Fine grinding of raw meat using the emulsifiers with a new cutting mechanism

Автор: V.Y. Grudanov, A.A. Brench, L.T. Tkacheva, A.A. Ryndin, G.N. Egorova

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Процессы и аппараты пищевых производств

Статья в выпуске: 3 (89), 2021 года.

Бесплатный доступ

The efficiency of fine grinding largely of raw meat in emulsifiers depends on design and geometrical parameters of the cutting pair “knife- hole plate” and the process modes, and also on the dynamic and kinematic characteristics of the system: machine – cutting instrument – raw materials. The disclosure of the essence of the ongoing processes when fine and ultrafine grinding of raw meat is the basis for improvement of equipment in operation and creation of new working parts of machines. The new grinding hole plates of the emulsifier, according to the developed mathematical model, have the same flow capacity over the entire working surface and equal hydraulic resistance due to a decrease in the thickness of the hole plates when switching to smaller perforation holes. The cutting edges of the knife blades are made obliquely tangentially to the inner radius of the grinding hole plate and have a maximum length, which ensures a high-quality slipping cutting process. An experimental stand containing industrial emulsifier KS F10/031 and test and measuring equipment was made for research in the sausage-making shop of the JSC “Oshmyany meat processing plant”. Based on experimental data and analysis of the significance of the influence of each input parameter, analytical and graphical dependences were obtained, which makes it possible to determine the temperature increase, the efficiency of the emulsifier, and the specific energy intensity of the process when changing the operating and designing parameters of the process within the range of varying factors. Production tests of new cutting tools pilot samples were passed successfully in the sausage-making shop of the JSC “Oshmyany meat processing plant”. They showed an increase in the performance of emulsifiers by 12–15% with higher-quality fine grinding and a decrease of 10–15% in specific energy consumption per unit of final output.

Raw meat, emulsifier, cutting mechanism, knife, hole plate, cutting edge, slip coefficient, flow capacity

Короткий адрес: https://sciup.org/140259859

IDR: 140259859 | УДК: 664.66.047:536.024(021) | DOI: 10.20914/2310-1202-2021-3-38-45

Текст научной статьи Fine grinding of raw meat using the emulsifiers with a new cutting mechanism

Груданов В.Я. и др. Вестник ВГУИТ, 2021, Т. 83, №. 3, С. 38-45 Introduction

A modern large-scale meat processing enterprise operates more than 400 units of technological equipment and complex machines. The major part of them is intended for grinding different kinds of raw meat: from fallen stock parts, blocks of trimmed meat and by-products to mincemeat preparation and its further use.

According to the degree of grinding the operating equipment of meat processing plants can be divided into the machines for course, medium, fine and ultrafine grinding (meat shredders, cutters, colloid machines, emulsifiers, etc.). Besides the type of grinding depends on the way the cutting instruments affect the basic material, and fine and ultrafine grinding is characterized by application of cutting, crushing and attrition. Fine and ultrafine grinding is principally marked by crumbling and the final goal of the operation is to receive a homogeneous mass with definite structural and mechanical characteristics making it different from raw products. The working element used for fine grinding is a set of multiblade knives with hole plates, crescentshaped knifes or a kit of combined cutting parts having a special form. When going from medium to ultrafine grinding the particle size decreases by more than 100 times. The process of grinding in this case is considerably influenced by the structure and physical and mechanical features of the product, functional and geometrical parameters of the cutting instrument, technical performance, the state of the grinding machine and accuracy of adjustment. All these factors must be taken into account when designing machines and its operating equipment that are mainly represented by a cutting pair “knife – hole plate” [1-10].

So far, no scientific and methodological foundations have been laid for providing high-quality process of raw meat fine grinding; the design of the knives and hole plates are not interconnected and the structural features of the ground raw meat such as viscosity and elasticity have not been taken into consideration.

