Chinese lacquerware from the Pazyryk burial ground Chineta II, Altai

Автор: Dashkovskiy P.K., Novikova O.G.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 4 т.45, 2017 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145332

IDR: 145145332 | DOI: 10.17746/1563-0110.2017.45.4.102-112

Текст обзорной статьи Chinese lacquerware from the Pazyryk burial ground Chineta II, Altai

The burial ground of Chineta II is located on the second terrace above the floodplain of the Inya River, 1.0–1.4 km to the south-southeast of the village of Chineta in the Krasnoshchekovsky District of the Altai Territory (northwestern Altai) and belongs to the Chineta archaeological microregion. This burial ground includes objects of the Scythian-Saka period, as well as the Turkic, Kyrgyz, and Srostki cultures (Dashkovskiy, Usova, 2011; Dashkovskiy, 2014, 2015; and others). During the study of mounds No. 21 and 31 at the Chineta II burial ground, a complex of specific artifacts including fragments of Chinese lacquerware was discovered, which show parallels to the Pazyryk culture.

Since ancient times, Chinese artisans covered their products with a mixture based on the sap of the Chinese lacquer tree ( Rhus verniciflua ) of the Anacardiaceae family (Chinese ‘qi-zhu’ ( 漆樹 )), and used lacquer coatings based on qi -lacquer ( 漆 )* not only as decorative,

but also as moisture-protective and waterproof films (Novikova, 2000). Notably, not all modern organic coating materials possess a set of physical, mechanical, and adhesive properties that ensure superpreservation (superdurability). The number of natural substances that since ancient times have been used as coating materials with similar qualities is extremely small, and their coatings are quite specific. One such “long-living” filming agent is the unique Chinese qi -lacquer (since ancient times, it was called “the king of paints”). By modifying it, adding pigments to it, and developing the technology of applying mixtures made of it, the Chinese initiated the development of East Asian coating materials*.

The resistance of coating materials of qi -lacquer not only to moisture, but also to acids and alkalis results from the high degree of polymerization of the phenolic components, formation of chemical bonds with the metals of the substrate, and the affinity with the lignins of the wood. In terms of their durability, lacquer-based composites are comparable to artifacts made of inorganic materials** (Kumanotani et al., 1979). According to their physical and mechanical properties (hardness, heat resistance, etc.), casting biopolymers from qi -lacquer are the precursors of synthetic materials of the phenolic type invented in the 20th century—thermosets, such as resite or bakelite (Elikhina, Novikova, 2013).

In the context of the discussion of qi-lacquer, we should mention old film-forming agents used in painting. Vegetable drying oils (tung oil, linseed oil, etc.)—full esters of glycerol and unsaturated fatty acids—also dry in the air. The process of solidification of qi-lacquer and oils has some differences caused by their chemical structure and molecular weight. Lacquer coatings from natural oils do not achieve a high degree of polymerization, and according to a whole range of properties they are not comparable to those based on qi-lacquer. Films of drying oils are chemically unstable, which is confirmed by the methods of analytical chemistry.

Non-polar substances, such as vegetable oils, are well-combined with Chinese lacquer, since qi -lacquer is an emulsion of a polar liquid in a non-polar urushiol continuous phase (“water-in-oil” type). Qi -lacquer has always been expensive*, and people often tried to reduce its cost (often with a loss of quality) using modifiers/ diluents, such as natural film-forming agents, for example, drying natural oils (due to high elasticity of their films). Complex coating materials with a large number of modifiers represent a specific feature of lacquers made during the Han period**. Currently, drying vegetable oils are used mainly in paints for art. Lacquer coatings based on qi -lacquer are still used today in various industries of China (for example, military production) due to their unique properties (strength, electrical and thermal protection, anticorrosive properties, etc.). Nowadays, qi -lacquer is modified using materials based on synthetic resins, such as epoxy, acrylic, etc.

