Application of polyvinyl chloride for nanocomposites (analysis and optimization of quality indicators)

Автор: Yulia F. Kovalenko, Ekaterina A. Shulaeva, Nikolai S. Shulaev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 6 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The application of nanocomposites in various industries has increased in recent years due to their unique properties and performance characteristics. Enhancing the quality performance of nanocomposites presents a formidable challenge, primarily attributable to the intricate interactions among their constituent elements. This paper presents an overview of the methods used to analyze and calculate the quality performance of nanocomposites using PVC as the base material. Methods and materials. To calculate technological parameters that are not directly measurable, we conducted a thorough analysis of literature sources related to the specific process under consideration. Through this analysis, we established appropriate relationships between empirical data in accordance with the fundamental principles of thermodynamics and mass transfer processes. In the course of the research, the method of neural networks was applied in order to describe the process of vinyl chloride polymerization carried out by suspension method. To solve this problem, a cascade network with forward propagation of the signal and backward propagation of the error was applied. Network composition: in the hidden layer – ten sigmoid neurons, in the output layer – two linear neurons. Results and Discussion. Throughout this research, it was observed that the heat flux during polymerization exhibits temporal variation, contingent upon the concentration level of the initiator. Further the dependencies obtained can be used in controlling the flow rate of refrigerant into the reactor cooling jacket, to ensure that the entire process is isothermal. It was found that by varying the stirrer speed, it is possible to change the particle size and hence the molecular weight distribution of polyvinyl chloride. The developed neural network was tested. The obtained results have minimal error and are close to the real values, from which we can conclude that the network is trained correctly and the dependence between the data is found. Conclusion. Dependencies linking physicochemical parameters of the technological process with the design features of the apparatus have been established. To maintain the quality of PVC, in particular the appropriate molecular weight distribution, a neural network (a cascade network with direct signal propagation and reverse error propagation, consisting of ten sigmoidal neurons in the hidden layer and two linear neurons in the output layer) was developed in MATLAB environment. The network was trained on a sample and tested on test values, which showed that the network predicts the outcome of the process with minimal tolerable error, with other parameters unchanged.

Polyvinyl chloride, nanocomposite, neural network, polymerization, nanotechnology

Короткий адрес: https://sciup.org/142239109

IDR: 142239109 | DOI: 10.15828/2075-8545-2023-15-6-519-530

Текст научной статьи Application of polyvinyl chloride for nanocomposites (analysis and optimization of quality indicators)

Original article

P olyvinyl chloride (PVC) has found widespread use in the construction industry due to its versatile properties and relatively low cost. PVC is a type of polymer that is composed of repeating vinyl chloride monomer links. In recent years, the characteristics and properties of PVC have been significantly improved using nanotechnology, making it an even more sought-after material for construction.

The use of nanotechnology involves modifying the structure of the material at the nanoscale, which ranges in size from approximately 1 to 100 nanometers. Modification of PVC using nanotechnology allows to increase mechanical strength, durability and resistance to ultraviolet radiation and chemicals. This makes it a sought-after material for construction products that must withstand the negative effects of environmental parameters (temperature difference, humidity, UV radiation).

The application of nanotechnology of PVC composites in construction is promising and relevant. Nanocomposites are materials that contain small nanoparticles of other materials, such as clay or carbon nanotubes, which

CONSTRUCTION MATERIALS SCIENCE are dispersed throughout the PVC matrix. The nanoparticles also help to improve the mechanical properties of PVC, making it stronger, more elastic.

Another example is the use of PVC nano-coatings, which can protect building materials from corrosion, weathering and other forms of degradation. These coatings also improve the appearance of PVC surfaces, making them more aesthetically pleasing.

The grade of PVC can affect the properties of nanocomposites, such as their mechanical, thermal and electrical properties. Different PVC grades can have different molecular weights, degree of branching and chemical composition, which can affect the compatibility of PVC and nanofillers, as well as the dispersion and interfacial interactions within the nanocomposites. Therefore, it is important to obtain the appropriate grade of PVC and select the processing conditions to optimize the performance of nanocomposites.

The stage of vinyl chloride (VC) polymerization by suspension method is an important industrial process of polyvinyl chloride (PVC) production. To date, modeling of this process has become a hot topic of research in the field of polymer property management. Models developed for the polymerization process that determine the polymer properties are usually based on the use of computational tools and methods such as molecular dynamics simulations, Monte Carlo methods and finite element methods.

The current state of the problem of modeling the process of VC polymerization by suspension method is characterized by the lack of reliable and accurate models.

A number of studies have been devoted to the development of computational models of the polymerization process. However, the accuracy of these models is often limited due to incomplete or inadequate data or assumptions made. In addition, the complexity of the process and the number of variables involved make it difficult to accurately predict the performance of the polymerization reaction.

The most commonly utilized models for the polymerization process rely on Monte Carlo and finite element methods. These models have been employed to develop various techniques for simulating the polymerization process. However, their predictive accuracy regarding process parameters is constrained due to their reliance on assumptions and incomplete data.

In addition to the existing models, a number of new approaches to modeling the polymerization process have been proposed. For example, some researchers suggested using artificial neural networks to model the process. Other approaches included the use of machine learning algorithms and data mining techniques.

In general, the current state of the problem of modeling the process of VC polymerization by suspension method is characterized by the lack of sufficiently reliable and accurate models. This leads to the need for further research to develop more reliable and accurate models of the polymerization process.

