Конструкция, расчет и применение универсальной вакуумной фаршемешалки

Автор: Вербицкий С. Б., Копылова Е. В., Пацера Н. Н.

Журнал: Вестник Мурманского государственного технического университета @vestnik-mstu

Рубрика: Процессы и аппараты пищевых производств

Статья в выпуске: 3 т.23, 2020 года.

Бесплатный доступ

Фаршемешалки, с помощью которых осуществляется перемешивание измельченной мышечной ткани с другими предусмотренными рецептурой ингредиентами, являются одним из наиболее распространенных видов специализированного мясоперерабатывающего оборудования. Качество фарша – пищевой дисперсной среды, включающей в себя твердую, жидкую и, частично, газовую фазу, – определяется дисперсностью и однородностью его структуры, а также равномерностью распределения компонентов, т. е. эффективностью процесса перемешивания. Проведенные исследования позволили теоретически обосновать процессы перемешивания фаршей с помощью специализированного технологического оборудования, в том числе обеспечивающего вакуумирование обрабатываемых пищевых масс. Приведен перечень нормативных требований к конструкциям промышленных фаршемешалок, определяющих их технологическую эффективность, безопасность и гигиеничность. Описаны две основные компоновочные схемы указанного оборудования, горизонтальная и вертикальная. Представлена конструкция горизонтальной компактной вакуумной фаршемешалки с коаксиальной двойной рабочей спиралью. Приведены результаты работы по созданию модельного ряда вертикальных вакуумных фаршемешалок, доказана возможность применения вакуумных вертикальных машин для мацерации путем массирования средне- и мелкокускового мясного сырья. Такую трансформацию оборудования целесообразно осуществлять путем замены рабочих органов перемешивания специальными массирующими лопастями, обеспечивающими наиболее эффективное выполнение указанной технологической операции. Представлена схема, описана конструкция и охарактеризован рабочий цикл вертикальной вакуумной машины с геометрической емкостью рабочей дежи 0,15 м3, приведены основные технологические и динамические расчеты указанной машины. Выполненные расчеты позволили создать современную неметаллоемкую конструкцию вакуумной машины для перемешивания фарша и/или массирования мясного сырья, соответствующей действующим требованиям к оборудованию указанного назначения. Исследования качества перемешивания фарша показали, что вакуумирование позволяет стабильно достигать более плотной консистенции фарша, а для фарша, обработанного на атмосферной мешалке, характерно более равномерное распределение компонентов.

Перемешивание фарша, мацерация, массирование, фаршемешалка, массажер мяса, вакуумирование, mixing of ground meat, maceration, massaging, ground meat mixer, meat massager, vacuum treatment

Короткий адрес: https://sciup.org/142224583

IDR: 142224583 | УДК: 62-9; 637.5.03 | DOI: 10.21443/1560-9278-2020-23-3-224-236

Текст статьи Конструкция, расчет и применение универсальной вакуумной фаршемешалки

e-mail: , ORCID:

*Институт продовольственных ресурсов Национальной академии аграрных наук Украины, г. Киев, Украина; e-mail: , ORCID:

Modern meat processing production consists of a variety of technological processes and specialized equipment used for their implementation ( Barbut, 2016; Bekhit, 2017; Cummins et al., 2016; Toldrá, 2017 ), which is selected based on various technical and technological criteria, the main of which is energy efficiency ( Hamawand et al., 2017; Pathare et al., 2019 ). Without the involvement of innovative technologies and appropriate means of production, it is impossible to achieve progress in the food industry, in particular, such its sector as the meat and meat processing industry ( Diachenko, 2017; Kovalenko et al., 2017; 2020 ).

Along with mincing raw materials, filling casings and heat treatment, mixing of ground meat is one of the main technological operations of sausage production, which largely determines the proper quality of the finished product. Meat mixers, which mix minced muscle tissue with other pre-formulated ingredients, are among the most common types of specialized meat processing equipment. Although the mixing of raw materials is carried out simultaneously with its comminuting directly in cutters with a rotating bowl in the manufacture of minced meat of structureless sausages, the use of flow cutters for comminuting, which are increasingly widespread, is also not complete without the use of a ground meat mixer ( Verbytskyi, 2016; Rogov et al., 2000 ).

