Framed composites based on liquid glass roller molding

Автор: Meshalkin V.P., Erofeev V.T., Kopytin A.V., Zavalishin E.V., Astashov A.M., Nikitin L.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.17, 2025 года.

Бесплатный доступ

Introduction. The work is devoted to the experimental and theoretical study of the technology and properties of composite materials based on soluble glass. The prospects for the manufacture of floor coverings and other products using frame technology and roller molding are shown. Materials and methods. The frame technology for the manufacture of building composites consists in the first stage of gluing grains of large filler to each other according to the shape of the future product, and in the second stage – filling the voids of the hardened porous frame with a solution component. Roller molding is used both when performing the operation of compacting the frame and when filling its voids with a matrix. The purpose of the work was to conduct an experimental and theoretical study of the manufacturing technology, physical and mechanical properties and chemical and biological stability of composites based on liquid glass. To analyze the mechanism of the stress-strain state of compacted mixtures, a rheological model is considered, in which the mechanical characteristics of the medium are determined by fundamental properties: viscosity, elasticity and plasticity. When conducting experimental studies, sodium liquid glass was used, sodium fluorosilicate was the hardener, and powders based on mineral and organic materials served as fillers. Furyl alcohol was used as a polymer additive. Results. The optimization of the compositions of frames and matrices for framed concretes was performed. The studies were carried out using mathematical methods of experiment planning. Three-factor matrices consisting of 10 experiments were considered. Discussion. The best strength characteristics are demonstrated by matrix compositions that include filler mixtures of quartz sand, pyrite cinders and diatomite, and the greatest strength of the framework is achieved by including granules of 5–10 mm in the composition – 7%, 2.5–5 mm – 23%, 1.25–2,5 – 70%. The chemical and biological resistance of composites on silicate and polymer silicate binders was studied. Chemical resistance was determined in water, aqueous solutions of caustic soda, technological environments of soft drink factories, and biological resistance – in a standard environment of mycelial fungi. It was found that composites containing modifying additives are characterized by higher resistance rates. Conclusion. Scientific and technological foundations for managing the structure and properties of liquid glass framed composites of vibration-free roller molding have been developed, as well as scientifically based solutions for improving the compositions of frame and matrix mixtures by regulating the processes of chemical interaction between components, the grain composition of fillers and aggregates, and the introduction of special additives to ensure increased strength, chemical and biological resistance of concrete.

Composites, liquid glass, sodium fluorosilicate, dispersed fillers, aggregates, furyl alcohol, frame technologies, roller molding

Короткий адрес: https://sciup.org/142245491

IDR: 142245491 | DOI: 10.15828/2075-8545-2025-17-4-361-376

Текст научной статьи Framed composites based on liquid glass roller molding

Review article

Мешалкин В.П., Ерофеев В.Т., Копытин А.В., Завалишин Е.В., Асташов А.М., Никитин Л.В. Каркасные композиты на основе жидкого стекла роликового формования. Нанотехнологии в строительстве. 2025;17(4):361–376. – EDN: ETZXEV.

Concrete is one of the most widely used building materials in the construction, repair and reconstruction of buildings and structures for various purposes. Various compositions and technologies are used to prepare concrete and other composite materials and manufacture products and structures from them. The most widely used in construction are concretes on cement, silicate, polymer, geopolymer binders, as well as those composed using complex binders

CONSTRUCTION MATERIAL SCIENCE

[1–7]. When designing buildings and structures that are used in aggressive environments, much attention is paid to the selection of building materials and products that must be durable in specific operating conditions. For the production of building materials and structures operating in aggressive environments (chemical, biological), both domestic and foreign specialists recommend the use of polymer concretes based on epoxy, polyester, furan, urea and other binders [1, 2, 6–12]. However, polymer concretes are relatively expensive materials. In this regard, silicate and polymer silicate concretes are promising, the cost of which is 2–3 times lower than the cost of polymer concretes [13]. Silicate materials are those in which liquid glass (sodium or potassium) is used as a binder, as well as acid- and alkali-curing organic compounds (monomers or oligomers) [14, 15]. Polymer silicate building materials differ from silicate materials in the content of a polymer additive [2, 14, 16]. Construction practice shows that composite materials based on liquid glass have a fairly high durability when used in acid-containing environments. This allows them to be used for the production of anti-corrosion coatings, laying acid-resistant floors, etc. [17–19].

The chemical resistance of silicate solutions is determined by the properties of the reaction products released during their hardening, as well as the properties of the unreacted alkali silicate, the dosage of hardening initiators (sodium fluorosilicate or any other additive), the nature and amount of fillers [2, 16].

Composites based on liquid glass have high chemical resistance in highly concentrated acid solutions. When exposed to acids, they even gain strength at first. At the same time, it is known that materials on a silicate binder are weakly resistant to dilute acids, are practically not resistant to alkalis, and are also characterized by insufficient water resistance [2, 8]. To increase the density, strength and resistance to water and alkali solutions, liquid glass composites are modified with polymer additives. Polymer materials used to modify acid-resistant concretes on liquid glass can be diverse both in nature and in the mechanism of their effect on the constituent components. According to these characteristics, they are divided into:

– compacting or dispersing (furan, phenolic and other resins, furyl alcohol, furfural);

– water-binding (compounds with NCO groups, etc.); – reducing shrinkage (oligoesters);

– retarding hardening (sulfanol, organosilicon liquids); – colmatating (rosin, sulfur, etc.) [8, 13].

Composites containing structural elements as additives – dispersed and fibrous fillers of various sizes and nanoparticles – have qualitatively new properties, functional and operational characteristics [20–24]. The latter are ultra-fine fillers, the geometric dimensions of which in at least one direction do not exceed 100 Nm. Recently, the issues of studying biodegradation and increasing the biological resistance of various materials have become relevant. Literature data indicate that more than 40% of the total volume of biodegradation is associated with the activity of microorganisms [25–29]. At the same time, microscopic fungi have the greatest damaging effect on industrial and construction materials. Their high destructive activity is due to the ability to adapt to materials of various chemical nature, which is primarily due to the presence of a well-developed powerful and mobile enzyme complex. Theoretical studies of the biostability of composite building materials are devoted to the works [30–32].

