Light-transmitting concrete using ash and slag, and glass waste

Автор: Tang Van Lam, Le Xuan Thanh, Bulgakov B.I., Aleksandrova O.V., Bazhenova S.I.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 4 Vol.17, 2025 года.

Бесплатный доступ

Introduction. The article discusses the potential for producing “green” light-transmitting concrete products in Vietnam using the available resources of ash and slag and glass waste, which will contribute to the development of a closed-cycle economy and sustainable “green” transformation of industrial production in order to achieve zero carbon dioxide and other greenhouse gases emissions by 2050. The aim of the study is to develop formulations and manufacturing technologies for light-transmitting cement-free concrete products with sufficient strength using high-tonnage waste in the form of ash, slag, glass waste, etc. in combination with an activating solution. To achieve this goal, it was necessary to explore the possibility of using the multi-tonnage waste available in Vietnam, suitable for the production of light-transmitting concretes, in order to select the optimal raw materials, and to assess the potential volumes of suitable secondary resources. Materials and methods. The following raw materials were used in the study: finely ground blast furnace slag, fly ash from incineration power plants, glass waste, ceramic powder “TOTO”, obtained by crushing defective plumbing products, activating alkaline solution, polycarboxylate superplasticizer and water. The research methodology is based upon calculating the compositions of concrete mixtures for the production of light-transmitting cement-free concretes by the absolute volume method and testing the developed concretes to determine their average density, compressive and tensile strength during bending, water absorption and natural moisture of samples in accordance with current Vietnamese standards, as well as in assessing the light transmission capacity of the resulting concrete products. Results and discussion. As a result of the conducted research, compositions of decorative cement-free and light-conducting optical fiber-free concretes has been obtained using multi-tonnage man-made waste with sufficient strength (40÷50 MPa for compression and 11.5÷13 MPa for bending tension), low water absorption (6.5÷10% by weight) and good light transmission ability have been developed. Conclusion. A technology is proposed for the production of decorative thin panels and wall tiles in laboratory conditions that have the ability to transmit light and give architectural expressiveness to outside walls and interiors of residential and public buildings.

“green” light-transmitting concrete, finely ground blast furnace slag, fly ash, glass waste, activating alkaline solution

Короткий адрес: https://sciup.org/142245501

IDR: 142245501 | DOI: 10.15828/2075-8545-2025-17-4-475-484

Текст научной статьи Light-transmitting concrete using ash and slag, and glass waste

Original article

Tang Van Lam, Le Xuan Thanh, Bulgakov B.I., Aleksandrova O.V., Bazhenova S.I. Light-transmitting concrete using ash and slag, and glass waste. Nanotechnologies in construction. 2025;17(4):475–484. – EDN: ENHLKJ.

Танг Ван Лам, Лe Суан Тхань, Булгаков Б.И., Александрова О.В., Баженова С.И. Светопропускающие бетоны с использованием золошлаковых и стекольных отходов. Нанотехнологии в строительстве. 2025;17(4):475–484. – EDN: ENHLKJ.

Given the current rapid industrialization of production and modernization across various sectors, energy consumption for artificial lighting has increased significantly, negatively impacting the environment. Additionally, evaluation criteria are continually being refined, and the demands for interior design and the aesthetic appeal of buildings are rising [1]. Consequently, technical solutions that enhance natural lighting in homes and public build- ings, while also creating unique architectural structures to attract potential clients and investors, are becoming increasingly relevant [2].

Alongside architectural innovations, a key focus of modern research is the development of building materials that maximize the use of industrial waste, particularly those that eliminate cement-like binders entirely while maintaining light-transmitting properties. Currently, the primary light-permeable materials include glass products and translucent plastics [2]. However, conventional

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION glazing technology requires substantial energy to melt raw materials at high temperatures [3]. Moreover, this production process emits significant amounts of carbon and other greenhouse gases, which contradicts the commitment of the Communist Party and the Government of the Socialist Republic of Vietnam to achieve net-zero emissions by 2050.

