Classic Samarra painted pottery from Yarim Tepe I, the Neolithic of Northern Iraq

Автор: Petrova N.Y.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 3 т.50, 2022 года.

Бесплатный доступ

This study focuses on the Classic Samarra painted ware from the Standard Hassuna layer at Yarim Tepe I, in Northern Iraq. Two groups of imports are described. The first consists of Classic Samarra, apparently related to Central Mesopotamia; the second, of Samarra Ware imported from the west. It is hypothesized that the Samarra pottery was imported not only from the center to various parts of the periphery, but also from one part of the periphery to another. As a result of comparison of the ceramics, a hypothesis is proposed that Classic Samarra was formed based on a symbiosis of two earlier cultural groups: the Proto-Hassuna period in Northern Mesopotamia, and Neolithic traditions originating from Central Zagros.

Neolithic Mesopotamia, Samarra pottery, ceramic technology, turntable, Yarim Tepe I

Короткий адрес: https://sciup.org/145146798

IDR: 145146798 | DOI: 10.17746/1563-0110.2022.50.3.029-038

Текст научной статьи Classic Samarra painted pottery from Yarim Tepe I, the Neolithic of Northern Iraq

The formation in the last quarter of the 7th millennium BC in Central Mesopotamia of the Samarra culture, which is known for its high-quality painted pottery with rich geometric, anthropo- and zoomorphic ornamentation, is one of the mysteries of Mesopotamian archaeology of the Late Pottery Neolithic. The archaeological materials from the main sites of the Samarra culture are subdivided into two periods: Classic Samarra (coinciding with the period of existence of the Hassuna culture in the north of Mesopotamia) and Late Samarra or the CMT (Chogha Mami Transitional) period (coinciding with the time of the Early Halaf sites in the north, and Early Ubaid (Ubaid 0 period) in the south of Mesopotamia) (Oates, 2003).

Pottery from the Early Classic Samarra period is decorated with carvings and paintings (Ippolitoni, 1970– 71). The latter are the most recognizable, but the origin of this tradition and its relationship to Hassuna is unclear. However, there are sites where Hassuna pottery is found together with Samarra pottery. It has been hypothesized that the Samarra tradition developed in parallel with the Hassuna one, during the period of the Proto-Hassuna in the Upper Mesopotamia (Oates, 2003), or that the Samarra Ware was a “chic” variety of Hassuna ceramics (Braidwood, 1945: 258; Perkins, 1949: 15). Another hypothesis holds that the Samarra ceramic style was formed on the basis of the Neolithic traditions of southern Iran (Fars Province) (McCown, 1942: 35); however, its relationships with the hinterland of the Central Zagros and the culture associated with Charmo (Jarmo) style ceramics has been denied (Mortensen, 1964: 36).

There are different points of view on whether the Samarra pottery of the Classic Samarra period, available at non-Samarra settlements, was imported (Lloyd, Safar, 1945: 282), or produced locally (Blackham, 1996), or whether only part of it was imported (Odaka, 2003).

The aim of this article is to describe the Classic Samarra pottery on the basis of the artifacts from the Yarim Tepe I settlement, get a better understanding of its origin, and identify various centers of its manufacture.

'AZERBAIJAN

TURKEY

Hakemi Use" -.- ~ ' :1/" la'^Sakgagozu) * V@SX2PAZt,. ■ "' A* -V . OChagarBazar^^ya^ ^Z'^S-'/Sabi Abyad - Nineveh*» Shimshara r\ EC'Halula/ YbrimTepek • -’SeidAhmadan

VBoueid II о U^ssuna # ’Nader, ° '

Caspian

Sea

Matarrah

SYRIA

Baqhouz \ Kah Sareh <^_ . о es-Sawwan-* <•■? s

-P \ ’.Serik J.

IRAN

Guran

Fig. 1. Map of the sites mentioned in the article.

£ Remremeh,

JORDAN

.EGYPT '«,

\ co 1

SAUDI

ARABIA

IRAQ

1000 km

( "Л Chogha'S'efid.

.el-'Oueili>

History of studies of the Samarra culture

Overview of the main sites of the Samarra culture and the spread of the influence of its pottery style

Classic Samarra Neolithic pottery was first discovered in 1911, during excavations of the city of Samarra in Central Mesopotamia, one of the capitals of the Abbasid Caliphate (Herzfeld, 1930). Most materials of the Samarra culture of the Classic period were studied at the settlement of Tell es-Sawwan (es-Sawwan)* (Fig. 1). This settlement is located in the Tigris River valley, a few kilometers south of the settlement of Samarra, and yielded the earliest items of the Samarra culture (Breniquet, 1991, 1992). In the Euphrates River valley, not far from the border between Syria and Iraq, another Samarra site is located, Tell Baghouz (Baghouz) (Nieuwenhuyse, 1999; Nieuwenhuyse et al., 2001; Odaka, 2003: 25–27). The Samarra settlements of Chogha Mami, Serik, and Safar, with younger materials from the Samarra culture (CMT period), were located in the Diyala River basin (Oates, 1968, 1969, 1987).

