Low-energy binding agent for stone wool-based products

Автор: Zhukov A.D., Artemenko S.O., Zhuk P.M., Bobrova E.Yu., Medvedev A.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.17, 2025 года.

Бесплатный доступ

Introduction. The primary objective of this study is to reduce the energy consumption involved in manufacturing mineral wool products by developing an innovative binder based on modified epoxy compounds. To achieve this objective, the potential use of epoxy compounds as binders and their modification methods were thoroughly investigated. Materials and Methods. The materials used included an epoxy binder, a modifier, and a plasticizer. The mineral wool featured an acidity modulus ranging from 1.8 to 2.1 and fiber diameters approximately 4–5 μm. Adhesion strength and tensile strength tests were conducted using an INSTRON 3382 testing machine. A methodology was developed and implemented to study the formulation and technological parameters for producing the modified epoxy binder. Results. The optimal composition of the modified epoxy binder was identified, comprising 6% modifier (latent component) and 3% plasticizer. The recommended thermal curing temperature was established at 150–154 °C, which is significantly lower than the 240–320 °C typically required for conventional binders. This work helps by creating a digital method to study the technology and showing that, obtained using a latent component and plasticizer, modified epoxy compounds can be used as binders for mineral wool products. Following curing, the adhesion strength to mineral surfaces reached 58.4 MPa, the tensile strength of the binder was 77.4 MPa, and the adhesion strength after climatic testing was 29.1 MPa. Conclusion. Assessment of the properties of mineral wool products demonstrated that their operational durability is comparable to that of products manufactured with traditional binders. Mineral fiber products – including basalt, glass, and stone wool – are among the most commonly used and effective thermal and sound insulation materials. Their application significantly reduces energy consumption for cooling during hot periods and heating during cold seasons. Using the modified epoxy binder cuts energy costs for heating by 50% and lowers overall heat use by 20–30%, which improves the energy efficiency of the products.

Epoxy binder, binder modifier, digital modeling, thermal treatment, operational durability, energy consumption reduction

Короткий адрес: https://sciup.org/142245492

IDR: 142245492 | DOI: 10.15828/2075-8545-2025-17-4-377-388

Текст научной статьи Low-energy binding agent for stone wool-based products

Original article

Жуков А.Д., Артеменко С.О., Жук П.М., Боброва Е.Ю., Медведев А.А. Малоэнергоемкое связующее для изделий на основе каменной ваты. Нанотехнологии в строительстве. 2025;17(4):377–388. – EDN: BORGVT.

A current trend in the development of the construction industry is a focus on energy efficiency and the creation of comfortable or technologically acceptable conditions in insulated spaces. Energy efficiency implies a justified reduction of heat loss during the production and operation of materials, while the creation of comfortable conditions involves forming an optimal temperature and humidity microclimate indoors, as well as acoustic and sanitary comfort.

CONSTRUCTION MATERIALS SCIENCE

The focus on energy efficiency stems from broader trends related to the general and specific problems of building operation, resource use, and energy cooperation or dependency. L. Pérez-Lombard, J. Ortiz, and C. Pout, in their review of energy consumption by buildings, showed that in economically developed countries, from 20 or 30% more of energy may be spent on heating or cooling [1]. Moreover, population growth, increased demand for construction services, the pursuit of higher comfort levels, and longer time spent indoors guarantee that energy demand will continue to grow in the future, as also substantiated by the study of R. Fouquet [2].

The cost of natural energy carriers, along with related issues such as shortages, rising prices, and logistical challenges in delivery, is also an important factor. R. J. Brecha [3] reviews the specifics of fossil fuel use. It is evident that human economic activity, as noted in studies by M. Höök and X. Tang [4], could become a major cause of anthropogenic climate change. This activity also predicts a significant increase in global fossil fuel consumption, which is the main source of emissions from combustion products, affecting the environment to varying degrees.

