Experimental and computational studies on the effectiveness of strengthening the concrete floor slabs of a hydroelectric power plant's powerhouse through the use of an external reinforcement system involving carbon tape application. Part I

Автор: Rubin O.D., Kozlov D.V., Antonov A.S., Galimov A.M., Anshakov A.S.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 4 Vol.17, 2025 года.

Бесплатный доступ

Introduction. In accordance with the Federal Law of the Russian Federation ”On the Safety of Hydraulic Structures“, it is necessary to ensure the long-term safety and reliability of operating structures at hydroelectric power plants (HPPs). In a run-of-river HPP, the "headwall-turbine hall floor slab" system serves as the main load-bearing structure, absorbing a variety of external forces and loads during the operation of the turbine hall within the HPP. Over time, surveys have revealed the intensive cracking in reinforced concrete floor slabs, reducing their bearing capacity. To ensure safe operation and prolong the life cycle of the HPP, it is necessary to strengthen the reinforced concrete floor slabs of the turbine hall with external reinforcement, preferably with composite carbon tapes having high strength, low weight, dielectric qualities and other positive characteristics. At the same time, the method of installing carbon tapes should ensure that finely dispersed conductive dust does not form, since the reinforced concrete structures of the HPP turbine hall, saturated with electrical equipment that powers the HPP, are reinforced. It is also necessary to ensure that the operation of the strengthened reinforced concrete floor slab with an external reinforcement system with carbon tapes is monitored over time by means of embedded control and measuring equipment. The solution of the tasks set in the present experimental and computational studies made it possible to substantiate the effectiveness of strengthening the floor slab with external reinforcement based on the use of carbon tapes and to implement it in the HPP turbine hall. Materials and methods. The reinforced concrete floor slab in the HPP turbine hall, which has been subjected to both external and non-design loading during operation, is the object of this study. The cracking and deflections recorded by the surveys led to the need for experimental studies in field conditions, including using a load weighing 150 kN. The stresses in the working metal stretched reinforcement were determined before and after the external reinforcement device with FibArmTape-530/300 carbon tapes. The stress in the carbon tapes was also determined. The experiments of reinforced concrete floor slab models’ fragments of the stretched zone were carried out in laboratory conditions in order to determine the effectiveness of the reinforcement using a new method of installing carbon tapes on a concrete surface. These experiments were carried out using a tensile breaking machine and confirmed the positive effect of using a new method of carbon tape device, preventing the formation of finely dispersed conductive dust in the operating electrical installations of the HPP turbine halls. At the same time, the necessary strength of reinforced structures is obtained. In order to determine the formed stress-strain state of the reinforced concrete floor slab of the turbine hall, computational studies were performed taking into account the revealed nature of cracking. Stresses in stretched working reinforcement under various loads before and after strengthening, as well as stresses in carbon tapes, were determined. Using the calculations performed, a schematic diagram of reinforced concrete floor slab strengthening is proposed – the pitch of the carbon tapes and the number of layers of the composite material. Results. From the results of the experimental studies of models fragments of the reinforced concrete floor slab stretched zone that have characteristics of hydraulic structures (concrete of class B15 and B25, low coefficient of reinforcement μs = 0.00445÷0.00692, it follows that an increase in strength of 1.62–1.96 times was obtained for composite carbon tapes on a concrete surface strengthened by a new method (applied to HPP). As a result of the strengthening of the reinforced concrete floor slab with external reinforcement using a new method (applied to HPP) for the installation of carbon tapes, as a result of experimental studies in the turbine hall of the HPP, a stress redistribution was established between metal working reinforcement and carbon tapes, which were included in joint work with the floor slab with the formation of tensile stresses in the tapes. Under loading on a reinforced floor slab with 150 kN, the tensile stresses in the metal reinforcement decreased by 1.8–2.9 times (directions – along the flow and across the flow) with the formation of almost equivalent stresses in carbon tapes of the external reinforcement. In order to calculate the changes in the stress-strain state of the floor slab of the turbine hall of the HPP building (with cracking, with support that is not designed in some places under the influence of non-designed loads) strengthening with external reinforcement with carbon tapes, a spatial finite element model was developed and applied.