Along with the original area of the Samarra culture (Central Mesopotamia), scholars usually identify a zone of distribution of the Samarra products and imitations that coincides in Upper Mesopotamia with the area of the Hassuna culture and is designated as Northern Samarra (Gut, 1995). The main sites of the Hassuna culture, which also contain Samarra pottery, are located on the territory of Northern Iraq. These are classic Hassuna settlements:

Hassuna (Lloyd, Safar, 1945: 281) and Yarim Tepe I (Merpert, Munchaev, 1993: 87–88), the lower layers of the large stratified settlements of Nineveh (Gut, 1995; Perkins, 1949) and Arpachiyah (Mallowan, Rose, 1935: 10–29), as well as many unexcavated settlements located near the Sinjar Range and on the banks of the Tigris (Tomson, 1969: 71–74).

The settlements of Matarrah (Braidwood, Howe, 1960: 26, 35–37; Odaka, 2019), Shimshara (Mortensen, 1970: 62–63, 76), Said (Seid) Ahmadan (Tsuneki et al., 2015), and Nader (Kopanias et al., 2013), with Samarra pottery, were investigated in the Little Zab River basin, in the eastern part of Upper Mesopotamia.

To the west of this zone, Samarra pottery has been found at settlements in Syria: Chagar Bazar, Halula (Cruels, 2008: 674, 685), Boueid II (Suleiman, Nieuwenhuyse, 1999), and Sabi Abyad I (Le Mière, Nieuwenhuyse, 1996).

The northernmost sites with Hassuna and Samarra materials were found in southeastern Turkey, in the foothills of the Taurus: the settlement of Hakemi Use (Tekin, 2012: Fig. 44.8; 2021) and Takyan Höyük (Takyan) (Kozbe, 2013); beyond the Euphrates, settlement of Coba Höyük (Coba (Sakçagözü)), with fragments of Samarra ceramics (Taylor, Seton-Williams, Waechter, 1950: 56).

Subsequently, the Halaf culture, with its clear Samarra features in the ceramic traditions (Amirov, 2019: 425; Amirov, 2018; Oates, 2003: 415), was practiced in this area.

In the first half of the 6th millennium BC, the influence of the Late Samarra (CMT) culture extended far beyond its original territory into southern Mesopotamia. It is indicated by the materials of settlements on the alluvial plain of Lower Mesopotamia (Amirov, (s.a.)). The traditions of Samarra pottery manufacture had some effect on the production of the earliest pottery in the alluvial zone of southern Mesopotamia, which was observed in the materials of Tell el-’Oueili (Awayli) in the Larsa region (Lebeau, 1987; Larsa…, 1987; ’Oueili…, 1991). It is generally accepted that the decorative features of the ceramics of the Early Ubaid culture of the Ubaid 0 period were formed under the influence of the Samarra culture (Blackham, 1996: 1). Features of the Samarra culture are recorded in the foothills of the Southern Zagros, in modern Iran, in particular, at the Remremeh settlement in the Mehran Plain (Darabi et al., 2020: 50) and at the settlement of Chogha Sefid (Black-on-Buff pottery) in the Deh Luran Plain (Hole, 2011: 5).

Studies of the Samarra pottery

There are quite a number of descriptions of Samarra pottery, compiled by various researchers. They characterize items as covered with a layer of slip or lightcolored, painted in colors ranging from red to black, but predominantly chocolate-brown (Campbell, 1992; Lloyd, Safar, 1945; Perkins, 1949). The surfaces of Samarra pottery from the foothills of the Taurus (in the very north of Upper Mesopotamia) are light-orange (buff) in color, most often not lightened (Tekin, 2012).

The most numerous Samarra pottery collection from Tell es-Sawwan was studied by F. Ippolitoni (1970–71). According to her observations, the lower construction horizons 1 and 2 of the settlements of Hassuna, Matarrah, and Shimshara yielded coarse unornamented pottery, “indistinguishable from Hassuna”. Construction horizon 2 yielded the first few pieces of pottery with ornamentation made by incising and painting, which is typical of both the Hassuna and Samarra cultures. Construction horizon 3 (phases A and B) contained a lot of high-quality painted pottery, mostly with dense ornamentation, including anthropomorphic images, and a small amount of ceramics decorated with incises. These materials are designated as “Classic Samarra pottery”.

Horizons 4 and 5 at Tell es-Sawwan contained, along with the Samarra ceramics, the Halaf ceramic imports (Ibid.). The paste of painted pottery usually contains a small amount of mineral inclusions, sometimes a fine plant admixture. The surface color varies from lightorange to greenish. The pottery has light coating, but slip is rare. The color of the painting varies from red-brown to dark-green, most often chocolate-brown, and depends on the firing (Ibid.: 123, 126).

The manufacturing technology of Samarra pottery has been most thoroughly studied on the basis of finds from Tell Baghouz (Nieuwenhuyse, 1999; Nieuwenhuyse et al., 2001). Samarra pottery contains a small amount of mineral admixture, and can be classified into several groups (Nieuwenhuyse et al., 2001: 153). It is assumed that during the construction of Samarra vessels, the basal part was most likely formed by pressing clay into the mold with the fingers; after that, it was built up with clay coils. The interior surface was smoothed with a flint or obsidian tool. The outer surfaces of the vessels are usually pale owing to re-oxidizing. Only a few fragments showed a greenish tint of the surface, which suggests firing at a temperature of over 1050 °C. The surfaces of most of the fragments are light-colored or simply well-smoothed, but not slipped. The researchers of the pottery from the site argued that the light color of the ceramic surface was due to the presence of salts in the clay composition, which rose to the surface in the process of liquid evaporation. The painting is monochrome, matte, and dense. The color of the painting is brown, black-violet, or purple. The brown color probably resulted from the use of magnetite during re-oxidizing or hematite during oxidizing firing. During the process of painting and at some stages of shaping of the Samarra ceramics, a turntable was probably used (Ibid.: 158). The most common are bowls. Scholars suggest that all Samarra pottery was made in the settlements (Nieuwenhuyse, 1999; Nieuwehuyse et al., 2001).