The situation with liquid fuels, liquefied gas, and natural gas significantly impacts energy stability and, specifically, the stability of the economy overall and the construction industry in particular, as reflected in the review by D. Fantazzini, M. Höök, and A. Angelantoni [5]. The feasibility of preparing for scenarios where capital and energy costs are much higher than under normal business conditions is also considered. J. M. Dargay and D. Gately [6] argue that global oil demand is shifting toward fastergrowing and less price-sensitive products and regions.

These established patterns clearly highlight rational directions for the construction industry, confirming the necessity of developing effective insulation systems, advancing production technology, and applying modern thermal insulation materials.

The building’s insulation envelope, viewed from a construction perspective as an insulation system, significantly optimizes energy consumption and creates comfortable indoor conditions. As justified in the article by N.H. Cuong et al. [7], it is important to develop insulation envelope systems that minimize heat loss through areas of increased thermal conductivity. Active Insulation Systems (AIS) in buildings, researched by N. Kunwar et al. [8], are structures that include thermal insulation, thermal energy storage, and systems to control temperature. Research on dynamic insulation systems by M. Fawaier and B. Bokor [9] shows that such systems regulate heat transfer rates through building enclosures over time. The primary function of dynamic insulation is to change the heat transmission coefficient through the structure. Several existing dynamic insulation designs, implemented with airflow, can achieve energy savings exceeding 40% compared to alternative static insulation building enclo- sures. The most widely used passive insulation systems are ventilated facades and pitched roofs with an air gap, where airflow, according to A.H. Yoon [10], helps regulate air and heat flows.

Thermal insulation materials are essential for any such system. Insulation systems mainly use synthetic materials made from foamed polymers, as described in the textbook by V.A. Ushkov, K.S. Stenechkina, and M.G. Bruyako [11], or materials made from mineral foams, including those made from waste, according to G.A. Medvedeva and O.S. Sekarina [12]. Among the primary thermal insulation materials, are mineral wool is non-combustible and widely used; a detailed review of its production and applications is provided by R.Z. Rakhimov, N.S. Shelikhov, and T. V. Smirnova [13]. It has also been established that some types of synthetic binders may pose environmental and human health risks.

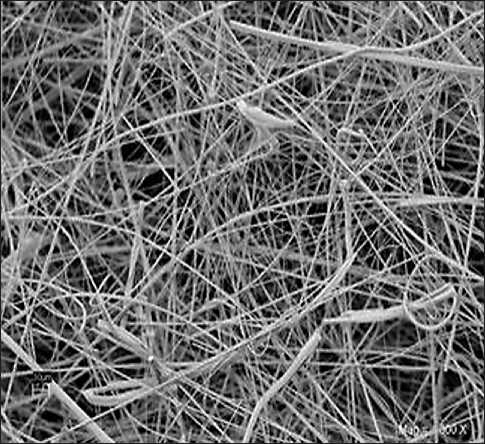

The structure of mineral wool products is formed by interweaving fibers and curing the introduced binder (Fig. 1) at points of fiber contact. Fiber bases include kaolin (aluminate), chrysotile (asbestos), basalt, and glass fibers, as well as mineral or stone wool.

The properties of fibers largely depend on their chemical composition, diameter, and length, which significantly influence both the manufacturing technology and the final characteristics of the products. The fiber type and the intended application of the product closely influence the choice of binder. For example, in refractory technologies, kaolin fibers require a clay-based binder, while chrysotile fibers use mineral binders. Mineral components are often used to modify the properties of these binders. In products based on glass- or basalt-containing fibers, such as glass wool and stone wool, synthetic binders are typically employed. The most common synthetic bind-

Fig. 1. Structure of mineral wool carpet

CONSTRUCTION MATERIALS SCIENCE ers are phenolics neutralized with ammonia water and phenol-formaldehyde resins.