Headwall wall of a hydroelectric power station, floor slab of the turbine hall of a hydroelectric power station, experimental studies, computational studies, stress-strain state, cracking, strengthening, stresses in metal reinforcement, method of application and stresses in carbon tapes of external reinforcement

Короткий адрес: https://sciup.org/142245497

IDR: 142245497 | DOI: 10.15828/2075-8545-2025-17-4-433-445

Текст научной статьи Experimental and computational studies on the effectiveness of strengthening the concrete floor slabs of a hydroelectric power plant's powerhouse through the use of an external reinforcement system involving carbon tape application. Part I

Original article

Рубин О.Д., Козлов Д.В., Антонов А.С., Галимов И.М., Аншаков А.С. Экспериментально-расчетные исследования эффективности усиления железобетонного перекрытия машинного зала ГЭС в результате применения системы внешнего армирования углеродными лентами. Часть I. Нанотехнологии в строительстве. 2025;17(4):433–445. – EDN: BNLETU.

Run-of-river hydroelectric power plants (HPPs) account for a significant share of all hydroelectric facilities. They are located within the river channel and, as the main element of waterfront of hydroelectric facilities, are subjected to a complex combination of loads: hydraulic, hydrodynamic, and wave loads from the upstream side. These loads are transmitted through the turbine hall headwall to the reinforced concrete slab of the hall and other structural elements of the HPP powerhouse.

At the same time, the reinforced concrete structures of the HPP turbine hall floor slab are subject to dynamic loads from operating hydraulic units and non-design loads caused by changes in the rules of operation of hydraulic units during the life cycle of the HPP.

The headwalls and turbine hall floor slabs due to their large and overall dimensions, are constructed in stages with interruptions in concreting, while interblock construction joints are formed.

During long-term operation of run-of-river HPP powerhouses, cracks inevitably develop in the main loadbearing reinforced concrete structures – both in the interblock construction joints and in the monolithic sections. These cracks cannot be fully repaired by injecting repair materials, which reduces the overall strength and operational reliability of the HPP powerhouse. As a result, the structures reinforcement is required.

It was established that when the main electrical equipment (hydroelectric generators) was operating, repair and restoration works of reinforced concrete structures were carried out in the turbine hall of HPP using carbon tapes of FibArmTape type. The traditional method of carbon tapes (fabric) arrangement on the surface of strengthened reinforced concrete structures, well-proven for industrial and civil constructions and structures, was applied, including:

-

- application of a layer of binder (adhesive);

-

- laying (after cutting) of the prepared tape (fabric);

-

- impregnation and rolling of the tape (fabric) to the surface of the reinforced concrete structure with application of the finishing layer of binder.

Using the traditional method, the fine-dispersed conductive carbon dust formed in the turbine hall of the HPP put out of operation the excitation systems of several hydroelectric generators, which led to the emergency shutdown of the operating hydroelectric units.

Thus, the repair of reinforced concrete structures of HPPs using the traditional common method of sticking carbon tapes (fabric) led to the prohibition of its use for strengthening of structures due to the possible danger for accident-free operation of electrical equipment.

Therefore, for such objects as hydroelectric power plants, which have electrical equipment, it is necessary to develop and provide experimental justification for a new method of applying carbon fiber tapes (or fabric), which consists of several stages:

-

- Prior to installation, carbon tapes (fabrics) are impregnated with epoxy composition.

-

- After impregnation of carbon tapes (fabrics) with epoxy composition (before installation), they are rolled up into rolls, using individual integral packaging, and transported to the place of repair.

-

- According to the technical data sheet, the viability of the epoxy binder used at a temperature of 10–30 °C is sufficient to prevent the hardening of the fiber or its irreversible adhesion during transportation.

As a result, the application of the new method of installation of carbon tapes (fabric) on the surface of reinforced concrete structure allows avoiding the appearance of fine conductive dust in full, which allows excluding the failure of electrical equipment of excitation systems of hydroelectric units.

To justify the strength of reinforced concrete structures strengthened using the new method of external reinforcement installation, tests were conducted on models of fragments of the tensile zone of reinforced concrete structures (e.g., turbine hall slabs of an HPP) with dimensions of 15×30×60 cm, according to the first limit state group (strength).

From the test results, the high efficiency of strengthening by a new method of sticking carbon tapes (fabric) on the concrete surface of the models follows for HPPs.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Tensile strength of reinforced models with reinforcement factor µs = 0.00445 increased on average by 1.96 times; at µs = 0.00692 increased on average by 1.61 times.

Based on the positive experimental results, it was decided to strengthen the turbine hall slab’s reinforced concrete structure with external reinforcement using a new method of applying carbon fiber tapes (or fabric) to its surface.