In the course of subsequent study, the Tell Baghouz ceramic collection was subdivided by the researcher into two technological groups: “import and imitation”— ceramics with a small amount of sand, fired at a high temperature, belongs to Classic Samarra; “localization”— ceramics with a large number of mineral inclusions, subjected to irregular firing, bearing a “unique” pattern (Odaka, 2003: 31–32).

Pottery of the Samarra appearance from Tell el-ʼOueili in southern Mesopotamia was studied in order to identify raw materials and pigments that were used in painting*. The analysis showed that the Samarra pottery found at the settlement was not imported; it was local (Ubaid) production (Blackham, 1996: 2, 13).

Pottery from the settlement of Yarim Tepe I

The settlement of Yarim Tepe I is located near the Sinjar mountain range in Northern Iraq; it was excavated under the leadership of N.Y. Merpert and R.M. Munchaev. In the 6-meter thick cultural layer of the site, 12 construction horizons were identified, which show the sequence of the main Neolithic stages in the region: Proto-Hassuna, Archaic and Standard Hassuna (Munchaev, Merpert, 1981; Merpert, Munchaev, 1993; Petrova, 2016; Petrova, 2021).

Research methodology

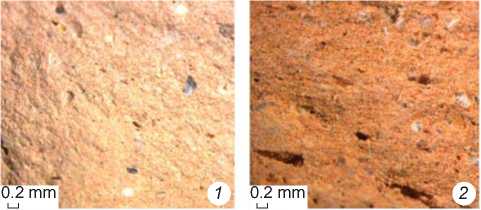

Analysis of all stages of the pottery technology included the following: composition of raw materials and pastes, techniques of vessel-shaping, surface treatment, firing (Bobrinsky, 1978), and decoration. The degree of ferruginization and sand-content in clay, and the sizes of natural mineral inclusions were determined in order to identify the differences in the traditions of raw material selection (Bobrinsky, 1999: 35–40; Lopatina, Kazdym, 2010). The degree of ferruginization was identified through re-firing small fragments in a muffle furnace at a standard temperature of 850 °C (Tsetlin, 2006). In the initial raw materials used for the pottery at the settlement, only very fine sand (0.1–0.3 mm) was found. If sand concentration does not exceed 10 %, it is assumed that the ceramic fragment was made of clay with a minor admixture of sand; the sand proportion of 20–30 % suggests a medium admixture of sand, the higher share indicates high sand-content.

The construction method was determined by the analysis of the direction of joints between individual clay elements in fresh horizontal and vertical cross-sections of ceramic samples. The presence of such joints indicates the use of the technology of hand application of slabs or coils (Bobrinsky, 1978: 139, 158, 174–184; Vasilieva, Salugina, 2010; Tsetlin, 2012; Roux, 2019: 164–166; Shepard, 1985: 184; Vandiver, 1987). With the use of slab technique, recorded on the studied ceramics, the joints were located at a small distance from one another and at a large angle to the walls of the vessel. However, the strong paddling inherent in the considered ceramics deformed (elongated) the joints.

The probability of applying the slip — an additional coating with clay of a different composition—was identified by the occurrence of cracks and losses on the layer’s surface (Rue, 1981: 41; Shepard, 1985: 67). Special experiments were carried out to clarify the signs of slip coating.

The firing method was described by its type: oxidizing regime—with oxygen access, characterized by warm orange shades of surface and in a fracture; or red-oxidizing/semi-redox—without/with partial access of oxygen, characterized by cold gray shades of varying intensity. The terminal firing-temperatures were also determined: a heating temperature of 800 °C corresponds to uniform color of cross-section (Bobrinsky, 1999: 93–95; Volkova, Tsetlin, 2016; Rice, 1987: 343–344), temperatures above 1000 °C produce a green tint of the surface (Nieuwehuyse et al., 2001; Rice, 1987: 336).

Description of the material

The main (Hassuna) collection of pottery from the settlement of the Standard Hassuna period contains items of various shapes and purposes (tableware, containers for cooking and storing foodstuffs, etc.). This pottery has the following technological features: the predominant share is made of slightly ferruginous, medium-sandy clay; there are also items made of non-ferrous and ferruginous, slightly sandy clay; the composition of the clay in all finds shows an insignificant admixture of limestone. The paste of coarser products, like that of the pottery of the Proto-Hassuna and Archaic Hassuna periods, includes dung. The vessels were hand-made using the technique of doublelayer slab application on base-mold, with subsequent paddling on it, which was typical of previous periods (Petrova, 2016, 2021). Many vessels are coated with a light slip, or are light-colored (this method had been used since the Archaic Hassuna period). The motifs are mostly painted with red paint, or incised. Firing was always carried out in an oxidizing environment, but its quality varied depending on the type of product and the firing device; at that time, two-tier furnaces were already widely used (Munchaev, Merpert, 1981), but not all products were fired in such furnaces.