The quality of ground meat – a food dispersed medium, including a solid, liquid and, partially, a gas phase – is determined by the dispersity and uniformity of its structure, as well as the uniformity of distribution of components, that is, by the efficiency of the mixing process using specialized equipment ( Murashev et al., 2015 ). The physical essence of the process of mixing ground meat, in general, is down to the fact that when the working bodies of the meat mixer rotate, there is a forced mutual convective diffusion – the mutual distribution of components in a multicomponent system. The mixing process is most efficiently fulfilled when the velocity gradients between the layers of the mixed masses are the highest, and the velocity gradients over the working volume of the mixer are the smallest. The larger the working volume of the mixer, the more difficult it is to ensure the quality and speed of mixing. The temptation to intensify the process by increasing the speed of the working parts of the mixer is fraught with the formation of discontinuities in the density of the processed mass under conditions of shear deformation, as well as an unjustified increase in power consumption ( Vas'ukova et al., 2002 ).

During the mechanical mixing of raw meat by the working bodies of the technological equipment, changes in muscle and adipose tissues are certain to take place. This contributes to an acceptable, in a technological sense, water-holding capacity of the resulting minced meat, the ability of mutual adhesion of fragments of muscle and adipose tissue, this minced meat components ( Sielaff et al., 2005 ). Ground meat being a dispersed medium includes solid, liquid and, partially, gas phase ( Murashev et al., 2015 ). Ground meat used for manufacturing sausages, before its heat treatment, is a typical representative of a body with a coagulation structure formed by the cohesion of particles through interlayers of a dispersion medium associated with them. Being a heterogeneous, dispersed phase of the ground meat is represented by protein particles and aggregates, particles of fat, the smallest scraps of muscle and adipose tissue, the continuous phase is an aqueous solution of some muscle proteins, other organic compounds, as well as sodium chloride and other electrolytes. The proteins dissolved in the continuous phase impart stickiness and plasticity to the ground meat. As the liquid phase is being removed, it is accompanied by the appearance of stronger bonds between particles, coagulation structures are formed from condensation structures, for example, ground meat for Mortadella type and raw smoked sausages ( Verbytskyi et al., 2019 ) .

Shear deformation at a high mixing rate and density discontinuities in the mixed system does not contribute to the desired uniformity of the mutual distribution of phases, and at a high-speed mode, the power consumption increases sharply ( Vas'ukova et al., 2002 ). It is extremely important to accurately select the shape of the working blades of the mixers and the elements of their working bowls, since the above-mentioned features of the process of mixing viscous food media, in particular ground meat, lead to the fact that high-speed and energy-intensive mixing is by no means always high-quality mixing. However, in the total balance of electricity consumption at a meat processing plant, 55 % are energy consumption of refrigeration equipment, 25 % – various grinders, 11 % – ventilation equipment, 6 % – fillers, and only 3 % falls on all other technological equipment, including mixing devices 1 ( Verbytskyi et al., 2019; Kang et al., 2016 ).

The uniformity of mixing of the entire volume of the loaded product is one of the main requirements that the design of meat mixers must meet according to the national standard of Ukraine DSTU 7511:2014 developed by the employees of our scientific institution 2 , which regulates the manufacture of these machines. In addition to the general norms for all food equipment, the standard establishes the following requirements directly related to the design of meat mixers:

-

– availability of devices that protect service personnel from accidental contact with the working mixing body;

-

– presence of blocking of the mixing working bodies and the loading device during the operation of the mixing working bodies or when unloading the product from the bowl;

-

– blocking in case of opening the cover;

-

– reverse mixing bodies;

-

– possibility of CIP cleaning and disinfection;

-

– mechanized movement of the cover, openings for unloading minced meat in machines with a fixed bowl attachment.

The specified regulatory requirements correspond to the well-founded long-term successful practice of development and industrial production of meat mixers to the requirements of the standard GOST 28107-89 3 .

