Ceramics from Novoilyinka III, a Chalcolithic site in Kulunda, Western Siberia

Автор: Kiryushin K.Y., Stepanova N.F.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.44, 2016 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145266

IDR: 145145266 | DOI: 10.17746/1563-0102.2016.44.3.101-110

Текст статьи Ceramics from Novoilyinka III, a Chalcolithic site in Kulunda, Western Siberia

Any discovery of a new archaeological site attributable to the Neolithic and Chalcolithic periods in the south of Western Siberia provides a new insight into the history of these periods. The site of Novoilyinka III has been discovered in the Kulunda steppe that is located at the crossroads between large archaeological areas of the Altai steppe, Kazakhstan, and the Baraba steppe. Novoilyinka III is among the few well-stratified sites discovered in the region. Studies at the site provide important information on the ethnic and cultural processes existing in the south of Western Siberia as early as in the Chalcolithic period.

Novoilyinka III (Fig. 1) was discovered by S.M. Sitnikov in 2004, and an area of approximately 40 m2 was excavated in 2005–2006 (Kiryushin K.Y., Sitnikov, 2009: 101). The area excavated in 2010–2014 reached 608 m2. Archaeological finds including ceramics, stone artifacts, and animal

Fig. 1. Location of the site of Novoilyinka III.

bones, were concentrated over the area of 360 m2 in the central part of the excavation site, and around the spot of burnt soil in the eastern part of the site. In the central part, archaeological finds were associated with the patches of sandy loam with amorphous borders in both horizontal and vertical directions. The fragments belonging to particular vessels were distributed at depths of 0.35 to 0.85 m, while potsherds belonging to the vessels of various morphological and ornamentation classes were embedded in a single layer. The Novoilyinka III lithic industry was based on flakes; no traces of blade-based reduction typical of the Chalcolithic have been noted. A series of radiocarbon dates has been obtained on the recovered animal bones: 4270 ± 170 BP (Le-7534), 4585 ± 170 BP (SOAN-8318), 4310 ± 110 BP (SOAN-8319), and 4250 ± 120 BP (SOAN-8320), suggesting a date of the middle-second half of the 3rd millennium BC. The calibrated dates make the age of the culture-bearing layer nearly one thousand years older. The values spread by 1σ (probability of 68.2 %) are within the range of 3650–3600 to 2650–2630 BC, those by 2σ (95.4 %) 3700–2850 to 3500–2400 BC. The maximum spread of values is 1020–1300 years, while the minimum is 650–950 years. This interval is quite considerable. It is most likely that the culture-bearing layer was accumulated over a shorter period. The calibrated radiocarbon dates suggest the date of the Novoilyinka III materials to be the first half of the 3rd millennium BC (Kiryushin K.Y., 2015: 26).

