Fatty acid composition of soft whey cheese

Автор: Zhakupova G.N., Tultabayeva T.Ch., Sagandyk A.T., Kalemshariv B., Nurtayeva A.B., Toregeldy Z.S.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 4 (142), 2023 года.

Бесплатный доступ

Due to the existing environmental and economic situation, there is a tendency to produce new food products with a balanced composition and beneficial properties for the human body. In this context, new groups of products are appearing on the market, whose composition and properties differ from the standards. The key factor for the nutritional and biological value of products is again the fatty acids, which consist of saturated and unsaturated acids. Saturated fatty acids are carbon chains with a number of 4 to 30 or more atoms, found mainly in animal fats. Their function is to saturate the body with energy. Excessive saturation with fatty acids leads to a disturbance in fat metabolism and an increase in blood cholesterol levels. Unsaturated fatty acids are part of the components of cells and tissues, provide growth and metabolism, as well as the elasticity of blood vessels. The studied soft whey cheese was made from whey and is a new product of the dairy industry. In this work, the indicators of soft whey cheese such as proteins, fats, moisture, dry matter as well as fatty acid composition of the product are studied. From the analysis results, it is found that the product contains unsaturated fatty acids and its lipid composition has an optimal balance.

Whey soft cheese, nutritional value of cheese, whey, fatty acid composition of soft cheese, saturated fatty acids, unsaturated fatty acids

Короткий адрес: https://sciup.org/140303458

IDR: 140303458 | DOI: 10.48184/2304-568X-2023-4-138-144

Текст научной статьи Fatty acid composition of soft whey cheese

Every year the situation in the country and in the world changes. Dairy production as a source of vital products is subject to change due to economic, political and demographic factors. The demand for milk and dairy products, as well as for functional and dietary products, is increasing among citizens of all ages [1]. In this context, new product groups are appearing on the market whose composition and properties differ from the standards. The most important criteria for the nutritional value and biological value of products are, in turn, fatty acids, which consist of saturated and unsaturated acids. Saturated fatty acids are carbon chains with a number of 4 to 30 or more atoms, found mainly in animal fats [3]. Their function is to saturate the body with energy [2-3].

According to the framework of the national project for the development of the agro-industrial complex of the Republic of Kazakhstan for 20212025, subsidies are provided to processing enterprises for the purchase of agricultural products for the production of deep processed products (butter, milk powder, hard cheese) [4]. This measure was taken due to a shortage of raw milk for the production of a sufficient number of dairy products [5], as only 1.7 million tons of commercial milk for processing are obtained when dairies need 2.2 million tons of raw materials. In this regard, it is clear that the development of a waste-free technology for dairy products using secondary waste of dairy products, namely whey, is an urgent task in the modern life [5].

In the dairy farming, the range of products made from condensed whey, especially soft cheeses, is not very diverse [1]. In this regard, the development of a resource-saving technology for a new type of soft cheese from the raw material complex, which includes the main and secondary raw materials of the dairy industry, is relevant and economically justified [6-7].

In this study, several samples of soft cheese from whey were developed. The aim of the investigation is to study and analyze the composition of the obtained samples.

Materials and methods of research

The following samples of soft whey cheese were selected as study subjects:

-

- Sample 1 - Soft whey cheese made from whey, condensed whey and pasteurized whole milk.

-

- Sample 2 - soft whey cheese made from condensed whey and skimmed pasteurized milk.

The following physicochemical methods were used in the scientific research:

-

1. Determination of moisture content by drying in a drying oven at a temperature of 105 0C and by an accelerated method on a Chizhova apparatus according to State Standard 3626-73 [8].

-

2. Determination of titrated acidity according to State Standard 3624-92 [9].

-

3. Determination of active acidity (pH) according to State Standard 32892-2014 [10].

-

4. Determination of protein mass fraction according to State Standard 23327-98 [11].

-

5. Determination of dry matter content in food – State Standart 3626-73 [8].

-

6. Determination of fatty acid composition of fat phase by gas chromatography according to State Standart 32915-2014 [12].

