Innovation development of dairy cattle breeding in the north-west of the Russian Federation as the basis for enhancing the competitiveness of milk production

Автор: Surovtsev Vladimir Nikolayevich, Bilkov Valentin Alekseyevich, Nikulina Yuliya Nikolayevna

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Branch-wise economy

Статья в выпуске: 4 (28) т.6, 2013 года.

Бесплатный доступ

The article considers the implementation of innovation technologies in dairy livestock breeding as the main factor enhancing the production competitiveness in the conditions of Russia’s accession to the WTO and the establishment of the Customs Union. The article also reviews the capabilities of innovation technologies in achieving the target production indicators on the one hand (enhancement of manageability, cost reduction, improvement of production quality, increase of the period of productive use of cows), and in minimizing the influence of human factor on the final results, on the other hand. The indicators of production and economic efficiency at the innovation farms of the Vologda and Leningrad oblasts have been analysed.

Dairy cattle breeding, innovation technologies, modernization, efficiency

Короткий адрес: https://sciup.org/147223481

IDR: 147223481 | УДК: 637.13

Текст научной статьи Innovation development of dairy cattle breeding in the north-west of the Russian Federation as the basis for enhancing the competitiveness of milk production

The implementation of resource-saving and eco-friendly innovation technologies in dairy cattle breeding is becoming a necessary prerequisite for the enhancement of competitiveness of milk production after Russia’s accession to the WTO and the establishment of the Customs Union.

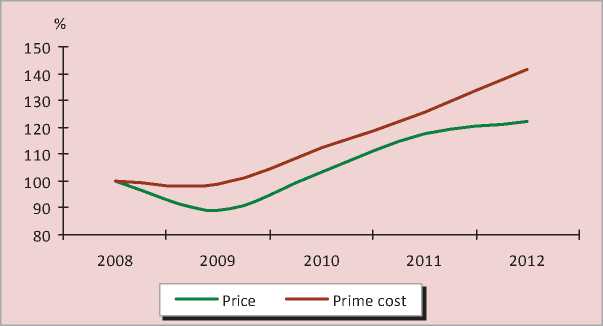

Increasing competition in product and resource markets equalizes the domestic and world prices for milk and key production factors. It becomes impossible to provide competitiveness on the basis of extensive resource-consuming production due to the low prices for fuel and lubricants, power, grain; low wages; insufficient expenditures on the environmental safety of production. High resource intensity of production increases the gap between the growth rate of production costs and selling prices, which has negative consequences for milk producers. For instance, in the Vologda Oblast farms this gap was 19 percentage points in 2012, having increased more than twice in comparison with 2011 (8 p.p.) (fig. 1) .

The climatic conditions for milk production in the North-West of Russia are not so good in comparison with Russia’s main competitor states; this economic sector is lagging behind in technology development and receives a smaller amount of state support. Consequently, competitiveness in the conditions of globalization can be ensured if the advantages of returns to scale are realized to the fullest degree, which is conditioned by the following factors:

-

• availability of sufficient areas of grassland;

-

• experience of efficient milk production by major agricultural producers;

-

• possibility of increasing the production output of processing enterprises, oriented toward urban markets.

The main comparative advantage of dairy cattle breeding is connected with the ability of cows, as ruminants, to digest cheap voluminous (herbal) feed and produce expensive products. Therefore, the realization of potential benefits associated with the concentration of livestock population, should not lead to increasing problems in fodder production, herd reproduction, and disposal of manure.

Currently, the management level allows the economies of scale to be implemented only partially. The competitive level according to the costs, quality, and ecological safety of milk production is not achieved.

Figure 1. Growth rates of price for and prime cost of milk production at the Vologda Oblast farms, in % to 2008 [1]

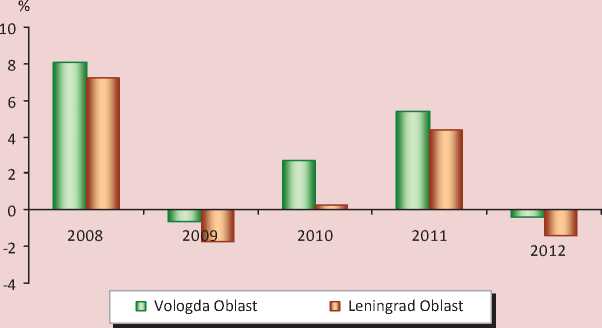

Consequently, the level of profitability in the industry on the whole and in the leading dairy farming regions of Russia’s North-West remains very low (fig. 2) .

