Dry protein mixture for food rations fortification based on membrane methods for processing secondary dairy raw materials

Автор: Glotova I.A., Tihonov G.S., Galochkina N.A., Shahov S.V.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевая биотехнология

Статья в выпуске: 4 (94), 2022 года.

Бесплатный доступ

Protein deficiency in the diets of various determined groups of consumers is a serious nutritional problem. The problem of protein deficiency in diets can be solved by developing protein mixtures for their enrichment, taking into account trends in personalized nutrition. Whey processing using membrane technologies corresponds to the concept of Green, Circular, Bio economy. Membrane technologies make it possible to fractionate various whey components and obtain high-tech protein products. The aim of the study is to develop a basic recipe, assess the organoleptic properties and physicochemical characteristics of a dry protein mixture based on whey proteins obtained on the basis of membrane methods. Whey protein concentrate UF WPC - 80 was used as the main component of the protein mixture. Whey protein concentrate and isolate in a 6:1 ratio form the basis of the protein mixture we have developed. We offered options for expanding the range of flavoring additives for dry protein mixtures by combining traditional flavoring additives "Strawberry", "Cherry", "Apple", "Pineapple", "Melon". We have provided an optional addition of papaya and pineapple extracts in case of decreased activity of digestive enzymes, for example, in the elderly people. The technological scheme for obtaining the finished product provides for two-stages dry mixing of the components and the use of commercially available equipment. The protein mixture is a dry powder and is recommended for use in liquid form by restoring it with water, milk or natural juice, for example, veatgrass. We investigated the composition and properties of the developed dry protein mixture in accordance with official and generally recognized test methods. The developed product meets the requirements of TR CU 021/2012 "On food safety" and can be recommended to increase the adaptive capabilities of consumers of various age and physiological groups to physical and neuro-emotional stress, as a fortifying component of diets

Whey, fortification, whey protein concentrate, whey protein isolate, dry protein mixture

Короткий адрес: https://sciup.org/140301790

IDR: 140301790 | УДК: 641.561 | DOI: 10.20914/2310-1202-2022-4-69-75

Текст научной статьи Dry protein mixture for food rations fortification based on membrane methods for processing secondary dairy raw materials

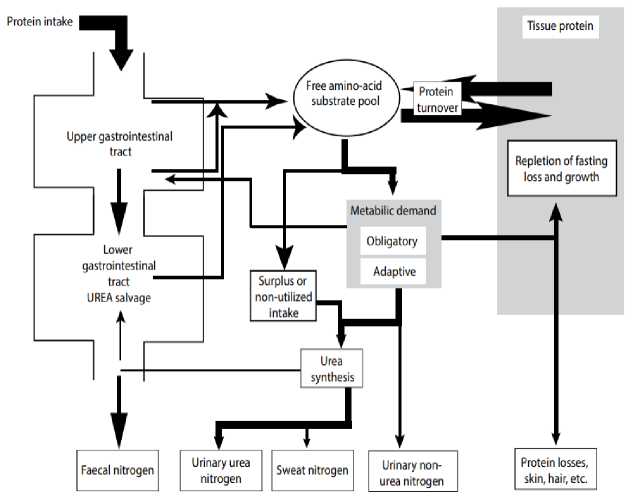

The development of food industry technologies should comply with the concept of Green, Circular, Bio economy, as it is aimed at achieving integrated "economic, environmental and social goals" [1]. Among the enterprises of the food industry, milk processing enterprises attract attention as objects that are potentially hazardous to the environment [2]. It is necessary that they apply effective methods aimed at protecting the environment and rational use of secondary raw materials [3, 4]. The works of a number of authors have shown that membrane technologies make it possible to fractionate various components of whey and obtain high-tech protein products with added value [5]. On the other hand, protein deficiency in the diets of various determined groups of consumers is a serious nutritional problem [6]. Protein deficiency is characterized by a deficiency in the human body of proteins due to their inadequate intake, or a violation of their assimilation and metabolism (Figure 1). The problems of protein deficiency in diets can be solved by developing protein mixtures for their fortification, considering the trends in personalized nutrition [7]. Thus, the improvement of formulations and technologies of dry protein mixes based on secondary resources of livestock products whey proteins, is an urgent task [8].

