Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part II

Автор: Ivanov L.A., Xu L.D., Pisarenko Zh.V., Wang Q., Prokopiev P.S.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 2 Vol.13, 2021 года.

Бесплатный доступ

The article provides an abstract review of patents. The results of creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials, being implemented, allow achieving a significant effect in construction, housing and community services, and related sectors of the economy. For example, the invention «Method for liquidphase synthesis of nanostructured ceramic material in the CeO2–Sm2O3 system to create a solid oxide fuel cell» can contribute to the active development of alternative, hydrogen energy. Fuel cells have a wide range of applications – from batteries in portable electronic devices to large-scale power generation and autonomous use (for example, in remote areas). Power plants based on fuel cells are almost twice as economical as traditional ones. Their efficiency can reach 85%, and the amount of harmful emissions is almost 100 times lower due to the lack of direct chemical contact of the fuel with the oxidizer. The specialists can also be interested in the following inventions in the area of nanotechnologies: method of increasing the tensile strength of fiber composites by means of preliminary modification of carbon fibers with carbon nanotubes and molecules containing amino groups; preparation method of pure silver nanowires; towards safe and sustainable innovation in nanotechnology; method of distribution of carbon-based nanoparticles in the production of nanocomposite unidirectional thermoplastic tapes; device for reducing the impact of vibration and shock effects on the performance of technological equipment; high-density three-dimensional electrically conductive micro- and mesoporous material based on carbon nanotubes and / or low-layer graphenes and a method for its preparation; nanotechnology as a viable alternative for the removal of antimicrobial resistance determinants from discharged municipal effluents and associated watersheds; and others.

Nanotechnologies in construction, nanoparticles, carbon nanotubes, nanocomposites, nanostructured materials, nanostructured coatings

Короткий адрес: https://sciup.org/142226917

IDR: 142226917 | DOI: 10.15828/2075-8545-2021-13-2-79-89

Текст научной статьи Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part II

MAIN PART

A dvanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries.

A method for increasing the tensile strength of fibrous composites by means of preliminary modification of carbon fibers with carbon nanotubes and molecules containing amino groups (RU 2743566 C1)

The technical objective of the invention is to increase the mechanical strength of the composite by forming

REVIEW OF NANOTECHNOLOGICAL INVENTIONS a network of carbon nanotubes on the surface of carbon fiber. To increase the mechanical strength of the formed composite, a hardener is also added to the solution of carbon nanotubes, which, due to interaction with the amino groups present in the hardener, can chemically interact with epoxy groups in the epoxy resin – a binder, which ultimately leads to an increase in the strength of the entire composite [1].

The technical result is the development of a method for forming a network of carbon nanotubes bonded with carbon fiber and surrounded by molecules of the hardener, chemically interacting with the molecules of the binder. In this case, an improvement in the binding of epoxy groups to carbon fiber is achieved by improving the wettability of carbon fiber with resin during the treatment, due to the selection of effective solvents included in the composition of solutions applied to the surface of carbon fibers.

The concentration of CNT’s in the dispersion was selected based on the need to cover the carbon fiber surface with a grid of misoriented CNT’s, while ensuring acceptable uniformity. An increase in the concentration of CNT’s in the dispersion, higher than that proposed (250 µg/ml) in the invention, leads to an increase in the instability of the system as a whole (the formation of conglomerates and precipitation from the solution), and also leads to the complexity of application by aerosol, which leads to an inhomogeneous distribution of CNTs. on the surface of carbon fibers. The lower concentration limit (20 µg/ml) is defined as the minimum possible concentration for the formation of a CNT network by aerosol spraying, a decrease in concentration below 20 µg/ml leads to the formation of areas completely free of CNT’s and is unjustifiable economically, due to the duration of the layer deposition for uniform formation of CNT grids, since at this concentration, almost nothing but solvent is applied.

Preparation method of pure silver nanowires (CN111922359B)

The invention aims to solve the problem that PVP coated on the surface of a silver wire is difficult to remove after the silver wire is prepared by a conventional polyol method, and the silver nanowire material with high transparency and good conductivity is obtained.

A preparation method of pure silver nanowires belongs to the field of silver nanomaterial preparation, and comprises the steps of firstly preparing a solution A (ethylene glycol solution of polydiene dimethyl ammonium chloride) with the concentration of 0.05–0.1 mol/L and a solution B (ethylene glycol solution of silver nitrate) with the concentration of 0.4 mol/L; then dropwise adding the equal volume of the solution B into the solution A under magnetic stirring, magnetically stirring the mixed solution at room temperature for 10–20 min, heating to 160–200оС, and reacting for 6–10 hours to obtain a product; cooling the product at room temperature, separating the product by using a centrifugal machine, washing the centrifuged product, and dispersing the washed product in ethanol; silver nanowires are prepared by using a novel coating agent polydiene dimethyl ammonium chloride, and a protective agent coated on the surfaces of the silver nanowires can be removed by washing, so that pure silver nanowires are prepared, and better conductivity and light transmittance are realized [2].