The quantitative content of the components of materials based on liquid glass is selected based on the lowest consumption of the binder, subject to optimal density and workability. High viscosity and increased adhesive capacity of the liquid glass used as a mixing medium determine the presence of a number of technological difficulties in traditional vibration molding. To achieve the required workability, it is necessary to introduce excess water into the concrete mix, which leads to a change in the reactivity of the binder composition and to deterioration of the structural characteristics of the hardened material.

According to the molding and compaction conditions, composite materials are divided into self-compacting, compacted by vibration, rollers or slabs, etc. [33–35]. Speaking about molding, it should be noted that the purpose of any molding process is to transform a loose bulk mass (concrete mix) into a product characterized by a strong bond between the constituent components without breaking the continuity of the compacted mass [17]. All pressure treatment processes occur under conditions of contact friction of the deformed mass with the surface of the compacting working element. One of the options for solving this problem is the use of vibration-free roller technology, which allows to significantly expand the range of possible combinations of the initial components of the concrete mix, including the binder components [34]. In this case, the content of liquid glass can be reduced by 20–25% compared to vibration molding. In terms of consistency, concrete mixes molded using roller technology are classified as super-rigid. In our opinion, a combination of roller and frame technologies is promising in the manufacture of floors, roof slabs, and wall panels. The frame technology for producing concrete consists of preliminary gluing of grains of large aggregate together according to the shape of the future product and, in the second stage, filling the voids of the hardened porous frame with a solution component [33].

The physical and technical properties of the framed structure materials depend on the nature of the fillers and binders, the ratio of the elastic-strength properties of the binder and fillers, and the degree of adhesion between them [12]. The granulometric composition of the fillers and aggregates used has a significant effect on the properties of the framed structure composites. An analysis

CONSTRUCTION MATERIAL SCIENCE of the available literature data indicates that the greatest strength of frames based on cement and polymer binders is achieved with an optimal combination of granules of different fractions [33].

The roller molding method seems to be effective both in the compaction operation of the frame and in filling its voids with a matrix. Experimental and theoretical studies of roller molded framed composites based on liquid glass are presented below.

RESEARCH AIM AND OBJECTIVES

The aim of the reserch: to conduct an experimental and theoretical study of the manufacturing technology, physical and mechanical properties and resistance in chemically and biologically aggressive environments of roller-molded framed composites based on liquid glass.

Research objectives:

-

1. Justification of the prospects for manufacturing products based on liquid glass using frame technology and roller molding.

-

2. Obtaining a mathematical equation establishing the relationship between the main parameters that determine the mechanism of material compaction by a pressing roller.

-

3. Optimization of the compositions of frames and matrices based on liquid glass binders from the main structure-forming factors.

-

4. Study of the chemical resistance of liquid glass composites in water and an aqueous solution of caustic soda.

-

5. Establishing quantitative dependencies of the biostability of composites and obtaining biocidal compositions for buildings with chemically and biologically aggressive environments.

MATERIALS AND METHODS

In this paper, theoretical studies on the technology of molding products are based on the development of a rheological model associated with the properties of elasticity, viscosity and plasticity. Sodium liquid glass was used for experimental studies, and sodium fluorosilicate was used as a hardener. When studying the frames, fillers based on granite screenings of various grain sizes were used. Powders and granules of various granulometric compositions based on perlite, diatomite, pyrite cinders, and sawdust of various species served as fillers for the matrix compositions. Mathematical methods of experiment planning were used to optimize the compositions according to the indicators of physical and mechanical properties and biological resistance. Plans were developed, the components forming the material were selected and the levels of their variation were assigned. For this purpose, the simplex-lattice method and the Kono plan were implemented according to [36, 37]. The simplexlattice method is presented in Table 1.

According to the table presented, the content of fillers and aggregates of three fractions were taken as variation factors for each specific case. The continuous grain size distribution of the framework fillers and matrix composition fillers was divided into three groups in each case. For the framework: large fraction 5–10 mm (X1), medium fraction 2,5–5 mm (X2) and small fraction 1,25–2,5 mm (X3); for the matrices: large 0,16–0,315 mm (X1), medium 0,08–0,16 mm (X2) and very small less than 0,08 mm (X3). As follows from the above, granite crushed stone was considered as a filler when producing the framework. In this case, the high-strength filler contributes to the production of high-strength framework liquid glass composites. When producing matrix compositions, the goal was to form composites with improved contact interactions at the microstructure level in the binder-filler system. Four filler combinations were considered, taking into account these interactions. In all four cases, quartz sand (coarser fraction) served as one of such fillers, and the other two fillers were selected from the following materials related to the medium and smallest fractions: limestone, diatomite, pyrite cinders, expanded clay dust. Thus, samples were made and tested from compositions with the following filler combinations: quartz sand, ground quartz sand, ground limestone (combination No. 1); quartz sand, pyrite cinders, diatomite (combination No. 2); quartz sand, pyrite cinders, ground limestone (combination No. 3); quartz sand, pyrite cinders, expanded clay dust (combination No. 4). Physicomechanical tests were carried out using generally accepted methods.

Table 1. Third-order simplex lattice design for a three-component mixture

|

Nо. iп or. |

x1 |

x2 |

x3 |

y |

Nо. iп or. |

x1 |

x2 |

x3 |

y |

|

1 |

1 |

0 |

0 |

y1 |

6 |

0 |

2/3 |

1/3 |

y223 |

|

2 |

0 |

1 |

0 |

y2 |

7 |

0 |

1/3 |

2/3 |

y 233 |

|

3 |

0 |

0 |

1 |

y3 |

8 |

2/3 |

0 |

1/3 |

y 113 |

|

4 |

2/3 |

1/3 |

0 |

y 112 |

9 |

1/3 |

0 |

2/3 |

y 133 |

|

5 |

1/3 |

2/3 |

0 |

y 122 |

10 |

1/3 |

1/3 |

1/3 |

y 123 |

CONSTRUCTION MATERIAL SCIENCE

Table 2. Second-order Kono plan

|

Nо. iп or. |

x1 |

x2 |

y |

|

1 |

+1 |

+1 |

y1 |

|

2 |

–1 |

+1 |

y2 |

|

3 |

+1 |

–1 |

y3 |

|

4 |

–1 |

–1 |

y4 |

|

5 |

–1 |

0 |

y5 |

|

6 |

+1 |

0 |

y6 |

|

7 |

0 |

–1 |

y7 |

|

8 |

0 |

+1 |

y8 |

|

9 |

0 |

0 |

y9 |

When studying the chemical resistance of composites, water and aqueous solutions of caustic soda in various concentrations were used as aggressive media. The biological resistance of materials was assessed in a standard medium of mycelial fungi.