The efficiency of fine grinding largely depends on design and geometrical parameters of the cutting pair “knife – hole plate” and the process modes, and also on the dynamic and kinematic characteristics of the system: machine – cutting instrument – raw materials. The disclosure of the essence of the ongoing processes is the basis for improvement of equipment in operation and creation of new working parts of machines. Therefore, development of new designs of cutting instruments for raw meat fine grinding and manufacturing application is a primary task, the solution of which will increase equipment efficiency while improving the quality of the final product and reducing energy losses [11, 14-20].

post@vestnik-vsuet.ru Methods

The world-famous emulsifiers KARL SСHNELL (КS) have become commonly used at meat processing enterprises. The equipment of this German machine-building company enjoy traditional reliability and introduce on-going innovations aimed at creating economic equipment of high quality adapted for specific technological tasks. Today the machinery construction company KS is concentrating its activity on production of equipment for industrial processing of meat, pet food, delicatessen, processed cheese and confectionery.

The cutting mechanism KS consists of a knife head with two disposable blades which rotates together with a motor shaft and a disposable grinding hole plate which is immovably fixed in the cutting body. Due to the possibility of axial adjustment to regulate the interval between the knife insets and the grinding hole plate, it’s possible to control the capacity, temperature and the degree of grinding of the product. The knife heads with 3 and 6 disposable blades are also applied.

The standard option of machine KS contains:

-

1. The cutting system: two knife heads (3 or 6 rays); two replaceable hole plates (0.5–18 mm); an adjusting nut, two-blade extractor.

-

2. Microprocessor-based control;

-

3. Temperature monitoring of the product;

-

4. A folding unloading pipe;

-

5. A separate control panel;

-

6. A holding plate on the reception hopper.

The specifications of KS emulsifiers are shown in table 1.

As it is seen from table 1, the outside diameter of the hole plates varies between 86–225 mm; the diameter of the perforated holes in the hole plate ranges between 0.5–18 mm, and their number – from 90 to 6000 items, in this case the knife heads can have 2,3 and 6 blades (insets). The structural analysis of the cutting mechanism KS and study of the operational experience of emulsifiers of this company indicate the existence of significant drawbacks in the construction of the knife and hole plates, the main of them are summarized as follows:

-

• while decreasing the holes diameter and increasing their number, the flow (free) crosssection is reduced, which causes loss of efficiency and meat product quality, and increases normalized energy cost;

-

• the grinding hole plates of the standard machine set have equal thickness of 10 mm, which means that during raw meat grinding each grinding hole plate has a different hydraulic resistance, besides, while decreasing the holes diameter and increasing their number, the hydraulic resistance rises which causes steep increase in energy consumption right up to shut-off.

post@vestnik-vsuet.ru

Table 1.

Specifications of KS emulsifiers

Model

Knifeset diameter, mm

Funnel volume, l

Number of revolutions, rev/min

Engine power, KWh

Output capacity, kg/h

Mass, kg

FD 225/100

225

165

2975

74

3500

960

FD 225/130

225

165

2960

95

4500

1020

FD 225/140

225

165

2950

107

5500

1050

FV 175/30

175

30

1450/2900

7,5/10

*

500

FV 175/100

175

100

1450/2900

7,5/10

*

950

FV 175/160

175

160

1450/2900

7,5/10

*

1150

F28/F46/F75/F100/

KBFG

200/248/320

80-150

2880

21-74

1800-400

570

735

Desktop emulsifier

86

30

5700

5,5

90-800

85

F/F18/F25

150/200

50

2880

7-18

800-1800

100

210

* - the output capacity depends on raw materials, degree of grinding and the diameter of the holes in the plate

Thus, for instance, the calculations show:

-

— where the holes diameter d0 =10 mm. in a knife hole plate with the outside diameter D =200mm. and the number of holes Z = 90 the н 0

flow capacity coefficient K =0,248;

-

— where d 0 =5 mm.; Zo =362 items. and

D =200mm.; K =0,227; н

-

— where the holes diameter d 0 =1,2 mm. in a knife hole plate with the outside diameter D =200mm and the number of holes Z =5422 items., the flow capacity coefficient K =0,195.