The principle of the invention is as follows: firstly, different previous protective agents of polydiene dimethyl ammonium chloride are used, wherein the polydiene dimethyl ammonium chloride can induce the growth of silver wires, has adsorption effect on specific crystal face (100) of the silver and can control the growth of the silver wires. The dissociated chloride ions and silver ions can generate silver chloride, so that the nucleation effect is achieved, the concentration of the silver ions in the reaction process can be controlled, the reaction rate is adjusted, and the growth of silver wires is facilitated. Most importantly, unlike the traditional strong adsorption of PVP on the silver wire, the polydiene dimethyl ammonium chloride coated on the surface of the silver wire can be removed by washing, and then the pure silver wire is prepared.

Compared with the prior art, the invention has the following beneficial technical effects: silver nanowires are prepared by using a novel coating agent polydiene dimethyl ammonium chloride, and a protective agent coated on the surfaces of the silver nanowires can be removed by washing, so that pure silver nanowires are prepared, and better conductivity and light transmittance are realized.

The invention is realized by the following technical scheme:

-

– step 1, respectively preparing a solution A, namely a glycol solution of polydiene dimethyl ammonium chloride with the concentration of 0.05–0.1 mol/L, and a solution B, namely a glycol solution of silver nitrate with the concentration of 0.4 mol/L;

-

– step 2, dropwise adding the solution B with the same volume into the solution A under magnetic stirring, magnetically stirring the mixed solution at room temperature for 10–20 min, heating to 160–200оС, and reacting for 6–10 hours to obtain a product;

-

– and 3, cooling the product at room temperature, separating the product by using a centrifugal machine, washing the centrifuged product, and dispersing the product in ethanol. Further, the molecular weight of the polydiene dimethyl ammonium chloride in the step 1 is 100 000–500 000, the silver nitrate is sieved by a 20– 100 mesh sieve before the solution is prepared, and the ethylene glycol is anhydrous ethylene glycol.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Further, the solution B can be dissolved and prepared by ultrasonic, wherein the ultrasonic time is 3–5 min, and the ultrasonic frequency is 40 KHz.

Further, the solution A is mixed by magnetic stirring, and the stirring speed is 100–500 rpm.

Further, the speed of dripping the solution B in the step 2 is 1–3 mL/min, and the rotation speed of magnetic stirring is 350–600 rpm.

Further, the heating mode in step 2 is an oil bath preheated to a specified temperature, or an oven or other heating equipment.

Further, the reaction in step 2 is carried out under quiescent conditions.

Further, the rotation speed of the centrifuge in the step 3 is 10 000–20 000 rpm, and the centrifugation time is 3–10 min.

Further, the washing in step 3 is preferably performed by washing with an organic detergent for 1–4 times, such as acetone, ethanol, etc., and then washing with deionized water for 3 times.

Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials

The European Green Deal, the European Commission’s new Action Plan for a Circular Economy, the new European Industrial Strategy and the Chemicals Strategy for Sustainability launched in October 2020 are ambitious plans to achieve a sustainable, fair and inclusive European Union’s economy. In line with the United Nations Sustainable Development Goals 2030, these policies require that any new material or product should be not only functional and cost-effective but also safe and sustainable to ensure compliance with regulation and acceptance by consumers [3].

Nanotechnology is one of the technologies that could enable such a green growth. This paper focuses on advanced nanomaterials that actively respond to external stimuli, also known as ‘smart nanomaterials’, and which are already on the market or in the research and development phase for non-medical applications such as in agriculture, food, food packaging and cosmetics. A review shows that smart nanomaterials and enabled products may present new challenges for safety and sustainability assessment due to their complexity and dynamic behavior. Moreover, existing regulatory frameworks, in particular in the European Union, are probably not fully prepared to address them. What is missing today is a systematic and comprehensive approach that allows for considering sustainability aspects hand in hand with safety considerations very early on at the material design stage. The authors call on innovators, scientists and authorities to further develop and promote the ‘Safe- and Sustainable-by-Design’ concept in nanotechnology and propose some initiatives to go into this direction.

Method of distribution of carbon-based nanoparticles in the production of nanocomposite unidirectional thermoplastic tapes (RU 2741945 C1)

The invention relates to the chemistry of polymers and can be used in the manufacture of products and structures for construction, mechanical engineering, aviation, astronautics, shipbuilding, as well as the oil and gas industry. First, the powder of a thermoplastic polymer, for example, polyethylene, polypropylene, polyamide, polyphenylene sulfide, polyimide, polyamideimide or polyetheretherketone, is mixed, up to 2 wt.% modifying particles based on carbon in the form of fullerene soot with an average particle size of 80 nm, and sodium lauryl sulfate as a surfactant. Then the prepared powder mixture is kneaded with water to obtain a slurry through which the roving is pulled. The roving material is selected so that its melting point is higher than that of the indicated polymers. The invention makes it possible to provide such a distribution of modifying particles based on carbon in the production of unidirectional thermoplastic tapes with increased strength and elasticity of products made from them [4]. A method for distributing carbon-based modifying particles in the production of unidirectional thermoplastic tapes, comprising pulling roving through an aqueous suspension containing a thermoplastic polymer and said carbon-based modifying particles, characterized in that first a semi-finished product is prepared containing a thermoplastic polymer powder, for example, polyethylene, polypropylene, polyamide , polyphenylene sulfide, polyimide, polyamidimide or polyetheretherketone, and up to 2 wt.% fullerene soot, the average particle size of which is 80 nm, in the presence of sodium lauryl sulfate as a surfactant, then the prepared powder mixture is mixed with water to obtain a suspension, and the roving material is selected on the condition that its melting point is higher than that of the indicated polymers.

