Investigation of the dependence of the internal disruptive pressure in a fire hose on geometric densities on the warp and the weft of its woven reinforcing frame

Автор: Kaldybayev R.T., Aripbayeva A.E., Mirzamuratova R. Sh., Stepanov S.G., Bekzat A.B.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 1 (131), 2021 года.

Бесплатный доступ

In this article, based on the obtained formula for calculating the strength of a pressure fire hose(PFN) under the action of internal hydraulic pressure, the dependence of the disruptive pressure in alatex pressure fire hose, designed for an operating pressure of 1.6 H, on such parameters as geometric densities on the warp and the weft, is studied. As a result of the studies, the pattern of decreasing the disruptive pressure of a fire hose with an increase in the geometric densities on the warp and the weft of a reinforcing frame of a pressure fire hose was experimentally established. When designing new fire hoses, it is important to take into account the significant dependence of the disruptive pressure on the geometric densities on the warp and the weft of a reinforcing frame. Recommendations are given on choosing the optimal parameters for a woven reinforcing frame of latex pressure fire hoses with a diameter of 77 mm.

Pressure fire hose, woven reinforcing frame, disruptive internal hydraulic pressure, geometrical densities on the warp and the weft

Короткий адрес: https://sciup.org/140256801

IDR: 140256801 | УДК: 677.024 | DOI: 10.48184/2304-568X-2021-1-21-25

Текст научной статьи Investigation of the dependence of the internal disruptive pressure in a fire hose on geometric densities on the warp and the weft of its woven reinforcing frame

Pressure fire hoses (PFH) are one of the main means of fire extinguishing. Structurally, they are designed as lay-flat flexible piping systems on a woven basis with rubber layers (layer) and serve to supply fire-extinguishing liquid (water and water solutions of foaming agents) under the pressure to a distance to the fire site. In relation to the PFH, the requirement for their reliability and operability is extremely important, since the positive result in fire extinguishing directly depends on this, and as a result, saved lives of people and property.

In connection with the above, the priority is to establish its own production of new hightech PFH on the territory of the Republic of

Kazakhstan. To do this, along with the availability of equipment and production facilities, it is important to develop and deepen the theory of calculation and design methods of PFH, which will certainly be in demand when calculating, designing and creating new types of high-tech domestic PFH.

Materials and research methods

It is important, both from scientific and practical point of view, to investigate the dependence of the PFH(Pressure fire hoses)strength on a number of parameters of their woven reinforcing frame [1,2]. Since the decisive characteristic of the PFH strength is their disruptive pressure, regulated by state standard 51049-97, it is advisable to establish the dependence of the disruptive pressure in the PFH on such parameters as the geometric densities on the warp L0 and the weft Ly, breaking load of the weft threads Nbreak, hose radius R, coefficients of vertical collapse of the warp ηОВ and the weftηyВ threads, diameters of the warp d0 and the weft dy threads, coefficients β О , β У , characterizing the lengths of contact zones between threads in fractions of diameters of the warp and the weft threads. All these listed parameters according to the formula affect the disruptive pressure value.

Based on the formula:

p разр

2 NразрL

|

R - |

' L y (2 L o - e o d o ) + L o |

/2 1 0,212 L 2 ( d Пов + d ) 2 2 ( L y + ( d o n oB + d y n yB ) 2 ) 2 +------ у-^ОВ---yJyBZT - e y d y ^ _ ( L y + ( d o n oB + d y ^ yB )2 )2 J |

the dependences of the internal disruptive pressure in the PFH on the geometric densities on the warp and the weft of its woven reinforcing frame were studied [3].