At Yarim Tepe I, Samarra pottery appears at the boundary of horizons 6 and 5, in the layers of the Standard Hassuna period, and occurs up to the layers corresponding to the end of the settlement’s existence (Merpert, Munchaev, 1971: 156–157; Merpert, Munchaev, 1973: 104). The greatest amount of pottery was recovered from horizons 5 and 4. The collection of Samarra ceramics deposited in the Institute of Archaeology of the Russian Academy of Sciences, consists of 55 fragments from 50 vessels*.

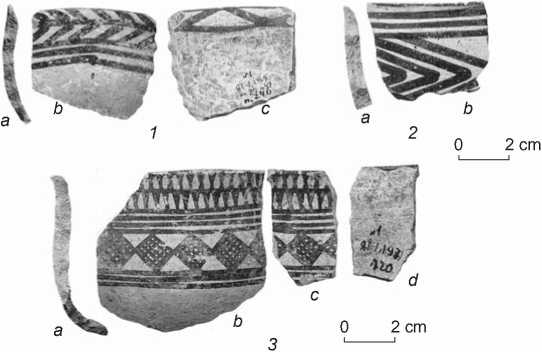

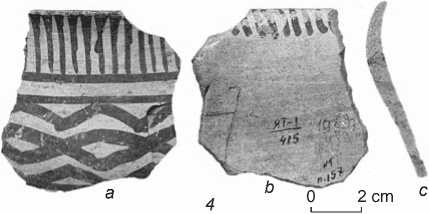

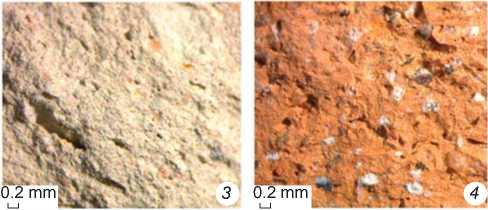

Among the Samarra ceramics from Yarim Tepe I, at least two groups of imported products, differing in the composition of the raw materials used, the firing mode, and, probably, their origin (Fig. 2–4), can be distinguished. The collection also includes vessels that can be interpreted as imitations of the Samarra pottery. Notably, authentic ceramics cannot always be distinguished from imitation, so for now I will not touch on this topic.

Classic Samarra pottery imports (see Fig. 2, 3) form the first group; most likely, they are associated with the main area of the Samarra culture—Central Mesopotamia. This category is the most numerous and shows a variety of elements and colors of the painted ornament, as well as technological features (differences in raw materials and surface coating methods). It is dominated by bowls (open vessels). Their diameters vary from 9 to 48 cm, but the diameters of the greater part of such vessels are in the range: 12–13, 16–18, and 21–24 cm. The potsherds thickness is in the range of 2–10 mm; however, within a single sherd, the thickness’s variation does not exceed

1–2 mm. The thickness of the fragments of four jugs (closed vessels with vertical necks) ranges from 4 to 13 mm, with diameters from 9 to 16 cm.

Classic Samarra pottery is made of four types of clays with an admixture of mineral inclusions: ferruginous–slightly ferruginous (predominant) (Fig. 5, 1 ), strongly ferruginous slightly sandy (Fig. 5, 2 ), non-ferruginous slightly sandy (Fig. 5, 3 ), and ferruginous medium sandy (Fig. 5, 4 ). The admixture of limestone in all types of clays is insignificant. Additional artificial impurities were not used.

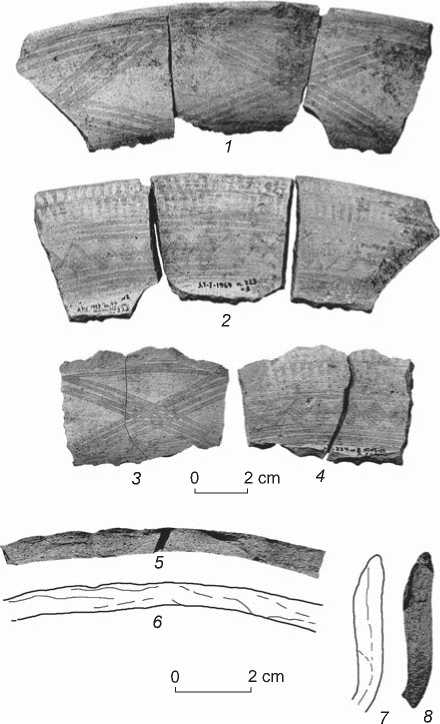

Judging by the directions of joints between individual clay elements (see Fig. 2, 5 , b , c ; 3, 5–8 ) and the flow of the pottery paste inside the clay elements, vessels were constructed using the double-layer slab technique. The joints are strongly elongated, multi-layered, often poorly visible. Taking this into account, as well as the thin walls and flattened areas on the surface, it can be concluded that the vessel’s surface was strongly paddled during shaping.

Traces of smoothing are almost invisible; it can be assumed that in some cases textile was used. In general, the entire surfaces of the vessels are light in color, which was achieved in various ways. Some items were made of non-ferrous clay (see Fig. 2, 1 , a–c ). Several vessels were covered with slip, an additional layer of clay, probably mixed with a light-colored pigment (see Fig. 2, 2 , b ). But in most cases, light coloring was performed, denser on the outer surface and less dense (but clearly visible, owing to uneven painting and paint-clots in surface irregularities) on the inner surface (see Fig. 2, 4 , b ).