An experimental batch of whey cheese was produced in the experimental dairy processing production workshop of S. Seifullin KazATRU using the developed starter culture.

As a result of laboratory tests, the temperature of heat treatment of the whey-milk mixture of 60-650C and the duration of heat treatment of 15 minutes were considered optimal, since under these conditions the maximum amount of coagulation was achieved to obtain a dense cheese mass.

The technological scheme for the production of whey cheese includes the following operations: acceptance and purification of whey, determination of the acidity of the whey, mixing of whey with pasteurized milk in a ratio of 70/30 (%) or cream with a fat content of 10% in a quantity of 90/10, normalization of the mixture, pasteurization of the mixture at a temperature of 90-950C, cooling of the mixture to the fermentation temperature, the addition of citric acid in a quantity of 2% and 3-5% LEL starter culture, fermentation of the mixture at a temperature of 32-330C for 30-60 minutes. To achieve better coagulation of proteins, the mixture is heat treated at a temperature of 60-65 0C for 15 minutes. The coagulum formed is collected and separated into molds. The resulting cheese mass is packaged and then stored.

Literature review

In view of the great demand from consumers, many companies in the food industry are now developing a fundamentally new generation of foods that meet the standards of healthy nutrition. With the help of advanced biotechnological techniques combined with food manufacturing methods, it is possible to produce milk and dairy products that are balanced in composition and properties and have proven physiological and biochemical properties [13].

By using innovative methods of processing raw materials in the dairy industry ensures a more complete and rational use of all components of milk. The most important by-product in the dairy industry is whey. For a long time, it was considered an undesirable component (waste) in cheese processing and was either fed to animals or processed as wastewater. In recent years, environmental protection requirements have become stricter, and one must consider the possibility of costly construction and operation of wastewater treatment plants [14].

Effective use of secondary dairy raw materials, especially whey, is an important reserve for increasing the volume of dairy products produced. In many companies of the dairy industry, the problem of rational processing of whey, which is a by-product of cheese and cottage cheese production and contains about 50% of milk solids, has not yet been fully solved. This harms the environment and increases the likelihood of environmental risks, as the pollution capacity of whey exceeds the same indicator for domestic wastewater by 500-1000 times [15-17].

The development of functional, healthy foods, including dairy products, and the improvement of traditional general food products are the main directions of processing raw materials to obtain health-promoting foods [16].

The composition of whey characterizes its high nutritional and biological value and determines the advisability of using whey as a basis for the production of products with functional properties that have a positive effect on many physiological functions in the human body. The possibility of whey as a raw material in the production of dairy goods has several positive factors [18].

Whey is obtained by rennet coagulation of milk with the addition of lactic acid bacteria cultures (in the form of a starter culture) and calcium chloride. The whey obtained by acid coagulation of milk as a result of the accumulation of lactic acid (the result of lactose fermentation) is called sour or curd [14].

The composition of whey is diverse and consists of many useful substances. The proteins of whey have important biological functions. Thus, immunoglobulins have a protective function as they are carriers of passive immunity, lactoferrin and lysozyme, which are related to milk enzymes, have antibacterial properties, beta-lactoglobulin has a transport function — they transport iron, vitamins and other important compounds to the intestine of a newborn. Whey protein a-lactalbumin has a special function: it is necessary for the process of lactose synthesis [19].

It is known that whey protein can be incorporated into cheese by various pretreatments of the original milk, such as heating, membrane technology, high hydrostatic pressure, homogenization under ultrahigh pressure, transglutaminase treatment, or hybrid variants of the previously described treatment methods. Furthermore, the addition of whey protein preparations (e.g., whey protein concentrate/isolate, whey protein microparticles) to cheese milk leads to cheese fortification [15]. Considering the abovementioned positive properties of whey, it was decided to use it in the formulation of soft cheese.

Results and their discussions

To obtain whey cheese, the necessary studies were carried out to determine the physicochemical composition in two variants of cheese:

Sample 1 – whey cheese obtained from whey.

Sample 2 – whey cheese produced with condensed whey.