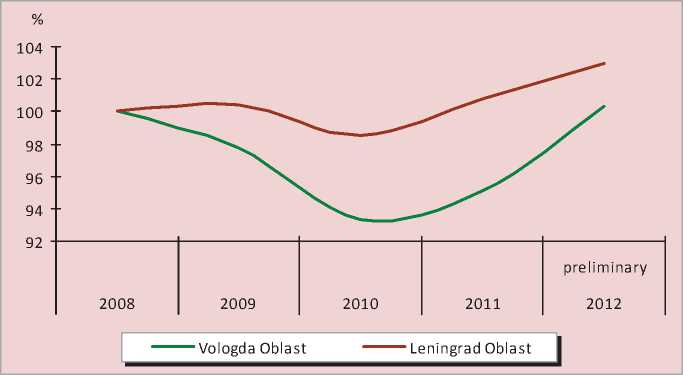

As a result, the opportunities for extended reproduction are limited, and the volumes of milk production remain at the 2008 level (fig. 3) given a significant decrease in cow population (tab. 1) .

The management of milk production in Russia’s agricultural organizations and agricultural holding companies is still more ‘art’, than ‘technology’; this fact leads to the increase in the direct and opportunity costs, risks, management costs related to the delegation of authority and responsibility, complexity of organizing efficient control with regard to foreign competitors.

In order to enhance the competitiveness of milk production, the following conditions should be fulfilled:

-

• high fodder conversion and their low cost;

-

• low costs of labour and other resources per cow and per unit of production (at the level of leading world competitors);

Figure 2. Profitability of dairy cattle breeding at the farms of the Vologda and Leningrad oblasts excluding subsidies, % [1, 2]

Figure 3. Growth rates of milk production at the farms of the Vologda and Leningrad oblasts, in % to the 2008 level [1, 2]

Table 1. Cow population in agricultural organizations of the Vologda and Leningrad oblasts [1, 2]

|

Indicators |

2008 |

2009 |

2010 |

2011 |

2012 |

|

Cow population, thousand head |

|||||

|

Vologda Oblast |

87.4 |

81.9 |

80.3 |

77.0 |

74.5 |

|

Leningrad Oblast |

77.5 |

77.6 |

76.5 |

76.2 |

73.8 |

|

Rates of cow population decrease, % to the 2008 level |

|||||

|

Vologda Oblast |

100.0 |

93.7 |

91.9 |

88.1 |

85.2 |

|

Leningrad Oblast |

100.0 |

100.1 |

98.7 |

98.3 |

95.2 |

-

• maintaining the health of cows, their long productive use, high reproductive function in animals;

-

• high quality of products, efficient logistics, meeting the requirements of the most attractive market segments;

-

• environmental safety of production.

Handling the issues concerning the enhancement of manageability in the industry, the reduction of production costs and improvement of product quality requires the transition to advanced technologies of cow milking and housing. On the one hand, these technologies should ensure the achievement of target production indicators, on the other hand – minimize the influence of human factor. However, better technologies have greater capital intensity, which results in more strict requirements to the quality of assessing investments efficiency.

When choosing a modernization technology, it is necessary to consider, in particular, whether it will contribute to the fulfilment of the conditions of state support for the industry. Thus, the share of subsidies in the revenues of the Vologda Oblast dairy farms accounted for 5.2% in 2012 and significantly influenced the profitability of dairy farms.

The state programme for the development of agriculture in 2013–2020 establishes the grading of milk as an indicator determining the amount of subsidy per litre of milk. Besides, it contains strict requirements to the recipients of subsidies on the health of livestock and indicators of herd reproduction. The choice of guidelines for the sector’s development, the estimation of efficiency of investment projects, including those related to the choice of cow housing option and type of milking equipment should be oriented toward the achievement of target indicators set in the state programme.

The pace of innovation-investment activity in the farms of the Vologda and Leningrad oblasts is higher than in Russia (tab. 2) , but it is still insufficient to enhance the competitiveness of the entire sector.

