Development of productive pseudocapsulated compound feeds for rainbow trout grown in the Central federal district of the Russian Federation

Автор: Vasilenko V.N., Frolova L.N., Kochkin I.Y., Eremin I.D., Zhiltsova S.I., Dorokhin R.V.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевая биотехнология

Статья в выпуске: 1 (95) т.85, 2023 года.

Бесплатный доступ

The decrease in catch of valuable fish species from natural water bodies is compensated by their intensive cultivation in artificial conditions. In order to realize the main task of trout farms associated with obtaining marketable products in the shortest possible period of time, artificial feed is used as a source of food. A economically feasible alternative source of raw materials is the products of plant origin. In the process of production of oil and fat products at various stages, numerous fat wastes and by-products are formed, wich have fodder value and are not used as feeding facilities in industrial scale. This is especially frue for fat processing (soapstock of Light oil, fatty bleaching clays, dezodoration chases, phosphatides, calcium salts of fatty acids), as well as waste oils in combination with fat processing waste. On the base of studying the classical technology of producing mixed fodders for valuable fish species and eliminating its drawbacks the technology of pseudocapsulated mixed fodders for salmon fish grown in the CFD of Russia Federation with given fodder value and a line for its realization is suggested. The best way to bring fats and vitamins contained in them to valuable fish species is to feed them as a part of mixed fodders. At present, however, it is difficult to increase the level of fat in feed on the existing Russian fats supply lines, since most plants can include up to 10% of fat in the bulk feed line. Therefore, the development of mixing formulations and techniques for valuable fish breeds using sturgeon fish with more than 10% fat in it as an addition of fat oily wastes such as epaulettes and phosphates is not only of scientific interest. In the course of studies optimization encapsulated optimal feeds for program "Feed Optima Expert" pseudorainbow trout were also developed. As a result, close results were obtained in terms of the rate of growth of trout, the development, conversion of feed and viability in comparison with the best feed counterparts on the Russian market.

Trout, optimal feed, fodder production, pseudocapsulation, dietary optimization

Короткий адрес: https://sciup.org/140301805

IDR: 140301805 | УДК: 636.086:598.5 | DOI: 10.20914/2310-1202-2023-1-174-179

Текст научной статьи Development of productive pseudocapsulated compound feeds for rainbow trout grown in the Central federal district of the Russian Federation

At present time in the production of complete mixed fodders for valuable fish species it is necessary to produce pellets fodder raw materials processing, according to modern technologies of with replacement of a part of expensive fish meal, with protein components of other scarce and origin. Therefore, fish producers refuse long-standing partners who produce mixed fodder for fish in pelleted form. They are forced to buy mixed fodder, where the methods of extrusion and pseudocapsulation are used [1, 7].

Mixtures for valuable fish breeds produced by the classical technology of simple mixing of components have significant disadvantages: loss of biological active substances due to dust, oxidation of vitamins and destruction of a number of trace elements, exposed to the environment. But the main thing is the stratification of components into fractions during shipment and transportation (self-sorting of the feed when moving by various transport mechanisms or during transport) and traceability during storage, limiting the processed product

Methods of extrusion and pseudocapsulation are of interest primarily in the production of mixed fodders for fish, since the long-term presence of feed in water imposes special requirements for its quality [6, 9, 10].

The known disadvantages of classical technology are taken into account in the advanced technology for the production of pseudo-capsuled feeds of a given feed value, allowing to increase technological capabilities, to expand the range of produced feeds of improved quality, t. e. Production of a finished product enriched with fats and vitamins, adapted for different species of salmon fish. Also, due to the fact that the pseudocapsulated mixed fodder is less in contact with moisture and oxygen in the air, it does not oxidize and decompose longer, which increases the storability of pseudo-capsulated fodder [1, 3, 8, 11-17].