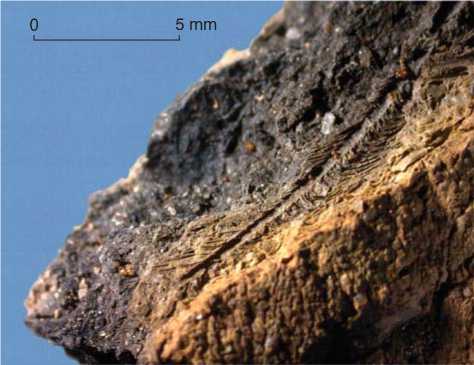

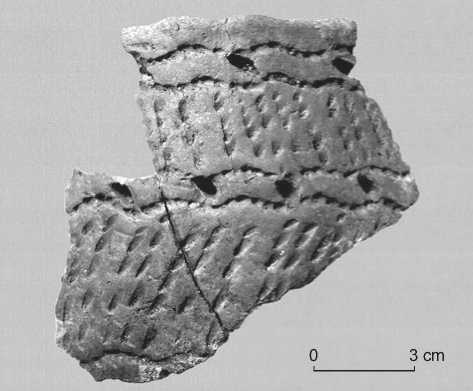

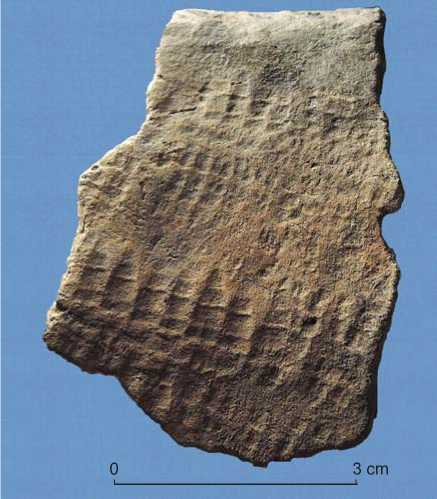

The unique ceramic collection, including a few thousands of potsherds belonging to at least 60 vessels, was recovered from Novoilyinka III. The original shapes of 18 vessels were partially or completely reconstructed. The rim-diameters are usually slightly smaller than those of the vessels’ bodies; the bases are pointed or rounded (Fig. 2). Vessel-walls were thoroughly smoothed over, so that any traces of mineral admixtures are not detectable on the surface. The walls are 6–7 mm thick on average; some vessels had walls 5 or 8–9 mm thick. The vessels were manufactured using the patch technique (Fig. 3). This ceramic set is unusual for Altai in both ornamentation patterns and paste composition.

The Novoilyinka III ceramic collection represents an important source of information about the ancient population, and has been subjected to various analyses. The study of ceramic-manufacturing technique provides information about human migrations, subsistence strategies, contacts between tribes, exploitation of new territories, and other matters. The Novoilyinka III collection was studied with the historical and cultural approach proposed by A.A. Bobrinsky (1978, 1999). The main purpose was to identify specific features of cultural traditions relating to raw material selection, paste preparation, and vessel ornamentation. The authors address the following issues: 1) identifying cultural traditions in the skills of raw material selection and paste preparation; 2) distinguishing between local and foreign techniques; 3) identifying the features suggesting a blend of traditions; 4) exploring the features of shaping a tool’s working edge, and techniques of pottery decoration. Fresh breakages and potsherdsurfaces were examined using a binocular microscope MBS-10. Examination of raw materials was focused on determination of the iron-admixture in clay, the characteristics of coarse admixtures in clay, and cases of using one or two different sorts of clay. Iron-admixtures in clay were determined through potsherd-heating in oxidizing medium in a muffle furnace at 850 °С. Analysis of ornamentationpatterns was focused on reconstruction of the tool’s working edge by its imprints, on features of the working edge’s formation, and on techniques of applying decoration. Analytical data have been supported by experiments.

Results of technical and technological analysis

Wall and rim fragments of 19 vessels were subjected to technical and technological analysis. These ceramic

ХЬЖЛ'Ж. 'v *2»^ж^>; ^№№Х$*Я("Кт« "iiix^'.i^S^ver.Uf.x::

5 cm

8ig^jv> v * * '

*> 4 > > -» = 1^ <» *

5 *''# * - *

«$5йЗ.«ий

Fig. 2. Graphic reconstructions of the Novoilyinka III ceramic vessels.

Fig. 3. Vessel-fragment with the traces of patch technique.

fragments varied in ornamentation-patterns and colors, and were apparently baked in fire at low temperature.

Raw materials. Pots were made of ferrous, mostly low-ductility clay tempered with fine riversand. The clay used varied in concentration and size of admixtures. Quartz sand with a particle size of less than 0.5 mm was observed, mostly; yet some specimens contained larger sand-grains, up to 1 mm.