Date and cultural attribution of burial mounds containing the remains of wooden lacquerware

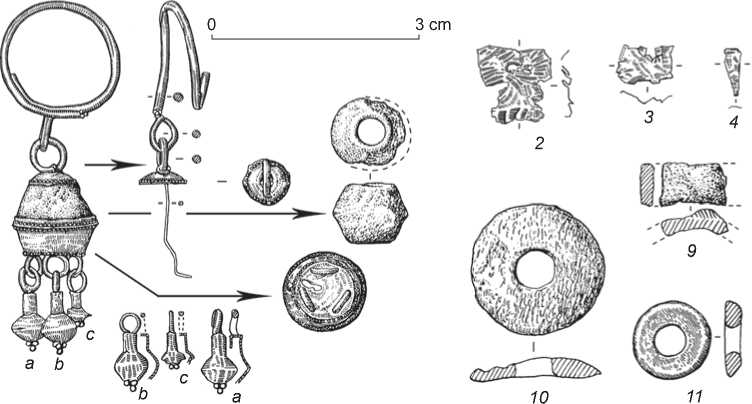

The burial ground of Chineta II, along with the previously explored necropolis of Khankarinsky Dol (Dashkovskiy, 2016; and others) marks the northwestern border of the Pazyryk culture area in the Altai. The diameter of mound No. 21 is 18 m, and its height is 0.6 m (Fig. 1, 2). This is one of the largest of the researched objects at the necropolis of Chineta II. A gold earring with pendants (Fig. 3, 1 ) deserves special attention among the grave goods. An earring of similar type was found in mound No. 27 at Balyk Sook I cemetery, dated to the second half of the 6th century BC (Kubarev, Shulga, 2007: 69–70, fig. 14, 3 ). Parallels also include earrings with pendants from mound No. 6 of the Lebedevka II cemetery in the Southern Transurals (Treister, 2012: 142–144, fig. 73),

*One of the greatest difficulties of the lacquer technology is the low recovery rate of sap. From 75 to 125 grams of sap can be collected from one tree per day; and 10 kg of lacquer can be collected from one tree during its entire life. To this day, there is a saying in China, “A hundred thousand knives give one pound <(0.4536 kg)> of paint.

**One of the ancient modifiers of qi -lacquer (tung oil) changes the rheological and decorative properties of lacquer (the compounds become more liquid and the coatings more shiny and plastic). In addition, tung oil, or tong-ou ( 桐油 ), is needed for grinding cinnabar in qi -lacquer, since this lacquer destroys the pigment. Oil protects the pigment from the impact of lacquer by encapsulating the pigment particles. In modern chemistry, this process is called transformation of the pigment surface.

Fig. 1 . Mound No. 21 of the Chineta II burial ground after clearing the embankment.

dated mainly within the 6th– 5th centuries BC (Kiryushin, Frolov, 1998: 124–125, fig. 11, 1 ; and others). It is notable that earrings of this type correlate with objects representing the jewelry tradition of Asia Minor, in particular, with the objects of the Achaemenid Circle (Treister, 2012: 142–144; and others).

Other objects of the grave goods from mound No. 21, including a ceramic jar-shaped vessel, iron two- link ringed bit, two bone tubular beads (Fig. 3, 10, 11), and a girth buckle (Fig. 3, 12), show parallels to the materials of the Pazyryk culture (Kubarev, 1987, 1991, 1992; Kubarev, Shulga, 2007; and others). Thus, close parallels to the girth buckle and

Fig. 2 . Grave in mound No. 21.

tubular beads were found in mound No. 99 at the Borotal I burial ground, in mound No. 11 of the Ala-Gail-3 cemetery (Kubarev, Shulga, 2007: 118, fig. 30, 12–16 ; 39, 8 , 12–16 ), and in mound No. 7 at the Kaindu burial

Fig. 3 . Grave goods from mound No. 21.

3 cm

ground (Kiryushin, Stepanova, 2004: 236–237, fig. 55, 8 ; 56, 7 ), investigated in the Altai Mountains. All these objects belong to the early Pazyryk period and date to the mid 6th–5th centuries BC.

