Origin and evolution of the earliest iron-smelting technologies in the Khakass-Minusinsk basin

Автор: Amzarakov P.B.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 1 т.51, 2023 года.

Бесплатный доступ

The Khakass-Minusinsk Basin is archaeologically one of the best studied regions of Russia. Bronze artifacts from the pre-Scythian and Scythian epoch from that area are famous worldwide. However, iron production appears rather late there. From 2009 to 2018, a joint Russian-Japanese expedition excavated several sites documenting the earliest iron manufacture in the Khakass-Minusinsk Basin. On the basis of these excavations and experiments, metallurgical technology was reconstructed. The results suggest an evolutionary model of metal production in the Khakass-Minusinsk Basin during the Xiongnu-Sarmatian period. Three types of iron-smelting furnaces are described, structurally differing in terms of air-blasting and slag removal. The conclusion is made that the initial iron production technology had been borrowed, and later evolved in situ.

Tes culture, Tashtyk culture, ancient metallurgy, bloomery furnace, slags

Короткий адрес: https://sciup.org/145146825

IDR: 145146825 | DOI: 10.17746/1563-0110.2023.51.1.127-137

Текст научной статьи Origin and evolution of the earliest iron-smelting technologies in the Khakass-Minusinsk basin

The Khakass-Minusinsk Basin is one of the best archaeologically studied regions in the steppe belt of Eurasia. Scholarly expeditions have been working there since 1722. The first detailed periodizations of the archaeological cultures of the Khakass-Minusinsk Basin were elaborated in the 20th century, and since the middle of it, the region has become a kind of center of rescue archaeology. The scale of works done was unprecedented (Krasnoyarsk expedition, Middle Yenisey expedition, etc.) (Kyzlasov, 1962; Vadetskaya, 1973, 1986; Belokobylsky, 1986; Savinov, 2009; and others). Currently, scholarly information on the cultures of the region is being actively accumulated, and their periodization is being improved (Polyakov, 2022).

Thus, since the late 20th century, because of the good state of research, detailed chronology, and well-elaborated typology, archaeological evidence from the Khakass-Minusinsk Basin has become a model for the study of the antiquities of the Eurasian steppe belt, from the Danube to Lake Baikal. It has been used for comparative analysis of the widest circle of assemblages of almost all chronological periods from the Chalcolithic to the Middle Ages.

It is traditionally believed that archaeology of the Khakass-Minusinsk Basin focuses solely on studying burial sites. Until recently, settlement complexes have become the subject of archaeological studies mostly by accident (Torgazhak, Byrganov V, Kamenny Log I, etc.) (Savinov, 1996: 13; Lurie, Lazaretov, 2021; Polyakov, Marsadolov, Lurie, 2022: 8, 9, 13). However, ancient economy and production are of

crucial interest to modern archaeology, answering a number of questions on the development of technologies and economic models for exploitation of the natural resources of the region.

The works of Y.I. Sunchugashev, who dedicated his life to the study of the ancient metallurgy and irrigation systems of the region, significantly contributed to our knowledge of ancient production in the Khakass-Minusinsk Basin. He wrote several monographs, which are now basic for research into ancient metal production (Sunchugashev, 1969, 1975, 1979, 1993). Studies of the Russian-Japanese expedition, which began in 2009, are largely based on the works of Sunchugashev, confirming and sometimes complementing and developing his scholarly conclusions (Murakami, 2015).

The highest level of copper metallurgy in the Khakass-Minusinsk Basin in the Late Bronze Age is indisputable, and is clearly illustrated not only by the quantity, but also by the quality of artifacts from collections in various museums. It is also confirmed by the unique production sites such as the Yuliya mine near the village of Tsvetnogorsk, and Mount Temir, where copper production reached an industrial scale (Sunchugashev, 1975: 34–40). The Khakass-Minusinsk Basin is extremely rich in occurrences of easily accessible polymetallic ore bodies. Noteworthy also are ores containing arsenic, which can produce low-alloy bronze of natural origin during smelting. However, the emergence and development of iron metallurgy in this region is still extremely debatable. It appeared significantly later there than in the neighboring territories, despite the success in bronze metallurgy. The wealth of the Khakass-Minusinsk Basin deposits of copper, plus the mass production of bronze items, might have influenced the delay in the coming of the Bronze Age to the region. The monoethnicity of the local population probably also affected the development of metallurgy, since the social group of people dealing with metal was always quite closed in the ancient world.