Purpose and tasks of work

The purpose of the work is to carry out a set of experimental design and research activities to create a vertical vacuum appliance with a geometric capacity of 0.15 m 3 for mixing and/or massaging raw meats. The achievement of this goal is stipulated by the solution of the main tasks listed below:

-

– study and analysis of scientific and technical information regarding the processes of mixing raw meats, the effect of vacuum on the specified process, as well as maceration of meat cuts by massaging them;

-

– study and evaluation the functionality of meat mixers of different designs, horizontal and vertical, atmospheric and vacuum, as well as vertical machines for mixing / massaging raw meat, in order to select rational technical solutions for the equipment being created;

-

– engineering calculations for assigning operating parameters of the created meat mixer and ensuring the reliability of its design;

-

– express-research of the ground meat masses obtained as a result of experimental-industrial operation to assess the quality of their mixing.

Materials and methods

A systematic approach to the research of factual materials, in particular regulatory documents, abstract-logical approach to generalization of research results and formulation of conclusions were used by the authors in the work.

The development of the equipment was carried out in accordance with the current industry guidelines for the conduct of research and development work in compliance with the current regulatory legal acts and standards.

Engineering calculations were carried out in accordance with the well-known profile manuals ( Ivashov, 2010; Logosha, 1966; Peleev, 1971 ).

Based on the goals of this engineering development work, an express-algorithm for assessing the quality of the ground meat stuff during mixing was proposed and implemented in practice using different models of specialized technological equipment: a traditional atmospheric horizontal mixer with coaxial working shafts and an experimental vacuum vertical type meat mixer.

The ground meat for manufacturing Odesskaya sausage of the first grade, DSTU 4435: 2005 4 , was studied. The ground meat, the essential raw materials for the manufacture of which are: desinewed beef – 65 %, desinewed semi-fat pork – 10 %, sausage backfat – 25 %, was produced in the meat processing workshop of the Experimental Technological Enterprise of the Institute (ETE). Immediately after the end of the mixing, the members of the expert panel, consisting of 4 representatives of the developer and 6 representatives of the ETE, evaluated the ground meat according to two indicators being the verbal analogs ( Verbitskyi, 2019 ) of the rheological parameters of the ground meat and expressed by the following questions: "How tough is the consistency of the ground meat?" (from "too loose" – 0 to "too tough" – 10) and "How well is the minced meat mixed?" (from "unevenly" – 0 to "evenly" – 10). Conceptually, the procedure for sensorial evaluation was in accordance with DSTU 4823.2: 2007 5 for ready-to-use meat products.

The corresponding minced meat samples were also investigated by the instrumental method – the penetration values were measured according to GOST R 50814-95 6 , using for this purpose an automatic penetrometer model 1719 manufactured by the British company Stanhope Seta Ltd., equipped with an electronic unit model 1720.

The obtained values of the sensorial parameters and penetration of the corresponding samples of the ground meat were compared and conclusions were drawn about the quality of its mixing.

Results and discussion

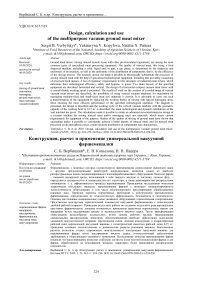

There are two basic design layouts of meat mixers: with horizontal and vertical arrangement of the working shaft (working shafts). Much more often, the subject of consideration of scientists and specialists is horizontal meat mixers, and numerous scientific and technical sources are devoted to them, for example ( Angel'uk et al., 2014a; b ). Scientists and designers of our scientific institution were also engaged in the development of devices of this type – meat mixers Ya5-FFE.150 and Ya5-FFE.300 with coaxial spiral working bodies, protected by the Patents of Ukraine for a useful model ( Shevchenko et al., 2007; 2008 ). These designs differ from each other by the drive of the working spirals: if in ( Shevchenko et al., 2007 ) both spirals are rigidly connected to each other (Fig. 1), then in ( Shevchenko et al., 2008 ) the applied drive scheme ensures their rotation at different speeds, due to which the mixing of the components of the ground meat is more intensive.

Sometimes ground meat mixing machines are equipped with two ellipsoidal blades rotating in opposite directions, with the small blade rotating in the sphere of the large blade. There are horizontal meat mixers with working bodies in the form of augers, with working bodies being Z-shaped or of another configuration. The technical characteristics of some domestic meat mixers – horizontal machines L5-FM2-U-150 and FMV-0.15, as well as a vertical type experimental vacuum meat mixer Ya5-FFV of our own design are presented in Table 1.