The eastern orientation of the buried female in the burial mound under consideration and the presence of an accompanying horse burial are also typical of the Pazyryk culture, although the animal was buried at the western, and not at the northern wall of the grave, and was oriented with its head to the north. Non-canonical position of accompanying burials of horses in Pazyryk cemeteries has also been recorded in some other sites of this time in the Altai: mound No. 27 of the Tytkesken VI cemetery, mound No. 7 of the Kastakhta cemetery, mound No. 23 of the Maltalu IV cemetery, and mounds No. 11 and 21 of the Kok-Su cemetery (Kiryushin, Stepanova, Tishkin, 2003: 68; Kiryushin, Stepanova, 2004: 234; Kubarev, 1992: 114; Sorokin, 1974: 79). Notably, the above mounds at the Tytkesken VI and Kastakhta burial grounds belong to the early Pazyryk period of the mid 6th–5th centuries BC, and the mounds of the Maltalu IV and Kok-Su cemeteries are not earlier than the 3rd century BC. We should keep in mind that the fragments of lacquerware objects in a certain way “make the dates younger”, since Chinese products occur in the Pazyryk mounds mainly of the 4th– 3rd centuries BC (Shulga, 2015: 30).

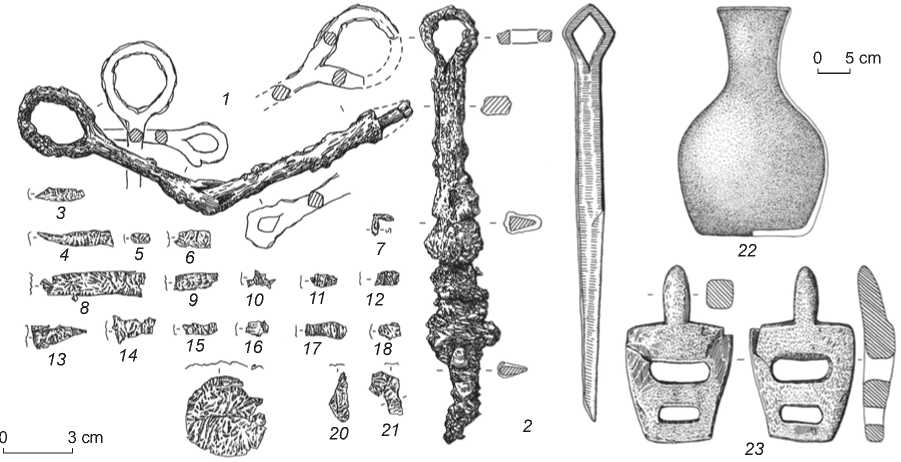

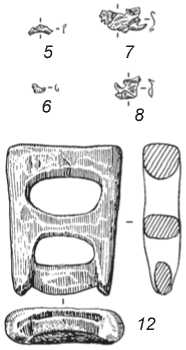

Mound No. 31, studied at the Chineta II burial ground (Fig. 4, 5), was up to 15 m in diameter, and up to 0.85 m in height. During its excavation, traces of the burial rite were found, which show similarity to those at previously studied Pazyryk sites both in the northwestern Altai (the cemeteries of Khankarinsky Dol and Inskoi Dol (Dashkovskiy, 2016)) and in other parts of the Altai, including the central and southeastern areas (Kubarev, 1987, 1991; Kubarev, Shulga, 2007; Kiryushin, Stepanova, Tishkin, 2003; and others). Scarce grave goods were found in mound No. 31. It included an iron ringed bit (Fig. 6, 1 ), iron knife (Fig. 6, 2 ), fragments of gold foil (Fig. 6, 3–18 , 20 , 21 ), ceramic vessel (Fig. 6, 22 ), horn girth buckle (Fig. 6, 23 ), and forehead plate made of

Fig. 4

. Mound No. 31 of the Chineta II burial ground after clearing the embankment.

Fig. 5

. Grave in mound No. 31.