Phenol-containing binders are beneficial because they resist mineral fibers well and don’t break down much when exposed to changing temperatures. However, their main drawbacks stem from the presence of phenol, a strong odor, and a toxic substance. Urea-based binders do not have these disadvantages but exhibit poorer adhesion to mineral fibers and are susceptible to property degradation under climatic influences. These binders are introduced into the fiber deposition chamber as aqueous emulsions (since the binder itself is not water-soluble). The sprayed binder settles on the fibers and fixes them within the forming mineral wool mat. The synthetic binder, introduced by spraying, distributes evenly within the material and, due to surface tension, concentrates in the areas of fiber contact. Subsequently, the mat is transferred to a thermal treatment chamber, where the binder cures through a thermosetting reaction.

The use of synthetic binders has several important considerations. Firstly, the components of these binders in their uncured state are toxic. Secondly, failure to follow the technological process correctly may result in incomplete curing of the binder in the mineral wool mat, making the final product unsafe for use. Moreover, phenol vapors have a strong odor and exhibit a cumulative effect, accumulating in the human body. Thirdly, the curing temperature of these binders typically exceeds 260–320 °C, leading to increased energy consumption and complicating uniform curing within the product.

Binders based on modified epoxy resins offer advantages such as lower environmental hazard due to their minimal toxicity and the ability to cure at temperatures not exceeding 160 °C. The multifunctional nature of epoxy resins allows them to be adapted to various technological tasks. According to studies by R.R. Mukhametov and A.P. Petrov [14], binders, adhesives, and binding agents remain an active research area. Various types of epoxy compounds and the effects of modifiers and additives on their properties are being investigated, primarily to reduce curing temperature, increase the elasticity of the cured contact, and improve adhesion to fibers, thereby enhancing the operational durability and reliability of insulating shells.

Research by P. Apostolidis and colleagues [15] has demonstrated the potential use of epoxy resin derivatives combined with curing agents and modifiers as binders. Modified epoxies can solve many problems linked to traditional binders like phenol-formaldehyde resins and provide better performance. M. Rahmathullah and colleagues [16] confirmed that one of the key advantages of epoxy resin is its relative environmental safety.

The formation of epoxy resins involves an esterification reaction between the epoxy group and the carboxyl group of acrylic acid. M. Saif et al.’s studies demonstrated that benzimidazole catalyzes this reaction, enhancing its efficiency by reducing the activation energy required. The reaction mainly involves the carboxyl group connecting to the epoxy, creating an ester bond with few unwanted side reactions [17].

Amines are commonly used as curing agents in epoxy systems, selected for their ability to provide high mechanical properties and chemical resistance. These include aliphatic, cycloaliphatic, and aromatic amines [18]. Aliphatic amines are characterized by low viscosity and outstanding processability, while cycloaliphatic amines such as bisphenol F provide increased strength and modulus of elasticity.

The use of anhydrides, such as phthalic anhydride and its analogs, as curing agents has also been demonstrated. When catalysts like tertiary amines are added, anhydrides react with epoxy groups to create complex esters and cross-links [19]. Studies by Z. Sakoshev and A. Blaznov found that these curing agents are particularly effective for applications requiring high thermal stability and are often used in combination with epoxy resins like ED-20 [20].

M. Alikin and others found that materials made from epoxy resin with bisphenol F became stronger when heated during the curing process, and the type of curing agent used improved these strengths even more [21]. Modification of epoxy compositions allows the creation of fast-curing formulations stable even at low temperatures. For example, adding diglycidyl phthalate accelerates curing, making these compositions suitable for cold environments [22]. Post-curing at temperatures between 125 °C and 150 °C, as shown by the results obtained by Y. Kawashima and Y. Tsuji [23] has been shown to further improve mechanical strength and impact resistance by promoting uniform cross-linking.

Latent components are important for changing the properties of epoxy binders by managing the curing temperature, improving how well they stick to fibers, and enhancing their performance. Studies by T. Kohlan, M. Rahmathullah, [16, 24] and others indicate that latent components activate under certain conditions such as temperature, pressure, or pH, making curing more controllable and efficient. Mixtures of triarylimidazole and phytic acid from lignin have shown they can stay stable for a long time and have strong mechanical properties after curing, indicating potential for these bio-based epoxy systems.