The purpose of the study is to develop a basic formulation, evaluate the organoleptic properties and physicochemical characteristics of a dry protein mixture based on whey proteins obtained using membrane methods.

Materials and methods

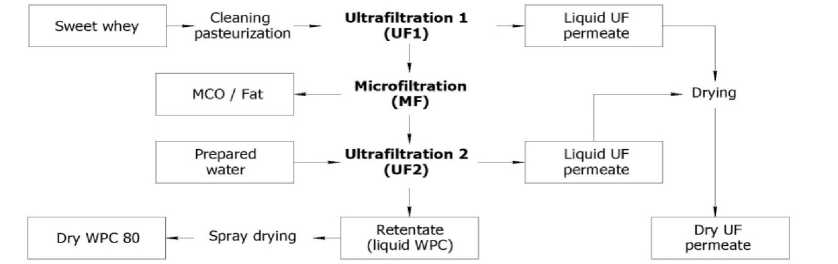

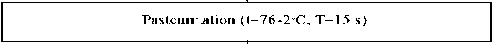

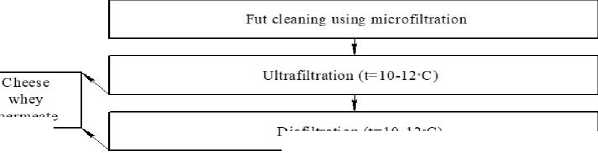

When developing the formulation of the dry protein mixture, whey protein concentrate UF WPC 80 produced by Molvest JSC, Kalach was used as the basis. The block diagram of the production of KSB is shown in Figure 2. The conditions and modes of production, the characteristics of the organoleptic and physico-chemical indicators of KSB-UV-80 are presented in Figure 3, tables 1 and 2.

Figure 1. Diagram of amino acid metabolism pathways in the human body, according to Report of an FAO Expert Consultation (Aucklend, New Zealand, 31 March – 2 April, 2011)

Figure 2. Initial, intermediate and final products in the processing of cheese whey by ultra – and microfiltration methods to obtain dry whey protein concentrate [9]

Acceptance of raw materials, quality control (GOST 34 352-2017)

Cooling (t=4±2*C) and storage (if necessaiy)

Cleaning whey from casein dust and milk frit (t=43±2 -C)

permeate

Dianltration (t=10-12”C)

Spray drying (in temperature 140-160’C, out temperature- 70-10 0"C)

Table 1.

Organoleptic characteristics UF WPC – 80 [11]

|

Characteristic |

Characteristic content |

|

Taste and smell |

Clean, whey, sweetish, without foreign tastes and odors |

|

form |

Fine powder or powder consisting of single and agglomerated particles. A small amount of lumps is allowed, crumbling under light mechanical stress |

|

Colour |

White with a cream shade, homogeneous throughout the mass |

Packaging, marking and storage before sale

Figure 3. Technological scheme to produce UF whey protein concentrate [10]

Table 2.

Physical and chemical indicators UF WPC – 80 [11]

|

Indicator |

Value |

|

Mass fraction, %: |

|

|

moisture |

5,0 |

|

protein |

≤76,0 |

|

protein in DM, % |

≥80,0 |

|

fat, % |

≤8,0 |

|

lactose, % |

≤9,0 |

|

pH |

6,1–6,8 |

|

Solubility index, cm3 |

<0,3 |

|

Purity group |

>II |

|

Temperature at discharge, оС |

2–20 |

The composition and properties of the developed dry protein mixture were studied in accordance with official and generally recognized test methods. The mass fraction of moisture was determined according to GOST 15113.4 “ Food concentrates. Moisture determination methods ” ; mass fraction of protein – according to GOST 26889 “ Food and flavor products. General guidelines for the determination of nitrogen content by the Kjeldahl method ” ; mass fraction of fat – according to GOST 15113.9 “ Food concentrates. Methods for determination of fat ” ; mass fraction of carbohydrates – according to GOST R 54667 “ Milk and milk processing products. Methods for determining the mass fraction of sugars. The content of lead and cadmium was determined according to GOST 30178 “ Raw materials and food products. Atomic absorption method for determination of toxic elements ” ; arsenic content – according to GOST R 51766 " Atomic absorption method for the determination of arsenic " ; mercury content – according to MI 5178 – 90

" Guidelines for the detection and determination of the total mercury content in food products by flameless atomic absorption " .