When studying the biostability of matrix compositions and their optimization, the Kono plan on a square was used, consisting of 9 experiments (Table 2). The content of sodium fluorosilicate (x1) and a mixture of additives (x2)

were taken as variation factors: copper sulfate + potash; potassium permanganate + potash.

The processing and analysis of the experimental results were carried out using statistical methods.

ANALYSIS OF THE MECHANISM OF THE STRESSSTRAIN STATE OF COMPACTED CONCRETE MIXTURE

The mixtures formed using vibration-free roller technology are a multi-component structure, which contains both solid particles (fillers) of various sizes and a liquid phase (binder) distributed over the surface of the solid particles. Accordingly, the forces of interaction between individual components are very diverse, and it is impossible to describe their behavior under mechanical action using the simplest model. A sufficiently objective display of the stress-strain state of the compacted material is provided by rheological models, in which the mechanical characteristics of the medium are determined by fundamental properties: viscosity, elasticity and plasticity.

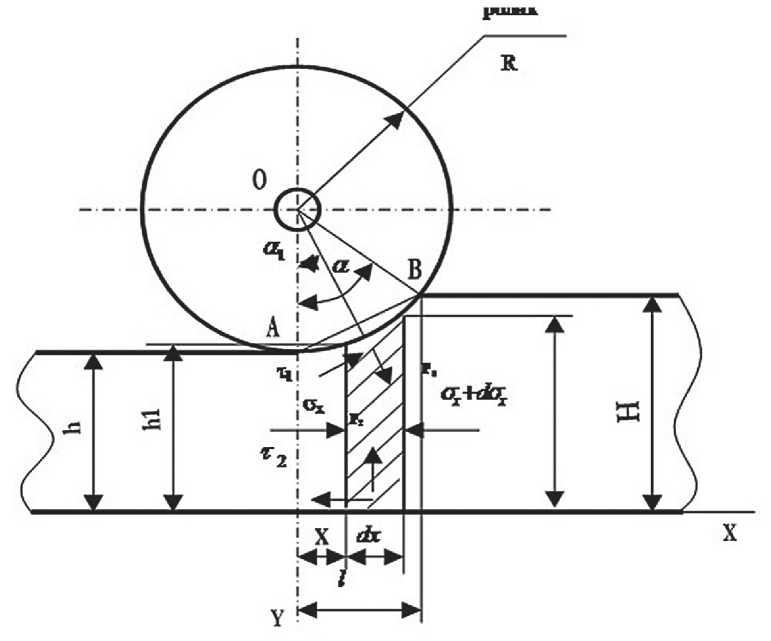

To analyze the mechanism of the stress-strain state of concrete material laid using frame technology with compaction, we will consider the version of the calculation scheme shown in Fig. 1.

Fig. 1. Calculation scheme for analyzing the mechanism of the stress-strain state of concrete material

CONSTRUCTION MATERIAL SCIENCE

Some differences in the structural and mechanical properties of the frame and matrix and the conditions of their placement using roller technology can be neglected and the method of jointly solving approximate equilibrium equations and plasticity conditions can be used when considering the deformation mechanism [17].

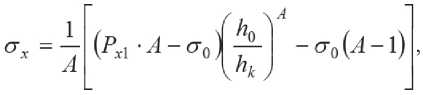

To analyze the mechanism of compaction of a material mass in the deformation zone, the width of which is equal to the horizontal projection of the arc of contact of the direct compacted material with the working surface of the roller, we select an infinitely small volume on a section of unit length dх and consider the equilibrium conditions of the forces acting on it during compaction. Joint solution of the equilibrium equations relative to the X and Y axes and the plasticity equation for the boundary conditions x = l, hx = h 0, Px = Px l = σ0–σ x after a number of transformations and simplifications allows us to obtain an equation of the form

where A is a constant value determined by the values of the coefficients of adhesion of the compacted material to the surface of the roller and the base:

The resulting equation establishes the relationship between the main parameters that determine the mechanism of compaction of the material by the pressing roller.

It combines both the properties of the concrete mixture (σ0), (µ1, µ2) and the parameters of the compacting roller (φ, h 0/ hk ).

In the future, it seems appropriate to solve this problem taking into account the elastic component of deformations as well as to describe the volumetric stress-strain state.

OPTIMIZATION OF FRAME AND MATRIX COMPOSITIONS FOR FRAMED COMPOSITES BASED ON LIQUID GLASS

We optimized the fractional composition of frame fillers based on liquid glass binder using mathematical methods of experimental planning. To perform the experiment, a matrix in the form of a plan consisting of 10 experiments was used. The variation factors were the contents of different filler fractions: X1 – for the fraction of 5–10 mm; X2 – 2.5–5 mm; X3 – 1.25–2.5 mm. The compositions were prepared in each case from the following components (parts by weight): liquid glass – 100, sodium fluorosilicate – 18, crushed stone with a fractional composition according to the experiment – the rest. The samples were made in the form of cubes with face sizes of 4×4×4 cm and were kept under normal temperature and humidity conditions for 28 days, after which they were tested under mechanical load. The compressive strength limit was considered as the parameter to be optimized. The planning matrix in natural values and the test results are given in Table 3.

