Insight into ceramic technologies at the Maikop site of Ust-Dzheguta, Karachay-Cherkessia

Автор: Iserlis M.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 2 т.47, 2019 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145422

IDR: 145145422 | DOI: 10.17746/1563-0110.2019.47.2.013-023

Текст обзорной статьи Insight into ceramic technologies at the Maikop site of Ust-Dzheguta, Karachay-Cherkessia

Various scholars have linked the Maikop phenomenon of the fourth millennium BC and its pottery to the cultures of the Southern Caucasus, Mesopotamia, Anatolia, Syria, Northern Iran, and Europe (Andreeva, 1977; Von Majkop…, 2010; Lyonnet, 2007; Narimanov, Akhundov, Aliev, 2007; Nechitajlo, 1991; Rezepkin, 2000). Many researchers suggested that some Maikop vessels were made using additional technology introduced from the south, a potter’s wheel (Munchaev, 1975: 324–332; 1994: 197–201; Korenevskiy, 2004: 36–39, 49–62). The last twenty years have seen an influx of new data from the Maikop settlements, including dozens of calibrated radiocarbon dates (Chernykh, Orlovskaya, 2007; Kohl, 2007; Korenevskiy, 2004; Lyonnet, 2000, 2007; Trifonov, 2001), as well as results of genetic studies (Allentoft et al., 2015; Sokolov et al., 2016), and ceramic studies (Lyonnet, 2007; Korenevskiy, Kizilov, 2015; Rezepkin, 2012; Rezepkin, Poplevko, 2009; Rezepkin, Kulkova, 2018; Poplevko, 2018; Shishlov, Kolpakova, Fedorenko, 2013).

Various theories have been introduced, modified, and applied to the archaeological data. However, these have not fully taken into consideration the pottery— the most frequent and basic component of the material culture. Thus, a description and definition of Maikop pottery and its technology is necessary for further discussion.

This study forms part of a project that seeks to establish the technological principles of Maikop pottery production by means of comparisons among various Maikop assemblages. The methodology is derived from chaîne-opératoire analysis (Lemonnier, 1986; Leroi-Gourhan, 1943), a detailed reconstruction of artifact-manufacture, use and discarding, focusing on producers’ behavior and decision-making (Bobrinsky, 1978; Lemonnier, 1986).

Geographical location and geological environment of the Ust-Dzheguta site

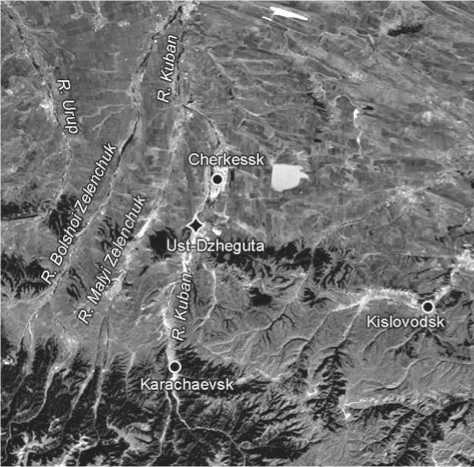

The Maikop settlement of Ust-Dzheguta (870 m asl) is located on the eastern terrace of the Kuban River, north of the town of Ust-Dzheguta, 12 km south of Cherkessk, in the Karachay-Cherkess Republic (Fig. 1). The relief of this region, located on the slopes of the northwestern Caucasus, is divided by parallel ridges into three main areas: flat-or-hilly in the north, foothills, and mountainous in the south. Ust-Dzheguta is located in the southern part of the flat-or-hilly area (400–900 m asl), characterized by a flat landscape with hills and a dense river network, and bounded to the south by the Pastbishchny ridge (900–1500 m asl).

The Greater Caucasus, a folded sedimentary structure formed during the Alpine Paleocene-Cenozoic orogeny, is composed mainly of Cretaceous and Jurassic rocks, with some Paleozoic and

Fig. 1. Location of the Ust-Dzheguta settlement.