Device for reducing the impact of vibration and shock effects on the performance of technological equipment (RU201829 U1)

The presented utility model relates to the devices for reducing the impact of vibration and shock effects, which could affect the performance of automatic controls for technological equipment during the operation of technological equipment while moving a vehicle [5].

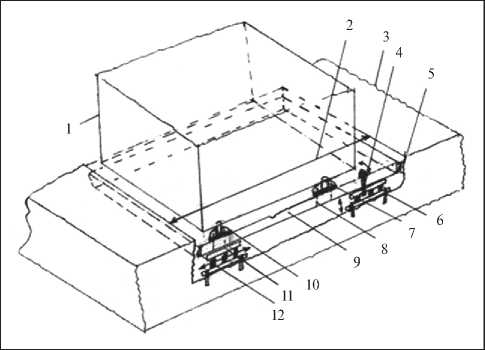

The utility model is aimed at solving the technical problem of improving the reliability of technological equipment installed in closed-body trucks during transportation over rough terrain. Fig. 1 shows the conceptual basis of the utility model.

The basic idea of this technical solution is based on the fact that the equipment is fixed firmly and immobile on a special platform. It is rigidly connected to the vibra-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Fig. 1. Device for reducing the impact of vibration and shock effects on the performance of technological equipment: 1. Technological equipment. 2. Niche.

3. Floor. 4. Fixing device. 5. Retainer. 6. Holder.

7. Leg. 8. Bolt. 9. Platform. 10. Thrust-bearing. 11. Vibration isolator. 12. Bearer.

tion isolator, which provides vibration and shock suppression.

Operation of the “Device for reducing the impact of vibration and shock effects on the performance of technological equipment”. When the base chassis moves over the rough terrain (not shown in the figure), sharp oscillatory movements can occur, the effect of which on the automation of technological equipment (see Fig. 1, number 1) is reduced due to the operational properties of the vibration isolator (see Fig. 1, number 11), which provides stability during prolonged static and dynamic load. The presence of rigidly fixed support bearer (number 12) on a platform fix end (number 9) and on the end wall of the niche (number 2) of the retainer (number 5) provides additional protection to the equipment (number 1) from vibration and shock effects.

The technical task is solved due to the fact that the «Device for reducing the impact of vibration and shock effects on the performance of technological equipment» is characterized (1) in that a niche is built in the floor, to which a vibration isolator (item brand SP1180-03) is rigidly fixed by a holder, connected by a fastening device to a platform made of a polymer composite material, 30 mm thick, and (2) a support bearer is fixed rigidly along the perimeter of the platform, and (3) a 50 mm thick rubber (item brand TMKSH) retainer is rigidly attached to the wall of the niche.

Experimental studies conducted on the production base of LLC “Projectintertechnika” allowed authors to establish that placing a for example of washing machine on the proposed device increases the duration of its working capacity by 1.35–1.4 times, reduces vibration and shock effects on automation by 1.35–1.51 times.

The proposed device has a novelty and significant differences from the prototype. It provides an increase in the reliability of the technological equipment installed inside the container body during transportation over rough terrain. The technical solution can be used in any closed-body trucks, inside which technological equipment is placed.

Application filed by Federal State Military Educational Institution of Higher Education “Military academy of material and Technical Support named after General of the Army A.V. Khrulev” of the Ministry of Defense of the Russian Federation.

High-density three-dimensional electrically conductive micro- and mesoporous material based on carbon nanotubes and / or low-layer graphenes and a method for its production (RU 2744163 С)

The group of inventions [6] relates to the field of obtaining materials – compacts based on multilayer carbon nanotubes (MCNT’s) and / or low-layer graphite fragments (LGF), as well as metal and metal oxide nanoparticles that can be used in the production of composites for absorbing sounds and electromagnetic radiation, carriers of biologically active objects, catalysts and sorbents, elements with controlled resistance, magnetic composites, etc., which can be used in nanoelectronics, energy, aerospace, engineering and construction industries, etc.

The technical result is to obtain compacts based on MCNT and / or UTP, characterized by the mechanical strength and stability of the frame under ultrasonic influences with a power of more than 700 W on the diameter of the base of the emitter 10 mm, incl. in viscous media, the parameters of the dynamic viscosity of which are higher than 1 mPa at a temperature of 25оC.

In one embodiment of the invention, the presence of metal inclusions in the composition of the compacted product provides carbonization of MCNTs and UGFs with several structured carbon shells, which further strengthens the framework structure and makes the particles stable during catalytic tests.