The discussion of the results

The solution of the problem of fortification of food rations of various deterministic groups of consumers is the subject of study and discussion by many researchers [12–14].

Scientific research is being carried out aimed at improving prescription-component solutions of specialized products for the nutrition of various deterministic consumer groups, in particular, sports nutrition [15, 16], nutrition for pregnant and lactating women [17], school meals [18].

The issues of nutritional support in the nutrition of people who are unable to combine a rational regime of work and rest due to social deprivation are discussed [19].

The subject of research is the effect of individual products and ingredients on physical fitness, endurance, health status of athletes and people with increased physical activity [16]. However, the problem of nutrition of older and elderly people, in our opinion, has received little attention [20, 21, 22], especially taking into account the criterion of minimizing raw material costs based on the effective use of whey protein components. The solution to this problem is associated with the development of specialized food products, applicable, among other things, for correcting the basic diets of older and older people.

In 2019, the pension system was reformed in Russia, which provides for a gradual increase in the retirement age for women from 55 to 60 and for men from 60 to 65 years. In this regard, there is a strategic task of maintaining the health of the body of the elderly (60–74 years), which implies two directions for its implementation. The first is the promotion of a healthy lifestyle. The second is a healthy diet, taking into account the physiological characteristics of the body.

In the works of other authors scientifically substantiated and experimentally confirmed the feasibility of using milk proteins, vitamin and mineral fortifiers when creating dry mixes intended for the nutrition of the elderly [19, 21, 22]. They showed that the quality, safety and high consumer properties of products should be due to the use of high-protein whey preparations with an optimal amino acid composition.

The closest in composition and properties to the developed product are specialized products for athletes and baby food, the composition of which provides for the use of animal proteins. At the same time, considering collagen and whey proteins as an alternative, it should be emphasized that among all proteins of animal origin, milk whey proteins are the most valuable for the human body due to the rate of their assimilation, which is determined by the amino acid composition of these proteins, which is almost identical to the amino acid composition of human skeletal muscle.

We have developed a basic formulation of a dry protein mixture to ensure the protein status of the human body (Table 3). Whey protein concentrate and isolate in the ratio of 6:1 form the basis of the protein mixture formula developed by us. An important stage in the development of a dry protein mixture for fortifying food rations is the formation of its flavor profile. for which the use of flavors, sweeteners, natural food colors is provided. Options for expanding the range of flavor solutions for dry protein mixtures by combining traditional flavoring additives "Strawberry", "Cherry", "Apple", "Pineapple", "Melon" are proposed. In case of reduced activity of digestive enzymes, for example, in the elderly, the optional addition of papaya and pineapple extracts is provided.

To attract the attention of consumers, satisfy their preferences, the product must have excellent tastes, the originality of which comes down to changing several production parameters – the use of various flavoring additives. So, for example, the usual tastes of "Strawberry", "Cherry", "Apple", "Pineapple" and "Melon" with the addition of a certain amount of flavor additive "Biscuit" can be organoleptically identified as the modern taste of the French confectionery "Macaron", which exists in combined with strawberries, cherries or other fruit jams. When using "Strawberry" and "Marshmallow" flavors in equal proportion, you can get the taste of "Strawberry Marshmallow", and when using several fruit flavors (VAD) at once, you can get the tastes of "Malibu" and "Tutti-Frutti".

In addition to expanding the range of flavor solutions, due to such techniques in a limited list of dietary supplements, it is possible not only to increase the variety of products, but also to more rationally use the stocks of raw materials in production, increase the originality and recognition of the brand of this group of goods in a competitive environment.