This commitment was reaffirmed by SRV Prime Minister Phạm Minh Chính at the 26th UN Climate Change Conference (COP26), held from October 31 to November 12, 2021, in Glasgow, UK. The event brought together 25,000 delegates from 200 countries, including 120 heads of state. By adhering to this goal, Vietnam aims to contribute to the objectives of the Paris Climate Agreement, which replaced the Kyoto Protocol 1997, adopted unanimously in December 2015 under the UN Framework Convention on Climate Change during the 21st International Climate Conference (COP21) with participation from 195 countries. The agreement’s overarching aim is to limit global warming to no more than 1.5°C above preindustrial levels by the end of the 21st century. Through the development and implementation of effective measures, Vietnam seeks to ensure a consistent reduction in atmospheric carbon and other greenhouse gases starting from 2020 [4–6].

In addition, Vietnam operates numerous coal-fired power plants and metallurgical facilities, generating millions of tons of industrial waste annually. According to recent data [7, 8], the metallurgical sector alone produces approximately 45–55 million tons of slag per year, while thermal power plants contribute an additional 50–60 million tons of mineral waste. Given these staggering figures, recycling this waste and repurposing it as secondary raw material for construction holds significant economic, environmental, and social value for Vietnam [6].

Currently, the most widely recognized sunlight-permeable concrete material in modern construction is translucent concrete, commercially known as LiTraCon (short for Light Transparent Concrete, LTC). The development of LiTraCon traces back to Hungarian architect Aron Losonczi, who, after 15 years of collaborative research with scientists at the Budapest University of Technology and Economics, patented the material in 2001. By 2004, LiTraCon entered the global construction market, with its namesake Hungarian firm remaining the primary producer today.

The concept of “transparent concrete” is very simple on the surface: thousands of optical light-conducting glass fibers of different diameters from 2 µm to 2 mm are inserted into a fine-grained cement concrete mixture, laid in layers and parallel between the two main external surfaces of the concrete block. In this case, the proportion of glass fiber in the volume of fine-grained concrete matrix is quite small and is 4–5%. Optical fibers become a kind of structural component that performs several functions, the main one is to provide translucency to products made from translucent concrete. In addition, optical glass fibers are also reinforcing elements that increase the resistance of concrete to bending and tensile forces. The result is a concrete that has the transparency of matt glass, provided that the plates, panels or blocks made from it are illuminated on the opposite side to the viewer. According to the statement of the creators of LiTraCon, said translucency is maintained until increasing the thickness of walls made of it up to 20 m, because glass fibers are able to transmit light through the material thickness at such a distance with almost no loss. The translucency of the material is ensured by the fact that the glass fibers contained in it, which are located in parallel, transmit light from one face surface to another as small dots, as a result, the shadows on the lighter side of the product appear on the darker side of the product in the form of shadows with more contrasting contours. Thanks to this, the walls of translucent concrete become luminescent and animated by shadows while maintaining the color of the object behind the wall. In this case, both on the external and internal surface of the wall can be created various shadows, patterns and even drawings. The resulting visual effect creates a general impression of disappearance of the thickness and mass of the concrete wall. Moreover, the small size of optical fibers included in the composition of light-conducting concrete makes uniform not only its internal structure, but also the external surface. In practice, mainly use products made of translucent concrete small thickness and for this block and plate from it cut into thin plates across the optical fibers using standard equipment for cutting stone building materials. The optimal light conductivity of the plates is achieved provided that the optical fibers are located perpendicular to their working surface, and also if the face surfaces are polished and polished to a mirror gloss by machine or hand [9, 10].

The main areas of application of translucent concrete in construction are architectural and decorative purposes: it is used for the production of translucent blocks, boards, panels and plates both for the implementation of design projects of interiors, as well as for outside decoration of buildings, because translucent concrete not susceptible to thermal effects, temperature changes and the action of ultraviolet rays. For example, it is used to decorate facades, storefronts, advertising stands and panels, etc. In addition, this translucent concrete can be made of block structures of different sizes capable of working under load, due to the fact that the fiberglass in its composition do not have a negative effect on its sufficiently high compressive strength. Such blocks can also perform heat insulation functions [9].