On a light surface, painting was made with brown (in most cases), red-brown, and orange paints. Painting is present on the outer surfaces of all the vessels, and on the very edge of the rim on the inner surface of half of the finds. It

а

0 2 cm

b

c

а

0 2 cm

b

c

0 2 cm

can be assumed that drawing horizontal lines on a number of items (in many cases, very close in several rows) was made on a turntable. On some products, joints between the beginning and the end of line are visible (see Fig. 2, 1, b).

Vessels were subjected to oxidizing firing regime: walls are calcined through in almost all of them; the firing temperature reached ca 800 °C, and in some cases ca 1000 °C. The use of a forge cannot be excluded.

Imports associated with Northwestern Mesopotamia form the second group (see Fig. 4). Among the finds from Yarim Tepe I, six fragments comparable with the ceramics from Tell Baghouz were noted. The ceramics of this group differ from the rest of the ceramics of the site by the grayish color (of varying degrees of intensity) of the

Fig. 2. Fragments of Classic Samarra imports. Yarim Tepe I.

1–4 – bowls: 2 , 4 – horizon 5, 3 – horizon 4, 1 – horizon 3; 5 , 6 – jugs: horizon 5. Photo by A.A. Strokov .

surface and cross-section. Probably, these are fragments of bowls. Unlike the vessels of Classic Samarra, related to Central Mesopotamia, the walls of these items are thicker—from 6 to 11 mm .

All items are made of slightly ferruginous, highly sandy clay (see Fig. 4, 1 , d , g , 2 , c ; 5, 5 ), with the exception of one vessel made of slightly sandy clay. Artificial admixtures were not used. The construction method was the same as that used for manufacturing the vessels of Classic Samarra (double-layer slab

Fig. 3. Fragments of Classic Samarra imports – bowls.

Yarim Tepe I. Horizon 4. Photo by A.A. Strokov.

technique, paddling). Traces of smoothing (with a cloth or a rough scratching-tool) were recorded only on the inner surfaces. Two fragments showed no surface coating. The surfaces of three vessels were painted with light paint. This is shown by the uneven layer of paint and its concentration in relief depressions, especially on the inner sides of the fragments (see Fig. 4, 1 , b , 2 , b ). The items made of slightly sandy clay have a considerably thick slip coating (see Fig. 4, 3 ). All products are ornamented with brown (almost black) paint. The grayish-greenish tint of varying degrees of intensity of the surface and cross-section indicates that firing was carried out in a red-oxidizing or semi-redox environment, at a temperature of ca 1000 °C.

Discussion

At the settlement of Yarim Tepe I, as early as the Archaic Hassuna period, Hassuna vessels were made using similar types of raw materials and the same methods of surface coating (light coloring, slip) as those used in the manufacture of Classic Samarra pottery. The double-layer slab technique for construction the Samarra ceramics was also used at the settlement earlier, during the Proto-Hassuna and Archaic Hassuna periods, and contemporaneously, during the Standard Hassuna period, in combination with the use of base-molds (Petrova, 2021). Samarra pottery revealed no traces of spacers or molds; however, it is difficult to imagine that a thinwalled vessel with two layers of slabs, with strong paddling, could have been manufactured without a mold.

а

c

b

2 cm

f

d

e

2 cm

а

cd

0 2 cm

g

b

2 cm

Fig. 4. Fragments of Classic Samarra imports related to western Mesopotamia. Yarim Tepe I. Horizon 5. Photo by A.A. Strokov .

2 cm

Fig. 5. Microphotograph of clay types. Yarim Tepe I.

1–3 – slightly sandy; 4 – medium sandy; 5 – strongly sandy. The microphoto was taken using an Olympus MX 51 metallographic microscope by N.Y. Petrova .

The assumption that the Samarra vessels were shaped starting with the basal part formed by pressing clay into the mold with the fingers, and then built up with clay coils (Nieuwenhuyse et al., 2001: 153), has not been confirmed by the Yarim Tepe I materials.

Possibly, the Samarra vessels, which were less elaborate and were imitations, were made at the site; but this issue requires further consideration.

In contrast to the Standard Hassuna ceramics, which, as noted above, partially continued the tradition of an earlier time (Petrova, 2016, 2021), the Samarra pottery was made without artificial impurities. The degree of paddling of the vessels and the uniform thickness of the walls of Samarra ceramics testify to a more developed method of manufacture than that of the Hassuna Ware. In addition, it is possible that a slow turntable appeared in the Classic Samarra period, used in drawing even parallel lines on surfaces. Some fragments show the joints between the end of the painted horizontal line and the point of its beginning (see Fig. 2, 1 , b ). The distinctions are also observed in the color of painting. The Hassuna ceramics are mainly red, while the Samarra ware are brown, close to black, sometimes orange.

Given the differences in raw materials and ornamentation, it can be assumed that the imported Classic Samarra ceramics were manufactured in various places. The future studies of Yarim Tepe I ceramics by scientific methods will probably provide new data to prove this assumption, and to answer the question about the local or non-local origin of some of the products, including those that can be considered imitations.