Fig. 1. Meat mixer with working bodies in the form of coaxial ribbon spirals rigidly connected to each other: 1 – frame; 2 – working bowl; 3 – product unloading hatch; 4 – hatch cover for product unloading; 5 – cover of the working bowl; 6 – easily removable working body; 7 – drive; 8 – vacuum pump; 9 – vacuum system ( Shevchenko et al., 2007 )

Рис. 1. Фаршемешалка с рабочими органами в виде коаксиальных ленточных спиралей, жестко связанных между собой: 1 – рама; 2 – рабочая дежа; 3 – люк для выгрузки продукта; 4 – крышка люка для выгрузки продукта; 5 – крышка рабочей дежи; 6 – легкосъемный рабочий орган; 7 – привод;

8 – вакуумный насос; 9 – вакуумная система ( Shevchenko et al., 2007 )

Table 1. Specifications of domestic equipment

Таблица 1. Технические характеристики отечественного оборудования

|

Parameters |

Unit |

Values of parameters |

|||

|

Model |

L5-FM2-U-150 |

FMV-0,15 |

Ya5-FFV |

||

|

1 |

Capacity |

kg/h |

11000 |

1000 |

600 |

|

2 |

Geometrical volume |

l |

150 |

150 |

80 |

|

3 |

Nominal power |

kW |

3.0 |

5.2 |

2.0 |

|

4 |

Rotation frequency of working bodies |

-1 s |

0.52 |

– |

– |

|

5 |

Dimensions: |

mm |

|||

|

length |

2940 |

1220 |

1200 |

||

|

width |

965 |

825 |

670 |

||

|

height |

1330 |

1200 |

1475 |

||

|

6 |

Required area |

2 m |

2.26 |

– |

– |

|

7 |

Weight |

kg |

490 |

500 |

200 |

The vacuum system of the meat mixer (vacuum pump, vacuum trap, regulating devices, vacuum lines), according to 7 , must be air-tight. The norms stipulate that a vacuum in the working cavity from 0.025 to 0.040 MPa should be achieved within the period from 8 to 30 s. It also provides for automatic shutdown of the vacuum pump upon reaching the required vacuum depth. After switching off the vacuum pump, the decrease in the vacuum value should not exceed 10 % of the achieved value within 5 min.

Vacuum mixers are much more expensive than atmospheric mixers due to the need to equip the machine with elements of a vacuum system and a massive sealed cover, as well as due to the complication of other units associated with ensuring the tightness of the working cavity. On the other hand, vacuumation of ground meat while mixing is economically justified, as it allows more efficient filling of sausage casings and improve the quality of finished products. The vast majority of vertical type meat mixers on the domestic market are imported (Table 2) and belong to vacuum machines, however, atmospheric devices are also produced by machine-building firms 8 .

Table 2. Technical characteristics of foreign equipment Таблица 2. Технические характеристики зарубежного оборудования

|

Parameter |

Unit |

Values of parameters |

||||

|

Country |

Austria |

Germany |

Germany |

|||

|

Manufacturer |

LASKA |

RÜHLE |

STEPHAN |

|||

|

Model |

ME 130 |

MTR 50 |

MTR 75 |

VM 100 |

||

|

1 |

Capacity |

l |

130 |

130 |

150 |

125 |

|

2 |

Geometrical volume |

kW |

4.0 |

1.1 |

1.3 |

1.5 |

|

3 |

Nominal power |

–1 s |

– |

– |

– |

0.33 |

|

4 |

Rotation frequency of working bodies |

mm |

||||

|

Dimensions: |

1150 |

1050 |

1150 |

1080 |

||

|

length |

750 |

800 |

800 |

1000 |

||

|

width |

1150 |

1200 |

1250 |

1260 |

||

|

height |

kg |

500 |

200 |

220 |

150 |

|

|

5 |

Required area |

|||||

|

6 |

Weight |

|||||

The use of ground meat mixers with temperature control in the working bowl is not typical for the domestic practice of meat processing. The use of complex and expensive devices with forced cooling or heating of the mixed masses is justified only at large enterprises with special production specialization. However, vertical type meat mixers with working bowl cooling are widely represented in our market and are purchased by meat processing enterprises as universal devices applicable both for mixing minced meat and for massaging meat raw materials.