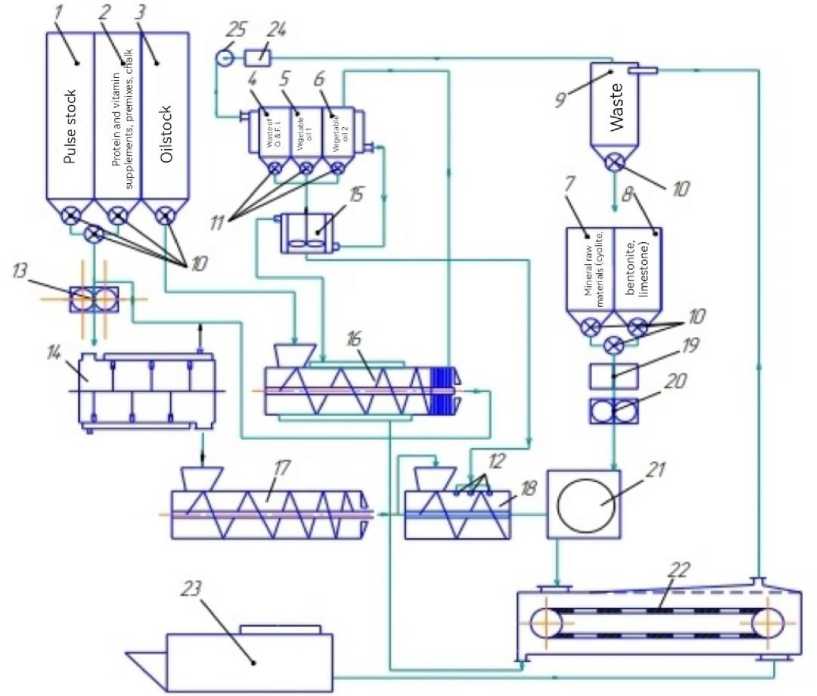

We propose a production line of pseudocap-sulated mixed fodder for valuable fish species, which works as follows (Figure 1) [2].

Figure 1. Production line of рsеudосарsulеd feedstock for valuable fish breeds: 1 – hopper for pulses, 2 – hopper for protein and mineral supplements, premix, chalk, 3 – hopper for oil stock, 4 – hopper for oil and oil waste, 5,6 – hoppers for vegetable oils, 7,8 – hoppers for mineral raw materials, 9 – hopper for waste, 10, 11 – rotary batchers, 12 – nozzles, 13 – crusher, 14 – mixer, 15 – tank for mixing fat and oil materials, 16 – extruder-oil separator, 17-extruder, 18 – fat and oil components coating machine, 19 – scales, 20 – crusher, 21 – disc granulator, 22 – belt dryer, 23 – filling and packaging machine, 24 – heater, 25 – fan

Initial pulse raw materials and protein and vitamin additives, premixes, chalk, oily raw material of a given fractional composition with initial moisture of 10–14%, stored in bunkers 1, 2, 3 are supplied by rotary bаtсhеrs10 come to crusher 13, and oil raw material into working chamber of extruder-oil separator 16. Pressed vegetable oil enters the hoppers for vegetable oil 5, 6. The cake is sent to the crusher 13 and further crushed grain pulses raw material, protein and vitamin additives, premixes, chalk, cake gets into the mixer 14 and then the product enters the working chamber of the extruder 17. The actuator is switched on and the rotating extruder 17 screw begins to capture and move the product, which passes in series through the loading, mixing, homogenizing and dosing zones.

The need to squeeze fat-containing components from various oil-bearing raw materials (soybeans, rape, sorghum and other) and their subsequent application to the surface of extruded granules is due to the fact that for the extrusion process to proceed normally, the fat content of the original oilseed must not exceed 6% [6]. Otherwise, the dissipation effect, that is, the conversion of mechanical energy into thermal energy due to friction forces, and the grain raw material is not inflated.

Vegetable oil and fat industry waste are fed into the fat and oil mixer 15 parallel to the shaft axis, the resulting mixture is radially ejected by the mixer and is intensively mixed with the emulsifier (grinding fat balls) effect.