Precambrian rock exposures (Geologiya Bolshogo Kavkaza…, 1976; Khain, Milanovsky, 1963; Philip et al., 1989). Ust-Dzheguta is located in the stable development zone (up to 400 m thick) of sea clays of the Maikop series of the Oligocene-Lower Miocene, stretching along the entire Northern Caucasus and continuing on the Crimean Peninsula and in the region of the Western Black Sea. The Maikop series within Karachay-Cherkessia in the basin of the Kuban River and its tributaries is represented by alternating layers (100–150 m each) of calcareous clays and marls, and non-calcareous clays, often with inclusions of dolomite and limestone nodules, and locally occurring interlayers of sandstones (Beluzhenko, Filippova, Pismennaya, 2014). The flat-or-hilly area around Ust-Dzheguta contains Quaternary alluvium, clays and siltstones, Paleogene clays, sandstones, marls, and limestones (Gosudarstvennaya geologicheskaya karta SSSR, 1957, 1987; Gosudarstvennaya geologicheskaya karta Rossii, 2000). Approximately 5–7 km north to the site, Paleocene and Eocene clays, marls, and siltstones are exposed (Gosudarstvennaya geologicheskaya karta SSSR, 1957). The Pastbishchny ridge is built of Cretaceous clays, siltstones, limestones, mudstones marls, and sandstones (Gosudarstvennaya geologicheskaya karta SSSR, 1987; Gosudarstvennaya geologicheskaya karta Rossii, 2000). South to the Pastbishchny ridge, there are the Skalisty range (max. elevation 2644 m) and the wide North Jura depression, bounded to the south by the Peredovoi range (max. elevation 3464 m). The Skalisty range is built of Jura sedimentary rocks. The southernmost Peredovoi range is composed of intrusive Paleozoic granites, granodiorites, tonalities, and diorites. Jura andesites, basalts, dacites, tuffobreccia, schists, sandstones, and siltstones are exposed on the slopes of the Great Caucasus south of the Peredovoi range (Gosudarstvennaya geologicheskaya karta SSSR, 1987).

Characteristics of the material culture of the site

The Ust-Dhzeguta kurgans and settlement were first investigated in 1964 by T.M. Minaeva and A.L. Nechitajlo (Nechitajlo, 1978, 2007). The finds stored in the Prozritelev and Prave Stavropol State Museum-Reserve aroused great interest among archaeologists, but until now have not been fully described in the literature.

Nechitajlo’s field observations and excavations indicate that the archaeological finds associated with the site were distributed over an area of 50 hectares (2007). The settlement has not been archaeologically excavated. The finds were collected from the surface or piles of earth, and include wattle and daub fragments, chipped stone, cores, grinding-stones, animal-bones, and a large amount of pottery.

The pottery assemblage from Ust-Dzheguta includes a large number of jars, bowls, basins/vats, and pithoi, as well as globular pots, a goblet, and cooking ware, such as pots and skillets. An additional component of the assemblage is a stand.

On the basis of visual inspection, it is possible to identify three main groups of ware in the Ust-Dzheguta assemblage:

-

1. Fine beige to pink or red ware with or without small amounts of organic temper; mainly slipped, and polished or burnished. A wide variety of serving and storage vessels belong to this ware: bowls, jars, globular pots, and a goblet;

-

2. Grayish, beige to pink, red or yellowish ware rich in vegetal material, slipped, and burnished or carefully polished; includes pithoi, vats/basins with the diameter up to 80 cm, and jars;

-

3. Dark gray to brown cooking ware with coarse sand, and with or without vegetal material temper; includes cooking ware, such as skillets and cooking pots.

According to S.N. Korenevskiy (2004: 50), the Ust-Dzheguta pottery assemblage typologically corresponds to the Galyugai-Seregino variant of Maikop pottery (3900–3600/3300 BC).

Research methods and procedures

179 pottery fragments and vessels from the Ust-Dzheguta settlement and kurgans have been examined, including 168 from the settlement and 11 from the kurgans. 51 vessels were sampled for mineralogical analysis, including 44 from the settlement and 7 from kurgans 13, 32, 40, and 45. Sampling was qualitative, to ensure the presence of a wide variety of types and fabrics. Although the preserved assemblage was small, the inspected sample included all types of vessels typical of the Maikop settlements.