The floor slabs of turbine halls are a complex reinforced concrete structure with a section length of about 60.00 m and a width of 23.50 m with two openings of 21.30 m diameter (for 2 hydraulic units within one section; for run-of-river HPPs there may be many such sections depending on the capacity of the plant). The thickness of reinforced concrete slab, taking into account large spans in two directions, is usually more than 0.60 m; reinforcement coefficients µs are usually about 0.005; concrete strength is not higher than class B25 in the presence of a significant number of vertical inter-block construction joints (in construction – this is the breakdown into blocks of concreting during slab erection).

Various scientists have carried out a significant number of laboratory scientific studies of reinforced concrete structures, including their strengthening, in a fairly small geometric scale.

It is difficult to reliably transfer the results of laboratory studies to the actual geometry and parameters of real structures. It is necessary to apply the apparatus of similarity coefficients, to take into account the scale factor and other parameters, which is not always possible to apply to reinforced concrete structures of HPPs having large scale.

The most appropriate and well-founded approach is to conduct scientific and experimental research under real operating conditions, obtaining direct and reliable results, particularly for in-service reinforced concrete structures with accumulated defects that are strengthened using external composite reinforcement. Only such an approach can confidently ensure the long-term safe operation of complex hydraulic structures, which, as a rule, belong to the highest hazard class.

In the present work, experimental studies were conducted on a real reinforced concrete slab with significant cracks, strengthened using an external reinforcement system with carbon tapes applied by a new method developed for HPPs. The results showed that the tensile stresses in the steel reinforcement under static loading decreased by more than 1.8 times.

As a result of the redistribution of stresses to the carbon tapes, stretching comparable in magnitude to those in the metal reinforcement was recorded in the tapes.

The developed spatial finite element model, used to calculate the stress–strain state (SSS) of the reinforced concrete slab (both unstrengthened and strengthened with carbon tapes) under experimental static loading, showed good agreement with the experimental results.

Thus, based on experimental and computational studies, the effectiveness of strengthening the turbine hall floor slab with external reinforcement using composite carbon tapes applied by the new method has been substantiated.

Studies of reinforced concrete structures (slabs, beams, columns) have been carried out by a number of authors with the use of carbon fibre, glass fibre, etc. composite materials as reinforcement.

The paper [1] investigates the shear reinforcement of flat slabs using carbon fibre reinforced polymer (CFRP) sheets. Fifteen reinforced concrete slab specimens were tested. Thirteen of these were reinforced with CFRP sheets and two specimens were left as controls. Four of these reinforced specimens were tested by cyclic vertical loading. The width of the CFRP sheets varied from specimen to specimen. The CFRP sheets were placed on the tensile side of the slabs in two perpendicular directions. The vertical load was applied using a hydraulic jack. No rupture of the CFRP sheets was observed in all specimens. The test results showed that the use of CFRP sheets in addition to steel reinforcing bars as flexural reinforcement improves the pushover shear strength of the slabs. This improvement can be significant for slabs made of high-strength concrete with low steel reinforcement ratio. However, under cyclic vertical loading, the improvement in pushover shear strength due to FRP reinforcement is reduced. For strengthened slabs, an equivalent reinforcement ratio should be used to account for the effect of flexural reinforcement with both steel and FRP reinforcement.

In [2], an innovative hybrid strengthening is investigated to improve the strength of reinforced concrete flexural elements. The main objective of this study is to evaluate the effectiveness of hybrid fibre reinforced polymer (FRP) strengthening in the overall evaluation of the flexural behaviour of reinforced concrete (RC) elements. Eight fullscale square RC elements were fabricated and strengthened using different FRP techniques, including near-surfacemounted (NSM) FRP carbon laminates only, externally bonded (EB) FRP only, and hybrid reinforcement using a combination of FRP NSM and FRP EB fabric. A threedimensional nonlinear microplane-based finite element (FE) model was developed to simulate the behavior of RC elements with and without FRP strengthening. Experimental results showed that hybrid FRP strengthening is able to increase the strength by 175% compared to control RC elements. RC beams strengthened by NSM alone increased the maximum strength by 111%, but with a decrease in ductility. Only external connection strengthening improved the ductility of the flexural elements but did not significantly increase the strength.

The paper [3] presents the results of experimental and numerical studies on the strengthening of reinforced con-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES crete elements using external CFRP reinforcement. The nature of failure of all beams under the action of static loading was determined by the crack opening width, formation of secondary cracks and deflections in the zone of action of the bending moment with subsequent peeling of CFRP. The analytical load-deflection curves and numerical simulations by finite element method agree well with the experimental behavior of reinforced concrete elements strengthened with CFRP, and a significant potential for strength increase has been established. It should be noted that the research was carried out on the action of static loads on reinforced concrete beam elements.