Innovations also include epoxy resins that are microencapsulated and curing agents that activate and harden when the capsules break, giving composite materials the ability to repair themselves [25]. Additionally, modifying additives can alter curing kinetics, influencing reaction speed and temperature [26]. For instance, adding zinc acetylacetonate and glycerin speeds up the curing process in epoxy-anhydride systems by greatly shorten-

CONSTRUCTION MATERIALS SCIENCE ing the time it takes to dissolve [27]. Accelerators like tris(dimethylaminomethyl)phenol (DMP-30) lower curing temperature and modify cross-link structure, optimizing dielectric properties. Biopolymers derived from microalgae have been shown to enhance the thermal stability and mechanical characteristics of epoxy composites [28].

It is important to note that many synthetic substances undergo polycondensation with curing agents (e.g., polycondensation of ED-20 epoxy resin with PEPA), but this method is not applicable in mineral wool technologies due to the use of aqueous binder dispersions and curing on fibers.

For epoxy-based binders, the best method is to use additives that improve stickiness and flexibility when combining fibers, along with hidden synthetic materials that lower the curing temperature. Compatible additives such as tricresyl phosphate or oleic acid can improve binder properties. Adding latent curing agents like diethylaminoborane allows control over the temperature and time of thermal treatment, reducing energy costs.

The aim of this work is to look at current information and conduct experiments (with digital and statistical methods) to make thermosetting epoxy binders stronger by adding plasticizers and hidden components. Additionally, it seeks to evaluate the performance characteristics of mineral wool products based on these binders

METHODS AND MATERIALS

The experiment was conducted along two main directions. First, we looked at the features of the modified epoxy binder and created basic methods for choosing its ingredients and predicting how it will perform. Second, the operational characteristics of mineral wool boards using this binder were studied.

Physical experiments in construction material technology are characterized by high material consumption, lengthy research times, and a large number of variable factors. Additionally, there remains an ongoing question about the reliability of the obtained results and the methods to verify this reliability. For this reason, the use of statistical methods for experiment organization and digital methods for analyzing results is always relevant [29–31].

The statistical methods used relied on regression analysis, which makes calculations easier by assuming that the errors in regression are normally distributed with parameters N(0,1). The regression errors for different results are considered independent. In the experiment conducted, to enable the use of statistical evaluation methods, each plan point was repeated five times using the randomization method. The mean values (modes) and deviations from these means were determined with a confidence level of 10%.

The method created at the National University of Science and Technology MISIS uses traditional statistical planning and ways to analyze experimental results, applying algebra or matrix analysis to nonlinear functions with multiple variables. This method has been widely tested in solving formulation and technological problems in construction materials science [32–34].

In the experiment, the results measured included how strong the composite binder was when pressed (У 1 ) and how well it stuck (У 2 ) to a glass surface, which represented mineral fiber with a glass-like structure. Additionally, the change in adhesion strength as a result of climatic exposure (У 3 ) was assessed. The optimization parameter chosen was У 2 .

Using the experimental methodology developed and digital analytical optimization of the results, the experiment was conducted in two stages. In the first stage, the linear influence of all significant factors on the optimization parameter was studied. As a result, three important factors were found: the amount of the hidden component in the composite binder (X 1 ), the amount of the plasticizer in the composite binder (X 2 ), and the temperature at which the composite binder cures (X 3 ). The influence of these three factors was further investigated during the second stage of the experiment, the conditions of which are presented in Table 1.

The strength of the adhesive joints between the synthetic binder and the base material, as well as their performance, was tested using standard methods outlined by the relevant regulations. The strength of the adhesive joints was assessed based on the method of load application and the characteristics of the test surfaces. Adhesive strength and tensile strength were determined using the

Table 1. Conditions for conducting

|

Name of the factor |

Symbol, Х i |

Average value of the factor, X. |

Variation interval, ΔХ i |

Factor values at levels |

|

|

–1 |

+1 |

||||

|

Content of component modifier, % |

Х 1 |

4.0 |

2.0 |

2.0 |

6.0 |

|

Plasticizer content, % |

Х 2 |

2.0 |

0.6 |

1.2 |

2.4 |

|

Curing temperature, °C |

Х 3 |

120 |

40 |

80 |

160 |

CONSTRUCTION MATERIALS SCIENCE

Fig. 2. Chamber for express testing of mineral wool slabs

INSTRON 3382 testing machine. We evaluated the performance durability of the binder, specifically the change in adhesion to a glass substrate, by exposing it to climatic effects over 60 cycles of alternating freezing and thawing in a temperature range from –30 °C to +60 °C.