Known methods for calculating the working bodies of tank equipment, for example, those described in 9 ( Shevchuk et al., 2020 ), allow effective selecting and calculating of the working blades of vertical meat mixers. A feature of vertical-layout meat mixers is their versatility, that is, the possibility of using these machines both for mixing minced meat, and for efficient maceration of medium-sized and small-sized pieces meat raw materials by massaging it with universal multi-purpose blades or by means of a simple readjustment, which consists in replacing the mixing working bodies with massaging ones. Due to this versatility, such machines are often positioned precisely as meat massagers, considering the maceration of meat raw materials to be their main technological function ( Shugurova, 2010 ).

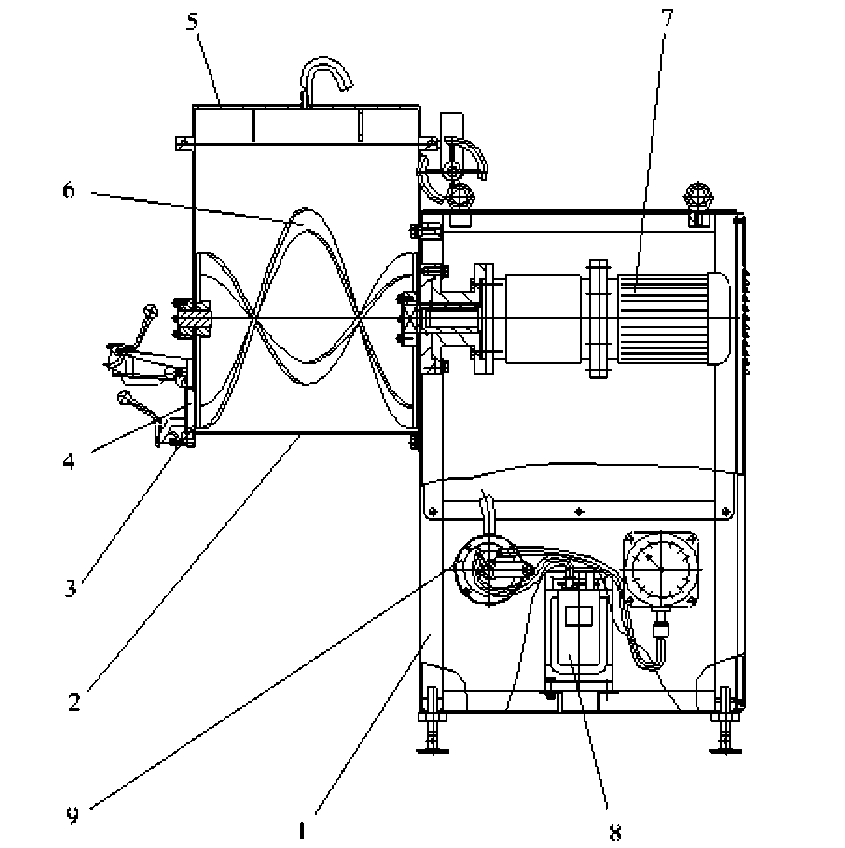

In our scientific institution, a series of projects has been performed to create universal vacuum meat mixers with the possibility of using them as meat massagers ( Verbytskyi et al., 2019 ). For small enterprises and workshops for the production of meat products, the Ya5-FFV unit with a working bowl of 0.08 m 3 is intended. For medium-sized enterprises, a Ya5-FSG vacuum machine with a working bowl of 0.15 m 3 is designed. Its design is as follows (Fig. 2). A cylindrical bowl (2) with working bodies (7), closed by a sealed cover, is attached to the frame of the welded structure (1) by semi-shafts. The unit consisting of an electric motor, a V-belt transmission and a gearbox is the drive of the installation (3). The shaft of the working bodies is connected to the output shaft of the gearbox. A pump-compressor (4) and a vacuum line with a pressure gauge and a vacuum relief valve located in the upper part of the bowl are intended to evacuate the working cavity. The control functions of the machine are carried out using the control panel (5). A mechanism (6) is provided for turning and overturning the bowl; it is a worm gear pair with a manual drive. A universal vacuum appliance for mixing / massaging raw meat works as follows. The raw meat to be processed and other components provided by the formulation are loaded into the working bowl, the lid is closed, the unit drive is turned on, and then, the pumpcompressor of the vacuum system. When the technological processing is completed, it is necessary to turn off the drive of the installation and the pump-compressor, open the drain valve, open the lid, turn the bowl and unload the product into the prepared transport container.