Most scholars attribute the first evidences on the use of iron in the Khakass-Minusinsk Basin to the late stage of the Tagar culture (5th–3rd centuries BC). Most often, these are randomly discovered non-domestic iron or polymetallic items (mostly weaponry). These belong to the Tagar culture only typologically, since they were found outside an archaeological context.

Numerous finds made of iron, identified directly in funerary and settlement assemblages, belong to the

Tes archaeological culture of the 2nd–1st centuries BC, as also the first reliably known sites of ancient iron metallurgy (Amzarakov, 2008: 65). In the 3rd– 2nd centuries BC, archaeological cultures in the Khakass-Minusinsk Basin changed with the arrival of a new group of population with well-developed funerary traditions; therefore, it should be assumed that the advanced iron metallurgy technologies were brought to the Middle Yenisey basin from the outside.

To date, in the Khakass-Minusinsk Basin, not a single production complex of ferrous metallurgy is known that can be reliably attributed to the Tagar culture (Sunchugushev, 1979: 20; Zavyalov, Terekhova, 2015: 219). At the same time, during the excavations led by Sunchugashev in the 20th century and expeditions led by the present author in 2009–2018, dozens of sites were explored that definitely belonged to the Tes culture of the 2nd– 1st centuries BC. It should also be mentioned that in the adjacent territories of Central Asia (Tuva, Altai, or northern Mongolia), no reliably dated sites of ferrous metallurgy earlier than the Xiongnu period are known either (Vodyasov et al., 2022); however, there are iron items from closed assemblages of the Scythian period (Arzhan-2 kurgan, kurgan 2 at the Teplaya cemetery, etc.) (Chugunov, Parzinger, Nagler, 2017: 44–46, 51–53; Bokovenko, 2014: 379).

A number of scholars suggest an imported origin for early iron items (Chlenova, 1992: 222; Zinyakov, 1980: 73; Zavyalov, Terekhova, 2015: 219). Especially noteworthy is the bimetallic production technology (Fig. 1), which was practiced in the Khakass-Minusinsk Basin in the Tagar period: if a part of an iron item was lost, it was replaced by a bronze one, even if its utilitarian properties were lost (replacement of the cutting part). This was possible with the presence/combination of two factors—the high prestige of an iron item, and the absence of a different technological possibility (ferrous metallurgy) for its restoration.

Study results

Since 2009, the Russian-Japanese expedition under the leadership of Professor Yasuyuki Murakami (Matsuyama, Japan) and the present author has been carrying out a joint project aimed at studying ancient iron metallurgy. The sites, discovered by Sunchugashev, have been examined; a number of new

Fig. 1 . Bimetallic daggers from the collection of the Martyanov Minusinsk Regional Museum of Local History.

sites have been identified, and some of these have been excavated. The most important results were obtained from studying the metallurgical complexes at Troshkino-Iyus (Shirinsky District of Khakassia, excavations of 2011–2012) and Tolcheya (Bogradsky District of Khakassia, excavations of 2015 and 2018). The first was radiocarbon dated to 1906 ± ± 27 BP (IAAA-103644), the second to 1983 ± 24 BP (IAAA-150561), 2007 ± 24 BP (IAAA-150562), and 2111 ± 24 BP (IAAA-150563). According to these dates, the sites belonged to the Tes and Early Tashtyk periods. The preliminary results from the excavations have been published (Amzarakov, 2014, 2015a, 2015b). Eight and nineteen furnaces were excavated at the Troshkino-Iyus and Tolcheya sites respectively. Such a large number of metallurgical objects investigated over a limited area demonstrates a high level of iron production in the period under discussion.

Using the evidence from excavations, the technology of metal smelting was reconstructed and tested in two scholarly experiments (2017, Niimi, Japan; Krasnoyarsk Territory, Russia). A technological model for evolution of iron-smelting furnaces can be proposed based on experimental results. Such approach, involving analysis of technologies, methods, and practical principles of metal production, as well as support from experiments, seems relevant, since the available typology of iron-smelting furnaces of the Altai-Sayan suggested by Sunchugashev and elaborated by a team of authors (Vodyasov et al., 2022) is based mainly on geometric (primarily spatial) parameters of furnaces, without proper attention to the technological aspects.

The furnaces studied at Troshkino-Iyus and Tolcheya can be divided into three conventional types, in accordance with their technological differences.