At the same time, the indicators of production and economic efficiency of innovation enterprises in comparison to the region average show the positive experience of introducing innovation capital-intensive technologies.

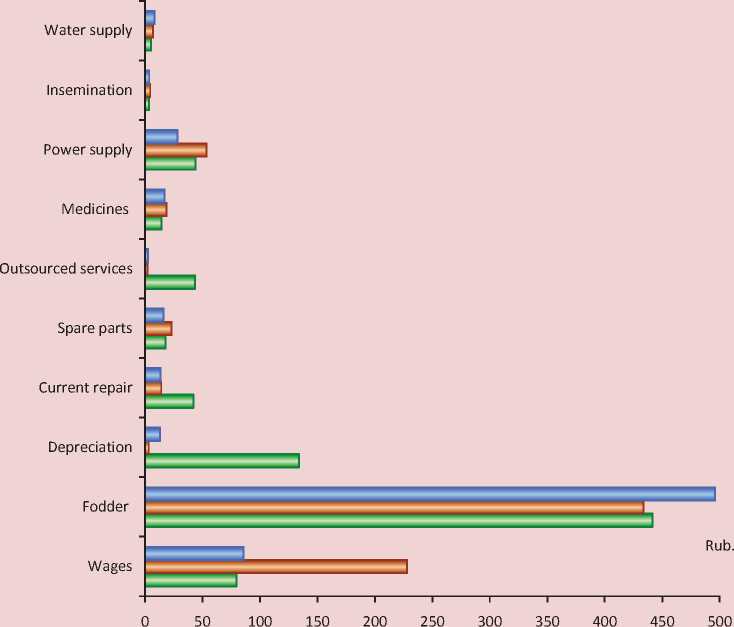

The analysis of items of expenditures for producing 1 centner of milk for different milking technologies has been conducted using the 2009 – 2011 average data of the Collective Farm Named after the 50th Anniversary of the USSR (Vologda Oblast). The analysis of various technologies used by one farm complies with the comparison condition ‘all other conditions being equal’ and levels the annual fluctuations of external factors (fig. 4, tab. 3) .

In comparison with linear milking installation, voluntary milking technologies provide a 65% reduction of labour costs; as for milking in milking parlours, it reduces labour costs by 62%. Fodder costs are higher, but it is connected with a greater productivity of animals due to the use of advanced milking equipment and loose housing. The expenses on medicines, insemination, spare parts and electricity are lower as well.

Table 2. Development of innovation technologies of cow housing and milking at the farms in the Vologda and Leningrad oblasts [1, 2]

|

2008 |

2009 |

2010 |

2011 |

2012 |

|

|

Number of milking parlours |

|||||

|

Vologda Oblast |

19 |

25 |

25 |

29 |

33 |

|

Leningrad Oblast |

36 |

41 |

46 |

48 |

50* |

|

Number of milking robots |

|||||

|

Vologda Oblast |

3 |

3 |

14 |

14 |

17 |

|

Leningrad Oblast |

0 |

2 |

6 |

10 |

13 |

|

including a 3-box robotic milking system |

0 |

0 |

0 |

1 |

3 |

|

Number of reconstructed and upgraded facilities in Russia |

368 |

176 |

148 |

92 |

data not available |

|

* According to the Leningrad Oblast Board on the Agroindustrial Complex, by 2012 30 farms have shifted to the milking in milking parlours [1], the total number of milking parlours in the oblast is more than 50. |

|||||

Figure 4. Items of expenditures in the costs of production of 1 centner of milk using different types of milking equipment in the Vologda Oblast Collective Farm Named after the 50th Anniversary of the USSR, on average for 2009 – 2011, rubles [3]

□ Milking robots □ Linear milking installation □ Milking parlour

Table 3. Items of expenditures on milk production using different milking technologies at the Collective Farm Named after the 50th Anniversary of the USSR, on average for 2009 – 2011 (in % to the indicators of the linear milking systems) [3]

|

Items of expenditures |

Level of expenditures compared to similar items when using linear milking systems, % |

|

|

Milking robots |

Milking parlour |

|

|

Wages |

35 |

38 |

|

Fodder |

102 |

114 |

|

Depreciation |

4096 |

398 |

|

Current repair |

299 |

95 |

|

Spare parts |

78 |

69 |

|

Outsourced services |

2057 |

127 |

|

Medicines |

77 |

92 |

|

Power supply |

82 |

53 |

|

Insemination |

76 |

81 |

|

Water supply |

76 |

121 |

|

Total expenditures |

104 |

88 |

|

Total expenditures excluding depreciation |

91 |

87 |

At the same time, depreciation costs and equipment maintenance costs (including outsourced services) are the main items of expenditures, by which milking robots and parlours exceed linear milking machines. The excess of costs according to the item ‘current repair’ is conditioned by the specific allocation of expenses during the upgrading of cattlebreeding premises.