Fig. 2. Ya5-FSG vacuum unit for mixing / massaging meat raw materials (geometric capacity 0.15 m 3 , drive power 2.2 kW, drive power of the vacuum pump 0.37 kW, weight 290 kg, dimensions 1300×800×1750 mm) ( Verbytskyi et al., 2019 )

Рис. 2. Вакуумная установка Я5-ФСГ для перемешивания / массирования мясного сырья (геометрическая вместимость 0,15 м 3 , мощность привода 2,2 кВт, мощность привода вакуумного насоса 0,37 кВт, масса 290 кг, габариты 1 300×800×1 750 мм) ( Verbytskyi et al., 2019 )

A series of necessary structural, kinematic and dynamic calculations was performed, the results of which are presented below.

We determine the performance of a vacuum meat mixer when working in a horizontal position by the formula о Vхq n/|0.15x1100i79kg

Q = 60 х a----= 60 х 0.4132—,

T 30

where a – the filling factor of the capacity of the meat mixer in the massaging mode ( a = 0.4); V – the volume of the mixing tank of the mixer, V = 0.15 m 3 ; Q – the specific gravity of minced meat, q = 1100 kg/m 3 ; T – the cycle time, min.

T = t1 + t2 + t3 = 9 + 12 + 5 = 26 min,(2)

where t 1 – the duration of loading the working bowl, min; t 2 – the duration of the mixing process, min; t 3 – the duration of unloading of the working bowl, min.

From the experience of operating meat mixers of a similar design: t 1 = 9 min, t 2 = 12 min, t 3 = 5 min. We accept for the calculation T = 30 min. Power of the electric motor of the drive of the working bodies of the vacuum meat mixer when operating in a horizontal position in terms of specific energy consumption

N =

q^xQ = 2 32 = 0.54 kw k 0.63

where q 1 – the specific energy consumption per 1 ton of raw meat of minced meat consistency, q 1 = 2.5–2.6; k – the efficiency of the geared motor k = 0.63.

We determine the required torque M o , N - m, on the output shaft of the gear motor using the formula

Mo = P1 x L1 + P2 x L2 + P3 x L3,(4)

where L – the distance from the mixer axis to the point of application of the force (structurally L 1 = 0.254 m, L 2 = 0.132 m, L 3 = 0.143 m); Р – the resistance by this blade, N

P = о x F,(5)

where F - the frontal surface of the blade, m2 (structurally F1 = 0.022 m2, F2 = 0.015 m2, F3 = 0.04 m2); о is the corresponding resistivity, N/m2, determined by the formula о = о0 + a x v,(6)

where σ0 – the specific initial resistance, N/m2 (we take σ0 = 13000 N/m2); a – the constant parameter depending on the type of raw material (we take a = 8000); v – the speed of movement of the corresponding blade, m/s v =

nx n x L

When n = 12 rev/min, then

M„ = P x L + P x L + P x L = в 1122 33

n xnxLA ( nxnxL A n„ + a-------1- L x F + ст. + a-------2 L, x F +

0 30 J ( 0 30 J 22

( nxnxL A

+ nn + a------- L, x F =

( 0 30 ) 33

= f 13000 + 8000 3.14 x12 x 0.254 A x 0.254 x 0.022 +

I 30

+l 13000 + 8000-------- 0---lx 0.132 x 0.015 +

I 30

( 3.14x12x0.143^1

+ 13000 + 8000-------------- x 0.143 x 0.040 = 199 Nm.

I

Nominal torque on the output shaft of the selected geared motor M n = 600 Nm. The geared motor is selected correctly because M n > M o .

Based on the data obtained and taking into account short-term overloads, we take a gear motor MV3-125-12-330 U3, 380, electric motor power ^ = 0.75 kW, output shaft speed n = 12 rpm.

From design conditions we use a pump-compressor of the 2NVR-5DM type. Electric motor power ^ = 0.55 kW, rotor speed n = 1430 rpm.