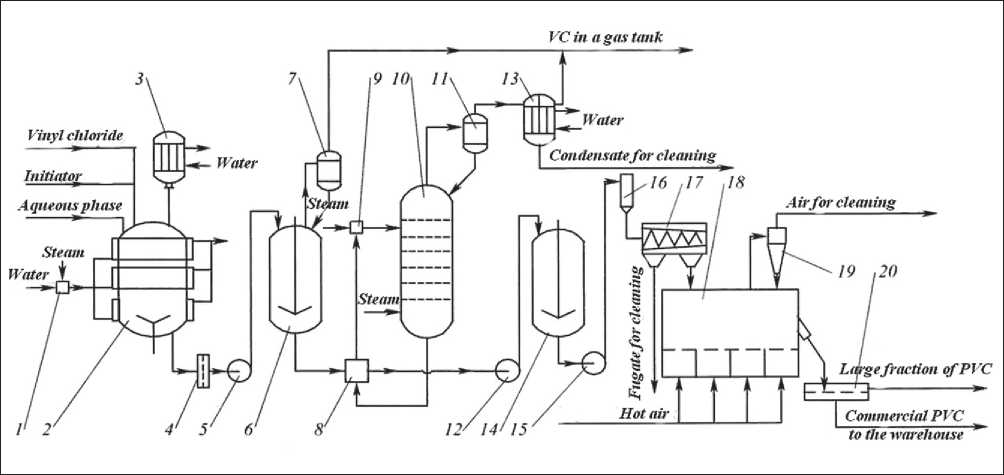

Fig. 1 shows a simplified technological process for production of suspension PVC by industrial method without using additional steps. Polymerization of vinyl

Fig. 1. Technological scheme of polyvinyl chloride production: 1, 9 – steam mixing heaters; 2 – reactor-polymerizer; 3 – reverse condenser-cooler; 4 – crust separator; 5, 12, 15 – pumps; 6 – capacitive degasser; 7, 11 – separators;

8 – heat exchanger; 10 – degassing column; 13 – condenser; 14 – PVC suspension collector; 16 – expander;

17 – centrifuge; 18 – fluidized bed dryer; 19 – cyclone; 20 – classifier

CONSTRUCTION MATERIALS SCIENCE chloride takes place in a polymerization reactor using batch method. The reactor has a stirrer and a jacket for heating and cooling.

Desalinated water from the collection tank is used for pumping. In order to prevent the PVC slurry from entering the mechanical seal, the desalinated water is dosed using a special pump. The control system then starts loading the reactor and subsequently runs the process according to the recipe format. After the vinyl chloride has been dosed in the amount specified in the recipe, the reactor begins to heat up to the temperature specified in the regulations. When the set temperature is reached, the cooling time sensor is triggered. At the same time, a valve in the pipeline supplying the pre-cooled water to the suction pump is fully opened. Cooling water is fed into the reactor jacket, which displaces the hot water and the reactor is brought to the set temperature by the control system. The polymerization process is then started. When the set time has elapsed, the control system adjusts and maintains the set temperature in the reactor. A control valve, which is installed on the pipeline supplying the direct pre-water circuit, maintains the temperature during the entire polymerization process. If the temperature deviation from the set temperature is ±0.5оC, an alarm is sounded at the operator’s workstation. If the set temperature limit is exceeded, the control system activates the corresponding alarm or automatically adjusts the reactor operating parameters to maintain the set pressure at the required level. When the specified amount is reached, polymerization is completed. Subsequently, additional polymerization starts, which is accompanied by a time countdown. If there is no gradual decrease in pressure in the reactor, it also switches to the process of additional polymerization. The latter can be carried out either when the reactor is heated or without heating in the presence of a polymerization temperature, which is reached as a result of heat generation during polymerization. After the polymerization is completed, the slurry is pumped from the reactors to the degassers by means of pumps through filters.

A two-stage degassing process is used to remove gas from the PVC suspension. First, overpressure of VC is released in vessel degassers, and then degassing takes place in column-type apparatuses. Simultaneously with discharge of slurry from the reactors, vinyl chloride is blown from the degasser into the gas holder, where the gas is separated from PVC particles by means of an abseiler. The water from the abseiler is periodically returned to the degasser and the discharge is monitored using a sight glass. The slurry drain line from the abseiler is piped to the abseiler for flushing and to prevent clogging of the slurry drain line. VC blowdown is considered to be completed when the pressure in the degasser reaches a value not exceeding 0.02 MPa (0.2 kgf/cm²).

From the degasser, the PVC slurry passes through a filter and is continuously pumped to the degassing column. The amount is kept constant by control valves, depending on how many reactors are operating.

Steam, which is fed from the top of the degassing column to the bottom, passes through the holes in the plates, enriching with vinyl chloride. A mixture of gaseous vinyl chloride, which is a hot slurry coming out of the cube portion of the column, passes through the heat exchanger. Both the mixture and the water vapor, which comes from the head end of the column, are fed to the abseiler, where polyvinyl chloride particles that have been carried away by the gas are separated.

When the PVC is separated and dried, the separated slurry is continuously transported from the cube section of the column by a pump. At the same time, the slurry is cooled to the set temperature in a spiral heat exchanger. The slurry is then fed to the column or to another heat exchanger, which is cooled with recycled water.