Translucent concrete has the following technical characteristics:

– medium density – 2100–2400 kg/m3;

– compressive strength – 50 MPa or more,

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

– Axial tensile strength – 7 MPa;

– Coefficient of thermal conductivity – 2.1 W/m•K.

Light-conducting concrete is produced in three color options: white, gray and black. At the same time, the use of color lighting allows you to change the color of illuminated blocks from translucent concrete.

Brick masonry of semitransparent concrete blocks meets the usual requirements for fire resistance classes depending on the place of their use, and walls of them can be both bearing and self-supporting. translucent concrete is frost resistant, environmentally clean and safe, its sound and noise insulation characteristics are the same as in ordinary concrete. As a rule, wall and floor elements are additionally treated with water-repellent impregnating compound.

Wall mounting of translucent concrete panels and plates is carried out on facade anchors, which are installed on supporting walls or on frame substructures, and on the same ones that are used for mounting natural stone panels. Outdoor installation is carried out with alignment of the side lines on any base. Masonry is carried out with a conventional Portland cement or lime solution and looks like brick masonry. Concrete blocks can also be glued together with thin seams filled with epoxy resin with quartz flour filler. In addition, when using translucent concrete with other materials, both heat insulation structures and other purpose structures can be obtained.

Translucent concrete hard glass and its main disadvantage is the high cost due to the high cost of fiberglass used: 1 m2 walls of this concrete with a thickness of 250 mm costs about 750 euros. This fact constrains its wider use in modern construction. But despite this, translucent concrete has found active use in the US in the enclosure structures of government buildings and banks, as well as in Europe and Asia – to create conceptual and competitive projects, examples of which can be taken sculpture “Gate of Europe” 4 m high, made of LiTraCon blocks and installed in 2004 in honor of Hungary’s accession to the European Union, the central building of the BMW Group automobile plant in Leipzig, the buildings of the University of Aachen and the City Library of Stuttgart, pavilion of Italy at the exhibition “Shanghai-Expo 2010” in China, the Al-Aziz Mosque in Abu Dhabi (UAE), as well as fountains, park benches and small architectural forms, etc. [10].

Thus, the light-permeable concrete LiTraCon, thanks to its visual effect, is able to transform the perception of concrete buildings as light and airy, rather than gray, heavy and gloomy.

This study presents the manufacturing technology and properties of “green” decorative concrete products, which pass light and do not contain clinker binding, as well as light-conducting optical fibers. It is a special form of decorative and light-conducting “green” concrete, which has sufficient strength, but does not require drying products at high temperatures. Thus, this technology saves 20–40% energy during the production process, as a result of which the resulting product in the form of thin plates and panels has a low price, fused structure and smooth surface, and has a long service life. The use of designed decorative tiles and panels that pass sunlight helps to reduce energy consumption in buildings for their lighting, while providing creative solutions for the application of new architectural design technologies. Unfortunately, at present in Vietnam this technology of manufacturing light-permeable concrete products is not implemented on an industrial scale, but at the same time it has good prospects for development.

Decorative light-permeable “green” concrete is a new decorative product, developed on the basis of “green” concrete with the use of cement-free binding compositions on the basis of multi-ton technological waste. This concrete is being studied by our scientific team since 2021 [1, 6, 11]. Given the initial obtained results, we expect that the introduction in Vietnam of the technology to produce “green” decorative light-transmitting concrete using multi-ton waste will contribute to the interests of society and improve living standards.

Main goal of the research is to develop scientific basics and technology for the manufacture of light-transmitting cement-free concrete products with sufficient strength using multilayer waste fly ash, slags, as well as crushed waste from glass and sanitary ceramic products in combination with activating alkaline solution and water reducing polycarboxylate superplasticizer.

In order to achieve this goal, it is necessary to examine the possibility of using Vietnam’s multilayer waste suitable for light-transmitting concrete in order to select optimal raw materials and assess the potential volumes of suitable secondary resources.