Fig. 6

. Grave goods from mound No. 31.

gold foil (Fig. 6,

19

). These things have stable parallels in the materials of the Pazyryk culture of the Altai (Kubarev, 1987, 1991, 1992; Kubarev, Shulga, 2007). An interesting element of the horse harness is the girth buckle, which according to the classification of V.D. Kubarev (1987: 29–30, fig. 14,

4

; 1991: 49–52, fig. 10,

3

; and others) can be attributed to the block-shaped type with two oval slots and an immovable outwardly protruding prong. Girth buckles of this type have been found in the burial mounds of the Pazyryk culture of the second half of the 5th to 3rd centuries BC (Kubarev, Shulga, 2007: 119–123, fig. 81,

4

). The inventory of other categories from mound No. 31 is also dated to a rather wide chronological range from the second half of the 5th to the 3rd centuries BC.

Taking into account specific features of the funerary rite and grave goods, mounds No. 21 and 31 can be preliminarily dated to the 4th to mid-3rd century BC. Further studies of materials from the burial mounds, including radiocarbon analysis, will make it possible to establish a more precise date. Natural science analysis of lacquerware finds Lacquerware artifacts in burial mounds No. 21 and 31 occur only in compact clusters of red lacquer residues, which must have been caused by significant pressure from stone filling of the graves, clay soil, and groundwater at the monument. The lacquerware fragments in both mounds were found in the same area. In mound No. 31, there were two closely located clusters. According to their shapes, the object to which the remnants of the lacquer coatings belonged is tentatively identified as a wooden cup. This assumption is also based on the fact that in the process of clearing, under the lacquer flakes, the remains of a very poorly preserved wooden object were found. On some fragments of the lacquer coating, primer residues have survived. Lacquer fragments (varying in size from 0.5 to 30.0 mm) were located to the northeast of the human skull, in the place where pottery and wooden vessels were usually placed in the Pazyryk burials. Materials from the Ulandryk I, Tashanta II (Kubarev, 1987: 49–50), Yustyd XII (Kubarev, 1991: 65–68), Barburgazy I (Kubarev, 1992: 49–51), and Ak-Alakha III (Polosmak, 2001: 194– 202) burial grounds and other sites in the southeastern Altai testify to the wide use of vessels made of wood by the nomads. Methods of analytical chemistry including microscopy, infrared (IR) spectroscopy, and X-ray diffraction*, and other methods of analysis were used to study the remains of lacquer coatings from the Chineta II burial ground. The Chinese qi-lacquer can be confidently determined by methods of analytical chemistry. In order to identify the components of Oriental lacquer materials, FTIR-spectroscopy is often used, and the spectrum of an unknown coating is compared with the spectra of identified materials (Urushi…, 1985). In the course of our study, the infrared spectra of the lacquer coating were determined, and X-ray fluorescence analysis and microphotography were performed. The results have been compared with the lacquer objects from the collection of the State Hermitage Museum, originating from mounds No. 1–7 of the Pazyryk burial ground (40 samples), mounds of the Noin-Ula necropolis (over 200 samples), mounds of Bugry burial ground, and other archaeological sites. The IR-spectra of the samples were in accordance with the IR-spectra of the traditional Chinese lacquers. Three bands typical of aromatic compounds of urushiol were observed in the spectra in the area of 1450– 1650 cm-1. The bands in the areas of 1630, 1543, and 1420 (1406) cm-1 and characteristic out-of-plane deformation vibrations of the –CH groups and –CH bond groups of the aromatic ring in the area of 670– 900 cm-1 (in our case, 651, 797, 875, and 919 cm-1) were identified for this site. The absorption bands of the –CH, –OH, –C=O groups specific for urushiol polymerization products, and the –CO group specific for plant and wood polysaccharides were also present. The red paint layer of the coating contained almost no tung oil (the band of 712 cm-1 was absent).

The multilayer lacquer coatings were created using a specific technique based on a natural film-former of lacquer tree sap—a biopolymer from pyrocatechins of urushiol. Kaolin, quartz, and albite (traditional materials/ fillers of primers of the Chinese coating materials based on

qi

-lacquer) were found in the layers of the primer. Microimpurities consisting of the salts of manganese, calcium, and potassium were detected. Titanium ions were found in one of the samples from mound No. 31, which is significant.

