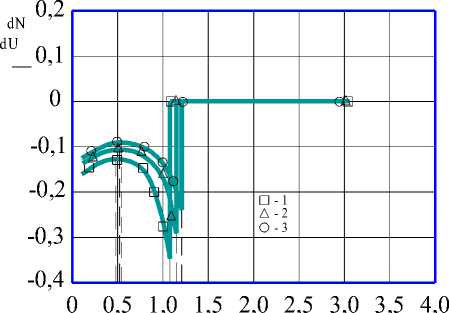

The error in measuring and plotting points on the graph during graphical differentiation was no more than 0.1 mm, and the error in determining the angle of inclination of the tangent at a point on the curve was no more than 1'. This gives grounds that the obtained results of processing experimental data on the kinetics of drying currant fruits are highly accurate. Based on the results of the graphical differentiation of the drying curves, graphs of «drying accelerations» (Figures 5 and 6) were constructed at various values of the microwave power and vacuum pressure.

The resulting graphs clearly show the periods of increasing and decreasing "drying acceleration". These graphs as well as the drying speed graphs should be read from right to left.

In the first period of drying, when the process speed is constant N 1 = const on the obtained graphs, the sections have a horizontal rectilinear

Antipov S.T. et al. Proceedings of VSUET, 2023, vol. 85, no. 1, pp. character, and the value of the function takes a zero value, that is, the rate of change in the drying speed («drying acceleration») is zero.

The negative value of the «acceleration of drying» of currant fruits indicates that this function decreases with a change in the moisture content of the material, which means that the rate of change in the drying rate decreases. This is explained by an increase in the value of the energy of binding of moisture with the dry skeleton of currant fruits with a decrease in the moisture content in them.

The analysis of the obtained curves indicates the presence of areas not defined on the curves of the drying rate, with a slowdown or acceleration of the change in the drying rate. Since each water fraction is removed at a rate varying according to different laws, it is possible for these areas to establish the intervals for moisture removal with different binding energies. Knowing the exact boundaries of these intervals, it is possible to quantitatively determine the fractional composition of moisture in the product removed during drying.

Figure 5. Curves of «acceleration of drying» of black currant fruits: 1 – h =0,015 м, p=0,75 кPа, P =750 W; 2 – h =0,015 м, p =0,75 кPа, P =455 W; 3 – h =0,015 м, p =0,75 кPа, P =160 W

U kgm kgdry. matter

Figure 6. Curves of «acceleration of drying» of black currant fruits: 1 – h =0,015 м, p =0,50 кPа, P =455 W; 2 – h=0,015 м, p =0,75 кPа, P =455 W; 3 – h =0,015 м, p =100 кPа, P =455 W

All graphs (Figures 5 and 6) clearly show the extrema of the function f ( U ) and inflection points corresponding to the first U cr1 and the second U cr2 critical moisture content, while on the curves of the drying rate of currant fruits, the values of the critical moisture contents are determined approximately.

The second critical point of moisture content is in the range from 0,48 to 0,52 kg m /kg dry. matter . Depending on the drying regimes, the second critical moisture content has a different meaning. This is due to the fact that microwave power and vacuum pressure intensify the internal diffusion of moisture, as well as an increase in the proportion of monomolecular adsorption moisture, the evaporation of which occurs together with polymolecular adsorption moisture.