There is no doubt about the non-local origin of the Samarra tradition, which involves red-oxidizing or semiredox firing of pottery. Neither signs of the use of this type of firing, nor the raw materials for the manufacture of such ceramics were available at the settlement at the time under study or earlier. However, the pottery’s features indicate Western origin; the sites in the western part of Upper Mesopotamia provide the evidence of this type of firing,

which is represented by the ceramics known as DFBW (Dark Faced Burnished Ware). This firing-technology was used both at an earlier time and the time corresponding to the existence of the Samarra and Hassuna cultures (Balossi Restelli, 2006). Samarra vessels, similar to those recorded at Yarim Tepe I, are likely present at the Tell Baghouz site (Nieuwenhuyse et al., 2001; Odaka, 2003: 31–32). Several fragments of ceramics with large amounts of mineral admixture, subjected to redox firing regime, were also reported from the settlement of Tell es-Sawwan (Ippolitoni, 1970–71: 123, 126). However, this group of ceramics from the settlement of Yarim Tepe I includes one unusual artifact that was fired in a semiredox environment, but was made from slightly sandy clay and slipped using the technique combining Eastern and Western traditions.

J. Oates’s suggestion that the Samarra tradition originated from the Proto-Hassuna culture (2003: 409) is probably reasonable, given the common features in the pottery technology of Samarra products and the Proto-Hassuna and Archaic Hassuna ceramics (Petrova, 2016, 2021). In this regard, it is important to note that the carvings on early ceramics from Tell es-Sawwan (Ippolitoni, 1970–71) appearing in horizon 2 can also be traced on separate products of the Archaic Hassuna, and even from the preceding Proto-Hassuna time (for example, Tell Sotto).

The Samarra community of the period of Classic Samarra was likely formed by representatives of various cultural traditions. For example, the decorative style of ceramics from the settlement of Tell es-Sawwan (see, e.g., (Ibid.: Fig. I. 6, 8; X. 4)), located on the eastern bank of the Tigris River, to the west of the mountain pass to the Central Zagros valleys, was probably formed (as shown by the study’s results) under the influence of the Guran ceramic style, developed on the basis of the

Charmo (Jarmo) style. The latter was widespread both in the inner part of Zagros (for example, the Guran Tepe in the Hulailan Valley (Mortensen, 2014: 60, fig. 66)), and in the area of exit from the mountain corridor into Central Mesopotamia (the settlement of Kah Sareh in the Sarpol-e-Zahab valley) (cf. (Alibaigi, Salimiyan, 2020: Fig. 6. 2 , 3 )). It was the place where the road from Ecbatana to Babylon passed through the valleys in Kermanshah Province, between the mountain ranges; in the Neolithic time, this road would have connected the valleys of the Central Zagros and the territory of Mesopotamia. The relationship with Zagros is also evidenced by the double-layer slab technique of vessel construction, which was identified in the ceramics of the first half of the 7th millennium BC at the settlements of Ali Kosh and Guran (Petrova, Darabi, 2022).

Conclusions

The issues discussed in this article are far from being fully resolved. However, it is clear that the culture of the Classic Samarra period was formed with participation of various cultural groups. Today it can only be assumed that these were the bearers of the traditions of the eastern part of Upper Mesopotamia during the Proto-Hassuna and Archaic Hassuna periods, as well as the representatives of the cultural traditions of the central part of the Zagros. It is interesting that ceramics with Classic Samarra ornaments (table vessels, e.g. bowls) were imported not only from the center to various parts of the periphery, but also from one part of the periphery, for example, from the western zone of Upper Mesopotamia, to another. All the noted phenomena and the relevant reasons require additional research, including field studies.

Acknowledgements

I am very grateful to Dr. Sahmardan Amirov and Prof. Halil Tekin for their valuable help during the work on the article.

Список литературы Classic Samarra painted pottery from Yarim Tepe I, the Neolithic of Northern Iraq

- Alibaigi S., Salimiyan A. 2020 Archaeological landscape of the Neolithic period in western foothills of Zagros mountains: New evidence from Sar Pol-e Zahab region, Iran-Iraq borderland. Iraq, vol. 7: 1-25.

- Amirov S. 2018 The morphology of Halafian painted pottery from Yarim Tepe II, and the process of Ubaidian acculturation. In II Workshop on Late Neolithic ceramics in Ancient Mesopotamia: Pottery in context. Barcelona: Museu dʼArqueologia de Catalunya, pp. 15-24.

- Amirov S.N. 2019 Syria. Kratkiy arkheologo-istoricheskiy ocherk ot paleolita do nachala epokhi ellinizma. In Kavkazskiye gory i Mesopotamskaya step na zare bronzovogo veka: Sbornik v chest 90-letiya R.M. Munchaeva. Moscow: IA RAN, pp. 423-445.

- Amirov S.N. (s.a.) Samarrskaya kultura. Ms.

- Balossi Restelli F. 2006 The Development of “Cultural Regions” in the Neolithic of the Near East. The “Dark Faced Burnished Ware Horizon”. Oxford: Archaeopress. (BAR Intern. Ser.; vol. 1482).

- Blackham M. 1996 Further investigations as to the relationship of Samarran and Ubaid ceramic assemblages. Iraq, [vol.] LVIII: 1-15.

- Bobrinsky A.A. 1978 Goncharstvo Vostochnoy Yevropy. Istochniki i metody izucheniya. Moscow: Nauka.

- Bobrinsky A.A. 1999 Goncharnaya tekhnologiya kak obyekt istoriko-kulturnogo izucheniya. In Aktualniye problemy izucheniya drevnego goncharstva. Samara: Samara. Gos. Ped. Univ., pp. 5-109.

- Braidwood R.J. 1945 Prefatory remarks. In Lloyd S., Safar F. Tell Hassuna: Excavations by the Iraq Government Directorate of Antiquities in 1943-44. Chicago: The Univ. of Chicago Press, pp. 255-259. (Journal of Near Eastern Studies; vol. 4 (4)).