In most cases, the pigment of cinnabar (HgS), the classical pigment of Chinese lacquers, gave the color to the upper layers of the lacquer coating. The admixtures of antimonite (Sb2S3) and galenite (PbS), typical of native cinnabar, were not found. For the final layer of paint, a thin protective layer of natural protein glue was used; it has been partly preserved. The specific feature of the samples of coating materials from the Chineta II burial ground was that the upper layers of paint on the object from mound No. 21 were made with paint in which iron oxide was used (possibly as a pigment/filler).

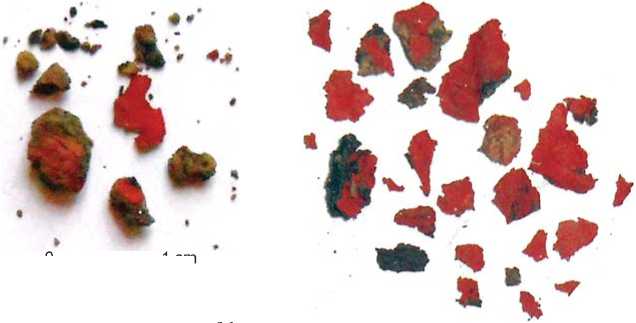

Remains of lacquer coating from mound No. 21

are represented by several large and firm fragments of red-brown color and fragile small accumulations of lacquer coating of red color (Fig. 7). The two largest conglomerates (1.5 × 2.8 and 1.2 × 2.3 mm) consisted of layers of brown lacquer and high-solid paint on the lacquer

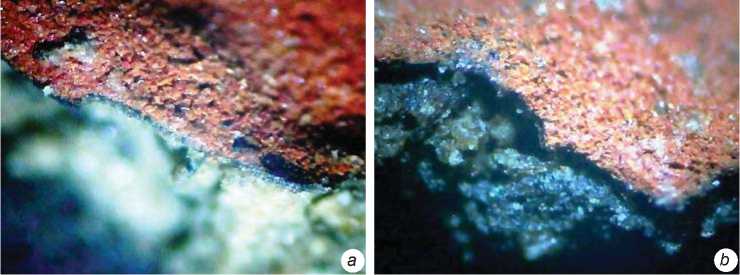

(yet the upper layers of paint have not chalked*). All layers of lacquer coating retained high adhesion strength between themselves and the layers of primer, which was not destructible in acids and alkalis and resulted in high durability of the fragments of lacquer coating. The pigment of the paint was ferriferous ocher of light reddish-brown color; its particles were coarse (Fig. 8). Small amounts of filler based on aluminosilicates were added to the paint. Both samples have doublesided coatings, and a relief of fibers (probably vegetable) saturated with lacquer in the inner layers. The gray primer was made of silica (it contains the ions of copper, zinc, titanium, and manganese) with the addition of large particles of coal. The preservation of the lacquer coatings is generally good; no cracks have been observed. The paint conglomerate has been preserved in a satisfactory state in the transverse direction, but has undergone some alterations which resulted in interlayer delamination in the longitudinal direction.

A flake of lacquer coating of bright red color was found in one of the samples. It lay on the surface of a layer of ocher with which it lost contact. This lacquer coating was also two-layered (15 μm thick) and consisted of a layer of red paint lying on a layer of dark lacquer. The color of this layer resulted from cinnabar—the classical pigment of Chinese lacquerware technology. The degree of filling the paint with cinnabar was high. The pigment was coarse, and although the paint was considerably well-filled with pigment, the process of chalking (flaking) of the upper layer of the lacquer coating was almost undetectable (Fig. 9). This testifies to the skill of the ancient technologists, who added the optimal amount of pigment to the lacquer and achieved a high degree of the components’ consolidation and longevity of the lacquer coating. Only a slight excess of the critical volume concentration of pigment with a minimum amount of

qi

-lacquer was observed.