We determine the performance of a vacuum meat mixer when working in a vertical position according to the formula

V x q 0.15 x 1100

Q = 60 x a ---— = 60 x 0.7 = 232 kg/h,

T 30

where a – the filling factor of the capacity of the meat mixer in the mixing mode ( a = 0.6–0.7); V – the volume of the mixing bowl of the mixer, V = 0.15 m 3 ; q – the specific gravity of minced meat, q = 1100 kg/m 3 ; T – the cycle time, min

T = t 1 + t 2 + t 3 = 9 + 12 + 5 = 26 min. (10)

where t 1 – the duration of loading the working bowl, min; t 2 – the duration of the mixing process, min; t 3 – the duration of unloading of the working bowl, min.

From the experience of operating meat mixers of a similar design: t 1 = 9 min, t 2 = 12 min, t 3 = 5 min. We accept for the calculation T = 30 min.

Checking the selection of the geared motor for the torque on the output shaft when the mixer is in vertical position is necessary.

We find the power required to overcome the resistance of the horizontal blades. The resistance coefficient is found by the formula

К =

Tx Q 2 x g ,

where у - the coefficient depending on the shape of the blade and the ratio of its height and length.

Due to the high viscosity of the liquid, this coefficient is taken in the range of 1.2-1.5. We take у = 1.5, then

K _ 1.5 x 1100 = 2 x 9.8

_ 84.

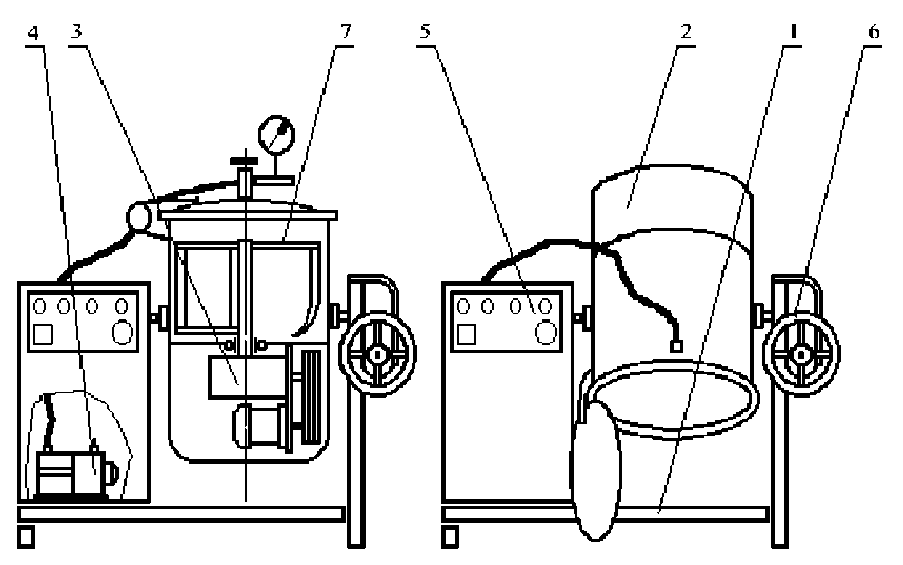

We find the surface of the blade (Fig. 3)

f = (fa + fb + fc) X Г1, where r1 = 0.295 m.

Fig. 3. Scheme for calculating the geometric parameters of the blade Рис. 3. Схема к расчету геометрических параметров лопасти

f a = a x cos a = 0.054 x cos70 ° = 0.054 x 0.342 = 0.0185 m;

f = a x cos a = 0.022 x cos45 ° = 0.022 x 0.7071 = 0.0156 m;

f C = a x cos a = 0.06 x cos75 ° = 0.06 x 0.2528 = 0.0156 m;

f = (0.019 + 0.016 + 0.016) x 0.295 = 0.051 x 0.295 = 0.015 m 2 .

Moving speed of the blade is determined by the formula

_ 2 x n x r1 x n v max ,

where n = 12 rpm – the number of blade revolutions in min.

The medium resistance of a rotationally moving horizontal blade is determined by the formula

Р 1 =

max

,

where z = 1 – the number of blades of the type, then

P i =

1 x 84 x 0.015 x 0.37

- = 0.016 kgm/s.

For a vertically rotating blade, the resistance of the medium is determined by the formula

K x h xo 3 4 .