The flow capacity coefficient characterizes the degree of utilization of the operating grinding hole plate and is defined as the ratio of total surface area of the holes to the total area of the grinding hole plate, i. e

К - Z f’ К f ’ • Z 0

K = — or K = , (1)

Fp Fp

Z f - the area of the holes, mm2.; Z o — the number of the holes, items; Fp - the area of the grinding hole plate.

On the hand, the technical efficiency of the machine is defined according to the formula

Qm = S'^ o ^ P e V 0 , (2)

Q - technical efficiency of the emulsifier kg/h; S - the area of the flow (free) cross-section of the grinding hole plate, m2; <90 - the speed of raw meat forwarding through the holes of the grinding hole plate, m/s; p - raw material density, kg/m3;

-

^ 0 - a utilization coefficient of the holes area in the grinding hole plate ( % = 0,8.. .0,9).

It follows from the formula (2) that for changing the hole plate for another one with smaller holes (from the same hole plates set) and

when S is reduced, there is a drop in Q , which is unacceptable. Grinding hole plates from the standard emulsifier cutting tool set must have an equal flow (free) cross-section between them despite the holes diameters and the number of holes, the geometric parameters of grinding hole plates must be linked by certain ratios.

A new formula for defining the number of holes in the grinding hole plate is proposed:

Z

n + 1

= Z n

d A

a

V n + 1 7

z n - the number of holes in the grinding hole plate with holes of the largest diameter; z n +1 - the number of holes in the grinding hole plate with holes of the smallest diameter; dn, dn +1 - holes diameter in hole plates with larger and smaller holes.

Applying this formula allows to obtain the same flow capacity for all hole plates from the standard set [5].

However, as calculations show, even if flow (free) cross-section is constant, the hydraulic resistance of the hole plate increases sharply as the diameter of holes decreases and the number

of holes is increased, which is the sum of local and linear pressure loss. In this case pressure loss (linear) ∆ρ can be significantly reduced by decreasing the thickness of the grinding hole plate, the new thickness of the hole plate must be defined according to the formula (the conclusion of the formula is presented in the thesis):

bn + 1

= bn

bn + 1 • Zn

bn • Zn + 1

in the case

∆ρn+ 1 =∆ρn ,

bn+ 1 - the thickness of the hole plate with the smallest diameter of holes; bn - the thickness of the hole plate with the largest diameter of holes; n - a sequence number of the grinding hole plate.

-

Thus, the application of this mathematical model and formulas (10) and (11) allows us to obtain:

─ the same flow capacity on the working surface of the grinding hole plate despite the hole diameters and the number of holes;

─ the constant value of flow (free) crosssection of grinding hole plates with different diameters of holes and the number of holes;

─ equal hydraulic resistance of hole plates when the holes diameter and the number of holes are changed.

Using formulas (3) and (4) the optimum parameters for the new grinding hole plates from the emulsifier cutting tool set can be determined, which are shown in table 2.

Table 2.

Constructional parameters of grinding hole plates

|

No |

Parameter |

Symbols |

Serial hole plates |

New hole plates |

||||

|

1 |

Outside grinding hole plate diameter, mm. Total hole plate area, mm2. Holes diameter, mm. The number of holes, items. Flow (free) cross- |

D H |

200 |

200 |

||||

|

2 |

F P |

314000 |

314000 |

|||||

|

3 |

d o |

10 |

5 |

1,2 |

10 |

5 |

1,2 |

|

|

4 |

Z o |

90 |

362 |

5422 |

90 |

397 |

6887 |

|

|

section area, mm2. |

||||||||

|

5 |

Flow capacity coefficient of the hole plate |

S |

77851 |

71092 |

61290 |

77851 |

77910 |

77859 |

|

6 |

K |

0,248 |

0,227 |

0,195 |

0,248 |

0,248 |

0,248 |

|

|

7 |

The thickness of grinding hole plates, mm. |

b |

10 |

10 |

10 |

10 |

5 |

3 |

From the data in table 2, you can see that new grinding hole plates with holes diameters of 10, 5 and 1.2 mm have the same flow (free) crosssection at K =const compared to the serial ones for which K ≠ const.