A sand-ratio of 1 : 2 to 3 is most typical, although some specimens demonstrate a sand-ratio of 1 : 4. The share of vessels made of ductile clay is 10.5 % of the total number of vessels. Comparative analysis of the used raw materials has shown that clay from several beds was used; the features of the clay are mostly homogenous in iron content, but vary in the amount of natural admixtures. The main (local)

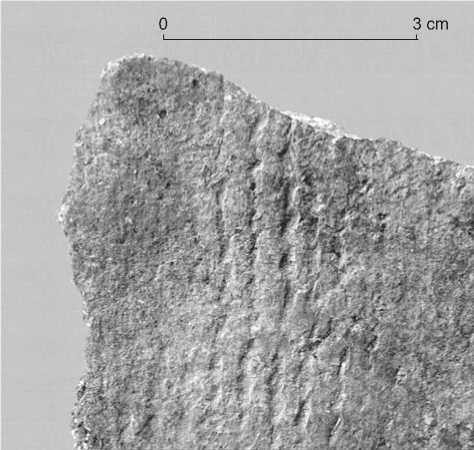

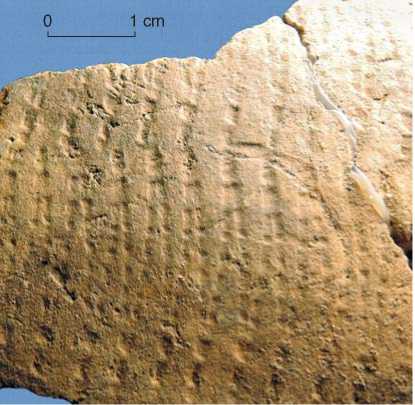

Fig. 4. Imprints of bird-down on the vessel-wall.

Novoilyinka III tradition was the use of ferrous, low-ductility clay tempered with fine river-sand.

Paste. Three main paste compositions were identified: clay + down + organic matter (89 %); clay + grog + grit + down + organic matter (5.5 %), and clay + grit + organic matter (5.5 %). The main paste-type 1 includes two sub-types: based on the low-ductility clay (84 %), and based on the ductile clay (5 %). Only one vessel was made of paste that did not contain down (5.5 %); only two vessels (11 %) contained mineral admixtures (grog and grit). In both vessels, grit represents granite with a high micacomponent. Mineral admixtures were added to the ductile and medium-ductility clays. One specimen shows grit-grains in grog, suggesting a blend of various cultural traditions. In general, the intentional introduction of mineral matter is not typical of the Novoilyinka III ceramic tradition.

Despite the various noted paste types, the main pottery manufacturing traditions at Novoilyinka III can be regarded as local (Bobrinsky, 1978: 67–113). This concerns the use of the low-ductility clay in ceramic paste with the admixture of down and some organic matter, most likely bird-droppings (Fig. 4). The non-local traditions show the use of ductile clay, grog, and grit, but the absence of down. The clay paste composition of clay + grog + grit + down + organic matter represents a blend of a non-local tradition (using mineral admixtures) and the local tradition (using organic admixtures).

Decoration

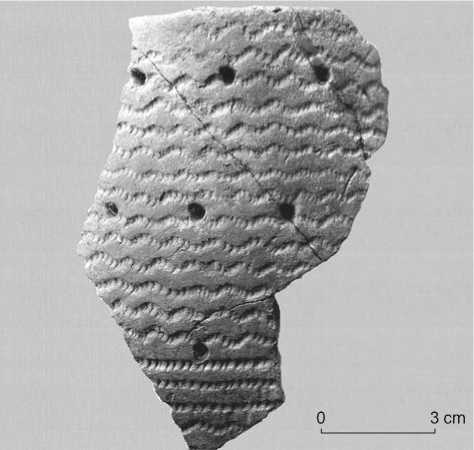

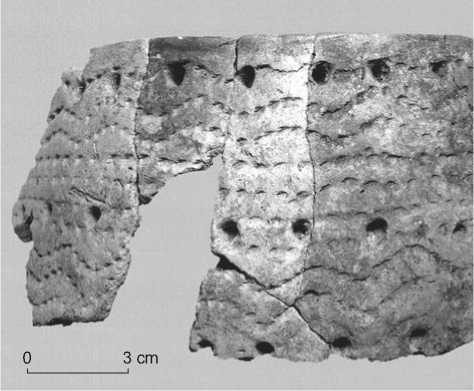

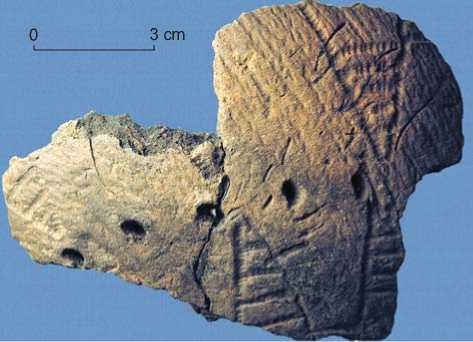

All vessels are decorated. Most vessels bear decorations all over the exterior surface, from the rim to the base