After statistical processing of the experimental results, a regression equation was obtained that characterizes the dependence of the optimized parameter on the variable factors:

Table 3. Working matrix and experimental results

|

No. |

Composition of the mixture. % |

Compressive strength Rstr. MPa |

||

|

Х 1 |

Х 2 |

Х 3 |

||

|

1 |

2 |

3 |

4 |

5 |

|

1 |

100 |

0 |

0 |

0.56 |

|

2 |

0 |

100 |

0 |

1.04 |

|

3 |

0 |

0 |

100 |

0.80 |

|

4 |

33 |

67 |

0 |

0.58 |

|

5 |

33 |

0 |

67 |

1.10 |

|

6 |

0 |

33 |

67 |

1.00 |

|

7 |

67 |

33 |

0 |

0.98 |

|

8 |

67 |

0 |

33 |

1.08 |

|

9 |

0 |

67 |

33 |

1.33 |

|

10 |

33.3 |

33.3 |

33.3 |

1.04 |

CONSTRUCTION MATERIAL SCIENCE

Rstr = 0.56Х1 + 1.04Х2 + 0.8Х3 – 0.09Х1Х2 +

+ 1.845Х1Х2 + 1.1025Х2Х3 + 3.78Х1Х2(Х1 – Х2) +

+ 0.405Х1Х3(Х1 – Х3) + 1.6875Х2Х3(Х2 – Х3) –

– 2.0925Х1Х2Х3. (3)

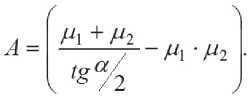

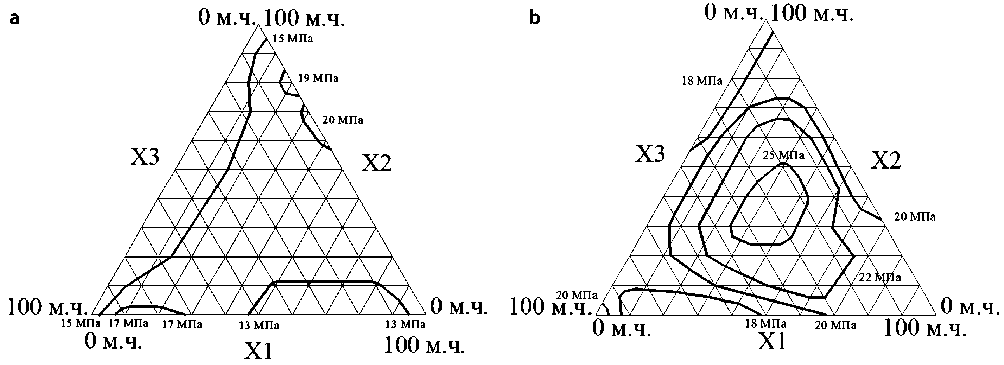

A graphical interpretation of the obtained dependence is shown in Fig. 2.

Fig. 2. Effect of crushed stone fractional composition on frame strength

Analysis of the equation and graph shows that the use of several filler fractions in the frame system has a positive effect on the strength characteristics of the material. The greatest frame strength is achieved with the inclusion of 5–10 mm granules in the composition in an amount of 7%, 2.5–5 mm granules – 23, and 1.25–2.5 mm granules – 70%. The composition using a filler with the specified fraction ratio showed an increase in strength compared to the composition containing 100% of the 1.25–2.5 mm fraction by 15%.

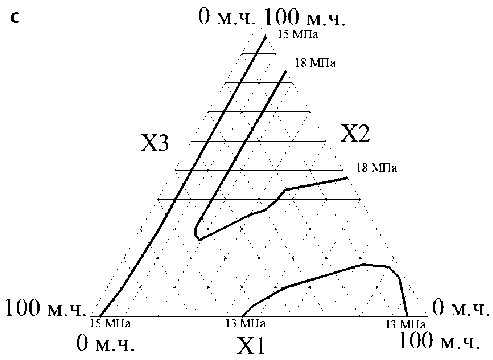

The properties of matrix composites are also largely determined by the nature and granulometric composition of the filler. In order to optimize the composition of matrices for framed concretes based on a liquid glass binder, the effect of additives of various microfillers was studied: diatomite; pyrite cinders; expanded clay; limestone; perlite; quartz. The composition under study included sodium liquid glass – 100 phr, sodium fluorosilicate – 18 phr, quartz sand and microfiller powders in various combinations – the rest. The studies were also carried out using the method of mathematical experimental planning, which makes it possible to determine the optimal compositions with a significant reduction in the number of experiments. To perform the experiment, a matrix in the form of a plan consisting of 10 experiments was used (see Table 2), as in the case of the framework study.

Preliminary experiments were carried out to establish the variation limits. The compressive strength limit was chosen as the parameter to be optimized. The tests were carried out on cube samples with an edge size of 2 cm. The variation factors were: X1 – the amount of quartz sand of fraction 0.16–0.315; X2 is the amount of filler of fraction 0.08–0.016 mm and X3 is the amount of filler of size less than 0.08.

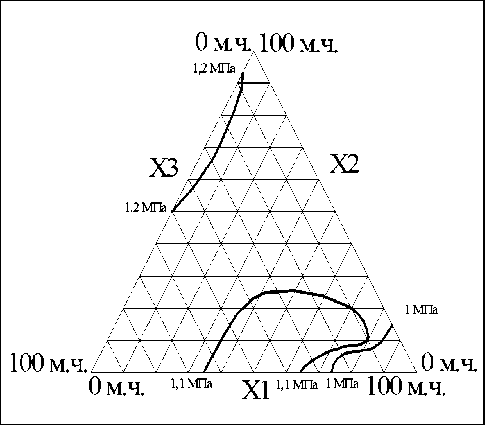

After statistical processing of the experimental results, regression equations were obtained that characterize the dependence of the change in the optimized parameter on the variable factors for all combinations of fillers, and graphs were constructed, presented in Fig. 3.

Analyzing the equations and graphs, we can conclude that the use of fillers of different nature and size in matrix compositions has a positive effect on increasing the strength characteristics of the material. The resulting compositions using the first combination of fillers showed an increase in strength compared to matrices with 100% content of quartz sand of fraction 0,016–0,315 mm – by 15%, in the second 65%, in the third 15% and in the fourth 10%. Thus, from the results of the studies it follows that the best strength properties are characterized by matrix compositions filled with a mixture of fillers based on quartz sand, pyrite cinders and diatomite.

CHEMICAL RESISTANCE OF LIQUID GLASS BASED COMPOSITES

To study chemical resistance, 1×1×3 cm samples were made from mixtures based on liquid glass with different quantitative contents of sodium fluorosilicate, with different fillers and a polymer additive. The samples were cured for 28 days under normal temperature and humidity conditions, then immersed in aggressive environments. Water, aqueous solutions of caustic soda, and other environments typical for beer and soft drinks factories were considered as aggressive environments.