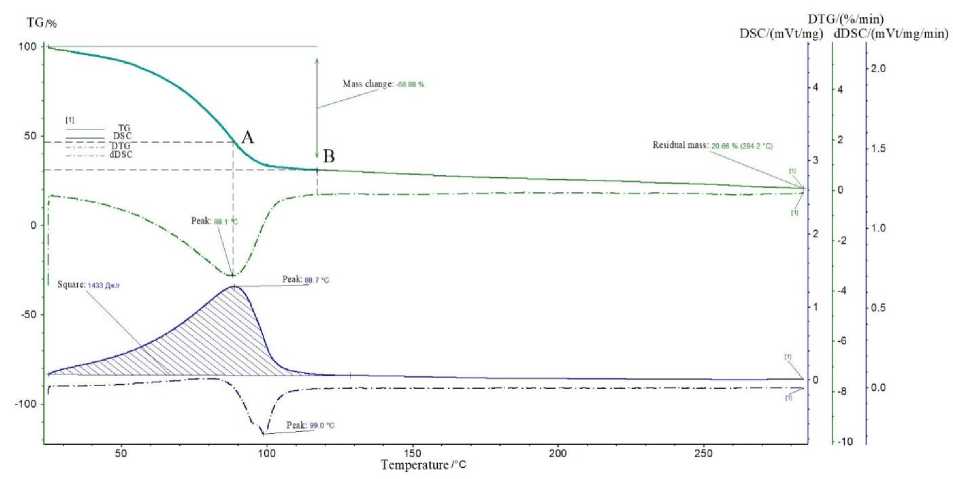

To carry out a comparative analysis of the results obtained by us on the quantitative and qualitative content of moisture in the fruits of black currant, we additionally carried out studies of the forms of moisture connection by the method of thermal analysis. The resulting derivatograms of black currant fruits are shown in Figure 7.

As a result of thermal analysis, points A and B were determined (Figure 7). Point A corresponds to the border of the interval for removing free moisture in currant fruits, its numerical value is 1,3 kgm/kgdry. matter. Point B corresponds to the boundary of the interval of polymolecular adsorption moisture in the material, its numerical value is 0,53 kgm/kgdry. matter.

From a comparative analysis of the deriva-tograms of currant fruits and the "drying acceleration" curves, it follows that the values corresponding to the first U cr1 and the second U cr2 critical moisture content obtained by two different methods are very close. The deviation of the values can be explained by a significant difference in the drying rate and the parameters of the process in the derivatograph and the drying installation. The use of microwave energy significantly intensifies the drying process and the share of polymolecular-adsorption moisture can be removed at the rate of free moisture, and the share of monomo-lecular-adsorption moisture can be removed at the rate of polymolecular-adsorption moisture. In this regard, the values of the first and second critical moisture content during drying in a drying installation have a slightly higher value than when drying in a deri-vatograph oven. However, for the practical application of the results obtained and the development of methods for controlling the drying process, it will be most correct to use the critical moisture content obtained as a result of drying the product in a real installation.

Figure 7. Derivatogram of black currant fruit

Conclusion

Using the example of graphical-analytical analysis of the curves of the drying rate of black currant fruits, the effectiveness of the approach to determining the forms of moisture-material connection is shown, which makes it possible not only qualitatively, but also quantitatively to assess the state of moisture in the product.

A comparative analysis of the data obtained as a result of graphical-analytical analysis of the kinetics of drying of black currant fruits and thermal analysis data, showing the reliability of the proposed approach, has been carried out.

The proposed approach will eliminate the time spent on laboratory studies to study the forms of moisture-material connection and can be used as the basis for a method for controlling and automating the drying process at food enterprises and in related industries.

The introduction into the theory of drying of such a value as "drying acceleration" will allow to more fully characterize the period of decreasing drying rate and open up additional possibilities for evaluating approaches to its intensification, optimization of energy costs and drying temperature regimes.

Список литературы Application of drying acceleration to study the forms of moisture bond in currant fruits

- Rudobashta S.P. The use of the theoretical propositions of Academician A. V. Lykov in modern models of heat and mass transfer during drying. Actual problems of drying and thermal moisture treatment of materials in various industries and agro-industrial complex. 2015. pp. 21-28. (in Russian).

- Lykov A.V. Theory of drying. Moscow, Energiya, 1968. 472 p. (in Russian).

- Sazhin B.S. Scientific foundations of drying technology. Moscow, Nauka, 1997. 448 p. (in Russian).

- Dornyak O.R. Modern problems of mathematical modeling of thermal-humidity processing of materials. Collection of scientific articles of the First international Lykov scientific readings. Kursk, pp. 36-42. (in Russian).

- Kholmansky A.S., Tilov A.Z., Sorokina E.Yu. Physico-chemical modeling of the drying process of vegetables and fruits. Modern problems of science and education. 2012. no. 5. pp. 83-83. Available at: http://www.science-education.ru (in Russian).