The sample consisted of a representative selection of vessels (n = 51), including cooking pots, skillets, and the stand. Formation techniques, surface treatment methods, and composition of raw material were examined by visual observation, and were analyzed using the methods of optical mineralogy (Iserlis et al., 2015; Whitbread, 1995). The color and orientation patterns of the matrix were identified and described according to the “Handbook for Soil Thin Section Description” (Handbook…, 1985). The minerals in silt and temper were identified; their frequency, classification, morphology, and roundness were described using visual charts (Ibid.). We define temper as non-plastic, coarse (>62 μm) particles added by a potter, or occurring naturally in the clay. The samples were divided into fabric groups in accordance with lithological affinities in both clay and temper. The lithology of thin sections was compared to geological maps and samples of raw materials (Geologiya Bolshogo Kazkava…, 1976; Gosudarstvennaya geologicheskaya karta SSSR, 1957, 1987; Gosudarstvennaya geologicheskaya karta Rossii, 2000).

Using the site catchment approach (Vita-Finzi, 1978), five potential samples of raw material from the environs of Ust-Dzheguta were taken in order to identify possible local clay sources. Each sample was examined in thin section in its natural appearance and after firing: test briquettes were prepared to test plasticity, shrinkage, and the firing behavior of the materials (Iserlis et al., 2015).

In this study, “ware” refers to a class of pottery with macroscopically similar clay composition, clay treatment, surface treatment, and firing. “Fabric” is a combination of various components and features of a ceramic body, including matrix, temper, and clay treatment, established under the microscope. Every fabric is based on one clay originating from a specific geological location. One ware class could have been made of various fabrics, and one clay source could have been used by producers of various wares. However, a specific fabric should be attributed to a single workshop or to an industry (that is, several closely related workshops).

Results

Techniques. The majority of the vessels were made using coiling technique. Coils and horizontal joint points between them are visible both in cross-sections and on the surfaces. There was no clear evidence for the use of a potter’s wheel or tournette. Techniques of shaving and scraping with tools were typical for noncooking vessels (Lyonnet, 2007; Nechitajlo, 2007).

Some basins/vats and pithoi show clear evidence of coiling technique, with slabs added as complementary parts. Impressions of mat and straw on the exterior of rounded base of a pithos suggest that the lower part of the vessel might have been made in the mold (probably a small pit), covered with textile and/or straw. Impressions of ropes on the exterior walls and deep impressions of fingers on the bottom part of the pithos suggest that the walls were built upwards and fixed with a rope; the vessel had not dried by the time it was removed from the pit. After removal, the potter shaved the exterior bottom surface and scraped the exterior walls, supported by ropes, with a hard tool (flint blade?). Sometimes, scraping and shaving techniques were used for removing excess clay from the exterior surface of bowls, and erasing joints between the coils.

In terms of techniques, cooking vessels (ware 3) show similarity to the non-cooking vessels (wares 1 and 2), except for the methods of surface treatment. After completing the body of a skillet, the potter smeared a thick layer of clay over the exterior surface, and a thin layer of clay over the interior surface. After that, the interior walls were carefully smoothed or polished. Cooking-pots’ surfaces were polished or smoothed, but potters invested much less efforts in smoothing the surfaces and erasing folds or stitches between the coils.

Thick slip layers characterize basins/vats and some pithoi. After completing the body of vessel, the potter smeared an additional layer of clay up to 2.5–2.9 mm thick over the vessel. The surfaces were burnished using hard or semi-hard tools with a width of 2–3.3 cm at the working edges, both on leather-hard dry and slightly wet surfaces.

Cross-sections and surfaces of some basins/vats and pithoi suggest that they were fired for short time in an oxidizing atmosphere. Vessels identified as cooking pots showed the signs of extended exposure to fire: soot marks and extensive surface cracking.

In terms of techniques, the pottery assemblage can be divided into three main groups:

-

1. Bowls, globular pots, goblet, and jars. Potters used coils for building the bodies; vessel walls were thinned using paddle and anvil technique. Vessels were slipped, smoothed, polished and rarely burnished.

-

2. Basins/vats and pithoi. These vessels were built of coils and complementary slabs; ropes were sometimes used for supporting their thick walls. After forming and thinning using shaving, potters followed a time-consuming process of surface treatment. This

-

3. Cooking-vessels. This group is distinguished by thick slips and limited effort (mainly smoothing) in surface treatment.

group is distinguished by well-treated burnished or well-polished surfaces.

Fabrics. Seventeen fabrics were identified on the basis of the relative quantities of minerals and on evidence for intentional manipulation and treatment of the raw material. The main clay groups (A, B, BB, C, D, and F) are indicated by uppercase letters, to which numerals indicating different types of inclusions may be added (see Table ).