Water resistance is the most universal characteristic for assessing the chemical resistance of liquid glass composites. Water, having high penetrating ability and polarity, promotes weakening and destruction of frictional, van der Waals, hydrogen and hydrolytically unstable bonds through the metal cation. Water resistance of silicate compositions depends mainly on the content of free liquid glass in their composition that has not reacted with sodium fluorosilicate. The more complete the reaction of interaction of alkali with hardening initiators, as a result of which poorly soluble products are formed, the higher the resistance of the material to water will be [6]. When conducting water resistance studies, filled compositions with various fillers were considered. In this case, the type of filler, its size and quantitative content were the variable parameters. Physicomechanical indicators were determined after 28 days of hardening of the samples. The

CONSTRUCTION MATERIAL SCIENCE

R1 = 14.6Х1 + 13.63Х2 + 14.55Х3 – 22.08Х1Х2 – – 9.07Х1Х2 – 15.873Х2Х3 – 18.52Х1Х2(Х1 – Х2) –

– 48.17Х1Х3(Х1 – Х3) + 1.226Х2Х3(Х2 – Х3) –

– 55.181Х1Х2Х3.

R2 = 14.6Х1 + 13.67Х2 + 20.125Х3 – 16.358Х1Х2 +

+ 4.399Х1Х2 – 2.53Х2Х3 – 25.72Х1Х2(Х1 – Х2) +

+ 40.51Х1Х3(Х1 – Х3) + 4.196Х2Х3(Х2 – Х3) –

– 208.125Х1Х2Х3. (5)

R3 = 14.6Х1 + 13.67Х2 + 14.55Х3 – 16.358Х1Х2 – – 9.07Х1Х2 – 0.765Х2Х3 – 25.72Х1Х2(Х1 – Х2) +

+ 48.17Х1Х3(Х1 – Х3) + 1.17Х2Х3(Х2 – Х3) –

– 74.43Х1Х2Х3.

R4 = 14.6Х1 + 13.67Х2 + 13.17Х3 – 16.38Х1Х2 –

– 7.64Х1Х2 – 4.88Х2Х3 – 25.72Х1Х2(Х1 – Х2) –

– 20.94Х1Х3(Х1 – Х3) +21.35Х2Х3(Х2 – Х3) –

– 95.05Х1Х2Х3. (7)

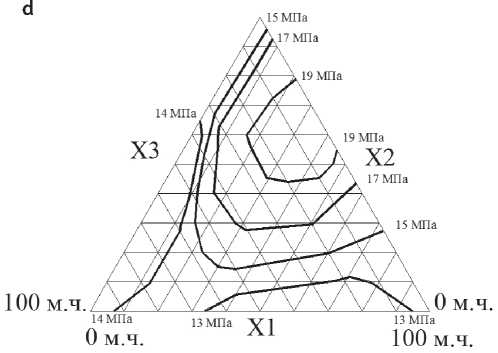

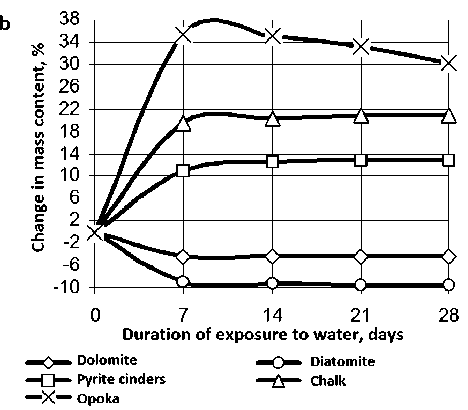

Fig. 3. Dependences of change in compressive strength of matrix composites with different combinations of fillers: a, quartz sand, ground quartz sand, ground limestone; b, quartz sand, pyrite cinders, diatomite; c, quartz sand, pyrite cinders, ground limestone; d, quartz sand, pyrite cinders, expanded clay dust test results (Fig. 4) showed that when exposed to water, all compositions exhibit a change in mass content, with some compositions intensively absorbing water, and some dissolving in it. For example, compositions with fillers of quartz sand, pyrite cinders, chalk and opoka actively gain mass under the influence of water in the first 7 days, and then, in the next 7 days, there is a slight dissolution of these composites, after which the mass of the samples stabilizes. Other compositions with fillers of dolomite and diatomite intensively lose mass in the first 7 days of exposure, and then in the subsequent time (up to 28 days of testing) dissolution stops, the mass of the samples also stabilizes.

Alkali solutions have a more aggressive effect on liquid glass-based composites. Fig. 4 also shows the results of testing materials using various fillers in a 10% aqueous

CONSTRUCTION MATERIAL SCIENCE

Duration of exposure to water, days

—О— Quartz sand (size 0,63-1,25 mm)

—CH Quartz sand (size 0,16-0,31 mm)

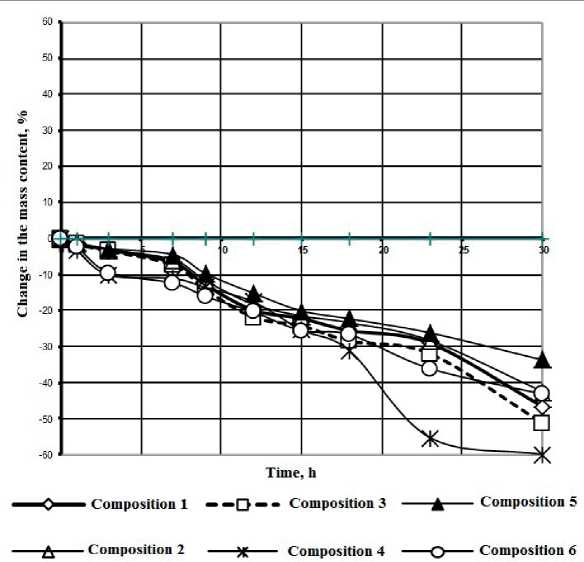

Fig. 4. Dependence of the change in the mass content of liquid glass-based composites on the type of filler and the duration of exposure to water solution of caustic soda. In the compositions under consideration, 2 levels of sodium fluorosilicate content were adopted. Six compositions were tested:

-

1. Liquid glass (LG) – 100 parts by weight, sodium fluorosilicate (SFS) – 18 parts by weight, quartz sand – 225 parts by weight;