The compactizate may additionally contain metal nanoparticles ranging in size from 4 to 100 nm, covered with a carbon shell, placed in the nodes of the framework (in the places where nanotubes / MGF are crosslinked) up to 30% by weight of the compactisate weight. As a rule, carbon shells of nanoparticles have a thickness of 2–8 graphene layers (from 8 to 12 nm).

Nanotechnology as a viable alternative for the removal of antimicrobial resistance determinants from discharged municipal effluents and associated watersheds: A review

Antibiotic resistance (AR) remains a serious challenge causing global outcry in both the clinical setting

REVIEW OF NANOTECHNOLOGICAL INVENTIONS and the environment. The huge influence of municipal wastewater effluent discharges on the aquatic environment has made the niche a hotspot of research interest in the study of emergence and spread of AMR microbes and their resistance determinants/genes. The current review adopted a holistic approach in studying the proliferation of antibiotic resistance determinants (ARDs) as well as their impacts and fate in municipal wastewater effluents and the receiving aquatic environments. The various strategies deployed hitherto for the removal of resistance determinants in municipal effluents were carefully reviewed, while the potential for the use of nanotechnology as a viable alternative is explicitly explored [7].

The following conclusions are made from this review: 1. The incidence of antibiotic resistance genes in treated wastewater are now consistently reported in various parts of the world even though there is no sufficient data on the fate and abundance of ARGs in WWTPs. 2. Several strategies have been employed for the removal of these genes from wastewater with little or no progress. 3. The consideration of the influence of operating conditions such as pH, temperature, COD, BOD, chlorine availability, dosage of adsorbent, water flow, removal mechanism and genetic conjugation, transformation and transduction, mutation and selection in the treatment of wastewater in plants is important. 4. The use of nanotechnology as a tool to eliminate ARGs by designing materials that will effectively remove nucleic acids from water should be further explored. 5. Since the surface of nucleic acids is negatively charged, the development of a nanoparticle with positive surface charge, will effectively remove this substance from wastewater by electrostatic interaction.

Method of obtaining multilayer wear-resistant diamond-like coatings (RU 2740591 C1)

The invention relates to the field of obtaining superhard wear-resistant coatings in a single vacuum cycle with predetermined properties, specifically to the technology of forming a multilayer diamond-like coating, and can be used in heavy and light industry, transport to improve the performance of products and increase their service life, parts of friction units , precision engineering parts. It is known that the main reason for the wear of heavily loaded friction units (gear and spline gears) is the appearance of cracks in its contacting part, which are the cause of the appearance of chips and chipping associated with fatigue failure and the phenomenon of fretting. One of the ways to increase the durability and performance of coated spline joints is the application of multilayer coatings. The presence in the coating of layers with certain thermophysical and mechanical properties can inhibit the formation and propagation of cracks without reducing microhardness, improve the thermally stressed state of the coated splines and increase wear resistance.

It should also be noted that during friction at high speeds and vibrations, the processes of fretting-oxidative wear are intensified, contributing to the softening of the coating and base material [8].

The technical result of the invention is to improve the quality of diamond-like films by changing their structure and composition, obtaining the lower layer with high adhesion to the substrate material, the middle layer with high hardness and increased wear resistance, and the upper layer with good thermal conductivity and heat resistance and a low coefficient of friction. Preliminarily, the products are cleaned by electro-pulse polishing in an aqueous solution of ammonium salts, followed by ultrasonic treatment of the product. After that, the product is moved to a vacuum chamber and treated with argon ions and nitriding in a mixture of gases. Then, by the magnetron method, surface deposition of alloying elements with a thickness of 0.2 µm from an Nb-Hf alloy is carried out on the surface of the article. After that, a composite metal-carbon layer is applied with alternating layers, while first a gradient Cr coating is applied with a linear change in parameters during the application from the initial value to the final value for 90 s, and then the next layer of the Al–Si gradient coating is applied. Thereafter, a diamondlike coating is applied with a low-energy ion source.

Development of Nanotechnology in the World and Nanotechnology Standards in Turkey

The aim of this study is to examine the development of nanotechnology in the world and present the evaluations of experts on the nanotechnology standards in Turkey. This paper focuses on in-depth interviewing that involves asking informants open-ended questions, and obtain data deemed useful by the researchers. Ten authorities in nanotechnology institutions such as Turkish Standards Institute, Nanotem, Economy Ministry, and universities were interviewed and their opinions were given. Turkey needs to overcome some issues on nanotechnology. Some of them include the lack of health and environment standards of nanotechnology, the lack of legal arrangements, problems with nanotechnology products and commercialization, the lack of a unity providing coordination between sectors in nanotechnology, the lack of an arrangement about using of nanotechnology. There are international nanotechnology standards but there is not health and environment standards in Turkey [9].

While regulations on standards are important for the application of nanotechnology, they are also necessary for the production and marketing of products. It also plays an important role in public information and awareness. In the first stage of the establishment of the standards, recommendations should be made by the academic parties such as research institution, government agency. Reasonable recommendations should be received and

REVIEW OF NANOTECHNOLOGICAL INVENTIONS evaluated by a government agency. The result of the evaluation should be enacted and implemented by the relevant institution.