P =---- -^ ----x ( r 2

- r i4 ) ,

where h – the blade height, m; ω – the angular speed of rotation of the blades, s –1 .

пх и 3.14 x 12

ю=----=-------= 1.27 s ,

30 30

where r 2 – the outer radius of blade rotation, m; r 1 – the inner radius of blade rotation, m.

P 2 =

84 x 0.42 x 1.27 3

---------------x

( 0.298 4 - 0.233 4 ) = 0.093 kgm/s.

For a vertically rotating blade-activator, the resistance of the medium is determined by the formula

K X h ХЮ 3 4 .

P 3 = ----- 4 -----X ( r 4

- r 34 ) ,

where h – the height of the activator blade, m; ω – the angular speed of rotation of the blades, s –1 .

пх и 3.14 x 12

ю=----=-------= 1.27 s ,

30 30

where r 4 – the outer radius of rotation of the activator blade, m; r 3 – the inner radius of rotation of the activator blade, m.

P 3 =

84 x 0.26 x 1.27 3

---------------x

( 0.25 5 4 - 0.05 7 4 ) = 0.03 6 kgm/s.

We determine the total resistance of the medium to the rotation of all blades

P = p 1 + p 2 + p 3 = 0.016 + 0.093 + 0.036 = 0.145 kgm/s.

Then the drive power of the meat mixer when working in a horizontal position

N = ——, 102 xn where ŋ = 0.63 is the efficiency of the drive, then

N = 0,145 = 0.0023 kw.

102 x 0,63

The resulting power value does not exceed the rated power of the selected geared motor.

The calculations made it possible to create a modern non-metal-intensive design of a vacuum machine for mixing minced meat and/or massaging meat raw materials, which meets modern requirements for equipment for the specified purpose and is not inferior in terms of technical characteristics and technological capabilities, similar to meat processing machines imported from abroad.

In accordance with the above-described express algorithm for studying the quality parameters of the ground meat subjected to mixing, comparative studies were carried out, covering 5 samples of the ground meat – processed on the atmospheric horizontal meat mixer L5-FM2-U-150 (the first sample) and four samples processed in the experimental mixer (samples from the second to the fifth one). The results of the measurements performed are shown in Table 3.

Table 3. Mixing quality of minced meat Таблица 3. Качество перемешивания фарша

|

Sensorial parameters (average scores for samples) |

Strain of the standard penetration, Pa |

||

|

Consistency of the ground meat |

Quality of mixing |

||

|

Sample 1 (control) |

5 |

10 |

1423 |

|

Sample 2 |

8 |

7 |

1813 |

|

Sample 3 |

10 |

8 |

1926 |

|

Sample 4 |

10 |

7 |

1887 |

|

Sample 5 |

9 |

9 |

1855 |

Thus, all the samples of the vacuum treated ground meat showed a tougher consistency – this is confirmed by both sensorial and instrumental studies. At the same time, the ground meat processed in an atmospheric mixer was characterized by a more even distribution of components. This may be due to the improper design of the working bodies and internal elements of the bowl requiring further improvement.

Conclusion

The research carried out made it possible to collect and analyze the necessary array of information regarding processes of mixing ground meat with the help of specialized technological equipment, including the one that provides vacuuming of processed food masses. Two principal design layouts of the specified equipment, horizontal and vertical, are presented, the possibility of using vertical vacuum machines for maceration by massaging medium and small meat raw materials is proven. The design of a vertical vacuum machine with a geometric capacity of the working bowl of 0.15 m 3 is described, and the main technological and dynamic calculations of this machine are given. The calculations made it possible to create a modern non-metal-intensive design of a vacuum machine for mixing minced meat and/or massaging meat raw materials, which meets modern requirements for equipment for the purpose. Comparative express-studies of the quality of mixing of the ground meat using routine equipment of meat processing plants and the newly developed machine showed that vacuuming allows consistent achieving a tougher ground meat consistency, while for the ground meat processed on an atmospheric mixer, a more uniform distribution of components was characteristic. This may be due to the improper design of the working bodies and internal elements of the bowl, so the said design requires further improvement. The issue of using the developed appliance as a meat massager, which is beyond the scope of this work, also requires a comprehensive study.

Acknowledgements