-

2. LG – 100 parts by weight, SFS – 15 parts by weight, quartz sand – 225 parts by weight;

-

3. LG. – 100 m.p., K.F.N. – 18 m.p., diatomite – 40 m.p.;

-

4. Zh.S. – 100 m.p., K.F.N. – 15 m.p., diatomite – 40 m.p.;

-

5. Zh.S. – 100 m.p., K.F.N. – 18 m.p., pyrite cinders – 50 m.p.;

-

6. Zh.S. – 100 m.p., K.F.N. – 15 m.p., pyrite cinders – 50 m.p.

It follows from the graphs shown in Fig. 5 that all compositions experience a decrease in mass when kept in the environment. The greatest drop in mass content is characteristic of compositions filled with pyrite cin-

Fig. 5. Dependence of the change in the mass content of composites with different fillers in a 10% NaOH solution

CONSTRUCTION MATERIAL SCIENCE ders. Materials filled with quartz sand and diatomite have a higher resistance to leaching processes.

One of the ways to increase the chemical resistance of liquid glass composites is to introduce polymer additives into their composition [16]. Table 4 shows the results of comparative tests: chemical resistance of the composition with a polymer additive, which was furyl alcohol; control composition without additives.

The analysis of the tests shows various processes occurring in liquid glass-based composites when kept in chemically aggressive environments. Composites degrade by various mechanisms. In some environments, the mass content of materials increases, while in others, it decreases. Tests in all environments showed a positive effect of the polymer additive on chemical resistance. The most aggressive effect on silicate and polymer-silicate materials is exerted by 63% sulfuric acid solution, 85% orthophosphoric acid solution, 50% hydrochloric acid solution and 44% caustic soda solution. Moreover, in the environment of 44% aqueous solution of technical caustic soda, samples based on silicate and polymersilicate compositions were destroyed within a short period of exposure. In other environments, such as, for example, brewer’s yeast, there is, at first, an increase in strength properties.

This is apparently explained by the positive influence of this environment on the processes of structure formation.

BIOLOGICAL RESISTANCE OF COMPOSITES

The use of composite materials based on liquid glass in buildings and structures where biodegradation processes are possible requires comprehensive studies of the interaction processes of composites with biological environments [38–41]. To date, the behavior of composites based on liquid glass under the influence of biologically aggressive environments has not been studied sufficiently, in our opinion.

In domestic and foreign practice, the most frequently used hardener for liquid glass is sodium fluorosilicate. Its peculiarity lies in the fact that it not only interacts with alkali, reducing its content, but also releases silicic acid during decomposition, which noticeably compacts the hardening system, reducing porosity [2, 13–15]. It is known that when the environment is acidified (pH is reduced), the vital activity of a significant number of microorganisms ceases [42–45]. When silicic acid is released, the environment becomes more acidic, which can obviously affect the growth and reproduction of microorganisms. From

Table 4. Test results

|

Aggressive environment and |

Change in mass content, in %, after exposure to an aggressive environment, in days |

Change in the resistance coefficient after exposure to an aggressive environment, in days |