The assessment of changes in the performance characteristics of mineral wool boards over time was carried out using standard procedures involving a climatic chamber, as well as an express method developed under the guidance of Yu.L. Bobrov at the Higher School of Economics and Moscow State University of Civil Engineering (MGSU). This quick method allowed for testing the properties of mineral wool products in special chambers made by JSC “MAXMIR” under different temperature and humidity conditions. Accelerated testing over boiling water was conducted for 20–25 minutes, during which the change in compressive strength at 10% deformation was assessed. This method currently has no analogs and provides reliable results in a short period of time, whereas standard-recommended procedures may require several months to complete.

The main idea of the method using the standard procedure was to expose the samples to changing weather conditions between –20 °C and +20 °C, which mimics how the material would be used in real life. The change in compressive strength at 10% deformation was measured after exposure. Material samples were tested after 20, 40, 80, 120, and 160 freeze – thaw cycles. Two cycles of climatic exposure were considered equivalent to one conditional year of operation. The comparability of the results obtained using different methods ranged from 89% to 94%, indicating a high level of consistency.

The study utilized mineral (stone) wool with a silica modulus of 1.8–2.1 and fiber diameters of approxi- mately 4–5 microns. Performance durability tests were conducted on semi-rigid boards with an average density of 117–123 kg/m³. In the first series of tests, a neutralized phenolic binder was used, while in the second series, a modified epoxy binder was applied. The binder content was set at 3.6%.

RESULTS AND DISCUSSION

The active experiment was conducted according to a full factorial experimental design to obtain nonlinear polynomials (regression equations). The processing of experimental data and testing of statistical hypotheses was carried out using the Statistica software. The significance of the regression coefficients was assessed by comparing confidence intervals (∆ b ) for each regression equation using Student’s t -test and the variance of parallel experiments. The adequacy of the resulting models was verified using the Fisher criterion.

Digital processing made it possible to derive regression equations (algebraic polynomials or digital models) of the following type: Tensile strength of the binder (confidence interval ∆ b ₁ = 2.2 MPa)

У1 = 56+7X1+8X2+9X3+4X1X2–3X32.(1)

Adhesion strength after curing (confidence interval ∆ b 2 = 3.7 MPa)

У2 = 32+8X1+13X2+10X3+5X1X2–6X32.(2)

Adhesion strength after climatic tests (confidence interval ∆ b 3 = 0.6 MPa)

У3 = 21+3X1+4X2+2X3+1X1X2–1X32.(3)

The analysis of the regression coefficients allows for several important conclusions. First, the factor with the greatest influence on the results is the plasticizer content (X 2 ), with the corresponding coefficients in the regression equations being 8, 13, and 4, respectively. Second, increasing the latent component content (X 1 ) values within the experimental range positively affects the increase in response functions, with respective coefficients of 7, 8, and 3. Third, a significant two-factor interaction term (X 1 X 2 ) with a positive coefficient suggests the possibility of a synergistic effect – that is, a mutually reinforcing influence of these two factors on the response – although this observation requires further investigation.

Fourth, the effect of the curing temperature (X 3 ) is nonlinear and ambiguous, as indicated by the negative coefficients for both X 3 and X 3 ². This complex effect supports using the analytical optimization method created at NRU MGSU, which has worked well in developing construction material technologies.

CONSTRUCTION MATERIALS SCIENCE

Analytical optimization of algebraic functions with three variables is performed using methods of mathematical analysis. By determining the extremum of function (2) with respect to X₃ and setting the derivative equal to zero, the optimal curing temperature is obtained.