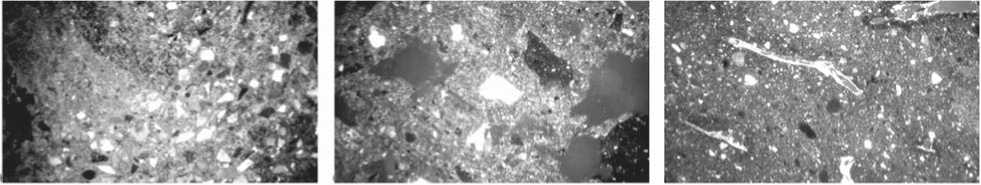

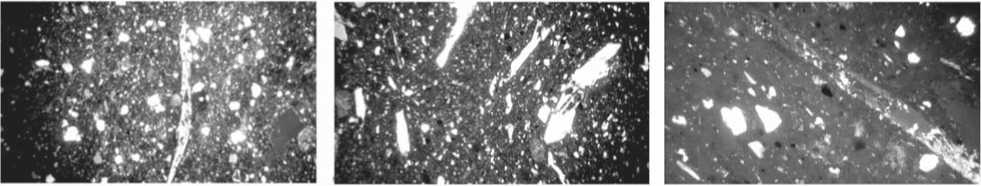

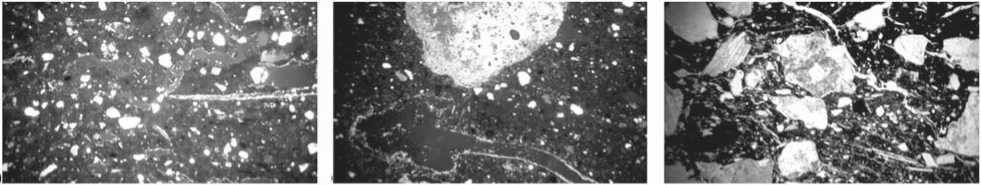

Group A . Fabric A2 (Fig. 2, a ).

The matrix is calcareous and contains foraminifera. The silty component includes limestone, iron oxides, feldspar, mica, and amphibole (< 7 %). The temper includes sub-rounded to sub-angular particles of feldspar up to 250 μm in size (sometimes up to 370 μm, 10 %), vegetal material “ghosts” (1300– 3200 μm, 5 %), secondary calcareous rock (up to 2000 μm, > 3 %), limestone (sometimes decomposed, mostly foraminiferous, up to 540 μm, > 7 %), subrounded grains of rhyolite (40 %) and basalt (up to 600 μm, > 3 %), mica flakes (up to 450–1000 μm, > 3 %), mudstone and sandstone (up to 300 μm, > 1 %), and amphibole (up to 400 μm, > 1 %).

Group B. Fabrics B3, B2, B2-17, and B3-17 (Fig. 2, b ).

The matrix of this group is clayey with very weak to strong optical orientation; contains iron oxides concentrations. The silt component contains feldspar, mica, iron oxides, amphibole, and calcareous rocks (3 %). The non-plastic ingredients include sub-angular to sub-rounded particles of feldspar (up to 180– 270 μm, < 3–7 %), limestone (up to 150 μm, < 1–1 %), mica flakes (up to 90 and 120 μm, rarely up to 200 μm, > 1–> 3 %), amphibole (up to 130 μm, > 1 %), and rhyolite grains (up to 380 μm (very rare), and up to 1 %). Sometimes, dolomite “ghosts” were observed in the thin sections.

Fabric B3. Grog (> 3 %) was added to the clay of one globular pot. Angular particles of grog (450– 1000 μm) belong to the same clay group.

Fabric B2. Ust-Dzheguta potters also used clay of group B, with added vegetal material. Two types of particles have been observed: long narrow, straight or slightly curved (20–30 × 1300–2000 μm) and short straight (50–130 × 500–800 μm, > 1 %). Both types sometimes contained traces of tissues and phytoliths.