The paper [4] presents the results of studies of reinforced concrete slab of the installation site of Ayuriquin HPP (Ecuador) after the fall of a load weighing 22 tons, under the action of which there was cracking and punching in the slab. Carbon composite materials were recommended to strengthen the reinforced concrete slab.

The work [5] conducts a finite element analysis, verified through laboratory experiments on 14 reinforced concrete (RC) beams. The primary focus is the final load of these components, considering varying carbon fiber-reinforced polymers (CFRP) orientations relative to the loading direction. In this research, the performances of control beams and RC beams are compared to assess the effectiveness and efficiency of different strengthening methods. The results demonstrated that bonding CFRP sheets with V-shaped end anchorages on the tension side was highly effective in improving the flexural capacity of RC beams in the weaker concrete strength group. This strengthening method resulted in a substantial increase in strength (of around 29.8%) in the higher concrete strength group. In addition, utilizing V-shaped end anchorages to bond CFRP sheets on the tension side proved to be a highly efficient technique for improving flexural strength. Conversely, bonding inclined CFRP strips to the sides of RC beams was highly effective at enhancing the shear capacity of the beams. These outcomes convincingly demonstrate the effectiveness of FRP for the reinforcement of structural components. The specimens strengthened with inclined strips exhibited enhanced shear and deformation capacity compared to those strengthened with vertical strips.

As researchers seek to restore deformations and minimise crack widths in existing reinforced concrete structures, the reinforcement technique using pre-stressed carbon fibre reinforced plastic (CFRP) has now been highlighted in the study [6]. Reinforced concrete beams with cracks were tested in flexural action with the degree of prestressing reflected in the amount and strength of prestressed CFRP sheet. The longitudinally strengthened CFRP sheet was bonded to the bottom surface of the test beam and secured with U-shaped CFRP sheets at the ends after tensioning. The concrete deformations, longitudinal extension of the steel bars and CFRP sheets were measured at the pure bending section of the test beams, and the cracking, mid-span deflection and failure patterns were recorded. The results show that the normal strain at mid-span of beams strengthened with prestressed CFRP sheets is consistent with the assumption of flat section, the cracks and deflection at mid-span decrease with the increase in the degree of prestressing of CFRP sheets, which provides better serviceability of the strengthened beams, the bearing capacity can be increased by 41.0–88.8% in the presence of longitudinal tensile steel bars and increased by 41.9–74.8% at the limit state, and the ductility at failure is sharply reduced by 54.9–186%.

The paper [7] investigates the most important design parameters for predicting the ultimate axial compressive strain limit of reinforced concrete columns strengthened externally with fibre reinforced polymer (FRP) materials. Since the existing experiments lack consistent recording of the deformation field of the polymer material, the results of three-dimensional pseudo-dynamic finite element analysis of characteristic cases of the tested columns are used to bridge this gap. Thus, a hybrid experimental-analytical database including several critical deformations of FRP and steel reinforcement is formed. A modified model is proposed to predict the ultimate axial strain of reinforced concrete columns externally strengthened with FRP materials. The proposed model aims to indirectly account for the influence of the internal steel cage, the shape of the concrete section and their interaction with the FRP outer shell on the critical tensile strain of the FRP shell at column failure. The predictive performance of the model from available tests of reinforced concrete columns under cyclic compression is significantly improved over other existing models. A prediction with an average ratio (AR) of 0.96 and an average absolute error (AAE) of 36.5% is provided and hence can contribute to safer redesign, including earthquake-resistant redesign.

In the research [8], an accurate multistep Bézier method is developed and implemented to determine the nonlinear vibrations and post-deflection configurations of composite Euler-Bernoulli beams reinforced with graphene nanoplates (GnP). A probabilistic model and an efficient modelling method are proposed to determine the effective elastic moduli of the GnP-reinforced matrix. It should be noted that the presented micromechanical model found by Monte Carlo simulation accurately fits the experimental data and predicts the elastic constants of the composite more accurately than other common methods including Halpin-Tsai theory. The presented multistep method is based on Bernstein polynomial basis functions and shows the potential to obtain reliable solutions to various initial and boundary problems. It is found that the addition of a relatively low GnP content dramatically increases the elastic constants of the composite, especially in the transverse direction to the fibre. Furthermore, the numerical results are

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES compared with those obtained using exact analytical solutions, and the stability of the results indicates the effectiveness of the presented methodology.