In the analyzed samples from mound No. 21, the lower layer of lacquer was brown with a minimum amount of iron ions;

qi

-lacquer without the addition of metal salts (similar lacquer coatings were found in the samples from the barrows at the Pazyryk cemetery) was used for its preparation. In later lacquer coatings on the objects from the Noin-Ula burial mounds, which we investigated, there were layers of black-colored

qi

-lacquer with a significant amount of iron ions underneath the red paint layers.

The analysis showed that the lacquerware finds from mound No. 21 constituted the remains of a wooden lacquerware object with the wall thickness reaching about 5 mm, painted on both sides. For its manufacturing,

qi

-

1 cm

Fig. 7

. General view of lacquerware fragments from mound No. 21.

Fig. 8

. Microphotograph of the top layer of paint from mound No. 21. Red ocher pigment. ×720.

Fig. 9

. Microphotograph of the top layer of paint from mound No. 21. Cinnabar pigment. ×500.

lacquer and the compounds based on qi-lacquer were used following the technology of alternating layers of lacquer coating, similar to the Chinese lacquer technology. Ocher and cinnabar, typical of Chinese lacquers, were discovered in the upper layers of coating. It can be assumed that there were two red shades in the painting/coloring of the lacquerware object. Such multicolor painting appears in the decoration on a fragment of the wall of a Chinese “eared” erbei lacquer cup (Chinese 耳 杯) (Sutyagina, Novikova, 2016) and on other Chinese products (Chu Qin Han…, 1996; Qin Han qiqi…, 2007).

Remains of lacquer coating from mound No. 31

.

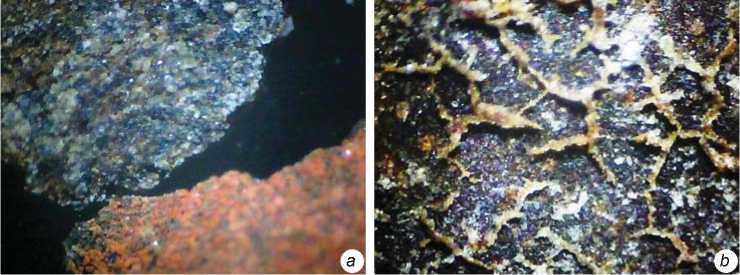

Most of the fragments from mound No. 31 (samples from clusters No. 1 and 2) are the remains of red-black lacquerware of varying degrees of preservation. The object was painted on both sides but has not survived (Fig. 10). The lacquer coating samples are extremely brittle, and the adhesion strength of the layers is minimal. The thickness of the lacquer flakes depends on the number of layers that have preserved adhesion: from 13 μm; two layers of lacquer coating (with the primer) up to 36.5 μm. The length of the samples is 20 mm.

Some fragments of lacquer coating have been preserved completely. They are double-sided; their obverse and reverse have a bright red color. A glue of animal origin was applied over the red coating. A black layer of

qi

-lacquer colored with iron salts is visible through small losses in the red layer (Fig. 11, 12). In general, the preservation of the lacquer coating (small number of cracks, scratches, chips, etc.) makes it possible to suggest that the object was in use only for a short time before being buried.

Other fragments are coating flakes which remained after the delamination of the lacquer coating along the layer of a weak base reaching complete loss of bonding with it. The samples of such loose films have simple stratigraphy and consist of two traditional layers: red and black (Fig. 13,

a

). The remains of a regular woven structure of vegetable threads of open weave, probably of Chinese ramie nettle, have been observed (Fig. 13,

b

). As it was customary for the Chinese lacquerware technology, the fibers were soaked in a natural filming agent. Although black

qi

-lacquer was most frequently used for sizing, in our case, different glue, probably of animal origin, was applied. This may be why the “woven” layer turned out to be the weakest in this fragment of the lacquer coating.

It may be assumed with high probability that two distinct lacquerware objects were located in mound No. 31. They were differently colored: the lacquer coating of two clusters in this barrow is different. The layer of red paint from cluster No. 1 is thinner than the layer from cluster No. 2 (see Fig. 12). Apparently, one object was painted with a more liquid paint, which gave a thinner paint layer after drying. Artifact No. 2 was made in the technique of a “hollow model”, without using a base. Fabric was glued upon a wooden or ceramic blank, and then the layers of lacquer coating were applied. The object was dried in a special room with necessary temperature and humidity conditions. 1 cm а 1 cm b

Fig. 10

. General view of lacquerware fragments from mound No. 31. Clusters No. 1 (

a

) and 2 (

b

).