In addition, the reduction in the thickness of the new hole plates from 10 mm to 5 mm and up to 3 mm, respectively, determines the equality of hydraulic resistances in linear pressure losses. Thus, the new grinding hole plates provide the same efficiency of the emulsifier.

Cutting mechanism. Building a mathematical model

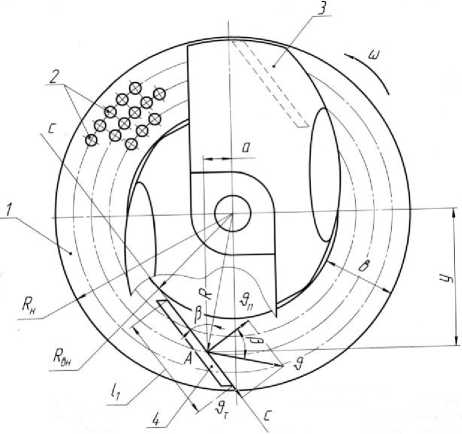

When slip cutting, the resistance to cutting through fibres and cell walls of meat product decreases as the slip angle increases or, likewise, as slip coefficient and the length of blade cutting edge increase. Therefore, in the system “knife-hole plate”, it is necessary to use not only the laws of slip cutting, but also the maximum length of blade cutting edge. Figure 1 shows the scheme for determining slip coefficient along the length of a straight blade in the friction pair “knife-hole plate”.

As shown in figure 1, the slip coefficient К β is determined according to the formula

V „а

К β = V r = tg β α (5) V n у

The blade cutting edge 4 of the rotating knife 3 passes along the tangent cc to the inner circle R вн , and in this case the length l of the blade cutting edge 4 will be maximum, and the slip coefficient К β has the largest value.

At point B ( у = 0), Vп = 0 and К β = ∞, i.e. there will be no cutting. As y increases, К β decreases. In this case у = соnst, К β increases with rising a. If а = 0 К β =0 – chop cutting takes place.

Figure 1. Scheme for determining slip coefficient along the length of a straight blade: 1 – grinding hole plate; 2 – perforation hole; 3 – rotating knife; 4 – knife blade; l – length of blade cutting edge; Rн – outer radius of the hole plate; Rвн – inner radius of the hole plate; C-C – tangent to the inner circle Rвн; V – linear velocity of an arbitrary point А; Vп – normal velocity; Vr – linear velocity component V; β – slip angle; a, у – coordinates of point A; R – rotation radius of point A; b – ring width

Thus, the location of the blade cutting edge is inclined tangentially сс to the inner circle Rвн of the grinding hole plate allows you to get the longest length l of the blade 4 and, as a result, create the best conditions for slip cutting and the grinding process as a whole.

As the slip coefficient К β increases, the total resistance forces to cutting the product Р and the normal component Рп decrease, which result in lower energy consumption of the grinding process.

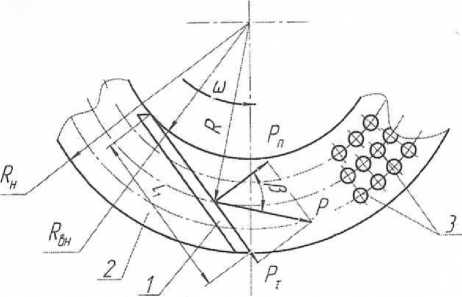

Figure 2. Scheme for determining the length of the blade cutting edge: Р – resistance force to cutting the product; Р п – force normal component Р; Р τ – force tangential component Р; β – slip angle

Normal Рп and tangential Рτ components of resistance to cutting Р (figure 2) are determined by the formulas:

Р п = Р cos β = ql cos2 β ; (6)

Р τ = Р sin β = ql sin β ·cos β (7)

q – specific product resistance per unit blade length, Н · m ; l – the length of the blade cutting edge used in cutting the product layer, m.