(see Fig. 2), excluding three specimens. The most typical designs are horizontal straight and wavy lines made using mostly non-comb tools (up to 90 %). Few vessels show vertical and slanting lines (see Fig. 2, 7 , 8 ). Another typical motif represents lines of small pits (sometimes, double lines of pits). Some vessels show zigzag mutual positioning of pits belonging to parallel lines. Bases also often bear special decorative motifs, for instance, a ray motif (see Fig. 2, 3 ). Decoration-patterns are based on linear compositions: rows of straight and wavy lines; geometrical figures separated by these rows; lines of herringbone images; ornithomorphic images; and straight and wavy lines. In one case, the vessel was decorated with triangles located checkerwise (Kiryushin K.Y., 2015).

The majority of vessels bear imprints of noncomb tools; only few were decorated with combimplements. The collection has a specific feature: the interior wall-surfaces of some vessels were ornamented with comb-imprints (see Fig. 2, 4 , 8 ). Cord-imprints seem to represent another decorationpattern of the interior walls (see Fig. 2, 7 ; 5). It should be noted that 56 % of the rims show other types of interior decoration; the motifs are: 1) short slanting lines (incisions) executed with tools having both smooth and comb working edges; 2) horizontal lines of varying length in depressions, made sometimes with a stick braided with cord and, in other cases, with a finger (see Fig. 2, 1 , 3 , 4 , 6 , 7 ) (Ibid.: Fig. 22). The vessels look variously ornamented owing to specific decorative techniques. The potters’ skills are remarkable: they are reflected in the locations of imprint-lines and the general uniformity of the arches of the wavy lines, the difference between the arch-sizes being around 1–2 mm (Fig. 6).

On the basis of the imprints of ornamenting-tools, decorative techniques, and only partially, the shapes of the working edges have been reconstructed.

Non-comb tools , according to their imprints, usually were 2–4 mm in cross-section. Several varieties of the working-edge shape can be recognized according to the imprint-forms:

-

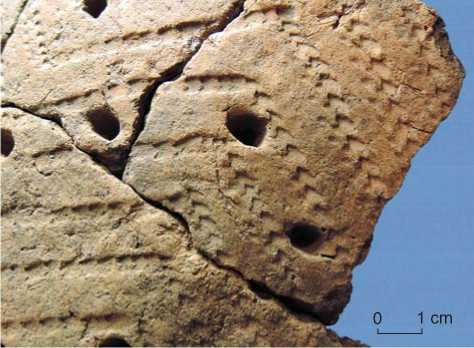

1) rounded imprints suggest the corresponding shape of the working edge (Fig. 7);

-

2) sub-oval and pointed-elongated imprints— a similar working-tool edge (Fig. 8);

-

3) crescent-shaped imprints are most typical of this ceramic collection; they could have been made using a specially-cut-off tool with a circular crosssection; the imprints vary in depth and diameter (see Fig. 6, 9);

-

4) pseudo-comb imprints were likely made using the ornamenting tools with uneven working edges

Fig. 5. Potsherd bearing cord-imprints on the interior surface.

Fig. 6. Vessel-wall decorated with non-comb imprints.

Fig. 7. Vessel-wall decorated using a non-comb tool with a rounded working edge.

Fig. 8. Vessel-fragment with sub-oval and pointed-elongated imprints.

(Fig. 10). It cannot be excluded that these are traces of animal-teeth. However, experiments with animal-teeth and mandibles did not produce completely analogous imprints (Kalinina, 1991, 1998, 2009: 97; Kazakov, Galchenko, Stepanova: 1994).