The article shows the results of the experimental work carried out to solve the problem.

MATERIALS AND METHODS

Materials

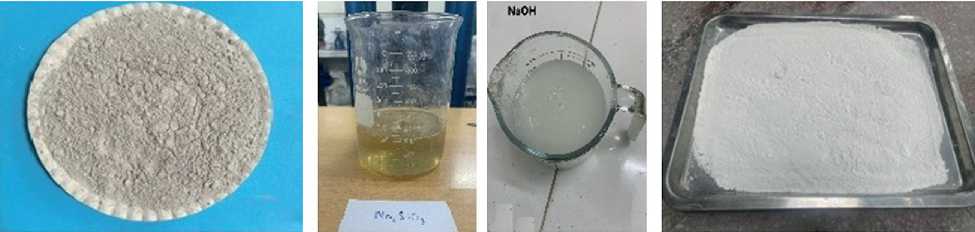

To produce light-diffusing concrete, the following raw materials were used:

– Fine-grinded glass waste (GW) with a size of 5–10 mm and a true density of 2.5 g/cm3, meeting the requirements of TCVN 7570:2006 standard, was used as lighttransmitting aggregate;1

– Fine-grinded low-calcium fly ash “Fa Lai” (FA) with true density of 2.34 g/cm3 and fine-grained granular slag from the metallurgical plant “Hoa Fat” (GS) with true density of 2.29 g/cm3, meeting the requirements

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fly ash from “ Pha Lai ” Thermal Power Plant

Superplasticizer SR 5000F

Crushed glass waste

Finely ground granulated blast furnace slag

Alkali-activating solution

Ceramic powder “ TOTO ”

Fig. 1. Raw materials used of TCVN 10302:2014 were used as active mineral additives;2

– Fine-grinded ceramic powder (CP) with particle size 0.1÷0.5 mm, obtained by crushing of scrap sanitary products manufactured in Vietnam at the factory of “TOTO” was used as a fine dispersed inert mineral additive;

– An alkaline solution for activation of cement-free binder of the developed composition, consisting of aqueous solutions of sodium hydroxide and metasilicate with densities respectively 1.45±0.01 g/cm3 and 1.55±0.01 g/cm3 in relation to Na2SiO3/NaOH = 2.5 [12, 13]. Mass percentage of solution: NaOH = 12%; Na2SiO3 = 30% water = 58%.

– SR 5000F polycarboxylate superplasticizer produced by “Silk Road” in the form of an aqueous solution with a density of 1.1 g/ cm3 at a temperature of 20±5 °C was used to reduce the water demand of the concrete mixture. It is a type G superplasticizer that meets the requirement of standard TCVN 8826:2011;3

– The sealing water conforms to the regulatory requirements of TCVN 4506:2012.4

The appearance of the raw materials used in this study is shown in Fig. 1.

Methods

Methodology of work included:

– determination of composition of concrete mixtures by calculation method of absolute volumes;

– average density of concrete was tested on samples – cubes 100×100×100 mm according to TCVN 3115:2022;5

– natural moisture of concrete samples was determined according to TCVN 4196:2012;6

– Water absorption of concrete samples was determined according to the method of TCVN 3113:2022;7

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 1. Concrete mixtures

|

Composition |

Raw material content, kg/m3 |

|||||||

|

FA |

GS |

CP |

GW |

NaOH |

Na2SiO3 |

SR 5000F |

Water |

|

|

Mix No. 1 |

595 |

170 |

85 |

1105 |

85 |

213 |

8.5 |

198 |

|

Mix No. 2 |

432 |

345 |

86 |

1122 |

86 |

216 |

8.6 |

199 |

|

Mix No. 3 |

263 |

526 |

88 |

1140 |

88 |

219 |

8.8 |

201 |

|

Mix No. 4 |

89 |

711 |

89 |

1156 |

89 |

223 |

8.9 |

202 |

– compressive strength was determined by testing concrete samples-cubes 100×100×100 mm according to TCVN 3118:2022, and tensile strength on sam-ples-prisms 100×100×400 mm according to TCVN 3119:2022.8, 9

– light permeability of concrete products (LP) in percent was estimated by the ratio of their surface area occupied by glass particles to the total surface area of the product according to the formula:

LP = (S/S0)•100%, where S is the surface area of the specimen occupied by glass particles, mm2; S0 – total surface area of the specimen, mm2.