Р = q ■ l ■

^А+ К в

P n = q ■ i ■

1 + kJ ;

Р т = q ■ I ■

К в .

1 + Кв’

It follows from formulas (8–10) that as the slip coefficient К β increases, the total resistance

a forces to cutting Р and the normal component Рп decrease, in the case Рп is more significant than Р. The tangential component Рτ increases at first, reaching a maximum value at Кβ = 1, then it decreases, approaching P in magnitude.

From figure 2 we determine the optimal length of the knife blade cutting edge:

L = 4 в 2 + 2 R н ( R H - в )

b – ring width of the hole plate working surface.

Results and discussion

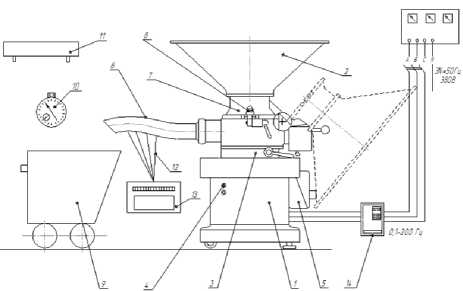

An experimental stand containing industrial emulsifier KS F10/031 and test and measuring equipment was made for research in the sausagemaking shop of the JSC “Oshmyany meat processing plant” (figure 3). The exterior of the experimental stand is shown in Figure 4. Raw meat pre-minced with the help of meat-shredder MP-1–160 was used as a sample in the experiments.

Figure 3. Experimental stand layout: 1 – frame; 2 – loading tank; 3 – filling neck; 4 – remote control; 5 – loading tank lock; 6 – meat spout; 7 – cutting mechanism; 8 – safety device; 9 – cart; 10 – timer; 11 – electronic scales; 12 – thermocouples; 13 – millivoltmeter; 14 – variable speed drive Delta VFD

b

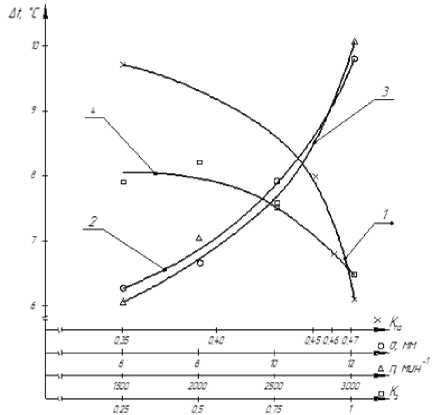

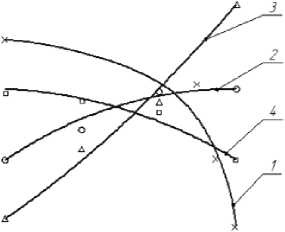

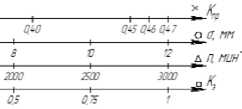

Figure 4. The results of the experiment 1 – К пр ; 2 – в , 3 – n вр , 4 – К з ; a – the dependence of the temperature increase on the controlled variables; b – performance dependence on the controlled variables; c – the dependence of the specific energy intensity of the emulsifier on the controlled variables

sx

0.25

c

After processing the experimental results, graphical dependences of the temperature increase, the efficiency of the emulsifier, and the specific energy intensity of the process from the controlled variables were obtained: flow cross- section coefficient of the hole plate, the thickness of the hole plate, rotation frequency and the filling factor of the funnel (figure 5).

Based on experimental data and analysis of the significance of the influence of each input parameter, analytical dependences were obtained (12–14), which makes it possible to determine the temperature increase, the efficiency of the emulsifier, and the specific energy intensity of the process when changing the operating and designing parameters of the process within the range of varying factors:

At = 0,003 8К -УСТ 0,63 n 0,66 пр

П = 70,53 К 1,05 n 0’51. пр

Пуд = 0,13 КПр/^ст0,15 n 0,44.