||||||||||||||

|

its characteristics |

3 |

5 |

7 |

10 |

15 |

21 |

35 |

57 |

3 |

5 |

7 |

10 |

15 |

21 |

35 |

57 |

|

1. Water |

–2.71 |

–3.92 |

–4.08 |

–4.08 |

–4.11 |

–4.23 |

–4.38 |

–4.38 |

1.0 |

0.95 |

0.82 |

0.62 |

0.51 |

0.5 |

0.47 |

0.11 |

|

3.86 |

10.8 |

6.83 |

4.75 |

4.75 |

1.76 |

1.63 |

1.55 |

1.0 |

0.97 |

0.91 |

0.9 |

0.9 |

0.89 |

0.89 |

0.88 |

|

|

2. Aqueous solution of sulfuric acid (63%) |

21.3 |

27.6 |

15.6 |

7.74 |

7.74 |

7.52 |

6.54 |

5.53 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

9.25 |

12.2 |

13.4 |

19.4 |

19.4 |

15.2 |

14.4 |

13.4 |

0.27 |

0.75 |

0.64 |

0.58 |

0.51 |

0.51 |

0.46 |

0.04 |

|

|

3. Aqueous solution of orthophosphoric acid (85%) |

10.4 6.24 |

13.8 7.1 |

14.0 10.1 |

13.9 10.6 |

13.9 10.8 |

12.6 11.2 |

10.8 11.4 |

9.57 11.4 |

0.65 0.44 |

0.88 0.64 |

0.39 0.53 |

0.15 0.45 |

0.07 0.44 |

0.07 0.38 |

0 0.36 |

0 0.24 |

|

4. Aqueous solution |

10.6 |

14.0 |

14.3 |

13.5 |

10.6 |

10.6 |

10.2 |

9.52 |

0.35 |

0.59 |

0.54 |

0.46 |

0.31 |

0.31 |

0.24 |

0.07 |

|

of nitric acid (50%) |

12.2 |

14.7 |

16.7 |

23.3 |

23.3 |

10.4 |

12.5 |

8.99 |

0.96 |

1.08 |

1.14 |

1.04 |

1.01 |

0.98 |

0.97 |

0.92 |

|

5. Aqueous solution of nitric acid (1–1.5%) |

–4.38 |

–9.22 |

–7.74 |

–7.74 |

–4.72 |

–2.78 |

0.48 |

–4.72 |

0.97 |

1.17 |

0.76 |

0.76 |

0.7 |

0.6 |

0.54 |

0.5 |

|

–3.55 |

–5.17 |

–4.16 |

–4.16 |

–2.74 |

–2.74 |

–1.71 |

–0.12 |

1.22 |

1.58 |

1.31 |

1.29 |

1.16 |

1.06 |

1.02 |

0.92 |

|

|

6. Aqueous solution of technical caustic soda (44%) |

Разр 6.57 |

Разр 10.9 |

Разр 4.23 |

Разр 3.15 |

Разр –0.59 |

Разр –0.59 |

Разр –7.43 |

Разр –7.43 |

Разр 0 |

Разр 0 |

Разр 0 |

Разр 0 |

Разр 0 |

Разр 0 |

Разр 0 |

Разр 0 |

|

7. Aqueous solution of technical caustic soda (2%) |

–25.4 –32.4 |

–30.5 –24.8 |

–32.7 –28.1 |

–32.7 –32.6 |

–31.8 –32.6 |

–31.8 –34.0 |

–32.8 –42.9 |

–43.0 –42.9 |

0.27 0.44 |

0.71 0.78 |

0.54 0.73 |

0.52 0.68 |

0.51 0.42 |

0 0.42 |

0 0.37 |

0 0.35 |

|

8. Brewer’s yeast |

–0.32 |

–0.58 |

–3.37 |

0.27 |

0.27 |

4.45 |

12.6 |

–3.37 |

1.72 |

2.26 |

1.93 |

1.46 |

1.07 |

1.06 |

1.06 |

0.71 |

|

(pH = 4.6–4.4) |

5.22 |

7.46 |

8.12 |

10.4 |

10.4 |

7.87 |

7.46 |

6.98 |

1.11 |

1.63 |

1.23 |

1.1 |

0.8 |

0.8 |

0.93 |

0.72 |

|

9. Brewer’s yeast |

–5.21 |

–9.8 |

3.86 |

4.99 |

4.99 |

7.69 |

10.4 |

12.7 |

1.96 |

2.02 |

2.23 |

3.32 |

2.02 |

2.01 |

1.51 |

0.98 |

|

(pH = 2) |

7.45 |

10.1 |

7.74 |

10.0 |

10.0 |

7.62 |

7.6 |

7.74 |

1.12 |

1.59 |

1.33 |

1.3 |

1.24 |

1.12 |

1.07 |

1.07 |

|

10. Water solution of alkafon – 1:5 (floor cleaning agent) |

–27.2 |

–32.6 |

–30.8 |

–2.46 |

–2.46 |

–0.14 |

3.14 |

–30.8 |

0.35 |

0.22 |

0.49 |

0.9 |

0.89 |

1.17 |

2.05 |

2.02 |

|

–25.4 |

–31.5 |

–32.9 |

–8.59 |

–8.59 |

–10.6 |

–8.47 |

–32.9 |

0.72 |

0.72 |

0.95 |

1.02 |

1.18 |

1.36 |

1.63 |

1.02 |

|

Note: above the line – silicate composition parameters, below the line – polymer-silicate composition parameters.

CONSTRUCTION MATERIAL SCIENCE this, we can conclude that the biostability of liquid glass composites can be regulated by changing the pH of the environment depending on the type of biodestructor of a particular material. According to literary data, the optimal concentration of sodium fluorosilicate for obtaining dense, water-resistant and acid-resistant materials is approximately 15% of the mass of liquid glass [2, 13, 15]. In order to test theoretical assumptions about the possibility of increasing the biostability of liquid glass composites by regulating the quantitative content of sodium fluorosilicate, studies were conducted on compositions in which its content varied from 15 to 20 wt. parts per 100 parts by weight of liquid glass. Quartz sand with a specific surface area of 600 cm2/g served as a filler. The amount of filler was taken in all compositions as 150 parts by weight per 100 parts by weight of binder. Samples were made in the form of beams measuring 1×1×3 cm. The test results are given in Table 5.

The presented data indicate that with an increase in the content of sodium fluorosilicate in the composites to 19 parts by weight per 100 parts by weight of binder, liquid glass materials become fungicidal.

In order to determine the biostability of liquid glass composites with fillers of various natures, studies were conducted on compositions in which quartz sand with a specific surface area of 200 and 600 cm2/g, diatomite, dolomite, pyrite cinders, chalk, flask and gypsum were considered as inorganic fillers. Sodium fluorosilicate with a content of 15 and 20 parts by weight per 100 parts by weight of binder served as a hardener. The amount of filler was taken from the condition of obtaining equally mobile compositions. The results of testing the samples are given in Table 6.

From the analysis of the data in Table 6 it is evident that the bioresistance changes depending on both the type of filler and the amount of hardener. With an increase in the content of sodium fluorosilicate in the composites from 15 to 20 parts by weight, liquid glass materials become fungicidal. Along with the specified compositions, fungicidal properties are also possessed by compositions filled with pyrite cinders with a lower hardener content. An assessment of the biological resistance of liquid glass-based composites showed that some compositions are fungus-resistant, but not fungicidal. In order to experimentally study the effect of fungicidal additives on the bioresistance of liquid glass-based composites, various additives of inorganic nature were considered. We have established that the introduction of copper sulfate, potassium permanganate, and aluminum powder into the composition of liquid glass composites makes them fungicidal. Quartz sand was used as a filler in the compositions in an amount of 150 parts by weight. parts per 100 parts by weight of liquid glass. The amount of hardener was constant in all compositions – 15 parts by weight per 100 parts by weight of binder. The results of the studies are presented in Table 7.