The analytical data are given in Table 1.

Table 1 – Physicochemical parameters of the studied samples

|

The name of the indicator |

Sample 1 |

Sample 2 |

|

Protein, g/100g |

21,12 |

36,3 |

|

Fats, g/100g |

3,9 |

3,9 |

|

Moisture, % |

63,5 |

54,08 |

|

Dry substances g/100 g |

36,5 |

45,92 |

From the data obtained, whey cheese falls into the category of low-fat soft cheese. Whey cheese contains a sufficient amount of protein and dry matter.

The study of the general chemical composition of lipids of food products allows you to get an approximate idea of the biological value of the product. As necessary components of food, lipids should be present in the diet in certain amounts and ratios to other foods [19].

The study of the lipid composition of the product helps to assess its biological value. The composition of lipids included in the component structure of products should be balanced in terms of fatty acid composition. A high content of polyunsaturated fatty acids and a low content of trans fats indicate the positive properties of the product. The triglycerides in all cheeses are hydrolyzed by the action of lipases, which leads to the release of free fatty acids in the cheese during ripening [20].

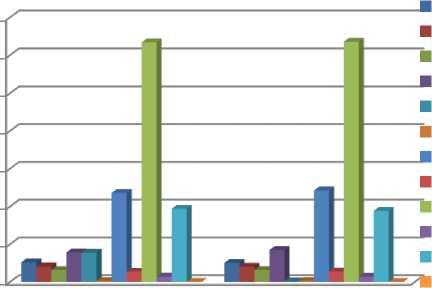

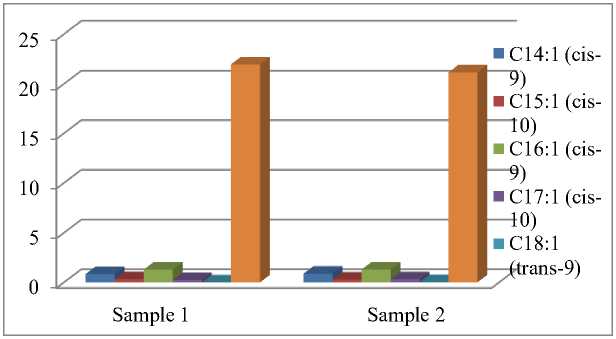

The main fatty acid indicators of whey cheese samples are shown in Figure 1-3.

Sample 1

Sample

С4:0

С6:0

С8:0

С10:0

С11:0

С13:0

С14:0

С15:0

С16:0

С17:0

С18:0

С20:0

Figure 1- The composition of saturated fatty acids (in %) in the studied samples

Figure 2- The composition of monounsaturated fatty acids (in %) in the studied samples

Figure 3- Composition of polyunsaturated fatty acids (in %) in the studied samples

10 saturated fatty acids, 6 monounsaturated fatty acids and 5 polyunsaturated fatty acids were found in the raw materials studied. Saturated fatty acids are present in small amounts, except palmitic acid, myristic acid and stearic acid, which account for 31.686%, 11.79% and 9.715% in sample 1 and 31.775%, 12.12% and 9.426% in sample 2, respectively. In the case of monounsaturated fatty acids, 6 indicators were determined, the highest of which was oleic acid with a content of 21.936% in sample 1 and 21.150% in sample 2. Besides, 4 polyunsaturated fatty acids were found in the investigated raw materials. Of the polyunsaturated fatty acids, linoleic acid had the highest content, 4.207% in sample 1 and 4.269% in sample 2. At the same time, sample 2 contains slightly more saturated fatty acids and polyunsaturated fatty acids in comparison to sample 1. However, in comparison with ordinary pasta filata cheeses [21] mozzarella has a higher content of free fatty acids, such as decanoic acid (120 mg/kg), and palmitic acid (76 mg/kg).

Condusions

The high content of monounsaturated and polyunsaturated fatty acids confirms the biological and nutritional value of the studied product. The content of 21 fatty acids was detected in these samples. Thus, overall studied products have a good combination of fatty acids.