Wear-resistant and yellowing-resistant decorative material and preparation method thereof (CN111923540B)

The invention discloses a wear-resistant yellowing-resistant decorative material and a preparation method thereof. The decorative material comprises decorative paper and a coating which permeates into the interior of the decorative paper and is cured, wherein the coating comprises at least one of acrylic epoxy ester, acrylic novolac epoxy ester, polyurethane acrylate oligomer, polyester acrylate and an active monomer, the coating also comprises modified nano titanium dioxide, and the surface of the modified nano titanium dioxide is coated with quaternary ammonium salt chitosan and sulfonated lignin, so that the wear resistance, the light color fastness and the yellowing resistance of the decorative material can be effectively improved [10].

The wear-resistant and yellowing-resistant decorative materials prepared in examples 1 to 9 and comparative examples 1 to 3 have good flexibility, and the surfaces of the materials are not cracked after the materials are bent and subjected to conventional flat pasting, coating and modeling pasting treatment.

In addition, the above embodiment can adjust the oligomer type, monomer type, plastic film type and related process parameters in the related coating according to the actual performance requirements, for example, the inventor finds that the viscosity of the coating is 5–200 cps, and the coating amount is 20–100 g/m2 after curing. The toughness of the wear-resistant and yellow-ing-resistant decorative material is improved, the bonding strength of the decorative paper and the plastic film is improved, and the decorative paper and the plastic film are prevented from being peeled off; the electron beam curing dosage is 5–50 kGy, the running speed of the wear-resistant and yellowing-resistant decorative material during curing is 10–200 m/min, and the cured wearresistant and yellowing-resistant decorative material has good toughness.

According to actual needs, a required pattern can be printed on the wear-resistant and yellowing-resistant decorative material prepared in the embodiment, so that the wear-resistant and yellowing-resistant decorative material has various wood grains or patterns.

Finally, it should be noted that the above embodiments are only used for illustrating the technical solutions of the present invention and not for limiting the protection scope of the present invention, and although the present invention is described in detail with reference to the preferred embodiments, it should be understood by those skilled in the art that modifications or equivalent sub- stitutions can be made on the technical solutions of the present invention without departing from the spirit and scope of the technical solutions of the present invention.

Application filed by: 广东天安高分子科技有限公司 (Guangdong Tianan Polymer Technology Co., Ltd).

Method for liquid-phase synthesis of nanostructured ceramic material in the CeO2–Sm2O3 system to create an electrolyte for a solid oxide fuel cell (RU 2741920 C1)

Currently, the demand for energy resources is increasing, while fossil fuels are gradually depleted, and the environmental situation in the world is deteriorating. In this regard, the alternative, hydrogen energy is actively developing [11]. For its further development, it is necessary to search for and create modern materials for electrochemical energy generators. Solid oxide fuel cells (SOFCs) are promising among them.

Fuel cells have a wide range of applications - from batteries in portable electronic devices to large-scale power generation and autonomous use (for example, in remote areas). Power plants based on fuel cells are almost twice as economical as traditional ones. Their efficiency can reach 85%, and the amount of harmful emissions is almost 100 times lower due to the absence of direct chemical contact of the fuel with the oxidizer.

Solid oxide fuel cells (SOFCs) are attractive electrochemical generators that efficiently convert the chemical energy of the interaction of hydrogen with oxygen into electrical energy with minimal impact on the environment. On the basis of such elements, pilot plants with a capacity of up to 100 kW were created. SOFCs are mainly applicable for power plants of high power, in which it is possible to minimize the relative share of heat losses into the surrounding space. One of the main advantages of this type of fuel cell is the absence of a liquid electrolyte and the possibility of creating a miniature unit cell consisting of thin layers of electrodes and electrolyte.

The method is carried out by choosing cerium nitrate salts Ce (NO3)3•6H2O and samarium Sm (NO3)3•6H2O as starting reagents, from which solutions with a concentration of ~0.5 M. evaporated in a water bath for 3 hours until a supersaturated solution is formed, which is cooled at a temperature of 3–5оC, after which the crystalline hydrate is subjected to ultrasonic treatment for 30 minutes. The synthesized powder of the solid solution is subjected to heat treatment at 600оC, then compacts are formed by the method of uniaxial cold pressing at a pressure of 150 MPa, which are fired at a temperature of 1300оC in a tube furnace with isothermal holding for 2 hours and a heating rate of 350–400о/h. The technical result is the development of a promising technology for liquid-phase synthesis of ceramics for obtaining a solid electrolyte based on cerium dioxide for solid oxide fuel cells.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Super-hydrophobic anti-icing aircraft aluminum alloy skin (CN212243774U)