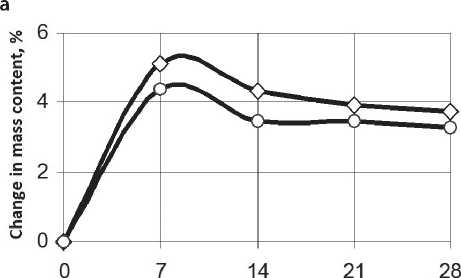

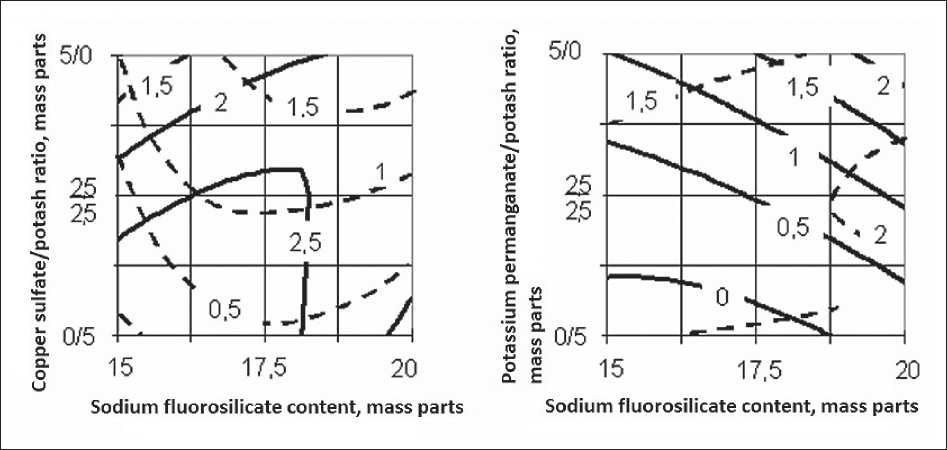

Analysis of the data in Table 7 confirms the fact that the introduction of modifying additives containing heavy metal salts into composites allows obtaining fungicidal compositions. At the same time, polyvinyl acetate emulsion and zinc oxide (5 parts by weight per 100 parts by weight of liquid glass) do not increase the biological resistance of liquid glass composites. Long-term studies in the field of biological resistance of composite building materials indicate that, of the wide variety of microscopic organisms, the greatest destructive effect on industrial and building materials, products and structures is exerted by the mycelial fungi Aspergillus niger and Penicillium chrysogenum [43, 44]. Based on this, we assessed the biological resistance of liquid glass-based composites under the influence of these types of fungi. The selection of fungicidal compositions was carried out using methods of mathematical experimental design. The variable factors were the sodium fluorosilicate content and the copper sul-fate/potash and potassium permanganate/potash ratios. The results of the studies are shown in Fig. 6.

As can be seen from the graphs, composites based on liquid glass with the addition of copper sulfate and potash are fungicidal against the action of the fungus Penicil-lium chrysogenum, when the content of these additives is 2,5/2,5 parts by weight per 20 parts by weight of sodium

Table 5. The effect of sodium fluorosilicate on the biostability of liquid glass composites

|

Amount of hardener, mass. parts |

Assessment of mushroom growth, points |

Characteristic according to GOST |

|

|

method 1 |

method 3 |

||

|

15 |

0 |

2 |

Mushroom-resistant |

|

16 |

0 |

2 |

Mushroom-resistant |

|

17 |

0 |

2 |

Mushroom-resistant |

|

18 |

0 |

2 |

Mushroom-resistant |

|

19 |

0 |

1 |

Fungicidal |

|

20 |

0 |

0; R = 5 |

Fungicidal |

CONSTRUCTION MATERIAL SCIENCE

Table 6. Biostability of composites depending on the type of filler and hardener content (per 100 parts by weight of liquid glass)

|

Type of filler |

Quantity of hardener, parts by weight |

Quantity of filler, parts by weight |

Assessment of mushroom growth, points |

Characteristic according to GOST |

|

|

method 1 |

method 3 |

||||

|

Quartz sand (specific surface area 200 cm2/g) |

15 |

350 |

1 |

3 |

Mushroom-resistant |

|

Quartz sand (specific surface area 600 cm2/g) |

15 |

150 |

1 |

4 |

Mushroom-resistant |

|

Diatomite |

15 |

40 |

1 |

5 |

Mushroom-resistant |

|

Dolomite |

15 |

150 |

0 |

3 |

Mushroom-resistant |

|

Pyrite cinders |

15 |

75 |

0 |

0; R = 8 |

Fungicidal |

|

Quartz sand (specific surface area 200 cm2/g) |

20 |

350 |

0 |

0; R = 5 |

Fungicidal |

|

Quartz sand (specific surface area 600 cm2/g) |

20 |

150 |

0 |

0; R = 4 |

Fungicidal |

|

Diatomite |

20 |

40 |

0 |

0; R = 10 |

Fungicidal |

|

Dolomite |

20 |

150 |

0 |

0; R = 8 |

Fungicidal |

|

Pyrite cinders |

20 |

75 |

0 |

0; R = 10 |

Fungicidal |

|

Chalk |

20 |

400 |

3 |

4 |

Not resistant to fungi |

|

Opoka |

20 |

200 |

0 |

0 |

Fungicidal |

|

Gypsum |

20 |

60 |

5 |

5 |

Fungicidal |

Table 7. The influence of the type and amount of modifying additive on the biostability of liquid glass composites

Thus, scientific and technological foundations for controlling the structure and properties of liquid glass framed composites of vibration-free roller molding have been developed, as well as scientifically based solutions for improving the compositions of frame and matrix mixtures by regulating the processes of chemical interaction between components, the grain composition of fillers and aggregates, the introduction of special additives to ensure increased strength, chemical and biological resistance of concretes effective for laying floors in buildings with aggressive technological environments.

CONSTRUCTION MATERIAL SCIENCE

Fig. 6. Dependence of the change in fouling during testing by method 3 (in points) of composites based on liquid glass, kept in the environments of the fungi Aspergillus niger ( – – – ) and Penicillium chrysogenum ( — ), on the content of the components

CONCLUSION

-

1. A technology for manufacturing framed composites and products based on liquid glass is proposed, based on the use of a vibration-free roller compaction method. The roller compaction method is used when laying a frame mixture based on large aggregates treated with a binder and filling the voids of the hardened porous frame with a mortar component under pressure.

-

2. By examining the rheological model of the «com-pacting roller – concrete mix» system, a dependence is obtained that establishes the relationship between the main parameters that determine the mechanism of material compaction by a pressing roller.

-

3. Comprehensive experimental studies were conducted to optimize the compositions of frames and matrices based on a liquid glass binder. Frames consisting of a mixture of grains of different granulometric composition and a matrix filled with a mixture of powders of different dispersion based on quartz, pyrite cinders and diatomite are characterized by increased strength.

-

4. Matrix composite compositions with increased chemical and biological resistance were selected. It was found that compositions on a diatomite filler have high chemical and biological resistance.

-

5. The chemical resistance of matrix compositions based on liquid glass in various aggressive environments was studied, including water, aqueous solutions of caustic soda, and operating environments of a beer and soft drink plant.

-

6. Comprehensive studies of biodegradation and biological resistance of composites based on liquid glass were conducted. Methods for increasing the bioresistance of composites by regulating the content of silicic acid in the compositions, which changes the pH, were proposed. Biocidal additives were proposed that impart fungicidal properties to liquid glass composites. With an optimal content of sodium fluorosilicate, high fungicidal activity of copper sulfate and potassium permanganate in the compositions of highly filled liquid glass composites was revealed.