The PVC slurry, which does not exceed a temperature of 85оC, after degassing, is fed through a pipeline to a heat exchanger to separate the crust from the slurry. Using a centrifugal pump, through a strainer installed in the discharge line and through an expander, the PVC suspension is fed to the centrifuge. The pump runs continuously. After the centrifuge, the PVC with a certain moisture content enters the disintegrator. The mother liquor coming out of the centrifuge is checked for PVC content and is directed by gravity through a pipeline to one of its collectors. If necessary, a centrifugal pump directs the matte either to the polymerization stage or to the flushing of equipment and pipelines.

In “fluidized bed” dryers, the wet PVC undergoes drying.

After the centrifugation process, the wet PVC products with a certain moisture content are sent to the disintegrator to break up the lumps formed. The products are then directed to the feed area of the dryer. It is located in the first section of the drying equipment, between the horizontal pipes, which are built-in heat exchangers. From below, through the distribution grid, hot air is supplied, as a result of which PVC products form a boiling layer. The heat supply for drying is not only by means of hot air, but also through the surface of the built-in heat exchangers, which are heated by hot water. The air enters the lower part of the dryer at a temperature of 90°C through the air distribution grille. In order to maintain a constant and sufficiently turbulent fluidized bed of products in the dryer, the air supply is controlled within predetermined values. The air flow rate is kept stable. The product in the dryer is dried until the required moisture content is reached. The dry PVC is then discharged from the dryer using vibrating screens. If necessary, the finished PVC product is analyzed for moisture and vinyl chloride content at the outlet of the dryer.

CONSTRUCTION MATERIALS SCIENCE

The air accompanying the PVC powder is fed into the cyclone hopper through a tangential inlet. In the cyclone, the PVC dust particles are separated from the air and then conveyed to the vibrating screen through a disk gate and sluice feeder. The sieved product fraction is directed to the pneumatic pump for further transfer to the silo.

When the PVC screening hopper is full, coarse particles from the process strings are transferred to the silos through a sluice feeder using a pneumatic pump and air pneumatic conveying.

In the process of vinyl chloride polymerization in the reactor, isothermal mode is used. This means that the temperature remains constant during the reaction and is controlled within specified limits (50 to 72оC), depending on the desired degree of polymerization. This approach is particularly important if the concentration of the polymerization initiator is changed, as it can affect the thermal characteristics of the reaction.

To provide the necessary conditions under which the time-varying heat must be dissipated, heat exchange devices such as a jacket and a return condenser are used. The polymerization reaction generates heat that must be efficiently dissipated to maintain a stable temperature. The jacket surrounds the reactor and is cooled by the chilled water, which takes up some of the heat. A special reverse condenser is used to cool and condense the vaporizing vinyl chloride in the reactor, which effectively removes excess heat during the time of maximum heat release.

The presence of such heat exchangers allows to effectively regulate the temperature in the reactor and provide the necessary conditions for the polymerization process when changing the initiator concentration or other process parameters.

One of the main characteristics of the quality of the resulting PVC is the molecular weight distribution of PVC particles, which in turn depends on temperature. As the temperature increases, the average molecular weight of the particles decreases, resulting in a broader molecular weight distribution. This can be explained by the fact that higher temperatures cause more chain breaks in the polymer molecules, resulting in a larger number of smaller particles. In addition, higher temperatures can cause chain breaks, which can also lead to a wider molecular weight distribution. Thus, higher temperatures tend to reduce the average molecular weight of the polyvinyl chloride particles and result in a broader molecular weight distribution.

Neural networks can be used to study the process of vinyl chloride suspension polymerization. Neural networks are powerful computational tools that can be used to analyze complex nonlinear relationships between various input and output data. Using a neural network, specific parameters affecting the polymerization process such as temperature, acid concentration, monomer concentration, and stirring rate can be determined. The neural network can also be used to develop a model that accurately predicts properties of the resulting polymer, such as molecular weight distribution. Such a model can be used to optimize the polymerization process and obtain the desired properties of the final product.

There are various programs for creating neural networks, some popular ones include TensorFlow, Keras, PyTorch, Caffe and Theano, Matlab.

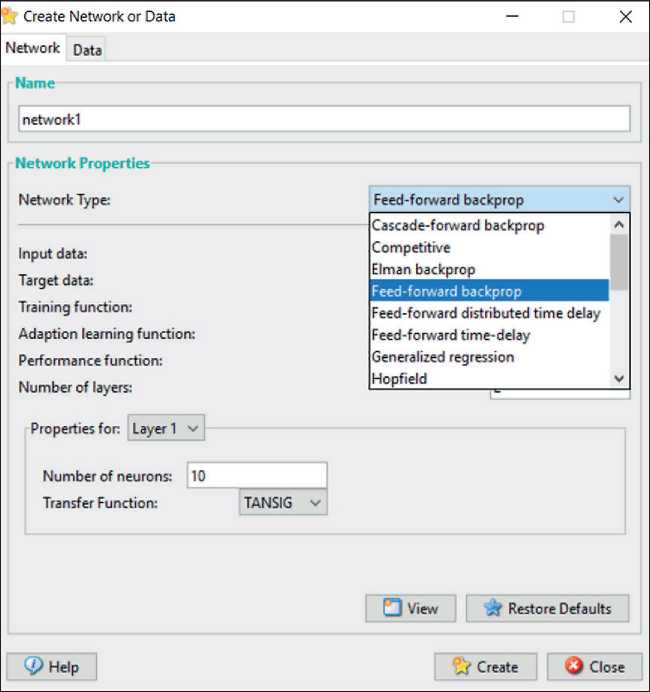

Matlab is a powerful tool in the education of engineering students. This programming language, developed by MATLAB, provides a high-level programming environment for performing technical computations, visualization, and data analysis. Its wide applications in engineering, physics, and mathematics make MATLAB a popular choice among students studying these fields (Figure 2).