Extruded raw material from extruder 17 is fed into and oil components coating machine 18 with nozzles 12 to apply the fat and oil components from tank for mixing fat and oil materials 15 and further to disc granulator 21, where weighed on scales 19 crusher on crushed 20 minerals raw materials (zeolite, bentonite, limestone) stored in hoppers 7, 8, in which the granules are coated with oil and fat components coming from fat and oil components coating machine 18 with nozzles 12 mounted inside it for the application of oil and fat components are treated with minerals. Due to good adhesion (surface adhesion forces) mineral raw materials are applied evenly to the surface of the granules. Pseudocapsulated mixed fodder are less in contact with moisture and oxygen contained in the air, which means that they are not oxidized and do not decay any longer, thus increasing the stored capacity of pseudocapsular mixed fodder. This allows you to keep the full vitamins, micro and macronutrients required for the fish are sent to the belt dryer 22, where the air and waste is sent to the waste bunker 9, the product is sent to the filling and packaging machine 23.

The disc granulator 21 for applying a mineral mixture is in the form of an inclined rotating drum. Discharge part of the disc granulator 22

is designed to be perforated for dripping and subsequent removal of the small (through) part of the granules into a confuser, as well as the excess amount of the mixture of mineral raw materials and waste oil and fut and vegetable oil. The loading funnel of the disc granulator is also supplied with extruded granules with oil and fat industry waste and mineral mixture applied to the surface thereof.

The original air is heated by a 24 to 60 °C calorifer and the fan 25 is pumped into the oil fat industry waste storage bunkers 4 and vegetable oil storage bunkers 5, 6 for the plasticity of waste oil and vegetable oil. Then air with a temperature of 50 °C enters the tank for mixing fat and oil materials 15, from it with an air temperature of 40 °C to the extruder-oil separator 16 and then air with a temperature of 30 °C enters the belt dryer for drying the pseudocapsuled mixed fodder. Then the air with a waste with temperature of 35 °C is directed to the hopper for waste 9, where after the deposition of the suspended particles of the waste air with a temperature of 20 °C again enters the calorifer 24, thus creating a closed cycle.

Before a pseudocapsule enters the digestive system, its contents are less in contact with the moisture and oxygen contained in the air, which means that they are not oxidized and do not decay any longer. This ensures that the vitamins, micro and macro elements necessary to unlock the genetic potential of the herd are retained.

The choice of the optimal shell material in the development of this technology was considered mineral raw materials for use as a shell: limestone, bentonite or zeolite [2].

For example, we developed a pseudocapsuled optimal mix from the following ratio of components for the trout age group (from 100 grams to 250 grams or more), mass% (table 1).

Methods

To compose pseudo-encapsulated optimal mixed fodder for salmon fish from available raw materials of plant and animal origin, by the example of rainbow trout, the optimization program "Feed Optima Expert" was used, which provides a recipe, in which the exchange and nutritive value, fully complying with the requirements is observed, while minimizing the cost of mixed fodder by 6… 9%. Rations are optimized by at least 27 nutritional indicators.

To replace fishmeal to reduce the cost of feed, to eliminate counterfeit fishmeal and poor quality flour due to contamination by afloxins in feed, included waste oil and fat industry (shrot, phosphate concentrates), as well as phytose to improve the absorption of this protein and phosphorus, as well as limiting feed amino acids of lysine and methionine, as part of them is lost during extrusion (table 1).

Table 1.