Results and their discussion

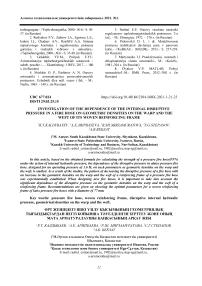

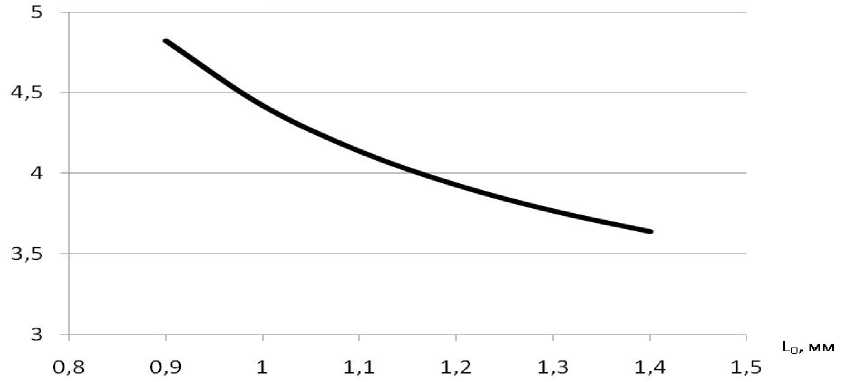

The dependences of the disruptive pressures’ values on the geometric densities of the warp and the weft threads of the woven reinforcing frame of the latex PFH manufactured by BEREG PA (production association) with a diameter of 77 mm, designed for the operating pressure of 1.6 H, are shown in accordance with Figures 1 and 2.

Р break, H

Figure 1 – The dependence of the disruptive pressure value p разр on the geometric density on the warp L O of the woven reinforcing frame of the latex PFHwith a diameter of 77 mm

Р break, H

Figure 2 – The dependence of the disruptive pressure value p break on the geometric density on the weft L у of the woven reinforcing frame of the latex PFH with a diameter of 77 mm

Based on the analysis of the presented dependences, it can be concluded that the disruptive pressure of the latex PFHwith a diameter of 77 mm substantially depends on the geometric densities on the warp and the weft of the woven reinforcing frame: with increase in the geometric density on the warp L 0 from 0.9 mm to 1.4 mm, the calculated disruptive pressure of the fire hose fall from 4.820 H to 3.637 H (1.325 times); as the geometric density of the weft L У increases from 2.1 mm to 2.7 mm, the calculated disruptive pressure of the fire hose decreases from 4.7 H to 3.666 H (1.282 times).

The revealed pattern of decreasing the disruptive pressure of the fire hose with increase in the geometric densities on the warp and weft of the woven reinforcing frame of the PFH can be explained as follows. In accordance with Figure 2.1 (a), the weft thread segment under consideration has a load from the hydraulic pressure inside the PFH acting on a strip with the length 2L0and with the width LУ, and in accordance with Figure 2.1 (b), the warp thread segment under consideration has a load from the hydraulic pressure inside the PFH acting on a strip with the length 2LУ and with the width L0. With increase in the geometric densities on the warp and the weft L0 and LУ of the woven reinforcing frame of the PFH, the areas of these strips increase, and, consequently, the loads falling on the considered thread segments increase. In this case, with the constant disruptive strength of the weft thread, the break of the considered weft thread segment will occur at a lower value of the hydraulic pressure of the extinguishing liquid inside the fire hose.

Thus, the increase in the geometric densities on the warp and the weft of the woven reinforcing frame of the latex PFH leads to the decrease in the disruptive pressure, i.e. to the decrease in its strength characteristics under the hydraulic action. And vice versa, the decrease in the geometric densities on the warp and the weft of the woven reinforcing frame of the fire hose leads to the increase in the disruptive pressure, i.e. to the increase in its strength characteristics under the hydraulic action. A similar conclusion was made by the author of [4], however a different formula was used to confirm it, characterizing the dependence of the disruptive pressure in the PFH on the woven parameters of its reinforcing frame. This formula, as already noted above, does not take into account such features of interaction of threads in the woven reinforcing frame of the hose, as experimentally found values of the coefficients of vertical collapse of the threads, the real lengths of the contact zones between the threads, the real shapes of the deformed axis of the threads.