There are the following types of neural networks:

-

1. Competing network: a type of unsupervised network in which neurons compete with each other for activation based on input signals. It is used for clustering and pattern recognition.

-

2. The forward and backward propagation cascade network is a supervised neural network used for model training. It consists of several hidden layers and is used in image and speech recognition tasks.

-

3. Back propagation Elman network: a type of recurrent neural network that can store and process sequential data. It is used for speech recognition and time series prediction.

-

4. Network with forward signal propagation and backward error propagation: a supervised forward-linked network that uses backward error propagation to train a model. It is used for classification and regression tasks.

-

5. Delayed back propagation network: a type of recurrent neural network that can process input signals with time delays. It is used for speech recognition and pattern recognition.

-

6. Generalized regression network. A type of neural network used for regression analysis. It uses one hidden layer and can handle multiple input and output variables.

-

7. Hopfield network: a type of associative memory network that can store and recall patterns. It is used to recognize images and patterns.

-

8. Linear layer (creation): a type of neural network used for linear regression problems. It uses one hidden layer and can handle multiple input and output variables.

Forward propagation is from the input layer to the output layer, where each neuron in a layer passes its output to the next layer. Back propagation of the error is used to correct weights and optimize the model. The errors are compared to the expected results and the feedback signal propagates back through the network to update the weights of the neurons.

This neural network architecture allows the model to be trained on a large amount of labeled data and significantly improves its recognition and classification ability.

CONSTRUCTION MATERIALS SCIENCE

Fig. 2. Definition of neural network view in Matlab

METHODS AND MATERIALS

For mathematical calculation of technological parameters that cannot be directly measured, we analyzed literature sources on the process under consideration and established appropriate relationships between empirical data in accordance with the basic laws of thermodynamics and mass transfer processes [1–6].

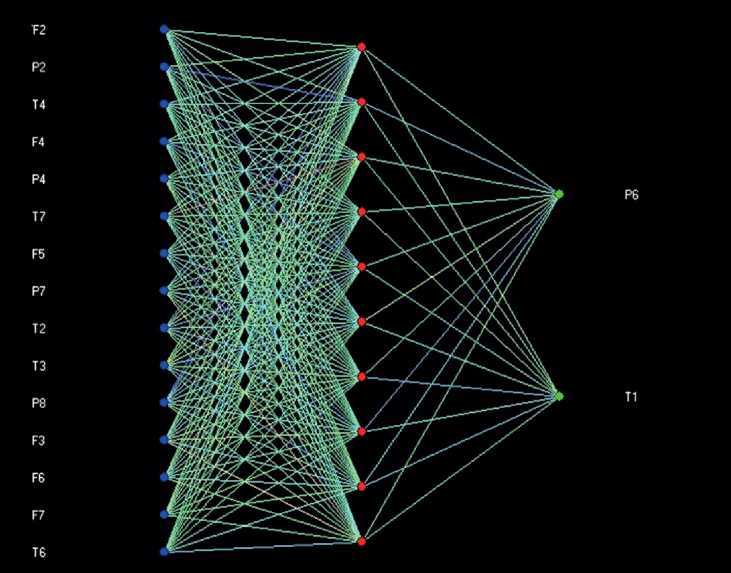

The study applied neural network method to describe the process of vinyl chloride polymerization by suspension method. To solve this problem, a cascade network with forward propagation of the signal and backward propagation of the error was used. There are ten sigmoid neurons in the hidden layer of the network and two linear neurons in the output layer.

It is a type of learning algorithm with a teacher used to train artificial neural networks. The cascaded back propagation algorithm is used to improve the performance of the standard forward-linked back propagation algorithm by using a multi-stage architecture. The multi-stage architecture is such that the output of one stage of the neural network is used as input to the next stage.

The cascade back propagation algorithm involves dividing the network into a number of subnets, with each subnet trained separately. The output of each subnetwork is then fed as input to the next subnetwork. This process culminates in the final output of the neural network.

During training, the algorithm first performs a forward pass through the network to generate the predicted output. The difference between the predicted output and the expected output is then calculated and error gradients are computed with respect to each weight in the network. These gradients are then used to update the weights in each subnetwork.

A cascade network having forward signal propagation and backward error propagation, whose composition has ten sigmoid neurons in the hidden layer and two linear neurons in the output layer, can be described as follows:

The input layer accepts input data, which are attributes or characteristics of the task.

The hidden layer consists of ten sigmoid neurons. Each neuron accepts input signals and applies the sigmoid activation function to generate an output value.

The output layer consists of two linear neurons. Each neuron accepts outputs from the hidden layer and computes a linear combination with weights and bias without applying an activation function.

Direct signal propagation:

CONSTRUCTION MATERIALS SCIENCE

The input data is transmitted through the network from the input layer to the hidden layer and then to the output layer.

Each neuron in the hidden layer applies a sigmoid activation function to the input signals and generates an output value.

The output values from the hidden layer are passed to the neurons of the output layer without applying an activation function.

Reverse propagation of error:

-

• The error is calculated by comparing the output values of the network with the expected values based on the selected error function.

-

• The error propagates back through the network starting from the output layer using the error back propagation algorithm.

-

• The weights and offsets of the network are updated according to gradient descent and weight update rule to minimize the error.

Training and Optimization:

-

• The network is trained on the training dataset by repeating the forward and backward error propagation process.