Fig. 11

. Microphotograph of the top layer of paint from mound No. 31. Cinnabar pigment. ×720.

Fig. 12

. Microphotograph of a section of lacquer coating from mound No. 31. Clusters No. 1 (

a

) and 2 (

b

).

Fig. 13

. Microphotograph of the top layer (obverse) and back (reverse) of lacquer coating from mound No. 31. Clusters No. 1 (

a

; ×20) and 2 (

b

; ×300).

After reaching hardness and durability, the base was removed, and the layers of coating material were applied to the inner surface of the solid lacquer coating. The object was dried again and at the last stage it was painted on both sides with thick opaque paint. The durable and light vessel has not stood the test of time. The ancient product has not reached our days in its original form, because the layers of

qi

-lacquer with the finest woven base have not survived the load of the soil. The object was broken into pieces, and the lacquer coating (due to the replacement of the

qi

-lacquer in the primer with glue) was delaminated along the weak layer.

Discussion In their color, the artifacts from the Chineta II burial ground, which have not survived to the present day, are similar to the examples of Chinese lacquer coatings, and find parallels among the lacquer materials from the elite monuments of the Scythian period in the Altai. A study of the stratigraphy of paint layers in the samples from the site under investigation has shown that the lacquer coatings were manufactured using the traditional lacquerware technology of ancient China. The upper lacquer layers of red color (the layer of pigmented red flakes) are similar to the layers of red paint zhu-qi (Chinese ‘zhu-qi’ ^^, a mixture of qi-lacquer with cinnabar). They were applied to thin layers of dark brown qi-lacquer (the remains of lacquer coating from mound No. 21), and in some cases of black lacquer (fragments of lacquer coating from mound No. 31). This is consistent with the principles of the Huainanzi Treatise (2nd century BC) that “the craftsman may paint Among the fragments of archaeological lacquer coatings from the collection of the State Hermitage Museum, which have been found in burials in Siberia and Central Asia (Novikova, Stepanova, Khavrin, 2013; Tishkin, Khavrin, Novikova, 2008), finds from the Chineta II burial ground correspond to the fragments from the sites of the Pazyryk circle according to the cumulative data (stratigraphy, microanalysis, physical and chemical analysis). Lacquer coatings from the Chineta II cemetery differ from the lacquer coatings with complex stratigraphy found in the Xiongnu burial mounds at Noin-Ula (Elikhin, Novikova, 2013; Polosmak et al., 2011; Polosmak, Bogdanov, Tseveendorj, 2011; Polosmak, Bogdanov, 2015) in the simple application technique (a minimum of basic layers typical of Chinese lacquer coatings) and in the lack of modifiers based on vegetable oils (thus, the cinnabar was poorly ground). A finely porous (“spongy”) structure of the top layer of paint is visible in microphotographs. Among 40 lacquer artifacts from mounds No. 1–7 of the Pazyryk cemetery, 28 samples showed relative similarity in terms of coincidence of characteristic bands with the spectra of lacquer coatings from the Chineta II necropolis, and 6 samples showed definite similarity. A specific feature of many lacquer coatings from Pazyryk burial mounds is the presence of water-soluble copper salts. Notably, copper ions were present only in sample No. 1 from mound No. 21 of the Chineta II burial ground*. Similarities between the lacquer coatings from the Chineta II site and mounds No. 3–5 of the Pazyryk burial ground, which are dated to the period between the middle and the end of the 5th century BC (Rudenko, 1953; Marsadolov, 2000) or the late 4th–mid-3rd century BC (Evraziya…, 2005: 165–166), have been found. It is also possible to draw parallels between the lacquer coatings from the burial ground under consideration and from Pazyryk mound No. 3, more precisely, with the sample No. 1685/400 with a carved bow-shaped bone onlay from a horse harness and the sample No. 1685/261. There is a similarity between the lacquer coatings from the Chineta II and the Pazyryk burials: lacquer coatings from the shield and from the components of the horse bridle in mound No. 4 (No. 1686/135 and 1686/146) and from the components of the horse bridle and saddle in mound No. 5 (No. 1687/138, 1687/144, 1687/153, 1687/156–157, and 1687/272). A distinctive imprint of fabric structure on the reverse of the lacquer coatings was a common feature in the Chineta finds and some of the artifacts from the Pazyryk mounds No. 1–5. The remains of the lacquer coatings under consideration show a relative similarity to the fragments of lacquer coatings found during the excavations of the Bugry mound cemetery in the Altai steppe zone (Rubtsovsky District of the Altai Territory). For comparison, 12 lacquer samples from Bugry II were used: from mound No. 1 (graves 1–3) and No. 4 (grave 6 and the dromos) (Chugunov, 2014; Tishkin, 2012: 507; Sutyagina, Novikova, 2016).