- Braidwood R.J., Howe B. 1960 Prehistoric investigations in Iraqi Kurdistan. Chicago: The Oriental Inst. of the Univ. of Chicago.

- Breniquet C. 1991 Tell Es-Sawwan. Réalités et problèmes, Iraq, [vol.] LIII: 75-90.

- Breniquet C. 1992 Rapport sur deux campagnes de fouilles à Tell Es-Sawwan, 1988-1989. Mesopotamia, [vol.] 27: 5-30.

- Campbell S. 1992 Culture, chronology and change in the Later Neolithic of North Mesopotamia: PhD Thes. Edinburgh: Univ. of Edinburg.

- Cruels W. 2008 The Proto-Halaf: Origins, defi nition, regional framework and chronology. In Proceedings of the 5th Intern. Congress on the Archaeology of the Ancient Near East. Madrid: pp. 671-689.

- Darabi H., Mostafapour S., Yari A., Mohammadi F., Zeinali S., Shahverdi M., Fadaeian I. 2020 Investigating the Late Neolithic in the lowlands of Southwestern Iran: Sounding at the site of Remremeh, Mehran plain. In Neo-Lithics 2020. Berlin: Ex oriente, pp. 47-52.

- Gut R.V. 1995 Das prähistorische Ninive. Zur relative Chronologie der frühen Perioden Normesopotamiens, Bd. 19. 355. Mainz am Rhein: Baghdader Forschungen.

- Herzfeld E. 1930 Die vorgeschichtlichen Töpfereien von Samarra. Berlin: Dietrich Reimer (Ernst Vohsen).

- Hole F. 2011 Interactions between Western Iran and Mesopotamia. From the 9th-4th Millennia B.C. Iranian Journal of Archaeological Studies, No. 1: 1-14.

- Ippolitoni F. 1970-71 The pottery of Tell es-Sawwan - fi rst season. Mesopotamia, [vol.] V/VI: 105-179.

- Kopanias K., Beuger C., Carter T., Fox Sh., Hadjikoumis A., Kourtessi-Philippakis G., Livarda A., Magginnis J. 2013 The Tell Nader and Tell Baqrta Project in the Kurdistan Region of Iraq. Preliminary Report of the 2011 Season. SUBARTU, vol. 6-7: 23-57.

- Kozbe G. 2013 The Later Neolithic in the Şirnak Area (Southeast Turkey). In Interpreting the Late Neolithic of Upper Mesopotamia. Turnhout: Brepols, pp. 479-492. (Papers on Archaeology from the Leiden Museum of Antiquities; [vol.] 9).

- Larsa et ʼOueili (1983). 1987 Rapp. Prélim., J.L. Huot (ed.). Paris: Ed. Recherche sur les Civilisations.

- Lebeau M. 1987 Aperҫu de la céramique de la phase ʼOueili (Obeid 0). In Larsa (10-e campagne, 1983) et ʼOueili (4-e campagne, 1983): Rapport préliminaire. Paris: Ed. Recherche sur les Civilisations, pp. 95-120.

- Le Mière M., Nieuwenhuyse O. 1996 The prehistoric pottery. In Tell Sabi Abyad. The Late Neolithic settlement. Istanbul: Nederlands historisch-archaeologisch instituut, pp. 119-284.

- Lloyd S., Safar F. 1945 Tell Hassuna: Excavations by the Iraq Government Directorate of Antiquities in 1943-44. In Journal of Near Eastern Studies, vol. 4 (4). Chicago: The Univ. of Chicago press, pp. 255-331.

- Lopatina O.A., Kazdym A.A. 2010 O yestestvennoy primesi peska v drevney keramike (k obsuzhdeniyu problemy). In Drevneye goncharstvo: Itogi i perspektivy izucheniya. Moscow: IA RAN, pp. 46-57.

- Mallowan M.E.L., Rose J.C. 1935 Excavations at Tell Arpachiyah. Iraq, vol. III: 1-178.

- McCown D.E. 1942 The comparative stratigraphy of Early Iran. Chicago: The Univ. of Chicago press. (Studies in Ancient Oriental Civilization; No. 23).

- Merpert N.Y., Munchaev R.M. 1971 Rannezemledelcheskiye poseleniya Severnoy Mesopotamii (po materialam raskopok Sovetskoy ekspeditsii). Rossiyskaya arkheologiya, No. 3: 141-169.

- Merpert N.Y., Munchaev R.M. 1973 Early agricultural settlements in the Sinjar plain, Northern Iraq. Iraq, vol. 35. Autumn: 93-113.

- Merpert N., Munchaev R. 1993 Yarim Tepe I. In Early Stages in the Evolution of Mesopotamian Civilization. Soviet Excavations in Northern Iraq. Arizona: The Univ. of Arizona Press, pp. 73-114.

- Mortensen P. 1964 Additional remarks on the chronology of early villagefarming communities in the Zagros Area. Sumer, vol. 20: 28-36.

- Mortensen P. 1970 Tell Shimshara. The Hassuna Period, vol. 5.2. Copenhagen: Munksgaard.

- Mortensen P. 2014 Excavations at Tepe Guran. The Neolithic Period. Leuven, Paris, Walpole, Ma: Peeters.

- Munchaev R.M., Merpert N.Y. 1981 Rannezemledelcheskiye poseleniya Severnoy Mesopotamii. Moscow: Nauka.