Gratitude, conflict of interest (financing)

The presented research was carried out under the Programme Objective Fund BR 21882184 “Development of a food safety system based on the creation of a set of measures for risk analysis at all stages of the life cycle of food products”, and the Programme Objective Fund BR10764998 “Development of technologies using new strains of beneficial microorganisms, enzymes, nutrients and other components in the production of special dietary foods”, the subproject “Development of a resource-saving technology for the production of economy-class dairy products from whey (whey cheese, soft drinks and starch drinks)”.

Список литературы Fatty acid composition of soft whey cheese

- Muehlhoff E., Bennett A., McMahon D. “Milk and dairy products in human nutrition” Food and agriculture organization of the united nations, Rome, 2013:376 https://www.fao.org/3/i3396e/i3396e.pdf

- Zaiceva, L.V. “Rol’ razlichnih zhyrnih kyslot v pitanii cheloveka I pri proizvodstve pishevih productov [The role of various fatty acids in human nutrition and in food production]” Food industry. Vol.10, 2010:60-63.

- Samigullin, D.I., Ezhkova, A.M., Volkov R.A., Ezhkov V.O. Zhirnokislotnii sostav molochnih productov pri ih modifikacii (falcifikacii) [Fatty acid composition of dairy products during their modification (falsification)]” Scientific notes of the Kazan State Academy of Veterinary Medicine named after N. E. Bauman, vol.6, no.2, 2021:194-197.https://kazanveterinary.ru/wp- content/uploads/2021/06/246-945-MB.pdf

- "Kazakhstanu neobkhodimo sokhranit sobstvennoe proizvodstvo moloka [Kazakhstan Needs to Preserve Its Own Milk Production]". Dairy News Qazakhstan, 2023. URL: https://dairynews.today/kz/news/kazakhstanu- neobkhodimo-sokhranit-sobstvennoe-proi.html.

- Zandona, E., Blažić, M., & Režek Jambrak, A. “Whey utilisation: Sustainable uses and environmental approach” Food Technology and Biotechnology Vol. 59, Issue 2. 2021. https://doi.org/10.17113/ftb.59.02.21.6968

- Syrai, N.M “Issledovanie I razrabotka resursosberegajushei technologii proizvodstva mjagkogo sira iz sgushenoi podsyrnoi syvorotki [Research and development of resource-saving technology for the production of soft cheese from condensed cheese whey]” Dissertation of Candidate of Technical Sciences for the degree, Kemerovo, 2011. https://tekhnosfera.com/issledovanie-i-razrabotka- resursosberegayuschey-tehnologii-proizvodstva- myagkogo-syra-iz-sguschennoy-podsyrnoy-syvorotki

- Tirishkina, M.E. “Issledovanie I rasrabotka tehnologii mjagkogo sychuzhnogo syra iz koncentrirovanogo moloka [Research and development of soft rennet cheese technology from concentrated milk] abstract of the dissertation on the topic 'Technology of meat, dairy and fish products and refrigeration industries (tekhnosfera.com)

- State Standart 3626-73. Milk and dairy products. Methods for determining moisture and dry matter. https://docs.cntd.ru/document/1200021586

- State Standart 3624-92. Milk and dairy products. Titrimetric methods for determining acidity. https://docs.cntd.ru/document/1200021584

- State Standart 32892-2014 Milk and dairy products. Method of measuring active acidity. https://docs.cntd.ru/document/1200114186

- State Standart 23327-98 Milk and dairy pro- ducts. The method of measuring the mass fraction of total nitrogen by Kjeldahl and determining the mass fraction of protein.https://docs.cntd.ru/document/1200021650

- State Standart 32915-2014 Milk and dairy products. Determination of the fatty acid composition of the fat phase by gas chromatography https://docs.cntd.ru/document/1200115746

- Pas'ko, O. V., Kulikov, D.A., Burakovskaya, N.V. “Resursosberegayushie technologii proizvodstva kulinarnoi produkcii iz bezsyvorotochnogo tvoroga s rastitel’nimy komponentamy[Resource-saving technologies for the production of culinary products from serum-free cottage cheese with vegetable components]” Food processing industry, no. 7, 2019:67-69.