Few imprints resembling cord have been noted. However, clear identification is extremely difficult because of the poor state of preservation of the vesselwalls (Fig. 11).

Pits have been observed on all vessels, excluding one specimen. They are rounded, oval, and crescent- shaped; and have sizes of mostly 5–6 cm and 5 × 4 cm. Few pits are 3 × 2 cm or smaller. Their depth is 5–6 cm, and sometimes they are through. Their vertical sections are mostly cone-shaped. Pits were made using various tools, mostly rounded (more rarely, sub-oval) in cross-section (see Fig. 2, 6–8, 11). Pits were formed after the other ornamentation had been executed.

Various decorative techniques were used. Retreating and pricking ornaments were executed using non-comb tools (see Fig. 6–8) (Kalinina,

Fig. 9 . Ceramic fragment with crescent-shaped imprints.

Fig. 10. Vessel-fragment with pseudo-comb imprints.

Ustinova, 1990: 15–18, fig. 5, 6). The cases of transition from one decorative technique to another on one vessel have been noted. For instance, pricking was replaced by retreating. The position of the workingtool also varies across the sample: the working edge was either parallel to the rim edge (see Fig. 7); or perpendicular (see Fig. 6), which was most popular. According to decorative techniques and workingedges of tools, sets of two or three similar vessels can be identified (see Fig. 6, 12); although the selection of raw materials might have been different.

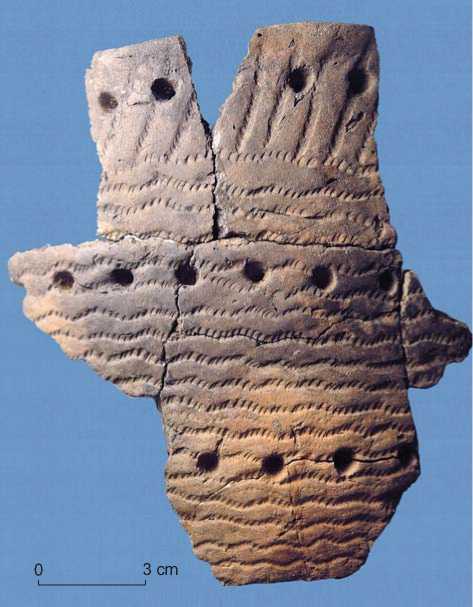

Comb-tools were used for ornamentation of six vessels: three vessels demonstrate decoration of their exterior surfaces (see Fig. 2, 6–8 ) and five vessels, interior surfaces (see Fig. 2, 4 , 8 ; 13). Stepping and rocking stamps were noted on four vessels (see Fig. 2, 6–8 ; 14), rolling and stepping with dragging, on one vessel each (see Fig. 13). The length of the imprints varies from 3 to 7 cm. One of the vessels in the collection bears the imprints of two different tools (or one tool with two working edges), executed by various techniques (Fig. 14). In one case, we see distinct groups of imprints (Fig. 15); in the other, separate imprints at approximately equal distances from each other (Fig. 16). Ornamenting

Fig. 11 . Vessel-fragment with cord-imprints.

Fig. 12. Vessel-wall decorated with non-comb imprints.

Fig. 13. Vessel-fragment with non-comb imprints on the interior surface.

Fig. 14. Vessel-wall which was decorated using two comb tools (see Fig. 15, 16).

Fig. 15. Vessel-fragment with stepping design.

Fig. 16. Vessel-fragment with comb-imprints.

tools of the first type are rare, yet few comparative analogs are known (Stepanova, 2012). We cannot exclude that similar decoration patterns were executed using analogous objects of natural origin.