- Nieuwenhuyse O. 1999 Tell Baghouz reconsidered: A collection of “Classic” Samarran sherds from the Louvre. Syria, [vol.] 76: 1-18.

- Nieuwenhuyse O., Jacobs L., Van As B., Broekmans T., Adriaens A.M. 2001 Making Samarra fi ne ware - technological observations on ceramics from Tell Baghouz (Syria). Paleorient, vol. 27: 147-165.

- Oates J. 1968 Prehistoric investigations near Mandali, Iraq. Iraq, vol. 30, 1 (Spring): 1-20.

- Oates J. 1969 Choga Mami 1967-68: A preliminary report. Iraq, vol. XXXI, Autumn: 115-152.

- Oates J. 1987 The Choga Mami transitional. In Colloques internationaux CNRS. Paris: Prehistore de la Mesopotamie, pp. 163-179.

- Oates J. 2003 Samarran issues. In Interpreting the Late Neolithic of Upper Mesopotamia. Brepols: Brepols publ., pp. 407-416.

- Odaka T. 2003 Samarra pottery in the National Museum of Aleppo, Syria. Al-Rafi dan, vol. XXIV: 25-35.

- Odaka T. 2019 Neolithic potsherds from Matarrah, Northern Iraq: The collection of the University Museum, the University of Tokyo. In Decades in Deserts: Essays on Near Eastern Archaeology in Honor of Sumio Fujii. Tokyo: Rokuichi Syobou, pp. 251-260.

- ʼOueili. 1991 Travaux de 1985, J.L. Huot (ed.). Paris: Ed. Recherche sur les Civilisations.

- Perkins A.L. 1949 The comparative archaeology of Early Mesopotamia. Chicago: Univ. of Chicago Press.

- Petrova N.Y. 2016 Tekhnologicheskoye izucheniye keramiki poseleniya Yarimtepe I (periody Protokhassuny i Arkhaicheskoy Khassuny). KSIA, No. 242: 48-59.

- Petrova N. 2021 Neolithic pottery technology of Sinjar Valley, Northern Iraq (Proto-Hassuna and Archaic Hassuna periods). In Neolithic Pottery from the Near East. Production, Distribution and Use. Analia-Istanbul: Koç University Press, pp. 213-228.

- Petrova N., Darabi H. 2022 Analysis of Neolithic pottery technolo gy along the Iranian Zagros foothills. Documenta Praehistorica, vol. XLIX: 2-27.

- Rice P.M. 1987 Pottery Analysis. A Sour cebook. Chicago, London: Univ. of Chicago Press.

- Roux V. in Collaboration with Courty M.A. 2019 Ceramics and Society. A Technological Approach to Archaeological Assemblages. Cham: Springer.

- Rue O.S. 1981 Pottery Technology. Principles and Reconstruction. Washington: Taraxacum, Australian National Univ.

- Shepard A.O. 1985 Ceramics for the Archaeologist. Washington: Carnegie Institution of Wash.

- Suleiman A., Nieuwenhuyse O. 1999 A note on the Hassuna/Samarra site of tell Boueid II. NeoLithics. A Newsletter of Southwest Asian Lithics Research, vol. 1: 1-2.

- Taylor J.D.P., Seton-Williams M.V., Wae chter J. 1950 The excavation at Sakce Gözü. Iraq, vol. XII (2): 53-138.

- Tekin H. 2012 The contribution of Hakemi Use to the prehistory of Upper Mesopotamia. In Interpreting the Late Neolithic of Upper Mesopotamia. Turnhout: Brepols Publ. n.v., pp. 493-502.

- Tekin H. 2021 An overview of the Late Neolithic period of Southeastern Anatolia. Journal of the Turkish Institute of Archaeology and Culture Heritage, vol. 1: 49-78.

- Tomson B.E. 1969 The archaeology of Northern Mesopotamia. A thesis submitted to the Faculty of the Department of Anthropology. Arisona: The Univ. of Arisona.

- Tsetlin Y.B. 2006 Ob opredelenii stepeni ozheleznennosti iskhodnogo syrya dlya proizvodstva glinyanoy posudy. In Voprosy arkheologii Povolzhya, iss. 4. Samara: Nauch.-tekhnich. tsentr, pp. 421-425.

- Tsetlin Y.B. 2012 Drevnyaya keramika. Teoriya i metody istoriko-kulturnogo podkhoda. Moscow: IA RAN.

- Tsuneki A., Rasheed K., Saber S.A., Nishiyama Sh., Anma R., Ismail B.B., Hasegawa A., Tatsumi Y., Miyauchi Y., Makino M., Kudo Y. 2015 Excavations at Qalat Said Ahmadan, Suleimani, IraqKurdistan: First interim report (2014 season). Al-Rafidan, vol. XXXVI: 1-63.

- Vandiver P. 1987 Sequential slab construction: A conservative Southwest Asiatic ceramic tradition, ca. 7000-3000 B.C. Paleorient, No. 13 (2): 9-35.

- Vasilieva I.N., Salugina N.P. 2010 Loskutniy nalep. In Drevneye goncharstvo. Itogi i perspektivy izucheniya. Moscow: IA RAN, pp. 72-87.

- Volkova E.V., Tsetlin Y.B. 2016 K metodike izucheniya rezhimov obzhiga drevney keramiki. In Traditsii i innovatsii v izuchenii drevneishei keramiki. St. Petersburg: IIMK RAN.