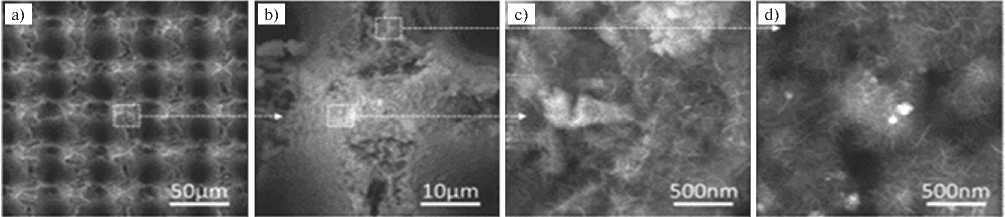

The surface of the skin consists of a multi-stage micro-nano structure, the micro-nano structure is based on a three-dimensional micro-cone structure periodically distributed on the surface of an aluminum alloy substrate, and nano sheets densely growing and nano flower clusters consisting of the nano sheets are distributed on the surface of the micro-cone; and one or two of submicron spheres and submicron popcorn are dispersed and distributed on the surface of the micrometer cone or between the micrometer cone and the micrometer cone.

Through the utility model discloses an aviation aluminum alloy covering surface that sets up has extremely low ice adhesion, and ice and adhesion strength between the surface can be low to 6 kPa, and ice can drop by oneself under its self action of gravity or under the slight vibrations condition. The skin can be widely applied to the anti-icing field of aviation key components, ships, ground transportation tools, refrigerators, air conditioners and the like [12].

Specific examples are set forth below to provide a better understanding of the present invention.

Example 1.

The utility model discloses a micro-nano structure of super-hydrophobic anti-icing aviation aluminum alloy skin with ultra-low ice adhesion, which is shown in Fig. 2, and the surface is composed of a complex micro-nano tertiary structure which is periodically distributed, wherein the nano structure is a two-dimensional nano sheet structure and densely grows on the surface of a threedimensional micrometer cone.

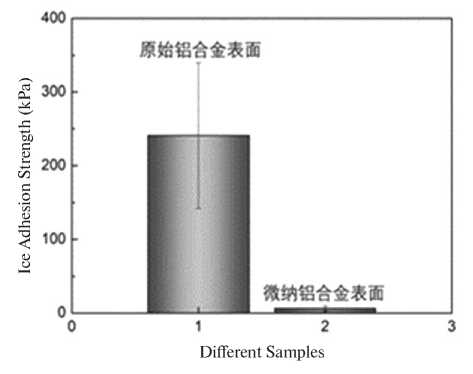

The submicron sphere structure is formed by stacking and growing nano sheets, the diameter of the submicron sphere structure is about 500 nm, the submicron sphere structure is dispersedly distributed on a micron cone, and the whole three-dimensional three-level complex micro-nano structure has the structural characteristic of integrated interconnection. After surface chemical modification, the surface may exhibit a water drop con- tact angle of about 160о. The ice adhesion strength of the skin surface was only 6 kPa, which was reduced by a factor of 40 compared to the untreated aluminum alloy skin surface (240 kPa), as shown in Fig. 3.

Fig. 3. Shows a comparison of ice adhesion strength of a conventional aluminum alloy skin and an aluminum alloy skin of example 1 of the present invention

Furthermore, the ice adhesion strength of the skin surface was still not higher than 20 kPa after 10 push ice tests, indicating that the surface had better mechanical durability.

Application filed by: 清华大学 (Tsinghua University).

Nanotechnology activities: environmental protection regulatory issues data

Despite the significant increase in the use of nanomaterials, little has been discussed about the possible toxic effects for the environment and human health. The same characteristics that make nanoparticles interesting

Fig. 2. Is a scanning electron microscope photograph of a multi-stage micro-nano structure of a super-hydrophobic anti-icing aircraft aluminum alloy skin with ultra-low ice adhesion in example 1 of the present invention

REVIEW OF NANOTECHNOLOGICAL INVENTIONS from the point of view of technological application, may be undesirable when they are released to the environment, given the intrinsic characteristics of nanoparticles, such as size, surface area and agglomeration/dispersion capacity, which can facilitate the translocation of these by the environmental compartments and cause, in a cumulative way, damages to the food chain. Experimental studies carried out so far have indicated that several types of nanoparticles may have adverse effects on the embryonic development of invertebrates such as sea urchins, oysters and freshwater snails; of non-mammalian vertebrates (fish and frogs) and of mammals – rats and mice. In view of the nanotechnology scenario, it is essential to adopt specific regulations that ensure the protection of the environment, so that we can benefit from the innovation that nanotechnology brings us without harming the planet [13].

This research provides a contextualization of environmental protection regulatory issues related to nanomaterials with respect to scientific research. Although numerous studies have already identified the negative impacts on the environment that nanoparticles can cause, the results show that studies related to the toxicity and use of nanomaterials were mostly directed towards studies aimed at human protection. A paradigm shift was noted. From 2003 to 2011, the focus of studies related to nanomaterials was focused on laws and regulations. In the period from 2012 to 2020, studies focused on the risk assessment of nanomaterials, including in the regulatory sphere.