Fabric B2-17. Two samples with typical clay of group B, with natural inclusions and artificially

Distribution of sampled vessels according to fabrics, pcs.

|

sod ‘|B)Oi |

о |

co |

CM |

CD |

1^ |

см |

ю |

^ ю |

||||

|

paiinuapiun |

1 |

|||||||||||

|

dd |

-- |

см |

||||||||||

|

Zk3d |

1 |

^- |

||||||||||

|

3d |

CM |

со |

||||||||||

|

fra |

1 |

|||||||||||

|

за |

t |

CD |

||||||||||

|

Zk3OO |

1 |

см |

см |

|||||||||

|

ZЮ0 |

1 |

|||||||||||

|

ZЮ |

1 |

^- |

||||||||||

|

Zk30 |

1 |

см |

||||||||||

|

gi.-z-9-заа |

1 |

см |

||||||||||

|

9к9-гаа |

1 |

CM |

T- |

CD |

со |

|||||||

|

э-заа |

co |

CM |

CD |

|||||||||

|

ZI.-93 |

1 |

|||||||||||

|

zi-за |

1 |

T- |

см |

|||||||||

|

ea |

1 |

^- |

||||||||||

|

за |

1 |

CM |

CM |

T- |

ю |

|||||||

|

SV |

1 |

|||||||||||

|

О |

1 о co |

"o ro о о |

ro о О |

ro |

о CD c о о о го |

(Л о ^ Й1 |

ГО ^ СЛ ГО 0Q |

(Л (Л го го го "с |

го й |

о СП о о о |

"с го со |

S [О |

added vegetal material (2.3–6.0 mm and 70–130 × 1300 μm, > 1–< 3 %) have been identified. The matrix of the fabric is silty (up to < 7 %). The temper includes angular to sub-angular grains of granite, feldspar, and quartz (up to 2000–2300 μm, < 30 %), mica flakes (up to 550–900 μm, < 3 %), amphibole (up to 200–400 μm, 1–> 1 %), and sub-rounded rhyolite (up to 600 μm, < 1 %). Dolomite “ghosts” (1–< 3 %) and traces of calcareous rocks have been observed.

Fabric B3-17. The temper of this fabric includes angular to sub-angular grog particles (250–2800 μm, 15 %), angular to sub-rounded grains of granite, feldspar, and quartz (up to 900 μm, 5 %), limestone (up to 180 μm, 1 %), mica flakes (up to 550– 900 μm, < 3 %), amphibole (up to 200 μm, > 1 %), and sub-rounded basalt and rhyolite (up to 600 μm, < 1 %).

Group BB . Fabrics BB2-6, BB2-6-16, and BB2-6-7-16 (Fig. 2, c , e–h ).

Fabric BB2-6. The clay of this group is almost identical with the clay of group B, but the matrix contains higher calcareous rocks component, and exhibits higher porosity. The limestone grains are mostly disintegrated or “milky”. High temperatures, in which the vessels of this group were fired, led to the explosion of calcareous grains. The matrix is porous (3 %), clayey, and shows weak optical orientation. The silty component contains calcareous rocks, feldspar, mica, iron oxides, and amphibole (< 5 %). The temper includes more limestone grains and smaller feldspar particles than clay of group B. Non-plastic components include sub-angular to subrounded particles of feldspar (up to 170 μm, rarely up to 330 μm, > 1–< 3 %), limestone and secondary calcareous rock (up to 230–660 μm, 3–< 7 %), mica flakes (up to 90 and 120 μm, > 1–< 3 %), amphibole (up to 130 μm, > 1 %), vegetal material (50–130 × 500–800 μm, > 1 %), mudstone (< 1 %), and very rare grains of rhyolite and sandstone. Judging by a higher content of calcareous material in the matrix, silt, and temper, limestone sand could have been added and crushed with clay of group B.

аb c

def

gh i

jkl

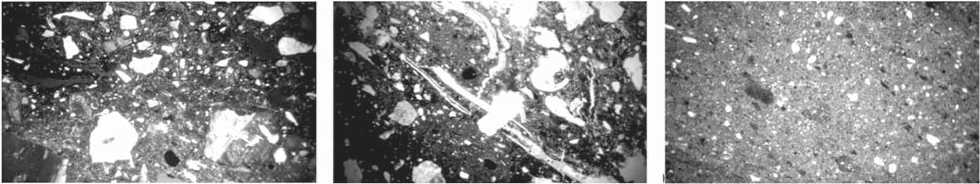

Fig. 2. Thin-section microphotographs.