-

• Hyperparameters such as learning rate and number of epochs can be customized for optimal results.

-

• After training, the network can be tested on a validation dataset and further on a test dataset to evaluate its performance.

-

• The cascaded forward back propagation algorithm has been shown to be effective in improving the accuracy

of neural networks, especially when the input data is noisy or when the input data is highly variable. In addition, the use of separate sub-networks can improve the computational fficiency of the algorithm because each sub-network can be trained independently of the others.

RESULTS

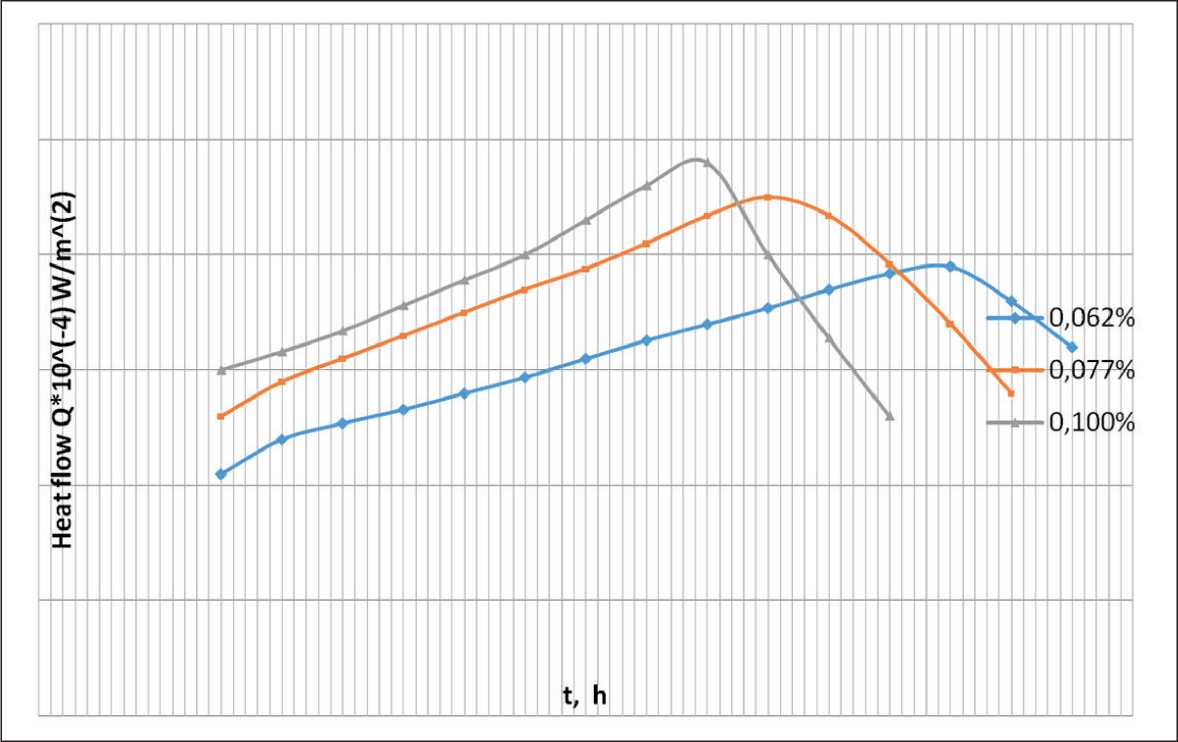

The process for producing the polyvinyl chloride discussed herein is carried out at a constant temperature, which requires control of heat dissipation, which may vary over time depending on what the process composition, including the concentration of the polymerization initiator, will be.

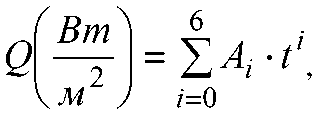

As a result of these studies, the relationships between the change in heat flux that occurs during the polymerization reaction and the change in initiator concentration with time were found (Fig. 3).

where t is time, h; Ai are the coefficients of the equation determined by the ratios A0 = –0,5962+6,4758Z; A1 = 1,7535–11,4222Z; A2 = –0,5806+8,7025Z; A3 = 8,64*10–2–3,4579Z; A4 = –4,6*10–3+0,748Z; A5 = –8,23*10–2Z; A6 = 3,6*10–3Z.

Z = C–C0/C1–C0, С1 = 0,1% wt. of BX, С0 = 0,065% wt. of BX.

Fig. 3. Dependence of heat flux on polymerization time at concentrations of initiator (triganox): 0.065% wt. of VC, 0.077% wt. of VC and 0.10% wt. of VC

CONSTRUCTION MATERIALS SCIENCE

These dependencies are used to control the refrigerant flow rate in the reactor cooling system to ensure a constant temperature during the process..

^^t^] - ^оК®^^1), (2)

where K = 0,9•10–4 m2/W.

In the polymerization process, the temperature of vinyl chloride polymer-monomer particles, denoted as T(r), differs from the temperature of the reaction medium, denoted as Tc. From the solution of the steady-state heat conduction equation for spherical polymer-monomer particles with radius R and heat transfer coefficient λ, it follows that the temperature is determined by the following relation:

r

.2 A

.

2X( R2J .

It can be seen that the temperature reaches the maximum value in the center of the particle at r → 0. The deviation of the temperature inside the droplet from the temperature of the reaction mixture can reach 10оC, which affects the molecular weight distribution of the polymer.

Based on the dependence of the polymer-monomer particle sizes on the mixing intensity and properties of the emulsion stabilizer [1] and analysis of empirical data, a formula was developed that establishes the relationship between chemical-technological parameters and the design features of the polymerization reactor (Fig. 5).