∂ У 2 /∂ X 3 = 10–12 X 3 = 0 → X 3 = 10/12 = 0.83. (4)

We substitute the obtained optimal value of the curing temperature (in coded form), substitute it into equations (1–3), and obtain optimized functions:

Tensile strength of binder (optimized function):

У1 = 61+7X1+8X2+4X1X2.(5)

Adhesion strength after curing (optimized function):

У2 = 36+8X1+13X2+5X1X2.(6)

Adhesion strength after climatic tests (optimized function):

У3 = 22+3X1+4X2+1X1X2.(7)

Using the conditions from Table 1, the natural value of the optimal curing temperature was calculated as t = 120 + 40 × 0.83 = 152 °C , or, taking into account statistical error, in the range of 150–154 °C.

The graphical interpretation of dependencies (5)–(7) made it possible to construct a nomogram, which enabled the solution of a direct (predictive) digital modeling problem: determining property performance indicators based on changes in the values of variable factors within the experimental domain of definition.

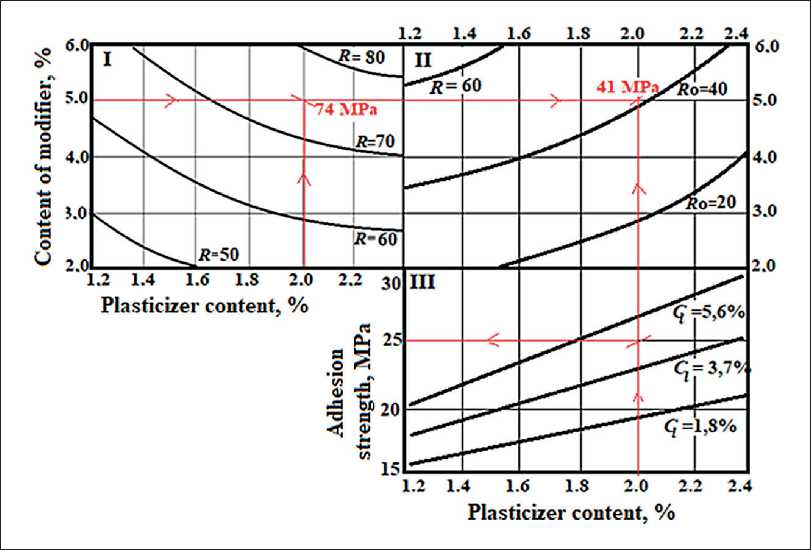

The nomogram (Fig. 3) consists of three sectors, each illustrating the relationship between variable components of the binder formulation and its performance characteristics. Sector I represent the relationship between the variable factors – the content of the plasticizer and the latent component – and the tensile strength of the adhesive composition (R). Sector II shows the correlation between these same variables and the adhesive strength after curing (Ro), while Sector III reflects their influence on the adhesive strength after climatic testing (R t ).

The predictive modeling task is performed by first selecting specific values for the latent component and plasticizer contents. The property values are then determined step-by-step using the nomogram. In the illustrated example (see Fig. 3, red lines), the content of the latent component (C l ) is set at 5% of the total binder, and the plasticizer content (C p ) at 2%. In Sector I, a horizontal line is drawn from the point C l = 5% and extended through Sector II. In Sectors I, II, and III, vertical lines are drawn from the point C p = 2%. At the intersection of these lines in Sector I, the tensile strength is identified as R = 74 MPa. In Sector II, the adhesive strength after curing is also 74 MPa.