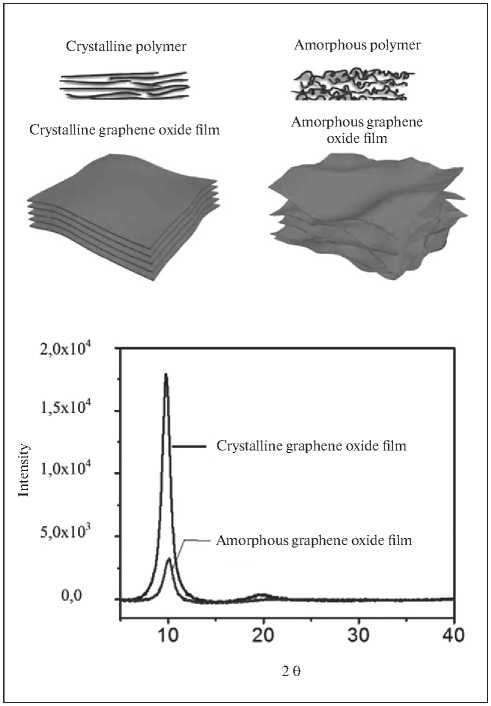

Flexible graphene film and method for its manufacture (RU 2742409 C1)

The invention relates to nanotechnology and can be used in the manufacture of electrothermal materials with high mechanical properties and low density for flexible electronic devices [14]. Graphene oxide or graphene is dispersed in a strong solvent. The resulting solution of graphene or graphene oxide is cast and a corresponding liquid film with a thickness of 0.5 to 30 mm is obtained, which is immersed in a weak solvent. After gelation, the film is dried at 50–100оC in an oven or in a suspended state for 5–24 hours to obtain a flexible graphene or graphene oxide film. Concentration of graphene oxide solution 5–20 mg/ml, graphene solution 5–40 mg/ml. A liquid film of graphene oxide is immersed in a weak solvent for 2–24 hours, and a liquid film of graphene for 1–24 hours. N, N-dimeth-ylformamide, water, N-methylpyrrolidone, acetone, dimethylsulfoxide, pyridine, dioxane are used as a strong solvent. N, N-dimethylacetamide, tetrahydrofuran, or ethylene glycol. Ethyl acetate, dichloromethane, alkanes, methanol, ethanol, n-butanol, ethylene glycol, propylene glycol, glycerin, isobutanol, methyl acetate, butyl

Fig. 4. Proportionally depicts a crystalline graphene oxide film, an amorphous graphene oxide film, a crystalline polymer, and an amorphous polymer acetate or acetic acid are used as a weak solvent. After drying, a flexible graphene film is reduced by chemical, thermal, or electrolytic methods. The resulting flexible films have a degree of crystallization below 60% and consist of multiple folded sheets of graphene oxide or graphene superimposed on each other. The invention makes it possible to increase the flexibility of macroscopic graphene films in a simple and technological way without the use of substrates.

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material [15].

-

• A method of obtaining a wear-resistant nanostructured coating [16].

-

• Ferroelectric nanocomposite material based on porous glass and materials of the potassium dihydrogen phosphate group [17].

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

-

• Preparation method of nanometric size metal oxide additives that reduce the temperature of sintering and/ or increase productivity in the manufacture of ceramic parts, improving mechanical properties without affecting the vitrification properties of ceramic bodies, tiles or coatings [18].

-

• Method for producing yttrium-aluminum garnet nanopowder [19].

-

• A method of obtaining polymetallic nanopowders [20].

-

• Experimental assessment of cement mortar using nano oxide compounds [21].

-

• A method for producing graphene-containing suspensions and a device for its implementation [22].

-

• Method for removing residual solvent from layers based on carbon nanotubes [23].

-

• Bubble electrospinning device [24].

-

• A method for modifying the surface of inorganic nanoparticles – bivalent metal oxides used to assess the toxic effect [25].

-

• A method for obtaining stabilized linear carbon chains in a liquid [26].

-

• Nanoscale digital logic element [27].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Therefore, we hope that the information published in this section will be in demand and useful for specialists.

Список литературы Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part II

- Nelyub V.A., Orlov M.A., Kalinnikov A.N. et al. A method of increasing the tensile strength of fibrous composites by means of preliminary modification of carbon fibers with carbon nanotubes and molecules containing amino groups. Russian Federation Patent 2743566. 2021-02-19.

- Preparation method of pure silver nanowires. Patent CN111922359B. 2020-10-19. Available from: https://patents. google.com/patent/CN111922359B/en?q=Nanomaterials&country=CN,RU&before=priority:20201231&after=priority:20200101&status=GRANT&type=PATENT&sort=new

- Gottardo S., Mech A., Drbohlavova J., Malyska A., Bowadt S., Sintes J. R., Rauscher H. Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact. 2021;100297.

- Bobrynina E.V., Vasilyeva E.S., Goncharenko D. et al. Method of distribution of carbon-based nanoparticles in the production of nanocomposite unidirectional thermoplastic tapes Russian Federation Patent 2741945.2021-01-29.