Discussion

The analysis of the obtained data has identified two traditions (typical and unusual) in the Novoilyinka III pottery, relating to the selection of raw material, paste processing, and decorative techniques. Specific features of this ceramic collection as compared to other Altai pottery assemblages of the Neolithic–early Bronze Age have also been established. The typical Novoilyinka III ornamental tradition included the following:

-

1) Use of low-ductility ferrous clay intentionally tempered with a considerably large amount of down;

-

2) Use of patch-technique for manufacturing the vessels;

-

3) Decoration of the entire vessel-surface;

-

4) Rows of pits as the essential ornamentationelement;

-

5) Decoration using mostly non-comb ornamenting tools;

-

6) Linear decorative compositions; and

-

7) Decoration of the interior surfaces of rim and walls with the imprints of comb-stamps or cord-design (about 40 % of the total number of vessels).

The unusual features included the use of the ductile clay tempered with mineral matter (grit and grog), decoration of the exterior vessel-surface with comb imprints and, partially, with ornamentation-design. Such features as absence of down in paste and lack of pit-design are most significant.

The majority of vessels in this collection demonstrate certain individual features; few vessels show several individual features or one significant feature. For instance, three vessels show sparse ornamentation (see Fig. 2, 6 ); yet down in the paste, plus pit-and-rocking design impressed by a cogged stamp (as well as ornamentation of the interior rim-surface), attribute these vessels to a complex belonging to the same chronological period and the same culture as the rest of the assemblage.

Two vessels are noteworthy. One of them (Fig. 2, 8 ) was made of the paste with mineral admixtures representing a blend of various cultural traditions (clay + grog + grit + down + organic matter), and showed decoration made using two comb-tools (or the ornamenting-tool with two working edges) through two different techniques: stepping and rocking. The rows of stamps are slanting. The noted imprints suggest specificity of one of the working edges: cogs were located in sets separated from one another (see Fig. 14, 15). However, this vessel shares some features with the main collection: the presence of down in the paste, and line of pits along the rim’s edge. The interior surface of the rim was decorated with rocking-stamp. This motif has been noted on several vessels, although it cannot be considered the leading motif in the collection.

The distinctive features of the other vessel (see Fig. 2, 7) are decoration with comb-imprints, and the composition of the paste (clay + grit + organic matter). This vessel is the only specimen manufactured from the paste free of down. The features shared with the main ceramic-collection are pits along the rim, and cord-imprints on the interior surface. Common to these two vessels are the presence of grit in the paste, decoration with comb-imprints, and pits located only in the upper parts, unlike other vessels in the collection. The unusual features of these two vessels are the decorative technique (rocking and stepping comb design), the slanting arrangement of rows, and paste composition. The presence of the unusual mineral admixture in the paste (grog containing grit), and the use of down (which is typical of this settlement) suggest a blend of various cultural traditions and contacts of the population, as well as adoption of new traditions of ceramic-manufacture by the incoming population. Pit-design over the rim and the presence of down in the paste allow the assumption that these vessels were made at the site of Novoilyinka III under the influence of the local ceramic tradition.

The pottery decorated with stepping combimprints has been reported from the vast territory from the Urals to the Altai Mountains, and is attributed to the chronological period from the Neolithic to the Bronze Age. For instance, a vessel from the disturbed Chalcolithic burial-site of Pavlovka III in the Uglovsky District of the Altai Territory (Southern Kulunda) shows vertical lines of plain rocker imprints (Kiryushin Y.F., Kazakov, 1996: 219, fig. 54, 1 ). The Novoilyinka III pottery shows the greatest similarity to the Bolshoy Mys vessels of the Chalcolithic period. The Bolshoy Mys pottery is characterized by decoration with comb-imprints, admixture of granite grit with the high mica content; some Bolshoy Mys vessels bear slanting and vertical lines of combed-rocking imprints (Kiryushin Y.F., 2002: Fig. 3, 1 , 4 ; 4; 8, 1 ; 15, 3 ; Stepanova, 2008).