The article [9] notes that for strengthening of reinforced concrete beams is used fabric and tapes glued on the external tensile surface, which are considered as external composite reinforcement in the presence of steel reinforcement. The results of experimental studies have shown the possibilities of effective application of technical polyamide (nylon) fabric and glass fabric for strengthening of reinforced concrete beams. Experimental studies have shown that external reinforcement of the tensile zone with technical polyamide (nylon) fabric and glass fibre changes the mode of beam failure, increases the load-bearing capacity of reinforced concrete beams in comparison with beams without reinforcement by 16–38% depending on the material and method of reinforcement.

External strengthening of reinforced concrete beams with and without shear reinforcement using polymer fabrics reinforced with carbon and basalt fibres has been investigated [10]. In addition, flexural tests were carried out on shear reinforced beams partially and wholly made of an engineered cement composite. Specimens made of selfcompacting concrete, engineered cementitious composite and their combination were prepared and tested by four-point loading. The strengthened beams were divided into two strength groups. Group 1 included shear strengthening of self-compacting concrete reinforced haunched beams (beams without stirrups) by considering different reinforcement configurations using both types of fibre-reinforced polymer fabrics. Group 2 included the flexural strengthening of reinforced haunched beams via fiber-reinforced polymer fabrics and/or engineered cementitious composite. The greatest increase in load carrying capacity was 72.8% for shear strengthening (Group 1) and the greatest increase was 28.8% for flexural strengthening (Group 2).

The paper [11] deals with the structural behavior of layered hybrid concrete composite flat monolithic slabs with a combination of reactive powder concrete (RPC) in the top layer and normal concrete (NC) in the bottom layer, reinforced with internal CFRP or conventional steel bars in the tensile zone, under impact load testing. For this purpose, ten full-scale square flat monolithic slab specimens of 1550 mm length and 150 mm thickness were fabricated and divided into eight specimens of layered hybrid concrete with 50% RPC and 50% NC and two specimens with NC only.

The experimental results showed that:

-

- the use of layered concrete reduced the deflection at failure to an average of 16.2%;

-

- layered concrete contributed to an average reduction in strain in the reinforcement at failure of up to 25.5%;

-

- layered concrete helped to reduce the strain in concrete at failure to an average of 45.6%;

-

- the use of carbon fibre-reinforced plastic as a top layer contributed to the strength of the specimens, increasing the maximum impact load at failure to an average of 44.5%.

In a study [12], it was demonstrated that ultra-high performance concrete (UHPC) has significantly higher tensile strength compared to normal concrete (NC). In this paper, the application of UHPC to the precast base plate of composite slabs was proposed, leading to the development of a reinforced truss UHPC-NC composite slab. This approach effectively improved the crack resistance of the slab. A finite element model (FEM) for the UHPC-NC reinforced composite slab was developed based on the ABAQUS (2016) platform using appropriate material relationships for UHPC, NC and steel reinforcement. The validity of the model was verified by comparison with the corresponding test results. Then, the effects of parameters such as cross-sectional area of the top and bottom trusses, reinforcement ratio of the precast base plate, strength class of the UHPC base plate and thickness of the UHPC base plate on the flexural capacity of the UHPC-NC composite slab were investigated. Equations were proposed to calculate the flexural strength of UHPC-NC composite slab.

It was found by the conducted studies that the cracking load, yield load and ultimate load of the slab increased with the increase of UHPC grade in the precast base plate. The proposed equations for calculating the flexural capacity of the reinforced truss UHPC-NC composite slab in normal section agreed well with the simulation results, providing theoretical and numerical support for the design and analysis of UHPC-NC composite slabs.

In [13], a new composite slab system consisting of permanent textile reinforced concrete (TRC) formwork (TRC deck) with trapezoidal cross-section is proposed. A methodology for the design of composite slabs is presented and validated with experimental data. The use of TRC structures has great potential: the average increase in flexural load-bearing capacity is 10% due to the change in geometry, and when going from 2 layers of GFRP reinforcement to 3 and from 2 to 4 layers, the average increase is 113.3 and 302.3%, respectively.

The presented analytical model allowed the calculation of the ultimate load, providing greater visibility with respect to Ultimate Limit State (ULS) design.

In the experimental study [14], unilaterally reinforced concrete slabs were strengthened with high performance fibre reinforced cement composite (HPFRCC) laminates in the tensile zone of the slab. Their lateral surfaces were then strengthened with carbon fibre reinforced polymer laminates to increase the shear strength. In the first step, the mixing design and mechanical properties of fiber-reinforced cement composites were investigated. In the second step, the flexural strength of the fibre reinforced cement composite laminates was determined separately

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES before bonding to the slab. In the final step, shear and strength tests were carried out on the reinforced concrete slabs. The results showed that the strengthening of the lateral sides of the specimens was improved the flexural capacity, fracture pattern, stiffness, and energy absorption by examining the shear behavior of the specimens.