RESULTS

Pre-mixes of concrete mixtures for light-penetrating cement-free concrete are presented in Table 1.

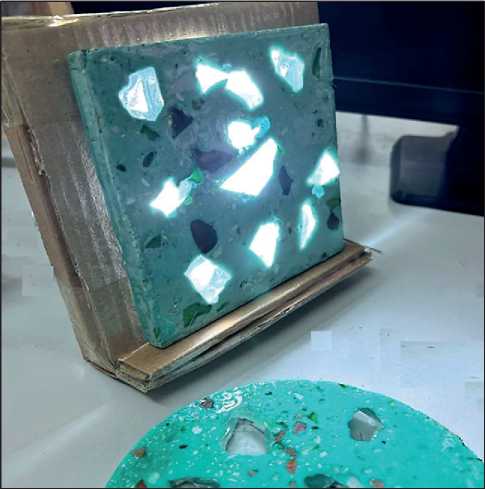

As result, “green” concrete product, which has sufficient strength and good light permeability, able to create various lighting effects in the interior and outside decoration of buildings with translucent panels, as well as decorative tiles, was obtained. In addition, the resulting light-permeable concrete has a much lower price than the products present on the construction market of Vietnam with the same function.

Traditional concrete technologies, most currently used in Vietnam, do not allow the production of concrete products that can pass sunlight. Our scientific team has developed a technology for the production of light-absorbing “green” concrete products, which do not contain cement and light-conducting optical fibers, whose application will allow to create unique architectural decorative and lighting effects on various building sites (Fig. 2).

The results of tests of samples from the developed decorative light-transmitting “green” concrete, carried

Fig. 2. Decorative translucent “green” concrete products out in the construction laboratory of Hanoi Mining and Geological University, showed that:

– their natural humidity ranges from 4 to 6%, and water absorption varies from 6.5 to 10% by mass;

– Average dry density is 2200–2400 kg/m3;

– compressive strength is 40–50 MPa and the flexural strength is 11.5–13 MPa.

With regard to the light-permeability of the developed concrete products, it was found that this is determined by the area taken up by the glass particles on their surface, which in turn is determined by the content of the glass particles as well as their dimensions. Using glass of different colors, light passing through the product gives a more diverse color range, which increases the decorative properties of products. The light-penetrating capacity of the obtained concrete products was between 20 and 30%, calculated according to the formula above.

The technology of production of light-permeable “green” concrete products does not require special infrastructure, machines and equipment and it can be implemented in active concrete production sites [14, 15].

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

By expanding the production of “green” concrete products on an industrial scale, it will facilitate the recycling of large quantities of solid multi-ton waste, which will contribute significantly to environmental protection in Vietnam. In the near future, our scientific team plans to continue work to implement the developed technology in Vietnamese enterprises producing concrete products, and also to attract attention of construction firms to use the developed decorative light-transmitting “green” Materials due to their good quality and low cost.

Developed “green” translucent concrete material is a new product for the construction industry of Vietnam, while not requiring complex manufacturing technology, and is decorative concrete, Produced without the use of cement and with the addition of light-conducting filler in the form of milled glass waste. “Green” translucent concrete has the ability to pass light through itself, which allows you to model various decorative color accents in the outside and interior of buildings of different purpose, as well as create light paths in parks, partially replacing light sources that consume electricity [16, 17].