In general, the direct production costs for 1 centner of milk excluding depreciation (since it is not reflected in the cash flow) are lower by 8.6% when using milking robots and by 13.0% when using milking parlours in comparison to linear milking installations.

It should be kept in mind that the expenses for herd reproduction are not included in the calculations and depend significantly on the milking technology and housing type. According to experts, the transition to robotic milking systems can reduce the rejection of cows on average up to 25% of the herd, i.e. reduce the loss on cattle meat, especially at breeding farms.

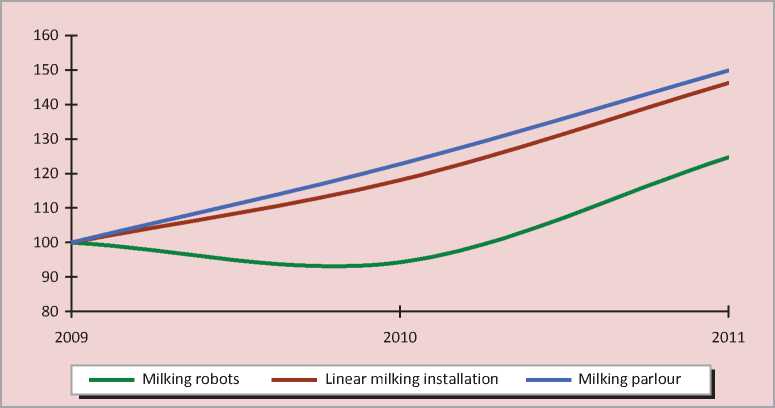

However, the growth rate of milk production costs over three years when using milking robots is more than 20% lower in comparison with other types of milking equipment (fig. 5) .

Besides, it should be kept in mind that, compared to widely used milking parlours and linear milking installations, voluntary milking systems have the capacity to reduce costs over time due to the optimization of processes, adjustment of the equipment, reduction of expenses on the current repair in the industry in general and at the enterprise in particular.

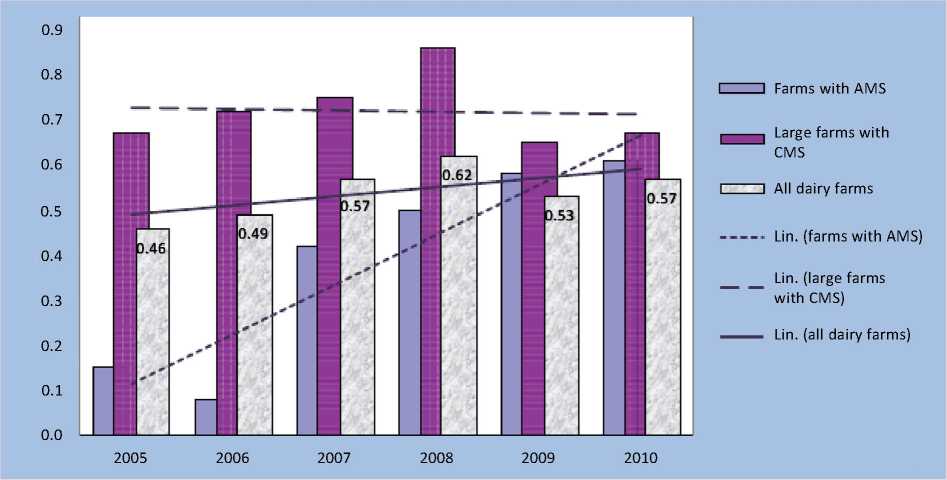

For instance, in Finland, where milking robots have been used since 2000, the profitability of voluntary milking systems is increasing annually, while the profitability of milking parlours tends to decline (fig. 6) .