Fig. 4. Spherical polymer-monomer particle of radius R

d =

°'6 1+2Ф n12d”8,

where We = ρn2dм3/ς – is the Weber number, Ф is the volume fraction of the dispersed phase in the emulsion, ρ – is the density, n, dм – are the rotational speed and diameter of the stirrer, respectively, ς is the surface tension coefficient.

Generalizing the obtained dependences, we can conclude that by changing the stirrer rotation frequency, it is possible to change the particle size and, consequently, the molecular-mass distribution of polyvinyl chloride.

Models at conceptual, topological and structural levels have been developed to improve the quality of the output product in the vinyl chloride polymerization process.

The model at the conceptual level is built with division of the selected parameters into input and output parameters. It contains initial information for further calculation, which is presented in Table 1.

This will help to optimize the polymerization process and obtain a polymer with a homogeneous molecular weight, which, in turn, will improve the quality of the product.

A Cascade-forward backprop neural network consisting of ten sigmoidal neurons in a hidden layer was chosen to solve this task (Fig. 7).

Fig. 5. Polymerization reactor

CONSTRUCTION MATERIALS SCIENCE

Table 1

Input and output parameters of the polymerization reactor

|

Technological parameters |

Variable |

|

Consumption of mortar B72 |

F1 |

|

Solution pressure B72 |

P1 |

|

Solution temperature B72 |

T5 |

|

Methocel solution flow rate |

F2 |

|

Methocel solution pressure |

P2 |

|

Methocel solution temperature |

T4 |

|

Initiation agent consumption – Triganox WD-100 |

F4 |

|

Initiator pressure |

P4 |

|

Initiator temperature – Triganox WD-100 |

T7 |

|

Desalinated water consumption |

F5 |

|

Pressure of desalinated water |

P7 |

|

Desalinated water temperature |

T2 |

|

Vinyl chloride temperature |

T3 |

|

Vinyl chloride pressure |

P8 |

|

Vinyl chloride consumption |

F3 |

|

Agidol solution consumption |

F6 |

|

Soda consumption |

F7 |

|

Temperature of sodium bicorbonate |

T6 |

|

Polyvinyl chloride suspension pressure |

P6 |

|

PVC suspension temperature |

T1 |

|

Fl__ |

|

|

Pl ___ |

-----► |

|

T5 |

|

|

-----► |

|

|

F2 ___ |

|

|

P2 --- |

T1 --------► 1 |

|

T4 --- |

b |

|

F4 ___ |

-----► |

|

P4 ___ |

-----► |

|

T7 -- |

-----► |

|

F5 --- |

► |

|

P7 --- |

-----► |

|

T2 --- |

-----► |

|

T3 --- |

|

|

PS --- |

------► P6 |

|

F3 --- |

-----► |

|

F6 --- |

----► |

|

F7 |

|

|

T6 |

|

|

\^___/ |

Fig. 6. Conceptual model for neural network development

Fig. 7. Conceptual model of a neural network for regulating technological parameters with ten sigmoidal hidden layer neurons

CONSTRUCTION MATERIALS SCIENCE

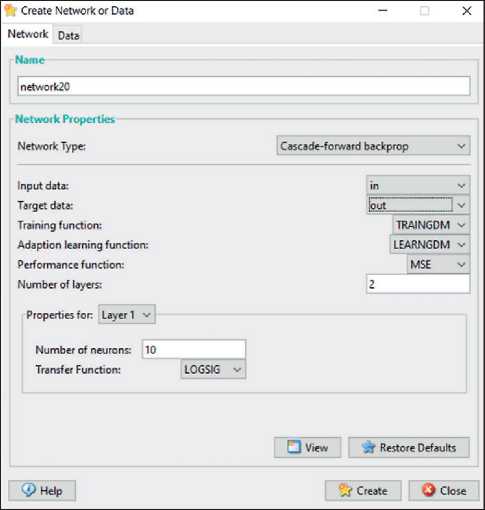

To design an artificial neural network, we used the nntool tool in Matlab program, which allows creating and customizing neural networks in the graphical environ-

Fig. 8. Creation of an artificial neural network ment Neural Network Toolbox. In the graphical interface the type of neural network Cascade-forward backprop is selected (Fig. 8). Number of neurons in input, hidden and output layers. Activation function for each layer is selected. The network is trained.