The adequacy of the calculated dependencies to the real process is evaluated and the measurement errors are analyzed.

Analyzing the obtained graphical and mathematical dependences, it was found that the greatest influence on the temperature increase is exerted by the cross-section coefficient of the hole plate, its thickness and the rotational frequency of the knife. Moreover, as it can be seen from the graphs, with the same degree of grinding (d o =10 mm), the use of the developed design of the cutting mechanism reduces the increase in the temperature of the raw material by 18.3% compared to the serial one. At do = 5 m, the use of a new cutting mechanism allows reducing the temperature increase by 15.1%.

The determining parameters that affect the performance are the flow cross-section coefficient of the hole plate and the rotational frequency of the knife. With the same degree of grinding (d o =10 mm), the use of the developed hole plate design increases productivity by 18.1% compared to the serial one. At d h = 5 m the use of a new cutting tool allows to increase productivity by 10.3%.

The main parameters of the studied ones affecting energy intensity of the fine grinding process are the flow cross-section coefficient of the hole plate, its thickness and the rotational frequency of the knife. As it can be seen from the graphs, with the same degree of grinding (do=10 mm), the use of the developed cutting mechanism allows reducing the specific energy intensity by 7.1%. The use of a new cutting mechanism with grid hole diameters of do = 5 mm allows to reduce the specific energy intensity by 10.8% [12-13].

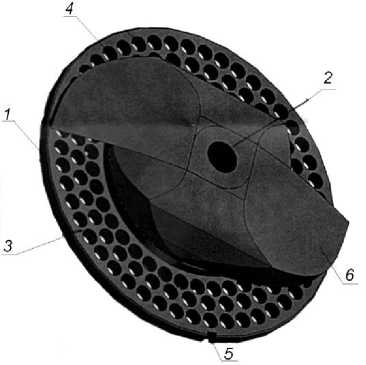

Figure 5. The exterior of the new cutting mechanism of the emulsifier: 1 – the base of the grinding hole plate; 2 – central fitment hole; 3 – working surface of the hole plate; 4 – perforation holes; 5 – keyslot; 6 – knife

A complete set of design documentation for new grinding hole plates and rotating knives has been developed, pilot samples of grinding hole plates with hole diameters of 3, 5, 8 and 10 mm and rotating knives with an offset cutting edge blade relative to the rotation radius have been manufactured. Figure 6 shows a pilot sample of a new cutting mechanism.

The new grinding hole plates of the emulsifier, according to the mathematical model, have the same flow capacity over the entire working surface and equal hydraulic resistance due to a decrease in the thickness of the hole plates when switching to smaller perforation holes. The cutting edges of the knife blades are made obliquely tangentially to the inner radius of the grinding hole plate and have a maximum length, which ensures a high-quality slipping cutting process. Pilot samples of new cutting tools passed production tests in the sausagemaking shop of the JSC “Oshmyany meat processing plant”. They showed an increase in the performance of emulsifiers by 12– 15% with higher-quality fine grinding and a decrease of 10– 15% in specific energy consumption per unit of final output.

post@vestnik-vsuet.ru Conclusion

The equations were first obtained which allow to optimize the geometric parameters of a single grinding hole plate and a kit of grinding hole plates included in the standard set, according to the coefficient of flow capacity and the flow (free) cross-section area for the entire model range of emulsifiers. The formula was derived to determine the optimal thickness of the grinding hole plate, which allows to obtain the same value of the hydraulic resistance of all grinding hole plates included in the standard set. The use of slip cutting in a friction pair “knife – hole plate” was theoretically justified and the formula was first obtained for determining the optimal length of the cutting edge of the knife blade depending on the width of the ring working surface of the hole plate and its outer diameter. A new engineering technique for determining the design, geometric and hydraulic parameters of the whole cutting mechanism was proposed and experimentally verified. New designs of cutting tools are protected by invention patent No. 14437, and the pilot samples have successfully passed production tests in the sausage-making shop of the JSC “Oshmyany meat processing plant”