- Oesen, T., Treblin, M., Staudacher, A., Clawin-Rädecker,I., Martin, D., Hoffmann,W., Schrader,K., Bode,K., Zink,R., Rohn,S., Fritsche J. “Determination and evaluation of whey protein content in matured cheese via liquid chromatography” LWT Vol.174, 2023:114-347. https://doi.org/10.1016/j.lwt.2022.114347

- Gabrieljan, D.S., Grunskaja, V.A. “ Resursosberegajushaja technologija obogashenih kislomo- lochnih napitkov [Resource-saving technology of enriched fermented milk drinks]” Food industry no.8, 2014:12-14. https://cyberleninka.ru/article/n/resursosberegayuschaya- tehnologiya-obogaschennyh-kislomolochnyh-napitkov

- FGBOU-VO-Vologda GMHA “Razrabotka receptur I technologi’ pererabotki selskohozjaistvennoi produkcii (ispol’zovanie koncentrata tvorozhnoi sivorotki) v ekologicheskie chistye funkcional’nie producty sportivnogo pitaniana osnove molochnogo I nemolochnogo sir’ja [Development of recipes and technologies for processing agricultural products (using curd whey concentrate) into environmentally friendly functional sports nutrition products based on dairy and non-dairy raw materials]” (Том 2) - Отраслевая сеть инноваций в АПК (apknet.ru)

- Ivkova, I.A., Chetvergovan, I.G. “Razrabotka I issledovanie specializirovannih molochnih productov zdorovogo pitania po pokazateljam kachestva I funkcional’noi napravlennosti [Development and research of specialized dairy products of healthy nutrition in terms of quality and functional orientation]” Bulletin of the Omsk State Agrarian University, no.2 (46),2022:100-106. DOI 10.48136/2222-0364 2022 2 100 file:///C:/Users/Jacalope/Downloads/razrabotka- i-issledovanie-spetsializirovannyh-molochnyh- produktov-zdorovogo-pitaniya-po-pokazatelyam- kachestva-i-funktsionalnoy-napravlennosti.pdf

- Gricaeva, M.V., Hramcov, A.G., Serov, A.V. “Perspectivy proizvodstva I ispol’zovanija prodyktov okislenija I vostanovlenija lactozy [Prospects for the production and use of lactose oxidation and reduction products]” Actual problems of equipment and technology of milk processing: collection of scientific tr. with international involving GNU SibNIIS, Vol. 5, 2008:308-311. https://viewer.rsl.ru/ru/rsl01004970593

- Donskova, L.A., Beljaev H.M., Leiberova, N.V. “Zhirnokislotni’ sostav lipidov kak pokazatel’ funkcional’nogo naznachenija productov iz mjasa pticy: teoreticheskie I prakticheskie aspect [Fatty acid composition of lipids as an indicator of the functional purpose of poultry meat products: theoretical and practical aspects]” Food industry, Ch. 3, no.1, 2018:4-10. DOI:10.29141/2500-1922-2018-6-1-1. https://foodindustry.usue.ru/images/6/1.pdf

- Prandini, A., Sigolo, S., & Piva, G. A comparative study of fatty acid composition and CLA concentration in commercial cheeses. Journal of Food Composition and Analysis, 24(1), 2011:55–61. https://doi.org/10.1016/j.jfca.2010.04.004 https://thescipub.com/pdf/ajavsp.2021.136.143.pdf

- Thierry, A., Collins, Y. F., Abeijón Mukdsi, M.C., McSweeney, P. L.H. , Wilkinson, M. G., Spinnler,

- H. E. Chapter 17 - Lipolysis and Metabolism of Fatty Acids in Cheese, Editor(s): Paul L.H. McSweeney, Patrick F. Fox, Paul D. Cotter, David W. Everett, Cheese (Fourth Edition), Academic Press, 2017:423-444, https://doi.org/10.1016/B978-0-12-417012-4.00017-X