It is important to consider the significant dependence of the disruptive pressure on the geometric densities of the warp and the weft of the woven reinforcing frame when designing new fire hoses. It is necessary to agree with the author’s conclusion [4] that decreasing the geometric densities of the warp and the weft threads of the woven reinforcing frame (if there are technological capabilities for this) seems to be the most effective way to increase the strength characteristics of the PFHunder the hydraulic action.However, the following conclusion of the author [4,5] on decreasing the cost of raw materials in the PFHmanufacture, if produce from threads of lower linear density more dense on the warp and the weft fabrics of the reinforcing frames of the PFH, while maintaining the strength characteristics of the threads, it is not obvious and requires confirmation. And this is due to the fact that in the manufacture of denser fabrics, the thread consumption increases, and a slight decrease in the linear density of the threads may not compensate for this increase.

Now, let’s make recommendations on the optimal choice of the geometric densities on the warp and the weft for the PFH of BEREG PA with a diameter of 77 mm. According to state standart 51049-97, the minimum disruptive pressure for the PFH with a diameter of 77 mm must not be lower than 3.5 H. The actual experimental disruptive pressure for the PFH by BEREG PA with a diameter of 77 mm was 4.2 H. Therefore, the excess of experimental values over the minimum requirements of state standart is 20%.The latter means that the geometric density on the weft according to the diagram in accordance with Figure 4.2 can be increased to 2.8 mm, which will just provide the minimum value for the disruptive pressure regulated by state standart in 3.5 H. However, we consider it appropriate to maintain a certain margin of the disruptive pressure, and therefore we recommend the value of the geometric density on the weft – 2.7 mm. The approximate value of the disruptive pressure in 3.67 H will correspond to this value of 2.7 mm according to the diagram in accordance with Figure 2.With the recommended geometric density, a noticeable decrease in the material consumption of the hose will occur. Our recommendation is valid if all other parameters of the woven reinforcing frame remain unchanged.

As for the optimal choice of the geometric density on the warp, according to the diagram in accordance with Figure 1, the value of this parameter should be recommended as 1.4 mm. The disruptive pressure of approximately

-

3.65 H (slightly higher than the state standart requirement) will correspond to this value, however with a noticeable decrease in the material consumption of the hose.

Conclusions

As a result of the study, it was found that the disruptive pressure of the PFH substantially depends on the geometric densities on the warp and the weft of the woven reinforcing frame (with the increase in the geometric densities, the calculated disruptive pressure of the PFH decreases, and, conversely, with the decrease in the geometric densities, the disruptive pressure increases).

Список литературы Investigation of the dependence of the internal disruptive pressure in a fire hose on geometric densities on the warp and the weft of its woven reinforcing frame

- Aripbayeva A.E., Myrkhalykov Zh.U.,Stepanov S.G. Ways for improvement of strength characteristics of a pressurefire hose. Известия Национальной академии наук РК. Серия геологии и технических наук. Алматы, НАН РК 2017. С.236-240.

- Арипбаева А.Е., Степанов С.Г. Исследование зависимости разрывного внутреннего гидравлического давления напорных пожарных рукавов от ряда параметров их тканой несущей оболочки // Молодые ученые - развитию текстильной и легкой промышленности: сб. матер. межвуз.научн.-техн. конф. асп. и студ. (Поиск-2016). - Иваново, 2016.- Ч. I. - С. 59-61.

- Арипбаева А.Е., Мырхалыков Ж.У., Степанов С.Г. Исследование зависимости разрывного внутреннего гидравлического давления пожарных напорных рукавов от параметров их тканого армирующего каркаса // Физика волокнистых материалов: структура, свойства, наукоемкие технологии и материалы (SMARTEX-2016): сб. матер. ХIХ междунар. науч.-техн. форума. - Иваново, 2016. - С. 238-240.

- Степанов О.С. Применение теории строения ткани для прочностного расчета напорных пожарных рукавов при гидравлическом воздействии: дис. канд.техн. наук: 05.19.02 / Ивановская государственная текстильная академия. - Иваново, 2012. - 141 с.

- Арипбаева А.Е., Степанов С.Г., Калдыбаев Р.Т., Калдыбаева Г.Ю., Мирзамуратова Р.Ш.Оценка точности зависимости для расчета разрывного внутреннего гидравлического давления в пожарных напорных рукавах // Изв. вузов. Технология текстильной промышленности. - 2019, №1(379).