The addition of HPFRCC laminate increased the strength of the strengthened specimens compared to the control specimen. Addition of carbon fibre reinforced plate for shear strengthening of the slabs resulted in increased strength and ultimate load.

In [15], a finite element (FE) model of reinforced concrete two-way slab strengthened using fiber-reinforced polymer (FRP) sheets. This model was validated against experimental data from the literature and it showed acceptable prediction accuracy. Although car-bon-FRP (CFRP) is the most commonly used composite in repairing and strengthening reinforced concrete structures, it is important to consider other types of FRP composites such as the eco-friendly basalt-FRP (BFRP) and the newly developed polyethylene terephthalate-FRP (PET-FRP). Therefore, the validated FE model was utilized to perform a parametric study for slabs having different values of concrete compressive strength (ranging from 20 to 80 MPa) and strengthened with other types of FRP. The results show that CFRP provides the highest strength enhancement with a 34.5% increase in the ultimate load, while PET-FRP provides the lowest improvement with an increase of 11.2%, compared with unstrengthened slab. The results also show that the concrete compressive strength (fc’) has moderate influence on the ultimate load. For example, increasing fc’ from 20 MPa to 80 MPa increased the predicted ultimate load for CFRP-strengthened slab from 15% to 62%. The FE model provides a suitable prediction for the ultimate strength and deformability of the strengthened two-way slabs that helps in better understanding of the performance of strengthened slabs and allows engineers to optimize design parameters.

In an experimental study [16] of the behaviour of reinforced concrete slabs subjected to punching wetested thirteen slabs with different configurations (control slabs, reinforced slabs, and reinforced slabs after preloaded). Tests showed that the effect of reinforcement with CFRP was an increase in the breaking load. The effect of strengthening with CFRP on preloaded slabs. With regard to this last test category we raise the following points:There is an increase in the tensile strength of reinforced slabs compared with control slabs.The area and the thickness of the CFRP have a considerable effect on the load in reinforced slabs and reinforcedslabs after preloaded.The CFRP reinforcement provides significant gains (resistance), which explains that the CFRP plays the role ofa weaver.Strengthening with CFRP can prevent the growth of thickness cracks by smaller cracks.The ultimate load of repaired slabs is increase by 10–30% for slabs preloading by 60% and 6–30% forslabs preloading by 80%.

The paper [17] presents the following technical ideology. The field of construction renews and develops itself every day, both in terms of materialsand techniques. After the 2000s, the use of FRP (fiber reinforced plastic) composites hasbecome widespread, especially in retrofit techniques. Retrofit is required for buildings that have-reached the end of their useful life or have lost their loadbearing capacity due to damage fromnatural disasters such as earthquakes. In addition, building owners or the ministry may want torevise their structures in line with the evolving regulations. In all these cases, it is known that-there are many different retrofit methods depending on the current condition of the structure.With the widespread and developing use of FRP, the retrofit technique with FRCM (fiber-reinforced cementitious matrix) composite has emerged. In this study, the subject of reinforcingflat slabs using FRCM, which has advantages and disadvantages for building earthquake safety,was discussed. Thus, it is aimed to investigate and reveal the effects of the FRCM retrofittingmethod on the structural rigidity of buildings using flat slabs and therefore on earthquake safety.As a result of this study, it was observed that retrofitting flat slabs with FRCM contributedpositively to the structural rigidity. The use of FRCM can be preferred in retrofitting flat slabsin reinforced concrete buildings.

In study [18] the flexural behavior of one-way concrete slabs reinforced with a grid-type carbon FRP (CFRP) (carbon grid), in the form of strands with embossed surfaces, was experimentally investigated. The experimental variables included the effective depth, number of carbon grid layers, and concrete compressive strength. The results exhibit that the surface embossing of the CFRP strands effectively improves their bonding with concrete based on the crack formation pattern. Concrete specimens reinforced with carbon grids exhibited an increased maximum load and stiffness as the effective depth, number of carbon grid layers, and concrete compressive strength increased. Among the experimental variables, the effective depth exhibited the greatest influence on the flexural behavior of the carbon-grid-reinforced concrete specimen. Furthermore, the ratios of the experimental to calculated flexural strength values for all carbon-grid-reinforced concrete specimens ranged from 0.74 to 1.22. Based on the results, a trilinear load-deflection curve was proposed to simulate the flexural behavior of carbon-grid-reinforced concrete members, considering the bond property between the concrete and the carbon grid. The proposed trilinear load-deflection curve reasonably simulated the flexural behavior of the specimens reinforced with carbon grids.