a – stand, sample 23 (XPL, field width 4.3 mm), fabric A2; b – miniature vessel, sample 24 (XPL, field width 4.3 mm), fabric B3-17; c – jar, sample 37 (XPL, field width 3.9 mm), fabric BB2-6; d – jar, sample 26 (XPL, field width 4.1 mm), fabric F2; e – pithos, sample 30 (XPL, field width 4.1 mm), fabric BB2-6-16; f – basin/vat, sample 47 (XPL, field width 3.2 mm), fabric BB2-6-7-16; g – basin/vat, sample 40 (XPL, field width 3.6 mm), fabric BB2-6; h – basin/vat, sample 40 (XPL, field width 3.4 mm), fabric BB2-6; i – cooking pot, sample 22 (PL, field width 3.9 mm), fabric C17; j – cooking pot, sample 20 (XPL, field width 4 mm), fabric C2-17; k – skillet, sample 16 (PL, field width 4 mm), fabric F2-17; l – bowl, sample 11 (XPL, field width 4.2 mm), fabric D2.

Fabric BB2-6-16. This fabric is represented by 13 samples with typical clay of group BB2-6, inclusions, and artificially added straw and chaff (180–400 × × 1700–7000 and 11,000 μm; > 7 %), large grains of foraminiferous chalk and limestone (up to 2000 or 2300 μm, < 1–< 3 %), and mudstone grains (up to 2300 μm, > 1–< 5 %). Long (7500–11,000 μm) vegetal particles, phytoliths, and vegetal tissues have been observed in the thin section of basin/vat (sample 40).

Fabric BB2-6-7-16. Sometimes, the Ust-Dzheguta potters added feldspar and quartz sand as a temper. Large vessels (one jar and one basin/vat) were made of typical clay of group BB, with added feldspar and quartz sand (up to 760 μm, < 15 %), straw and chaff (180–400 × 1700–7000 up to 10,500 μm; > 7 %), grains of foraminiferous chalk and limestone (up to 2000 or 2300 μm, < 1–< 3 %), and mudstone grains (up to 2300 μm, 1–< 3 %).

Group C. Fabric C17, C2-17, CC17, and CC2-17 (Fig. 2, i , j ).

Fabric C17. The matrix is clayey or non-calcareous; and exhibits strong optical orientation. The silt component contains feldspar, quartz, mica, amphibole, and iron oxides (5–7 %). Temper includes angular to sub-rounded granite particles, angular to sub-angular grains of feldspar and quartz (up to 2000–2300 μm, 25–30 %), mica flakes (up to 550– 1300 μm, < 3–> 5 %), amphibole (up to 200–400 μm, 1–> 1 %), and sub-rounded grains of rhyolite (up to 600 μm, < 1 %).

Fabric C2-17. Two samples were made of Group C17 clay, to which vegetal material (70–130 × × 1300 μm, 1–3 %) was added.

Fabric CC17. Typical C17 clay with temper of added vegetal material (> 1 %) and very rare limestone grains (up to 220 μm, < 1 %).

Fabric CC2-17 . Typical C17 clay and temper of added vegetal material (1–< 3 %) and very rare limestone grains (up to 230 μm, < 1 %).

Group D. Fabrics D4 and D2 (Fig. 2, l ).

The matrix is marly, and contains traces of dolomite, and foraminifera. The silty component includes limestone, feldspar, mica, iron oxides, and amphibole (< 5 %). Non-plastic particles include sub-angular to sub-rounded feldspar (up to 120–170 μm, < 3–5 %), micritic foraminiferous limestone (up to 600 or 760 μm, > 3–> 7 %), mudstone and sandstone grains (up to 500 μm, < 3–< 7 %), mica flakes (up to 90 μm, > 1–3 %), and amphibole (up to 100 μm, 1 %).

Fabric D4. Sub-angular grains of rhyolite (up to 1750 μm, < 3 %) were added to the clay of one jar.

Fabric D2. Ust-Dzheguta potters also used clay of group D with the addition of vegetal material (50–130 × 400–500 μm, < 1 %). Four bowls, one goblet, and one jar were made of this fabric.

Group F * . Fabrics F2, F2-17, and FF (Fig. 3, d , k ).

The matrix is marly or calcareous, and also foraminiferous, and silty. The silty component contains mainly calcite and limestone, accompanied by the particles of feldspar and quartz, iron oxides, and very rare mica and amphibole (< 5 %). Nonplastic components include angular to rounded grains of feldspar and quartz (up to 370 μm, 5–< 7 %), limestone (up to 400 μm, > 1–> 3 %), calcite (up to

0 3 cm

Fig. 3. Miniature vessel (sample 24).