Fig. 3. Nomogram for assessing the properties of the binder depending on the change in the consumption of the latent component and plasticizer at the optimum heat treatment temperature of 150–154 °C

CONSTRUCTION MATERIALS SCIENCE

Table 2. Determination of optimal values of variable factors (at optimal heat treatment temperature of 150–154°C)

|

Number of experiments |

Variable factors |

Adhesion strength, MPa |

Divergence of results, % |

||||

|

Content of the modifier, % |

Х1 |

Plasticizer content, % |

Х2 |

Calculated |

Experimental |

||

|

1 |

6.0 |

+0.9 |

3.0 |

+0.9 |

61.5 |

58.4 |

5.0 |

|

2 |

6.0 |

+0.9 |

2.0 |

0 |

43.6 |

45.1 |

3.3 |

|

3 |

2.0 |

–0.9 |

1.0 |

–0.9 |

20.4 |

22.6 |

9.7 |

|

4 |

2.0 |

–0.9 |

1.0 |

+0.9 |

36.5 |

37.9 |

5.3 |

|

5 |

4.0 |

0 |

2.0 |

0 |

36.0 |

35.2 |

2.2 |

|

6 |

4.0 |

0 |

1.0 |

–0.9 |

48.7 |

51.4 |

5.3 |

In Sector III, a line is drawn straight down from where the two guiding lines meet to the vertical axis, showing that the adhesive strength after climatic testing is Rt = 25 MPa. This type of predictive task can also be solved using a computer program that calculates values from the polynomial models.

The next stage of the study involved verifying the optimization outcomes by comparing them with actual results obtained from additional experimental series. Verification was performed using the optimization parameter (У2), which represents the adhesion of the cured binder to the substrate. The experimental conditions and results are summarized in Table 2. The best performance was recorded for Composition No. 1, which is recognized as optimal for the designed composite binder. This formulation included 6.0% latent component and 3.0% plasticizer, with a curing temperature of 150–154 °C. The mixture had an adhesive strength of 58.4 MPa after it was cured, and when using polynomials 5 and 7 for calculations, it showed a tensile strength of 77.4 MPa and an adhesive strength of 29.1 MPa after weather testing.

The experiment revealed that alternating exposure to positive and negative temperatures results in a significant decrease in adhesive strength – by approximately 50%. While this is undoubtedly a negative factor, its impact on the overall strength of mineral wool products is relatively minor. This is because the binder content in stone woolbased materials typically ranges from only 2.5% to 3.5% of the total mass of the mineral wool mat. The interlacing of mineral fibers largely determines the structural integrity of the mat, which plays a far more substantial role in defining the product’s mechanical properties.

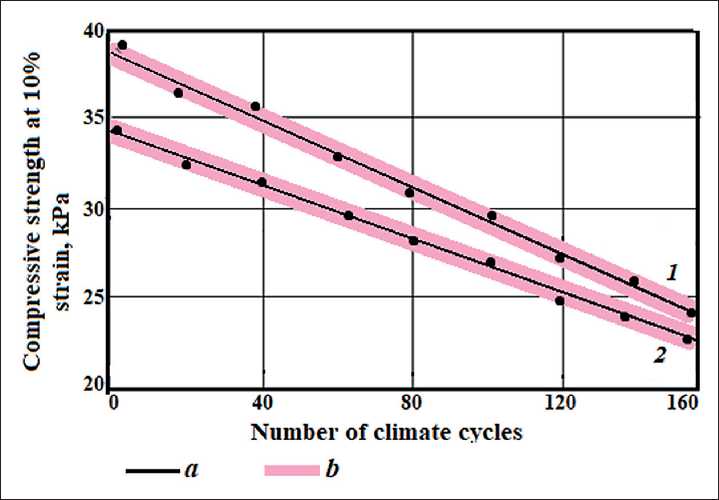

The research on how strong and long-lasting mineral wool boards made with a modified epoxy binder are showed that their strength changes are still within the acceptable limits for mineral wool materials. Figure 4 presents the results of compressive strength testing at 10% deformation, depending on the number of climatic cycles (z).

Fig. 4. Compressive strength of mineral wool boards at 10% deformation as a function of the number of climatic test cycles: ( a ) mean values; ( b ) result variance

CONSTRUCTION MATERIALS SCIENCE

Linear dependencies describe the relationship between the compressive strength at 10% deformation (in kPa) of mineral wool boards and the number of climatic cycles. taking into account the confidence interval obtained through statistical analysis of the results, with an accuracy level of 95%.