Paper [19] presents a programme of experimental research aimed at evaluating a retrofit method that uses high-strength, lightweight, corrosion-resistant composite materials to rehabilitate existing reinforced concrete slabs.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

The proposed method consists of using basalt textile reinforced mortar to increase the stiffness and flexural strength of concrete slabs. A total of seven full-scale reinforced concrete slabs were fabricated and tested under load at four points. When basalt textile reinforced mortar was used, depending on the amount of textile, the flexural strength of the slabs increased from 177 to 266%.

It is noted, however, that:

-

- the initial cracking load, yield load and ultimate load increase with increasing number of layers;

-

- deformation in steel and concrete decreases with increasing number of TRM layers;

-

- at the same reinforcement ratio, the reducing of the mesh size resulted in a 27% increase in the ultimate load-bearing capacity of the specimens, as the bond between textile and mortar is enhanced;

-

- The use of a mechanical anchor in the specimen increased the ultimate loads by 20%.

The study [20] presents the development of a new reinforced concrete (RC) slab strengthening method using carbon fibre reinforced polymer (CFRP) rods and ultra-high performance concrete (UHPFRC) external jacket with a Mechanical Anchorage System (MAS). The mechanical anchoring system includes two components: high-carbon steel plates and the Mechanical Expansion Anchorage Bolt System (MEABS). It is used to prevent premature failure of the bond between the existing concrete surface and the external strengthening layers (CFRP rods and UHPFRC jacket). The effectiveness of the proposed strengthening method was evaluated by conducting experimental tests on several strengthened slabs by applying cyclic loads using a dynamic actuator. For this purpose, three different concrete slabs were tested to evaluate different design parameters including a control slab, a slab strengthened with UHPFRC jacket only, and a slab strengthened with CFRP rods at the bottom of the slab with an external UHPFRC jacket. Experimental test results showed that the proposed strengthening system significantly improved the load capacity of the slab and prevented premature debonding failures between the old concrete of the slab and the new UHPFRC layer until the stage of slab failure.

The finite element modelling (FEM) results showed a high level of agreement with the experimental results and accurately predicted the maximum load and deflection, closely matching the values obtained from the experimental tests.

The analyzed studies [1-20] have shown the existence of new directions in strengthening of reinforced concrete structures with composite materials and the depth of their elaboration.

At the same time, experimental studies were carried out in laboratory conditions, which differ from the actual

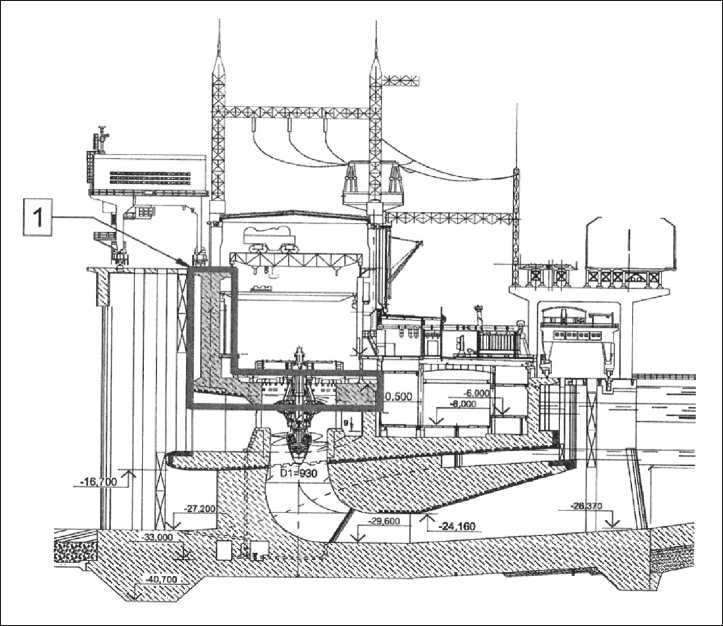

Fig. 1. Cross section of the run-of-river HPP powerhouse along the stream: 1 – headwall with a slap of the turbine hall

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES operating structures, including power facilities. At the same time, certain assumptions were naturally made in the modelling experiments and, first of all, the scale factor and similarity coefficients when extending experimental results to full-scale structures were not taken into account.

Also, the laboratory experimental studies did not use embedded instrumentation (measurement of actual deformations of metal reinforcement, composite fabric, etc.), which is extremely necessary to ensure the safe operation of reinforced concrete structures after their strengthening with composite materials to control the effectiveness.