Pseudoencapsulated recipe optimal mixed fodder for rainbow trout

|

Feed components |

Substitutes |

Optimum feed for fish (from 100 grams to 250 grams or more) |

|

Fish meal (Protein 63) |

– |

30,23 |

|

Soy concentrate (Protein 65) |

Soy, pea isolate |

3,0 |

|

Meat flour (Protein 68) |

Fish meal |

6,0 |

|

Blood flour (Protein 80) |

– |

4,0 |

|

Yeast (Protein 30) |

– |

3,0 |

|

Corn flour |

– |

4,0 |

|

Soybean meal (Protein 42) |

– |

7,0 |

|

Corn gluten (Protein 59) |

Wheat gluten |

15,6 |

|

Rapeseed meal (Protein 35) |

Lupin, sorghum and other meals |

6,0 |

|

Fish oil |

– |

10,0 |

|

Vegetable oil |

Phosphatides |

2,0 |

|

Wheat |

Barley |

6,0 |

|

L – lysine |

– |

0,2 |

|

Меthiоninе |

0,3 |

|

|

Phytase (Naturophos-10006) |

– |

0,02 |

|

Subtilis |

– |

0,4 |

|

Oxycap (antioxidant) |

– |

0,05 |

|

Calcium carbonate |

– |

0,6 |

|

Phosphate monocalcium |

– |

0,6 |

|

Premix P-110–1 |

– |

1,0 |

|

Raw protein, % |

– |

45,0 |

|

Raw fut, % |

– |

18,0 |

|

Raw carbohydrates, % |

– |

16,3 |

|

Raw fiber, % |

– |

2,4 |

|

Minerals, % |

– |

8,3 |

|

Moisture, % |

– |

6–7 |

|

Са |

– |

3,2 |

|

Р |

– |

2,1 |

|

Essential fatty acids of the linolenic series (ω 3), %, not less than: |

– |

2,5 |

|

Essential fatty acids of the linoleic series (ω 6), %, not less than: |

– |

0,8 |

|

Total energy, MJ/kcal |

– |

23,2/5545 |

|

Digestible energy, MJ/kcal |

– |

18,3/4380 |

The proposed recipe meets all the requirements for feed for the preparation of optimal feed for rainbow trout.

Results and discussion

Experienced batches of feed were manufactured on experimental equipment AC «Scientific and Production Center "All-Russian Research Institute of Feed Industry» Voronezh. Testing of these batches of feeds was carried out in swimming plants measuring 1 × 1 × 0,5 meters, with a flow rate of 5 l/min of Innovation and Technology Center «Aquabioresource» VSUIT on rainbow trout (from body weight 150 grams to body weight 350 grams) with full control of growing еnvirоnmеntЕасh group consisted of 20 individuals of rainbow trout, which received experienced and analog feed. Water temperature was maintained for rainbow trout 12–18 ºC, oxygen content 7–8 mg/l, рН 6.5–6.7.

The results of tests of pseudocapsulated optimal feed mix, in comparison with known similar formulations developed by AC «Scientific and Production Center "All-Russian Research Institute of Feed Industry» are presented in the table 2.

As a result, close results were obtained in terms of the growth rate of trout, the development, conversion of feed and viability in comparison with the best feed analogues on the Russian market.

Table 2.

Fish and biological indicators of rainbow trout cultivation

|

Production figure |

Experienced feed mix |

Feed developed by AC «SPC «All-RRIFI» |

|

Body mass, g: initial ultimate |

152,6 ± 5,5 357,8 ± 15,2 |

159,4 ± 4,4 372,4 ± 18,3 |

|

Average daily increase, r: |

2,29 |

2,37 |

|

Survival rate, %: |

98,5 |

96,9 |

|

Fееd conversion |

1,06 |

1,09 |

|

Growing period, days: (March – May 2021) |

90 |

90 |

In the test of pseudocapsulated optimal feed for rainbow trout in comparison with its analogue, close indices of growth rate, feed conversion, survival rate were also established. In 90 days, the year-old individuals reached a larger commercial mass of more than 350 g, the statistical differences in body mass in experience and control were unreliable (p > 0.05), close (see table 2). This testifies to the high productive action of the new pseudo-capsulated optimal mixed fodders, as well as the best Russian counterparts.

Conclusion

A range of scientific research in the development of pseudocapsuled optimal feed formulations may be of interest in the field of full feeding salmon fish, as well as through methods such as extrusion and pseudocapsulation, which provide a significant increase in the growth of living mass, the expansion of the assortment of produced feed with a sufficiently high biological, energy value, balanced in the composition of essential amino acids, vitamins and minerals, adapted to different species of valuable fish species.

Acknowledgement

The article was prepared within the framework of the Grant of the President of the Russian Federation for the state support of young Russian scientists Doctors of Science (MD-387.2022.5).