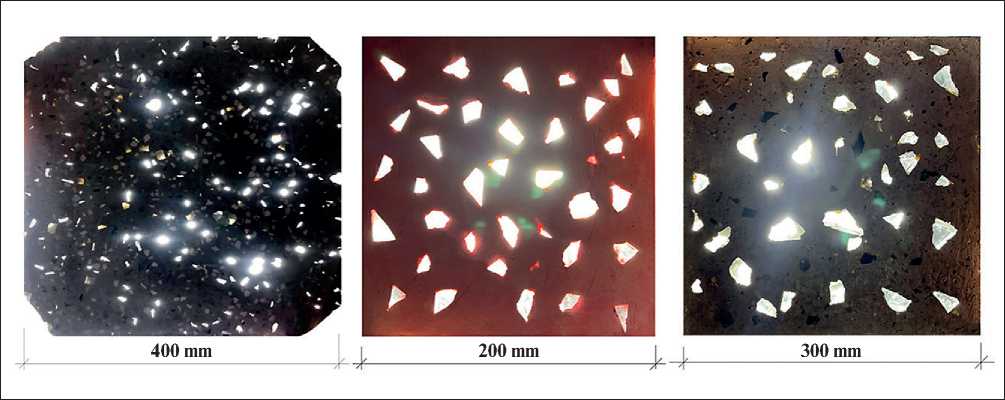

An example of the practical application of the developed concrete in the form of a decorative tiles for square walls with 400-, 300- and 200-mm long sides and 10– 15 mm thick are provided at Fig. 3.

The developed technology for producing decorative light-permeable concrete products under laboratory conditions consisted of the following operations [18–22]: – preparation of raw materials;

– manufacture of wooden forms of the required dimensions;

– preparation of a highly mobile concrete mixture, which was carried out in the following order:

– fly ash, fine-grained slag and fine-grained ceramic powder were mixed in a laboratory mixer to mix powder components with a speed of 100 rpm/min for

5 minutes to obtain a raw composition with astringent properties;

– resulting binder was mixed with crushed glass waste, SR 5000F aqueous superplasticizer solution, activating alkaline solution and remaining water in a doublewalled concrete mixer (0.37 kW; 150 rotations per minute) until producing a uniform concrete mixture;

– mixing time was 5–10 minutes;

– filling of prepared forms with concrete mixture.

– hardening of the concrete mixture in forms for 5 days under natural conditions at a temperature of 25±5 °C and relative humidity of not less than 90%, without heat treatment, with periodic wetting of the open surface of the products with sprayed water;

– Flattening of the finished products with subsequent grinding and polishing of their light-permeable surfaces.

Further research is required to adapt the developed laboratory technology for producing light-permeable concrete products to the conditions of industrial production in Vietnam.

CONCLUSION

As a result of the analysis of the current status and future prospects for the use of decorative light-transmitting “green” concrete in Vietnam, examination of the potential raw material base for its production in the form of multiton technological wastes and experimental studies carried out can lead to the following conclusions:

-

1. Developed compositions of decorative cement-free and non-adherent light-conducting optical fibers of concrete, obtained by using slag waste, ceramic powder “TOTO” and milled glass waste having sufficient strength, Low water absorption and good light transmittance. The technology of production from developed “green” con-

Fig. 3. Decorative square wall tiles

-

2. Implementation in Vietnam of the developed technology of production of decorative light-transmitting “green” concrete products using ash, slag, ceramic powder and milled glass waste will allow not only to obtain an innovative product, Has an architectural expressiveness and aesthetic value, but will also contribute to the solution of the environmental problem of protecting the environment from pollution through the recycling of multi-ton

-

3. However, there are currently a significant number of obstacles to the introduction of decorative lighttransmitting “green” concrete products into construction practice in Vietnam. Therefore, there is a pressing need for additional research and practical tests in this area to overcome them.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION crete decorative thin panels and tiles for walls, having the ability to pass sunlight and adding architectural expressiveness to outside walls and interiors in residential and public buildings.

waste, thereby bringing great benefit to the whole society. In addition, the use of decorative light-transmitting “green” materials for partial replacement of electricityconsuming lighting sources will be a new step towards more efficient use of limited fossil energy resources in Vietnam.