Список литературы Fine grinding of raw meat using the emulsifiers with a new cutting mechanism

- Weiss J., Gibis M., Schuh V., Salminen H. Advances in ingredient and processing systems for meat and meat products. Meat science. 2010. vol. 86. no. 1. pp. 196-213. doi: 10.1016/j.meatsci.2010.05.008

- Barbut S. Automation and meat quality-global challenges. Meat science. 2014. vol. 96. no. 1. pp. 335-345. Doi: 10.1016/j.meatsci.2013.07.002

- Zhang W. et al. Technological demands of meat processing–An Asian perspective. Meat Science. 2017. vol. 132. pp. 35-44. doi: 10.1016/j.meatsci.2017.05.008

- Mousavi A., Sarhadi M., Lenk A., Fawcett S. Tracking and traceability in the meat processing industry: a solution. British Food Journal. 2002. vol. 104. no. 1. pp. 7-19. doi: 10.1108/00070700210418703

- Zhou G., Zhang W., Xu X. China's meat industry revolution: Challenges and opportunities for the future. Meat science. 2012. vol. 92. no. 3. pp. 188-196. doi: 10.1016/j.meatsci.2012.04.016

- Pelenkov V.V. et al. Evaluation of the performance of meat shredders depending on design and physical and mechanical properties of the raw material. Journal of International Academy of Refrigeration. 2015. no. 1. (in Russian).

- Gavrilov T.A. Improving the efficiency of raw meat and fish grinding. Food. Ecology. Quality. 2016. pp. 257-260. (in Russian)

- Sodorjak A.N. Improving of grinding meat process. Thesis … c. t. s. Мoscow, 2007. (in Russian).

- Kosoy V.D. Improving the production process of cooked sausages. Мoscow, Light and food industry, 1983. 272 p. (in Russian).

- Kornushko L. M. Sausage production equipment. Мoscow, Kolos, 1993. 304 p. (in Russian).

- Daursky A.N., Machihin Y.A. Cutting of food materials. Process theory, machines, intensification. Мoscow, Food industry, 1980. 240 p. (in Russian).

- Grudanov V.Y., Brench А.А., Filippovich М.О. Influence of knife geometry on cutter quality. Proceedings of the National Academy of Sciences of Belarus, physical-technical series. 2007. no. 1. pp. 36–40. (in Russian).

- Grudanov V.Y., Brench А.А., Dazuk I.Е., Filippovich М.О. Equipment for raw meat grinding. Patent BLR, no. 14437, 2010.

- Sukhenko Y. et al. Changing the quality of ground meat for sausage products in the process of grinding. Eastern-European Journal of Enterprise Technologies 2017. no. 4 (11). pp. 56-63.

- Gao W., Chen F., Wang X., Meng Q. Recent advances in processing food powders by using superfine grinding techniques: A review. Comprehensive Reviews in Food Science and Food Safety. 2020. vol. 19. no. 4. pp. 2222-2255. doi: 10.1111/1541-4337.12580

- Batyrov U.D. et al. Research of ways of preserving the quality of grinded food products in the process of grinding. 2017 International Conference" Quality Management, Transport and Information Security, Information Technologies"(IT&QM&IS). IEEE, 2017. pp. 312-314.

- Honikel K.O. Reference methods for the assessment of physical characteristics of meat. Meat science. 1998. vol. 49. no. 4. pp. 447-457. doi: 10.1016/S0309-1740(98)00034-5

- Maksimov D.A., Zhukov V.G. Advanced equipment for frozen block meat grinding. Meat Industry. 2013. no. 2. pp. 30-33. (in Russian).

- Lisitsin A.B. et al. Grinding of frozen block meat by milling. All about meat. 2013. no. 4. (in Russian).

- Pelenko V.V. et al. Overview of foreign grinders and mixers for meat products. Scientific journal NRU ITMO Series "Processes and Food Production Equipment". 2008. no. 1. (in Russian).