Despite the high costs of reconstruction, including current repair and outsourced services, and a significant increase in depreciation expenses, the cost-effectiveness of milk production at innovative farms after their modernization significantly exceeds the oblast average indicator (tab. 4) .

Some decrease in profitability at the Breeding Farm Krasnogvardeyskiy in 2008– 2009 was caused by the fact that the modernization of cattle-breeding premises was carried out simultaneously with production processes.

Figure 5. Growth rate of costs for the production of 1 centner of milk when using different types of milking equipment at the Collective Farm Named after the 50th Anniversary of the USSR for 2009 – 2011 [3]

Figure 6. Profitability ratio of dairy farms in Finland for different types of milking equipment* [4]

* AMS – voluntary milking systems, CMS – milking parlours. Profitability ratio was calculated as the ratio of the farm’s revenues to the wages and return on capital employed.

CJSC Breeding Farm Krasnogvardeyskiy in the Leningrad Oblast is upgrading milk production by combining voluntary milking systems and automated linear installations (DelPro). Despite the reconstruction carried out in 2008– 2011, growth rates of milk production at the enterprise are higher than oblast average and district average.

While in the Leningrad Oblast, given the virtually unchanged number of cows, milk production increased by 4.7%, produc-tivity – by 2.4% (which is typical of the national average indicators as well), the cow population in CJSC Breeding Farm Krasnogvardeyskiy increased by 20.0%, milk production – by 45.3%, productivity – by 21.4% [3].

Table 4. Cost-effectiveness of milk sales in agricultural organizations of the Vologda and Leningrad oblasts, % [1, 2, 3]

|

Indicators |

2008 |

2009 |

2010 |

2011 |

|

On average at the Vologda Oblast farms |

26.9 |

11.2 |

21.5 |

20.1 |

|

Collective Farm Rodina |

44.6 |

8.1 |

24.0 |

29.0 |

|

Collective Farm Named after the 50th Anniversary of the USSR |

75.2 |

24.9 |

56.1 |

31.4 |

|

On average at the Leningrad Oblast farms |

26.7 |

14.8 |

17.6 |

17.2 |

|

Breeding Farm Krasnogvardeyskiy |

23.5 |

10.8 |

19.3 |

26.9 |

The cost-effectiveness of milk sales has increased by 3.5 percentage points, which under stage-by-stage reconstruction makes it possible to compensate for part of investment expenses by the revenues from operating activities.

In the conditions of current reconstruction, high-tech equipment makes it possible to conduct purposeful work on the enhancement of productivity: according to this indicator, the farm moved from the 27th to the 16th place over five years in the oblast rating. The productivity of cows has increased from 6735 kg to 8174 kg or 24.1% for 5 years, while the regional average productivity growth amounted to only 2.4%. As a result, the share of the enterprise in the oblast milk production and livestock population is growing.

In the course of the reconstruction, the main production and livestock indicators haven’t worsened that is usually observed in the modernization of dairy complexes when animals are transferred to loose housing with milking in high-tech milking parlours. A number of indicators have even improved.

In addition, due to the phased reconstruction and transition to the new equipment that is possible when modernization is based on robotic milking, the adaptation period of transition from one technology to another is reduced to minimum, as well as the time period, during which the new technologies will reach their full capacity.

Thus, when making decisions on the options and rates of investment and innovation development of dairy cattle-breeding, the farms should consider the whole range of information on the efficiency of technologies; they should select investment projects not from the position of ‘expensive or cheap’, but taking into account the ‘costs and results’ in both short-term and long term periods.

Список литературы Innovation development of dairy cattle breeding in the north-west of the Russian Federation as the basis for enhancing the competitiveness of milk production

- Agro-industrial complex and consumer market of the Vologda Oblast in figures. The Vologda Oblast Department of Agriculture, Food Stocks and Trade. Vologda, 2012.

- Main indicators of agricultural and fishery complex in the Leningrad Oblast in 2008-2012. The Leningrad Oblast Committee on Agriculture and Fishery. Saint Petersburg, 2009-2013.

- The data of annual reports of OJSC Breeding Farm Krasnogvardeyskiy, Collective Farm Rodina, Collective Farm Named after the 50th Anniversary of the USSR.

- Heikkila A.-M. Economic comparison between conventional and robotic milking systems in loose-housing cowsheds. Economic Research. MTT Agrifood Research Finland.