120 μm, > 1 %), mica flakes (up to 270 μm, < 1–3 %), and mudstone (up to 1300 or 9000 μm, < 3–7 %).

Fabric F2. Three samples with typical Group F clay, inclusions, and artificially added vegetal material represented by “ghosts” with residual tissues and phytoliths (70–200 × 1400–4000 or 120–700–1400 × × 10,000 μm, 1–< 5 %) have been identified.

Fabric F2-17. The temper includes angular to sub-angular (crushed) granite particles (500–2700 μm, < 20 %), angular to sub-rounded grains of feldspar and quartz (up to 150–580 μm, 5–< 7 %), traces of vegetal material (60–170 × 900–2600 μm, 5 %), mica (80–540 μm, > 1 %), and iron oxides (up to 90 μm, 1 %).

Fabric FF. This fabric is a finer variation of clays of group F (fabrics F2 and F2-17), with limestone and foraminiferous chalk (up to 360 μm, 3 %), mudstone (up to 1200 μm, > 1 %), angular to sub-rounded grains of feldspar and quartz (up to 170 μm, > 1 %), as well as rare mica and amphibole grains.

Provenance of the analyzed vessels

Judging by the microscopic observations, geological literature, and raw material samples from Ust-Dzheguta, Fabric A2 is equivalent to the soil from the site. One sampled stand was made of this clay.

Since the samples of group B are lithologically similar to the samples of group BB (21 pots) and to the geology of the site, except for the fact that clays of group BB show higher content of larger calcareous grains and lower content of feldspar, these clays must have originated from the same source, probably the Quarternary or Paleogenic formations. While the mixture of limestone and feldspar as temper is typical for both groups and for the region, the range and frequency of these components are different. This difference can be explained by potter’s manipulations. Fabric BB might therefore be identified as sifted of levigated clay B with added limestone, or as clay B crushed by the potters after adding the limestone sand.

Group D and its non-plastic components match the deposits in the vicinity of the site, and show similarity to clays of groups B and BB, except for the group’s marly matrix. Thus, this clay group should be identified as marl obtained at some distance from the outcrops of clays B and BB. Exposures of the Cretaceous and Paleocene-Eocene marls, covered by calcareous clays, were found by the author at distances of 2 and 8 km south of the site, and sampled (Gosudarstvennaya geologicheskaya karta SSSR, 1987; Gosudarstvennaya geologicheskaya karta Rossii, 2000). Owing to their distinctive matrix and inclusions, clays of groups B, BB, and D can be linked to the formations south of Ust-Dhzeguta, and especially the Pastbishchny ridge.

Group C and its non-plastic components match the deposits in the vicinity of the site, except for the presence of fresh granite and its derivatives. This group might therefore be identified as local clay with added crushed granite from the Kuban River. The riverbed is covered by cobbles and boulders of granite, as well as other magmatic and metamorphic rocks.

Samples of group F stand apart from the others identified in Ust-Dzheguta assemblage, and exhibit very local features. This group is identified as local marl. The inclusions accompanying the matrix indicate depositional environment within the area of the site.

On the basis of the analysis of samples of potential raw materials and geological maps, clays B, C, D, and F can be identified as originating in the immediate vicinity (up to 2–5 km) of the site.

Discussion

The immediate observation of optical mineralogy analysis was the segregation of raw materials used to create the main groups of ware:

-

1. All cooking vessels (Ware 3) were produced of clays with added granite or granite and vegetal material; six out of seven were made of Group C clays.

-

2. Non-cooking vessels (bowls, globular pots, goblet, jars and pithoi; Ware 1) were produced of Groups B, BB, or D clays, with added vegetal material, grog, limestone, mudstone, granite, and feldspar, or of Group F clay, with added vegetal material.

-

3. Basins/vats and pithoi (Ware 2) were nearly always produced from Group BB clays, with added vegetal material, limestone, mudstone, and feldspar.