DISCUSSION

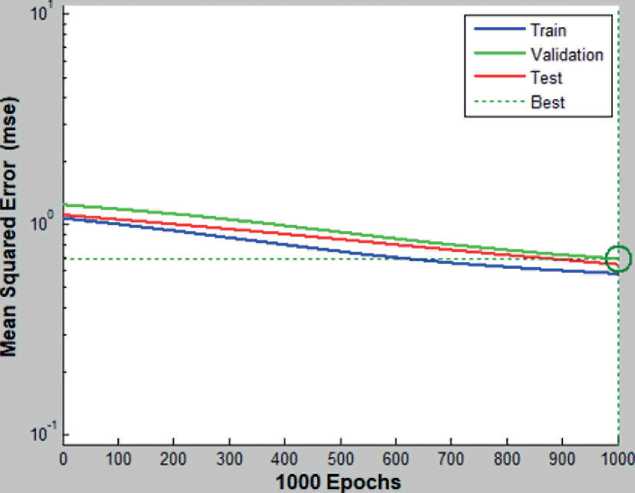

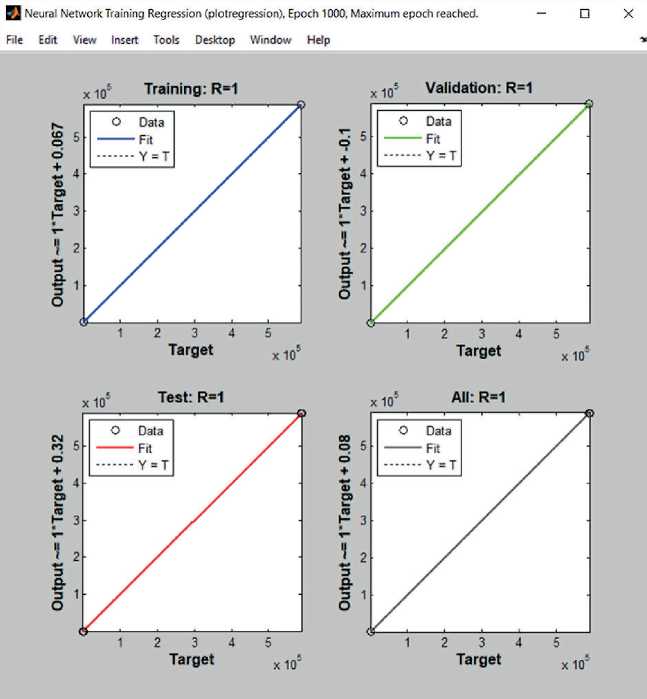

Verification data can be used to evaluate the results and verify the output values of neural networks. The “Simulate” tab in the neural network setup window allows you to feed input values and analyze the corresponding output values.

Table 2, containing test data, is used by the tool to evaluate the performance of the neural network. By feeding input values from Table 2 into the simulation window, the obtained output values are compared with the expected results, which makes it possible to evaluate the accuracy and reliability of the neural network in recognizing and classifying data.

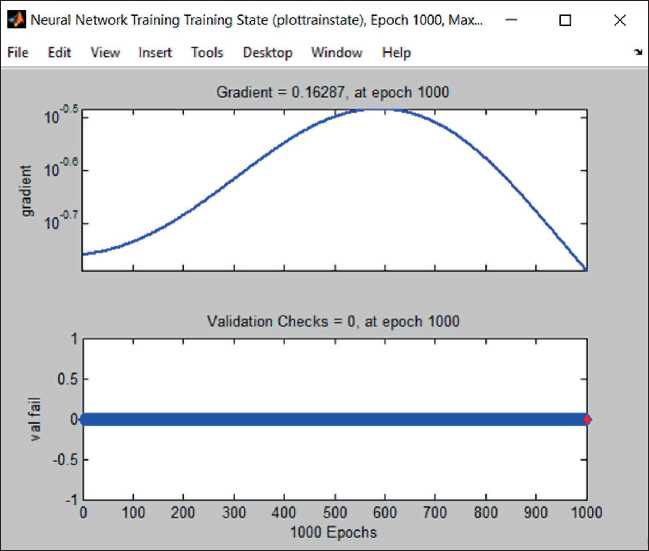

The obtained results have minimal error and are close to the real values, which indicates that the network is trained correctly and the dependence between the data is found.

Thus, the developed neural network can be used to predict the molecular weight distribution of PVC particles.

□ Neural Network Training Performance (plotperform), Epoch 1000, Maxi... — □ X

File Edit View Insert Tools Desktop Window Help

Best Validation Performance is 0.68262 at epoch 1000

Fig. 9. Mean square error

CONSTRUCTION MATERIALS SCIENCE

Fig. 10. Network training graphs

Fig. 11. Linear regression graph

CONSTRUCTION MATERIALS SCIENCE

Table 2

Neural network verification

|

Input values |

||

|

Group1 |

Group 2 |

|

|

F2, kg/h |

230.11 |

232.05 |

|

P2, Pa |

872796.85 |

872797.11 |

|

T4, С |

24.68 |

24.72 |

|

F4, kg/h |

74.73 |

75.91 |

|

Р4, Pa |

254973.62 |

254974.09 |

|

Т7, С |

–22.30 |

–22.34 |

|

F5, kg/h |

29005.33 |

29000.10 |

|

Р7, Pa |

200000.61 |

200000.95 |

|

Т2, С |

95.63 |

95.18 |

|

Т3, С |

38.15 |

33.86 |

|

Р8, Pa |

591000.05 |

524078.65 |

|

F3, kg/h |

26018.05 |

26004.93 |

|

F6, Па |

49032.10 |

49032.24 |

|

F7, kg/h |

5.50 |

5.47 |

|

Т6, С |

49.00 |

50.41 |

|

Output values |

||

|

Check values |

||

|

Р6, Pa |

588399.02 |

588397.64 |

|

Т1, С |

66.98 |

65.81 |

|

The values obtained |

||

|

Р6, Pa |

588400 |

588400 |

|

Т1, С |

66.74 |

65.23 |

CONCLUSION

The following results were obtained through the research.

The dependence of heat flux on initiator concentration was established and a mathematical formula was developed that allows to regulate the refrigerant flow rate in the reactor cooling system to maintain a constant temperature and ensure isothermal process. This formula is a tool for optimal control of the reactor thermal regime and ensuring its stable operation.

It was found that an increase in temperature leads to a broadening of the molecular weight distribution spectrum towards lower molecular weights.