Список литературы Development of productive pseudocapsulated compound feeds for rainbow trout grown in the Central federal district of the Russian Federation

- Vasilenko V., Frolova L., Dragan I., Mikhailova N. et al. The line for the production of feed for fish with vacuum coating. Mixed feed. 2019. no. 4. pp. 38-40.

- Vasilenko V.N., Frolova L.N., Dragan I.V., Tunyan N.O. Method for the production of functional pseudo-encapsulated aquafeeds. Patent RF, no. 2494640, 2013.

- Afanasyev V.A., Vasilenko V.N., Frolova L.N., Ostrikov A.N. et al. Method for the production of extruded feed for sturgeons. Patent RF, 2739798, 2020.

- Ponomarev S.V., Grozesku Yu.N., Bakhareva A.A. Feed and feeding of fish in aquaculture. M., Morkniga, 2013. 410 p.

- Ponomarev S.V., Gamygin E.A., Nikanorov S.I., Ponomareva E.N. et al. Technologies for growing and feeding aquaculture objects of the South of Russia. Astrakhan, Nova plus, 2002. 263.

- Vasilenko V.N. Development of a new generation of extrusion equipment for animal feed. Bulletin of mechanical engineering. 2009. no. 9. pp. 77-78.

- Afanasiev V.A., Ostrikov A.N., Bogomolov I.S., Filiptsov P.V. et al. Development of technology for highly digestible compound feeds with vacuum spraying of liquid components. Proceedings of VSUET. 2021. vol. 83. no. 1 (87). pp. 94-101.

- Vasilenko V.N., Frolova L.N., Dragan I.V., Mikhailova N.A. Development of production extruded feed for industrial production of tilapia. Proceedings of VSUET. 2019. no. 1. pp. 132-137.

- Afanasyev V., Bogomolov I., Ostrikov A., Startseva S. Technology and equipment for the production of feed for valuable fish species. Mixed feed. 2021. no. 1. pp. 24-28.

- Yapontsev A.E. Processing of technological regimes in the production of extruded feed for rainbow trout. Quality of products, technologies and education. Magnitogorsk, MSTU, 2007. pp. 95-96.

- Li M.H., Manning B.B., Robinson E.H., Bosworth B.G. Effects of dietary protein concentration on production characteristics of pond-raised channel catfish fed once daily or once every other day to satiation. North American Journal of Aquaculture. 2004. vol. 66. no. 3. pp. 184-190.

- Robinson E.H., Li M.H., Manning B.B., Mischke C.C., Bosworth B.G. Effects of dietary protein and feeding rate on channel catfish Ictalurus punctatus production, composition of gain, processing yield, and water quality. Journal of the World Aquaculture Society. 2004. no. 35 (4). pp. 468-477.

- Li M.H., Mannning B.B., Robinson E.H., Bosworth B.G. Effect of dietary protein concentration and stocking density on production characteristics of pond-raised channel catfish Ictalurus punctatus. Journal of the World Aquaculture Society. 2003. no. 34 (2). pp. 147-155.

- Armstrong M.S., Boyd C.E., Lovell R.T. Environmental factors affecting flavor of channel catfish from production ponds. Progressive Fish-Culturist. 1986. no. 48 (2). pp. 113-119.

- Watson A.M., Napolitano M.P., Schock T.B., Bowden J.A. et al. Evaluation of graded levels of soy oil as a fish oil replacement in high soy protein feeds for juvenile red drum, Sciaenops ocellatus. Aquaculture. 2020. vol. 529. no. 735627.

- Villanueva-Gutiérrez E., González-Félix M.L., Gatlin D.M., Perez-Velazquez M. Use of alternative plant and animal protein blends, in place of fishmeal, in diets for juvenile totoaba, Totoaba macdonaldi. Aquaculture. 2020. vol. 529. no. 735698.

- Zhu R., Li L., Li M., Yu Z. et al. The effects of substituting fish meal with soy protein concentrate on growth performance, antioxidant capacity and intestinal histology in juvenile golden crucian carp, Cyprinus carpio × Carassius auratus. Aquaculture Reports. 2020. vol. 18. no. 100435.