The remaining ingredients of the dry mix formulation can be optionally added, taking into account the physiological characteristics and hedonistic preferences of specific deterministic consumer groups, taking into account the gradation of the daily requirement for proteins of animal origin (g), recommended by the Norms of Physiological Requirements for Energy and Nutrients [23], which, in particular, includes: children from 7 to 18 years; men aged 18–29 years of the II group of physical activity; men aged 18–29 years of group V of physical activity; men over 60; women aged 18–29 years of the II group of physical activity; women during pregnancy, women during the period of feeding a child (1–6 months); women over 60.

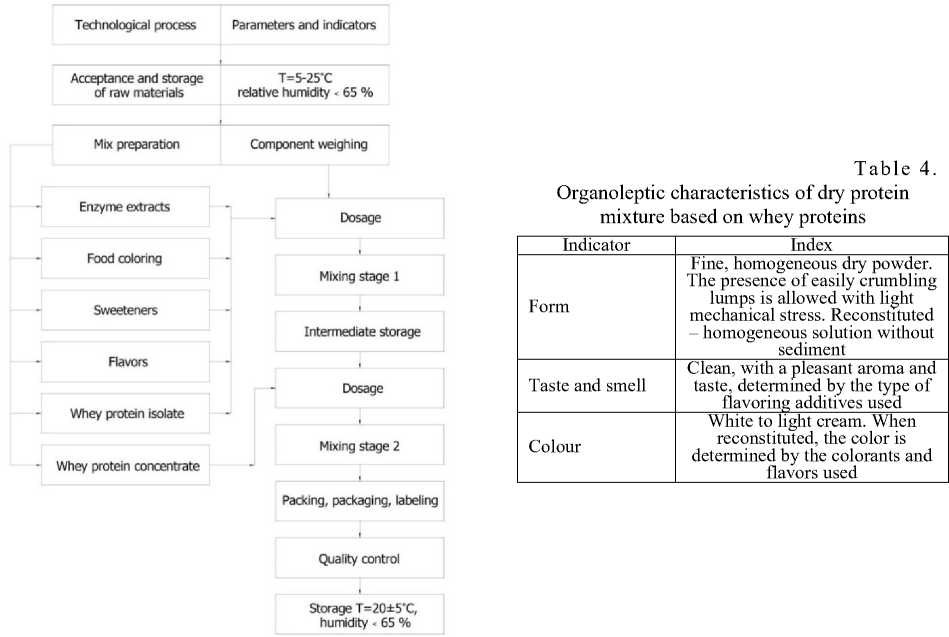

The technological scheme for obtaining the finished product provides for two-stages dry mixing of the components in accordance with the recipe developed by us and the use of commercially available equipment (Figure 4).

Whey proteins are characterized by increased solubility, foaming, and emulsifying properties, resulting in a reduced reconstitution process compared to other animal protein sources.

The effectiveness of the product is affected not only by its physical and chemical characteristics, but also by organoleptic properties. This makes it expedient to form a line of products that differ in flavor profile based on the basic variant of the mixture recipe (Table 4).

The physicochemical parameters of the developed dry protein mixture are presented in Table 5, the results of the assessment of the content of toxic elements are in Table 6.

Table 3.

An example of the basic formulation of a dry protein mixture based on whey proteins

|

Component name |

Mass fraction of the component, % |

|

Whey protein concentrate UF WPC – 80 |

78,000 |

|

Whey Protein Isolate |

12,800 |

|

Flavour intensifiers |

8,7000 |

|

Sweeteners |

0,4800 |

|

Food coloring agents |

0,0157 |

|

Papaya extract (optional) |

0,0022 |

|

Pineapple extract (optional) |

0,0021 |

|

TOTAL: |

100,0000 |

Figure 4. Technological scheme to produce a mixture of protein dry based on whey proteins

Table 5.

Physicochemical indicators of dry protein mixture based on whey proteins

|

Indicators |

Analysis result |

Test methods |

|

Moisture mass content, % |

4,7 ± 0,2 |

Federal standard 15113.4 |

|

Protein mass content, % |

73,2 ± 0,1 |

Federal standard 26889 |

|

Fat mass content, % |

8,2 ± 19 |

Federal standard 15113.9 |

|

Carbohydrates mass content, % |

7,7 ± 0,14 |

Federal standard R 54667 |

Table 6.