A specific feature of paint from Bugry was the absence (or just traces) of tung oil. Cinnabar in the lacquer coating was coarse; the paint was highly filled. The lacquer is close in its composition to the lacquer coating from the Chineta II burial ground (containing a significant amount of iron and calcium ions, and an admixture of titanium ions). The coatings are strong and solid, since they were made using high-quality

qi

-lacquer that did not contain significant quantities of modifiers (such as tung oil), as did the later Han lacquers from the Noin-Ula burial grounds (Elikhina, Novikova, Khavrin, 2013, 2015). The greatest similarity was observed between our fragments of lacquer coating and three red and black lacquer fragments from the necropolis of Bugry II: the fragment of the wall of a Chinese “eared”

erbei

lacquer cup with painting, manufactured not earlier than late 3rd century BC, from grave 3 of mound No. 1, and presumably the fragments of cups from grave 1 of mound No. 1 and grave 6 of mound No. 4 (Sutyagina, Novikova, 2016).

Fragments of lacquer coatings from Chineta II can be correlated with the remains of lacquer coatings from the tear-shaped plate that was a part of the breast collar of a horse harness found in the Second Tuekta burial mound. The circle of parallels from the burial mounds of the Pazyryk culture could be expanded, but this is not yet possible due to the small number of comparable samples of that time in the collection of the State Hermitage Museum that retain the set of all completely preserved lacquer layers. Conclusions

Research of lacquer coatings from mounds No. 21 and 31 of the Chineta II burial ground in the northwestern Altai has shown that they were made using traditional Chinese materials (

qi

-lacquer, cinnabar, kaolin, and albite) and observing traditional

qi

-lacquer technology with alternating paint and lacquer layers. Thus, the remains of the artifacts with lacquer coating found in the nomadic burials represent a special category of Chinese imported goods, and a specific social marker.

Comparison of the results of analysis of ancient remains of lacquers and paints from the burial mounds of the Pazyryk culture located at the Chineta II necropolis with the lacquer coatings from mounds No. 2–5 of the Pazyryk cemetery has revealed many similarities. The high price of imported lacquerware indicates a significant social status of those buried in mounds No. 21 and 31 at Chineta II. In terms of size, these mounds are smaller than the “royal” barrows at the necropolises of Pazyryk, Tuekta, Bashadar, and Berel, but greatly exceed other structures of the Chineta II burial ground. Chinese lacquerware discovered in mounds No. 21 and 31, along with other elements of funerary rite and grave goods, make it possible to consider the buried persons to be a part of the regional elite of nomads inhabiting the northwestern Altai. In addition, it can be suggested that lacquerware objects, the remains of which were found in the burials of the Altai Mountains (the Second Tuekta mound and mounds No. 3–5 at the Pazyryk cemetery) and the Altai foothills (mounds No. 21 and 31 at Chineta II, and mounds No. 1 and 4 at Bugry), reached the nomads in the Scythian period from the single center of lacquerware manufacture of ancient China.