- 5.Romanchikov S.A., Polpenyuk I.D. et al. Device for reducing the impact of vibration and shock effects on the performance of technological equipment.2020-10-06. Available from: https://patents.google.com/patent/RU201829U1/ru?q=Nanomaterials&country=CN,RU&before=priority:20201231&after=priority:20200101&status=GRANT&type=PATENT&sort=new&page=2

- Savilov S.V., Suslova E.V., Chernyak S.A. et al. Method for modifying the surface of inorganic nanoparticles – bivalent metal oxides used to assess the toxic effect. Russian Federation Patent 2744126.2021-02-03.

- Ojemaye M.O., Adefisoye M. A., Okoh A.I. Nanotechnology as a viable alternative for the removal of antimicrobial resistance determinants from discharged municipal effluents and associated watersheds: A review. Journal of Environmental Management. 2020;275:111234.

- Kolesnikov V.I., Sychev A.P., Kolesnikov I.V. et al. The method of obtaining multilayer wear-resistant diamondlike coatings. Russian Federation Patent 2740591.2021-01-15.

- Calipinar H., Ulas D. Development of Nanotechnology in the World and Nanotechnology Standards in Turkey. Procedia Computer Science. 2019; 158:1011–1018.

- Wear-resistant and yellowing-resistant decorative material and preparation method thereof. Patent CN111923540B. 2020-10-13. Available from: https://patents.google.com/patent/CN111923540B/en?oq=CN111923540B

- Kalinina M.V., Fedorenko N.Yu., Dyuskina D.A., Shilova O.A. The method of liquid-phase synthesis of nanostructured ceramic material in the CeO2–Sm2O3 system to create an electrolyte of a solid oxide fuel cell. Russian Federation Patent 2741920. 2021-01-29.

- Super-hydrophobic anti-icing aircraft aluminum alloy skin. Patent CN212243774U. 2020-08-04. Available from: https://patents.google.com/patent/CN212243774U/en?q=nanomaterial&q=construction&country=CN,RU,FI& before=priority:20201231&after=priority:20200101&status=GRANT&type=PATENT&sort=new&page=4

- Almeida L., Felzenszwalb I., Marques M., Cruz C. Nanotechnology activities: environmental protection regulatory issues data. Heliyon. 2020; 6(10):e05303.

- Gao Chao, Xu Zhen, Xiao Yuhua. Flexible graphene film and a method for its production. Russian Federation Patent 2742409. 2021-02-05.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021;13(1):23–31.Available from: doi: 10.15828/2075-8545-2021-13-1-23-31.

- Balaev E.Yu.O., Buzko V.Yu., Goryachko A.I. et al. A method of obtaining a wear-resistant nanostructured coating. Russian Federation Patent 2742751. 2021-02-10.

- Tarnavich V.V., Sidorkin A.S., Korotkova T.N. et al. Ferroelectric nanocomposite material based on porous glass and materials of the potassium dihydrogen phosphate group. Russian Federation Patent 2740563.2021-01-15.

- Ivanov L.A., Ishkov A.D., Pisarenko Zh.V., Wang Q., Prokopiev P.S. Nanotechnologies: a review of inventions and utility models. Part IV. Nanotechnologies in Construction. 2020;12(5):275–284. Available from: doi: 10.15828/2075-8545-2020-12-5-275-284.

- Abiev R.Sh., Zdravkov A.V., Kudryashova Yu.S. A method of obtaining nanopowder of yttrium-aluminum garnet. Russian Federation Patent 2741733. 2021-01-28.

- Spiridonov N.I., Sleptsov A.V., Seliverstov V.K. et al. A method of obtaining polymetallic nanopowders. Russian Federation Patent 2742634. 2021-02-09.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Nanotechnologies: are view of inventions and utility models. Part V. Nanotechnologies in Construction. 2020;12(6): 331–338. Available from: doi: 10.15828/2075-8545-2020-12-6-331-338.

- Pershin V.F., Alkhilo Z.A., Baranov A.A. et al. Method for producing graphene-containing suspensions and a device for its implementation. Russian Federation Patent 2743523. 2021-02-19.

- Nelyub V.A., Kalinnikov A.N., Borodulin A.S. et al. Method for removing residual solvent from layers based on carbon nanotubes. Russian Federation Patent 2743559. 2021-02-19.

- Ivanov LA., Demenev A.V., Pisarenko Zh.V., Wang Q., Nanotechnologies: a review of inventions and utility models. Part III. Nanotechnologies in Construction.2020;12(3):140–146. Available from: doi: 10.15828/2075-8545-2020-12-3-140-146.

- Ignatova A.M., Ignatov M.N., Zaitseva N.V., Zemlyanova M.A. Method for modifying the surface of inorganic nanoparticles – bivalent metal oxides used to assess the toxic effect. Russian Federation Patent 2744126. 2021-03-02.

- Kutrovskaya S.V., Kucherik A.O., Skryabin I.O. et al. A method for obtaining stabilized linear carbon chains in a liquid. Russian Federation Patent 2744089. 2021-03-02.

- Gurovich B.A., Prikhodko K.E., Kuleshova E.A., Kutuzov L.V. Nanoscale digital logic element. Russian Federation Patent 2744160. 2021-03-03.