The content of toxic elements in a mixture of protein dry based on whey proteins

|

Indicators |

Result |

Acceptable level |

Test methods |

|

Lead, mg/kg |

<0.02 |

≤0.3 |

Federal standard 30178 |

|

Arsenic, mg/kg |

<0.02 |

≤0.2 |

Federal standard R 51766 |

|

Cadmium, mg/kg |

<0.003 |

≤0.05 |

Federal standard 30178 |

|

Mercury, mg/kg |

<0.02 |

≤0.03 |

MI 5178–90 |

The protein mixture is a dry powder and is recommended for use in liquid form by reconstitution with water, milk, or natural juice, such as wheatgrass. Its use is promising in the manufacture of puddings, whipped desserts, vegetable, and sweet casseroles.

The developed product complies with the requirements of TR TS 021/2012 "On food safety" and can be recommended to increase the adaptive capabilities of consumers of different age and physiological groups to physical and neuro-emotional stress, as a fortifying component of diets.

Conclusion

Whey processing using membrane technologies corresponds to the concept of Green, Circular, Bio economy. A basic formulation of a dry protein mixture based on whey protein concentrate KSB-UV-80 and recommendations for its use, considering nutritional characteristics in determining the daily requirement for proteins for various consumer groups in accordance with the Norms of physiological needs for energy and nutrients, have been developed [23].

The technological scheme for obtaining the finished product provides for dry mixing of the components in accordance with the recipe developed by us and the use of commercially available equipment. Powdered protein powder is a dry powder used for nutrition in liquid form by reconstituting it with water or milk. and can be recommended to ensure the protein status of the human body, including increasing the adaptive capabilities of consumers of different age and physiological groups.

Список литературы Dry protein mixture for food rations fortification based on membrane methods for processing secondary dairy raw materials

- D'Amato D., Droste N., Allen B., Kettunen M. et al. Green, circular, bio economy : A comparative analysis of sustainability avenues // Journal of Cleaner Production. 2017. №. 168. P. 716-734. https://doi.org/10.1016/j.jclepro.2017.09.053

- Родионов Д.А., Лазарев С.И., Полянский К.К., Эккерт Е.В. Ультрафильтрационное концентрирование молочной сыворотки на пилотной установке трубчатого типа // Вестник ВГУИТ. 2019. Т. 81. № 2. С. 41-46. https://doi.org/10.20914/2310-1202-2019-2-41-46

- Korysheva N.N., Shakhov S.V., Titov S.A., Tikhonov G.S. et al. Method for milk whey micofiltration with filtrate pulsed backpressure and installation for its implementation // IOP Conference Series: Earth and Environmental Science. 2021. https://doi.org/10.1088/1755-1315/938/1/012019.

- Anisimov G., Ryabtseva S., Evdokimov I., Khramtsov A. et al. Еffect of electrodialysis on dairy by-products microbiological indicators // Journal of Hygienic Engineering and Design. 2019. №. 27. P. 49-57.

- Khramtsov A.G., Ryabtseva S.A., Nesterenko P.G. Paradigm of postgenomic conception on milk science lactomics formation // Foods and Raw Materials. 2018. V. 6. № 1. P. 14-22. https://doi.org/10.21603/2308-4057-2018-1-14-22

- Kamau E., Serrem Ch., Wamunga F. Rat bioassay for evaluation of protein quality of soy-fortified complementary foods // Journal of Food Research. 2017. № 6(6). P. 35. https://doi.org/10.5539/jfr.v6n6p35

- Кочеткова А.А., Воробьева В.М., Саркисян В.А., Воробьева И.С., Смирнова Е.А., Шатнюк Л.Н. Динамика инноваций в технологии производства пищевых продуктов: от специализации к персонализации // Вопросы питания. 2020. Т. 89. № 4. С. 233-243.