- Antipov S.T., Arapov V.M., Kazartsev D.A. Kinetics laws as the base for mathematical simulation of microwave vacuum drying process. Journal of Physics: Conference Series. IOP Publishing, 2020. vol. 1560. no. 1. pp. 012017. https://doi.org/10.1088/1742-6596/1560/1/012017

- Vasilenko V.N., Frolova L.N., Dragan I.V., Mikhailova N.A. et al. Exergy analysis of the technology of oscillating drying of oilseeds. Proceedings of VSUET. 2018. vol. 80. no. 1. pp. 81-89. (in Russian).

- Drannikov A.V., Shakhov S.V., Erofeevskaya M.O., Sukhanov P.M. et al. Determination and use of rational parameters of the drying process of beet pulp when creating a drum dryer with a combined energy supply. Proceedings of VSUET. 2019. vol. 81. no. 2. pp. 63-69. (in Russian).

- Ostrikov A.N., Shevtsov A.A., Drannikov A.V., Kvasov A.V. Distribution of temperature and moisture content fields in a rectangular beet pulp particle during convection drying Proceedings of VSUET. 2018. vol. 80. no. 1. pp. 11-19. (in Russian).

- Emelyanov A.B, Kazartsev D.A., Rudyka E.A., Baturina1 E.V. et al. On the issue of studying the forms of moisture coupling in thermolabile heterogeneous products. IOP Conference Series: Earth and Environmental Science. IOP Publishing, 2021. vol. 640. no. 7. pp. 072009. https://doi.org/10.1088/1755-1315/640/7/072009

- Calín-Sánchez Á., Lipan L., Cano-Lamadrid M., Kharaghani A. et al. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods. 2020. vol. 9. no. 9. pp. 1261. https://doi.org/10.3390/foods9091261

- Karam M.C., Petit J., Zimmer D., Djantou E.B. et al. Effects of drying and grinding in production of fruit and vegetable powders: A review. Journal of Food Engineering. 2016. vol. 188. pp. 32-49. https://doi.org/10.1016/j.jfoodeng.2016.05.001

- Nowak D., Jakubczyk E. The freeze-drying of foods-The characteristic of the process course and the effect of its parameters on the physical properties of food materials. Foods. 2020. vol. 9. no. 10. pp. 1488. https://doi.org/10.3390/foods9101488

- Sun Q., Zhang M., Yang P. Combination of LF-NMR and BP-ANN to monitor water states of typical fruits and vegetables during microwave vacuum drying. Lwt. 2019. vol. 116. pp. 108548. https://doi.org/10.1016/j.lwt.2019.108548

- da Silva Junior E.V. et al. Influence of ultrasound and vacuum assisted drying on papaya quality parameters. Lwt. 2018. vol. 97. pp. 317-322. https://doi.org/10.1016/j.lwt.2018.07.017

- Bhatta S., Stevanovic Janezic T., Ratti C. Freeze-drying of plant-based foods. Foods. 2020. vol. 9. no. 1. pp. 87. https://doi.org/10.3390/foods9010087

- Liu Y., Zeng Y., Hu X., Sun X. Effect of ultrasonic power on water removal kinetics and moisture migration of kiwifruit slices during contact ultrasound intensified heat pump drying. Food and Bioprocess Technology. 2020. vol. 13. pp. 430-441. https://doi.org/10.1007/s11947-019-02401-z

- Zhao R., Gao T. Research Article Research Progress of Hot Air Drying Technology for Fruits and Vegetables. Advance Journal of Food Science and Technology. 2016. vol. 10. no. 3. pp. 160-166.

- . Gouw V.P., Jung J., Zhao Y. Functional properties, bioactive compounds, and in vitro gastrointestinal digestion study of dried fruit pomace powders as functional food ingredients. LWT. 2017. vol. 80. pp. 136-144. https://doi.org/10.1016/j.lwt.2017.02.015

- Salahi M.R., Mohebbi M., Taghizadeh M. Foam‐Mat Drying of Cantaloupe (C ucumis melo): Optimization of Foaming Parameters and Investigating Drying Characteristics. Journal of food processing and preservation. 2015. vol. 39. no. 6. pp. 1798-1808. https://doi.org/10.1111/jfpp.12414