The use of clays of groups B-BB was observed for all non-cooking vessels. Large basins/vats and pithoi (in 11 out of 13 cases) were made of clay BB rich in vegetal material and added limestone or mudstone sand (fabrics BB2-6-16 and BB2-6-7-16). Smaller vessels were produced mainly of fabrics with added small amount of chopped straw, granite, limestone, or grog. Addition of vegetal material, limestone, and mudstone to the clay of the thick-walled pithoi and basins/vats could be explained as means of reducing plasticity and ensuring body strength. The Ust-Dzheguta potters consistently added temper to their clays, but the final mixture (fabric) was finely tuned to a set of specific vessels. Finer mixtures were used for producing pottery with thinner walls (jars, globular pots, and bowls), intended for carrying or for daily use.

The stand differs from the pottery assemblage in its composition. It was made of the local clay, which was never used by pottery producers.

Conclusions

The Maikop pottery from Ust-Dhzeguta exhibits relatively high internal variability in its proportions of matrix and temper, and between the compositions of various coarse elements. Ten fabrics have been identified for 41 non-cooking vessels (see Table ). There is linkage between the typology and clay/ temper type of basins, pithoi, and some jars and bowls. However, 12 sampled jars fall in no less than nine fabrics, and 10 sampled bowls were made of four varying mixtures. On the basis of visual observations and optical mineralogical analysis, it is possible to identify three main industries at Ust-Dzheguta:

-

1 – Basins/vats and pithoi were nearly always created by highly skilled potters, using very special fabrics (BB2-6-16, BB2-6-7-16);

-

2 – The bulk of the non-cooking pottery was produced by part-time potters, using at least eight different fabrics based on four clay types (B, BB, D, F);

-

3 – Cooking vessels differ from the above noncooking pottery industries in terms of function, clay, temper, and surface treatment techniques. The group is characterized by very high variability both in morphology, potting techniques and clay mixtures.

The pottery assemblage of Ust-Dzheguta exhibits a heterogeneity that may be ascribed to different potters, diverse family traditions, and mainly to the low level of specialization for industries 2 and 3. Massive and sophisticated vessels such as basins, most of pithoi, and some jars, were produced by expert potters, whose specialized knowledge was employed mainly for manufacturing large vessels. The bulk of the Ust-Dhzeguta pottery, especially bowls, globular pots, and most of the jars (industry 2), is the product of parttime specialists. These skilled specialists consistently used specific clays, but mixed variable, non-uniform fabrics and created slightly different vessels. Cooking vessels were made as part of household production or by part-time potters (Rice, 2015: 358–362).

The presented analysis reveals the technological signature of the Maikop tradition, as is expressed in the Ust-Dzheguta assemblage. The non-cooking vessel producers (Industry 2) used one of the four (B, BB, D and F) known local clays, and created sets of vessels using similar, but not identical fabrics. The producers of basins and pithoi invested more efforts in obtaining the most suitable clay (BB), mixing special fabric, and creating a burnished or polished surface. This may be linked to a perception of the expectations of consumers, who wanted to have the pots with predictable physical qualities, such as volume, durability, and resistance to stress.

The addition of both grog and granite sand to the clay of a miniature vessel (7.3 cm high) cannot be explained by an aim to increase strength or shock resistance. The potter created this vessel (Fig. 3) exactly following the methods used for making “regular” vessels, including coils and polish of the exterior wall. Use of these methods, as well as the addition of rarely used grog and granite to naturally tempered clay B of a miniature pot, must be ascribed to tradition and the function of the item, and to a form of knowledge transmitted between the tradition carriers. The item could have been used as mnemonic device, carrying information on raw materials and manufacturing, and was involved in interactions between potters—a community of practice (Blackmore, 2010). Reproduction of the tradition over time, using basic practices, such as “regular” clay type, coiling technique, and polish, is consistent with the existence of a community of practice.

The technological analysis of the Ust-Dzheguta ceramic assemblage provides a window into the Maikop phenomenon and its pottery production, makes it possible to establish its specific features with more precision, and gives an insight into relations between producers, pots, and users.

Acknowledgments

This research was supported by the Fritz Thyssen Foundation, and was conducted at the Eurasia Department of the German Archaeological Institute (Berlin). The author would like to thank N.A. Okhonko and S.L. Kravtsova from the Prozritelev and Prave Stavropol State Museum-Reserve for the opportunity to work with the materials from Ust-Dzheguta, and O.A. Brileva from the State Museum of Oriental Art (Moscow) for her assistance and valuable comments.