- Barukcic I. Whey as a Potential Functional Food-Properties, Processing and Future Perspective. // Journal of Food Biotechnology Research. 2018. V. 2. №. 1-2. P. 23-32.

- Храмцов А.Г. Инновационные разработки в использовании молочной сыворотки // Техника и технология пищевых производств. 2018. Т. 48. № 3. С. 5-15. https://doi.org/10.21603/2074-9414-2018-3-5-15

- Bogdanova E.V., Melnikova E.I., Koshevarova I.B. The research of the types of moisture bonds in protein-carbohydrate concentrates of cheese whey // Periodico Tche Quimica. 2020. V. 17. № 34. P. 33-44.

- СТО ВНИИМС 045-2019. Концентрат сывороточных белков сухой. Технические условия. Углич: Всероссийский научно-исследовательский институт маслоделия и сыроделия - филиал федерального государственного бюджетного научного учреждения "Федеральный научный центр пищевых систем им. В.М. Горбатова" РАН (ВНИИМС - филиал ФГБНУ "ФНЦ пищевых систем В.М. Горбатова" РАН), 2019.

- Кочеткова А.А., Воробьева В.М., Саркисян В.А., Воробьева И.С. и др. Динамика инноваций в технологии производства пищевых продуктов: от специализации к персонализации // Вопросы питания. 2020. Т. 89. № 4. С. 233-243.

- Ильина О.А., Иунихина В.С., Маслова А.С., Шатнюк Л.Н. Актуальные вопросы разработки обогащённой и специализированной пищевой продукции // Хлебопродукты. 2020. № 3. С. 43-45.

- Люблинский С.Л., Ливинская С.А., Сидоренко Ю.И., Ливинский А.А. Характеристика наиболее распространенных дефицитов в структуре питания россиян и обогащающие добавки для целевых пищевых продуктов // Товаровед продовольственных товаров. 2020. № 11. С. 47-56.

- Латков Н.Ю., Плешкова Н.А., Подзорова Г.А. Рынок продукции спортивного питания: перспективы развития, потребительские предпочтения // Экономика и предпринимательство. 2019. № 5. С. 1263-1268.

- Штерман С.В., Сидоренко М.Ю., Штерман В.С., Сидоренко Ю.И. Современные тенденции развития производства продуктов спортивного питания // Пищевая промышленность. 2019. № 1. С. 56-59.

- Swathi M., Waghray K., Babu N., Golla R. Development of malted millet mixes for pregnant women and lactating mothers // International Journal of Innovative Technology and Research. 2016. V. 4. № 6. URL: www.ijitr.com/index.php/ojs/article/view/1485

- Тихонов Г.С., Глотова И.А., Измайлов А.Н., Брекало Е.Р. Технология переработки молока с выпуском сухого молокосодержащего продукта // European Journal of Natural History. 2021. № 5. С. 29-33.

- Ших Е.В., Махова А.А., Ших Н.В., Никитин Е.Ю. Социальный джетлаг: возможности микронутриентной поддержки // Вопросы питания. 2022. Т. 91. № 3 (541). С. 85-95.

- Fukatsu К. Role of nutrition in gastroenterological surgery // Ann. Gastroenterol. Surg. 2019. V. 3. № 2. P. 160-168. https://doi.org/10.1002/ags3.12237

- Wobith M., Weimann A. Oral Nutritional Supplements and Enteral Nutrition in Patients with Gastrointestinal Surgery // Nutrients. 2021. V. 13. P. 2655. https://doi.org/10.3390/nu13082655

- Барановский А.Ю., Круглова Н.А. Специализированный продукт лечебного питания - белковая композитная сухая смесь, обогащенная кальцием молочного происхождения, в послеоперационной реабилитации больных пожилого и старческого возраста // Успехи геронтологии. 2022. Т. 35. № 2. С. 274-280.

- Попова А.Ю., Тутельян В.А., Никитюк Д.Б. О новых (2021) нормах физиологических потребностей в энергии и пищевых веществах для различных групп населения Российской Федерации // Вопросы питания. 2021. Т. 90. № 4 (536). С. 6-19.