The formula determining the relationship between chemical-technological parameters and design features of the polymerizer reactor is obtained. It is established that by changing the stirrer rotation frequency, it is possible to change the particle size and, consequently, the molecular-mass distribution of polyvinyl chloride.

The development of a neural network to describe and predict the process of vinyl chloride polymerization by suspension method is reasonable. A neural network using a cascaded forward and backward propagation architecture, ten sigmoidal neurons in the hidden layer and two linear neurons in the output layer was developed to ensure the quality of PVC including appropriate molecular weight distribution. The development was carried out in MATLAB environment.

Training on a sample and verification on test values were carried out, which showed that the network predicts the outcome of the process with the minimum tolerable error with other unchanged parameters. This, in turn, will allow to control and optimize the technological process and obtain products of a given quality.

Список литературы Application of polyvinyl chloride for nanocomposites (analysis and optimization of quality indicators)

- Ulyanov V.M., Gutkovich A.D., Shebyrev V.V. Technological equipment of polyvinyl chloride suspension production: Monograph. N. Novgorod. 2004. 253 с.

- Preparation and properties of polyvinyl chloride / Edited by E.N. Zilberman. Zilberman. Moscow: Khimiya, 1968. 432 с.

- Mathematical methods of modeling of polymerizer reactor for the process of polymerization of vinyl chloride. Kovalenko, Y.F., Shulaeva, E.A.AIP Conference Proceeding, 2022, 2467, 060023.

- Mathematical methods for modeling of the process of diaphragm electrolysis Shulaeva, E.A., Kovalenko, Y.F., Serebryakov, E.A. AIP Conference Proceedings, 2022, 2467, 060012.

- Modeling of the process of electrolysis production of caustic, chlorine and hydrogen. Shulaeva, E.A., Shulaev, N.S., Kovalenko, J.F.. Journal of Physics: Conference Series, 2017, 803(1), 012148.

- Simulation and modeling software in chemical technology: Polymerization of vinyl chloride. Shulaeva, E.A., Kovalenko, Y.F., Shulaev, N.S.Advanced Materials Research, 2014, 1040, pp. 581–584.

- Ksandrov N.V. Resource saving in chemical technology: textbook for universities / N.V. Ksandrov, O.R. Ozhogina, A.A. Peretrutov. N.Novgorod. 2014. 101 p.

- Kovalenko Y.F., Shulaeva E.A., Shulaev N.S. Modeling of molecular-mass distribution at obtaining polyvinyl chloride by suspension method. Bulletin of young scientist of UGNTU. 2016. № 1. P. 128–131.

- Shulaeva E.A., Shulaev N.S., Kovalenko Y.F. Computer modeling of technological processes. Butler Communications. 2018. Т. 54. № 4. P. 40–55.

- Muravyeva E.A., Kazantsev R.V., Podlesky D.V. Development of neural network to control the process of alkaline washing of isopentane-isoprene-toluene fraction using a virtual analyzer. Bulletin of Perm National Research Polytechnic University. Chemical technology and biotechnology. 2022. № 2. P. 120–137.

- Calculations of fluidized bed apparatuses / Edited by I.P. Mukhlenov, B.S. Sazhin, V.F. Frolov. Publisher: “Khimiya”, Leningrad Branch, 1986. 352 p.

- Shulaeva E.A., Kovalenko Y.F., Serebryakov E.A. Modeling of diaphragm electrolysis process. Natural and Technical Sciences. 2021. № 8 (159). P. 190–192.

- Shulaeva E.A., Daminev R.R., Islamutdinova A.A. Features of creating simulation and modeling complexes of common petrochemical processes on the example of the process of vinyl acetate synthesis // Electrotechnical and information complexes and systems. 2013. V. 9, № 4. 127–134.

- Shulaeva E.A., Kovalenko Yu.F. Mathematical modeling and analysis of parameters of technological process of diaphragm electrolysis. Natural and Technical Sciences. 2022. № 7 (170). P. 214–215.

- Shulaeva E.A., Shulaev N.S., Kovalenko Y.F. Modeling of electrolyzer parameters in the production of caustic soda, chlorine and hydrogen. Neftegazovoe delo. 2016. V. 14. № 4. P. 103–107. 16. Shulaeva E.A., Kovalenko Yu.F., Shulaev N.S. Simulation and Modeling Software in Chemical Technology: Polymerization of Vinyl Chloride. Advanced Materials Research Vol. 1040 (2014), pp. 581–584.

- Shtovba S.D. Ensuring accuracy and transparency of Mamdani fuzzy model when learning from experimental data // Problems of management and informatics. – 2007. – № 4. – P. 102–114.

- Yakhyaeva G.E. Fuzzy sets and neural networks: textbook. Moscow: Binom. Laboratory of Knowledge, 2008. 316 p.

- Galushkin A.I. Neural Networks: Fundamentals of Theory. MOSCOW: GLT, 2010. 496 p.

- Galushkin A.I., Tsypkin Y.Z. Neural networks: history of theory development: textbook for universities. Moscow: Alliance, 2015. 840 p.

- Rutkowska D., Pilinski M., Rutkowski L. Neural Networks, Genetic Algorithms and Fuzzy Systems. Moscow: RiS, 2013. 384 p.

- Shiryaev V.I. Financial Markets: Neural Networks, Chaos and Nonlinear Dynamics. Moscow: Librocom CD, 2016. 232 p.

- Redko V.G. Evolution, Neural Networks, Intelligence: Models and Concepts of Evolutionary Cybernetics. Moscow: Lenand, 2017. 224 p.