In general, the Novoilyinka III ceramic collection is unique among other Neolithic and early Bronze Altai assemblages owing to its manufacturing technology and decoration-patterns. Unusual for the steppe and forest-steppe Altai is the use of the low- and medium-ductility clay. The most peculiar Novoilyinka feature is admixture of a considerable amount of down in the paste (Stepanova, 2008, 2010). This cultural tradition has not been recorded elsewhere in Southern Siberia. The use of bird-droppings and down in the ceramic paste has been noted in some Neolithic collections from Eastern Europe (Bobrinsky, 1978: 102–103; Tsetlin, 1991: 93–98; 2012: 254–255). Ornamentation of the ceramicware with non-comb tools and the presence of pit-design as an essential decorative feature represent the main distinctive features of the Novoilyinka III pottery. Ceramics of the Chalcolithic period from Barnaul and Biysk regions in the Ob (Bolshoy Mys culture) and the Altai Mountains (Afanasyevo culture) are decorated mostly with combstamp imprints; few vessels also show the non-comb imprints, only as part of composition; decoration with the pit lines has not been noted. Ornamentation of the interior surface of the Novoilyinka III ceramics also represents its unique feature.

The tradition to decorate the entire vessel surfaces with non-comb stamps, recorded at the Novoilyinka III site, is also typical of the Kiprino ceramics from the

Barnaul-Biysk region of the Ob. Close analogs have also been noted in the archaeological materials from the settlements of Vengerovo-3 in Baraba (Molodin, 1977: 33, pl. XXXIII, 1–4 ; XXXIV, 3 ; XXXV, 2 ; XXXVI, 8 ; 1985: 17–18, fig. 3, 1–6 , 16 , 19 ) and Botai in Northern Kazakhstan (Zaibert, 1993: Fig. 22; Mosin, 2003: Fig. 45–46, 48, 51–56, 65). Similar features in ornamentation-patterns are explained by the fact that these collections, while belonging to various cultures, are derived from a single historical and cultural community of the Neolithic to Bronze Age (Chalcolithic or Early Metal) transitional period. The Novoilyinka III pottery bearing noncomb-stamp imprints and lines of pits is close to the comb-pit and pit-comb ceramics of the forest-zone of the Trans-Urals and Northern Kazakhstan, judging by its compositional patterns and motifs of decoration. Apparently, the Novoilyinka III settlement was located at the eastern periphery of the territory of the historical and cultural community practicing comb-pit, pitcomb, and retreating-pricked-pit decorative designs. This community occupied the vast territory from the forest-zone of Eastern Europe (the Baltic) to the Upper Ob. The distinctness of the Novoilyinka III pottery might be a result of its easternmost peripheral location (Kiryushin K.Y., 2015).

Conclusions

The Novoilyinka III population comprised two main groups practicing two ornamental traditions that correspond to various techniques of vessel-manufacture. Retreating-pricked-pit design represents the main local ornamental tradition for the Novoilyinka III site. It is related to the Kiprino pottery from the Barnaul and Biysk regions of the Ob. The Novoilyinka III ceramics of this type are characterized by an admixture of down into the paste, and the use of the low- and mediumductility clays.

Currently available data are regrettably not sufficient for reliable association of the Novoilyinka III comb-decoration tradition with the already identified ceramic types or archaeological cultures. The features of the paste’s composition suggest a blend of cultural traditions. It can be hypothesized that the tradition of grit-admixture to the paste was formed in the regions that were rich in stone outcrops (Rudny Altai, branches of the Salair Ridge, or the Kazakh Uplands, etc.). This incoming population-group adopted certain techniques of ceramic manufacture and decoration: downadmixture in the paste, pit-decoration pattern, cordimprints, ornamentation of the rims’ interior surfaces, and others. The noted features of two different traditions in mineral admixtures to the paste (grit and grog) suggest that people might have migrated from different places, because a grog admixture in the paste was typical of the regions lacking stone outcrops.

In general, the analysis performed on the Novoilyinka III ceramic manufacture and decorative techniques supports the attribution of the entire pottery assemblage to a single chronological and cultural unit. The described features suggest a mixture of certain cultural traditions that reflects a process of interaction and initial consolidation of the population-groups practicing various traditions, which apparently originated from various landscape zones. This process seems to have been natural for the site that was located on the crossroads between large cultural communities of the forest-steppe Altai, Kazakhstan, and Baraba.