For boards using neutralized phenolic binder:

R 10 ( z ) = 39.2–0.094 • z . (8)

For boards using a modified epoxy binder:

R 10 ( z ) = 34.8–0.075 • z . (9)

Cycle testing primarily decreases the strength of mineral wool slabs due to a reduction in the strength of the contact joints between the fibers. The experiment showed that slabs made with a neutralized phenolic binder are a bit stronger than those made with a modified epoxy binder (dependencies 8 and 9). Climate influences level out this fundamentally insignificant difference. The decisive factor is the change in the strength characteristic of the contact zone along the contact surfaces, “hardened binder-fiber.

The thermal conductivity of products made with a modified binder, like phenolic binders, is between 0.04 and 0.05 W/(m • K) and changes depending on the material’s average density. After climatic testing, changes in thermal conductivity were minor and did not exceed the experimental error margin of 3–4%. The vapor permeability of the materials complies with established standards and ranges from 0.29 to 0.31 mg/(m • h • Pa).

Lowering the polycondensation (curing) temperature of the binder achieves a reduction in heat loss due to changes in the curing temperature and, consequently, in the temperature of the heat carrier. This temperature reduction enables a significant decrease in energy consumption during the thermal processing of the mineral wool mat.

This energy-saving potential can be confirmed by calculation. As the curing temperature is reduced, the enthalpy of the heat carrier changes accordingly, leading to a lower thermal energy load in the system.

Q = G • c • t .

G is the flow rate of the coolant, which can be taken as 10,000 m³/h; c is the specific heat capacity of the coolant (1.315 kg/m °C), and t is the temperature of the coolant, taken as either 300 °C or 150 °C. When using phenolic alcohols cured at 300 °C, the heat content of the heat flow will be:

10000 × 300 × 1.315 / 3600 = 1096 kW

The heat content of the heat flow will be as follows when epoxy resins with latent hardeners cured at 150°C are used:

10000 × 150 × 1.315/3600 = 547 kW

Thus, in relative units, the reduction in heat consumption by heat flows will be (1096–547) / 1096 = 0.5 (or 50%).

Fully energy costs for the production of mineral wool products include costs associated with the production of mineral fiber, with the consumption of electricity for technological needs, etc. The total calculated economic (energy) effect from reducing the heat treatment temperature by 150 °C can be taken as 20–30 %.

CONCLUSION

Mineral wool products, particularly those based on stone wool, have proven to be effective materials for insulating building structures due to their non-combustibility and unique structural properties. The characteristics and manufacturing technologies of these products largely depend on the properties of the binders used and the parameters of their thermal treatment. Therefore, it’s a sensible idea to research different types of binders, including mixtures and compounds, to lower energy use in production while keeping the products’ performance high.

The experiment helped create ways to predict how modified epoxy binders will perform, improve their mixture, and identify the best temperature for heating them. The optimal epoxy binder composition was established with 6.0% modifier by binder mass and 3.0% plasticizer by binder mass. The optimal thermal treatment temperature was determined to be 150–154 °C. This binder composition corresponds to an adhesion strength of 58.4 MPa after curing, a tensile strength limit of 77.4 MPa calculated analytically, and an adhesion strength of 29.1 MPa after climatic tests. Mineral wool boards made with the modified epoxy binder exhibit operational properties very similar to those of products based on traditional binders.

The benefits of using the modified epoxy binder are due to two main factors. First, reduced toxicity of the binder lowers the risk of harmful emissions during product use. Second, lowering the temperature needed for heating by 150 °C greatly cuts down on harmful emissions from burning fuel and reduces the energy needed to process the mineral wool mat, which helps the binder fully set in the product. Thereby, using the modified epoxy binder instead of phenol-based binders cuts the energy needed for thermal processing by 50% and lowers the total energy costs for making mineral wool products by 20–30%.

CONSTRUCTION MATERIALS SCIENCE