In the laboratory experiments on reinforced concrete structures strengthened with composite materials, no or little data are available on the influence of the carbon tape (or fabric) application method on the safe operation of electrical equipment, on the redistribution of stresses between the steel reinforcement and composite reinforce- ment material, which is necessary for full-scale structures in terms of the joint work of concrete with external reinforcement composite materials and, accordingly, to ensure long-term safe operation of facilities.

The cross section of the run-of-river HPP powerhouse along the stream is shown in Figure 1.

In order to visualize the tasks being solved in these studies, the cross section of the run-of-river HPP powerhouse along the stream is presented (Fig. 1).

During the last 20 years the load-bearing structures of turbine halls of a number of HPPs have been inspected. Intensive cracking in reinforced concrete slabs, reduction of bearing capacity and the need for their strengthening were revealed.

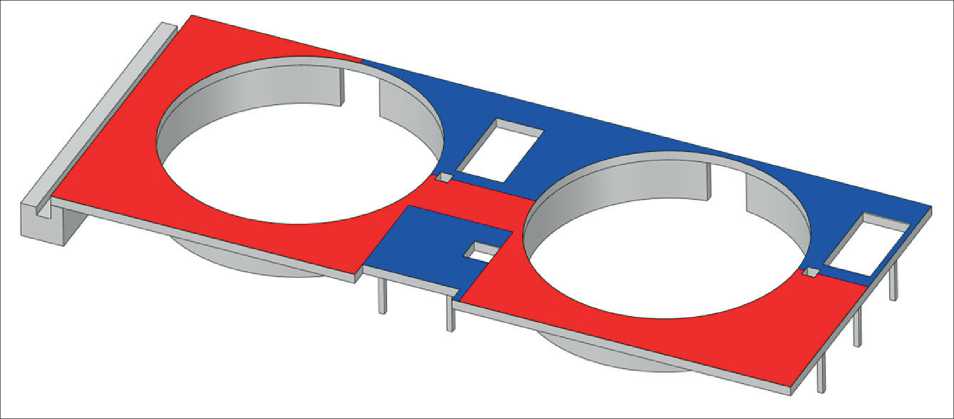

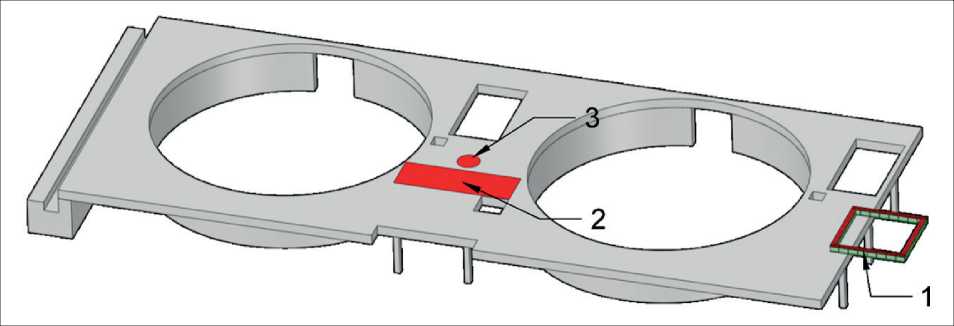

For example, a comparison of the allowable loads on the turbine hall floor slab and non-design loads are shown in Figure 2 and Figure 3.

Fig. 2. Permissible operational loads on the slab: before cracking detection – red zone – 0.049 MPa, blue zone – 0.01 MPa; after cracking detection – red zone – 0.01 MPa, blue zone м 0.01 MPa

Fig. 3. Distributed load: 1 – from the generator rotor (1.165 MPa); 2 – from the traverse (0.089 MPa); 3 – from the runner chamber (0.637 MPa)

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Unprojected slab loads (Figure 3):

-

a) in the area of the inter-sectional joint between the two slab sections, a temporary location for the installation of a generator rotor with an equivalent load of 1.165 MPa has been organized;

-

b) a traverse was installed between two hydraulic units for joint operation of cranes; the supports of the traverse were in the zones of permissible load 0.01 MPa (2 supports) and 0.049 MPa (2 supports); the actual bearing area of the traverse was 2 m2 for four supports, with

the agreed area of 17.116 m2, the load on one support is equivalent to 0.089 MPa, which exceeds the permissible value of 0.049 MPa.

-

c) due to processing necessity, a runner chamber with an equivalent load of 0.637 MPa was located on the slab.

As noted above, the practical situation in the operation of reinforced concrete structures of HPP in a number of cases leads to the need for strengthening with composite materials.

To be continued