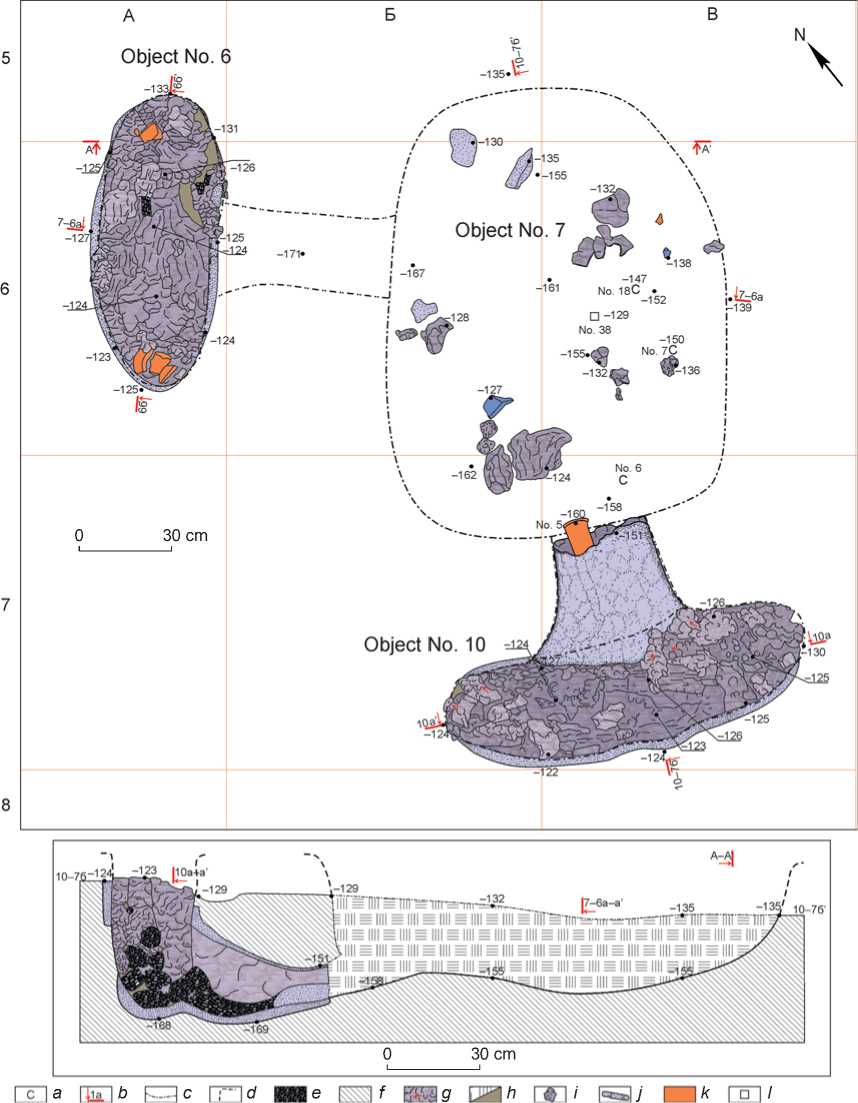

Type 1 (Fig. 2–4) includes almost all the furnaces from excavations at Tolcheya (except for objects P1-5, P1-27, P1-30, and P1-33), and one furnace (No. 10–11) at Troshkino-Iyus. The technological process of iron-smelting in this type of furnace was the following. The pit was dug with sizes suitable for smelting (at the sites in question, it was oval, from 0.8 × 0.5 to 1.6 × 1.2 m, and reached 1 m in depth), and a rounded production pit (with a diameter from 0.8 to 1.3 m, and a depth corresponding to the furnace

pit) was made next to it. These were connected by an underground tunnel, which most often approached the central part of the long side of the furnace, but in some cases could be shifted or even connected to the short wall (object No. 10–11 at Troshkino-Iyus). Ceramic nozzles (from two to four) were joined to the outer side of the furnace from the surface level for upper airblasting, and an area for bellows was made (Fig. 5). The locations of the nozzles were identified by their fragments in the slag-conglomerate masses, and by directions of slag streaks.

The process of smelting began with heating the furnace. At the first stage, larch firewood and natural air-draught from the underground tunnel were used; at the second stage, larch charcoal and artificial airblasting with bellows through the nozzle from the tunnel (Fig. 6, 1 ). Bellows for the lower blow were located in the production pit (it was apparently needed to place and maintain the bellows). The evidence of their use was recorded in furnace P1-10 at Tolcheya, where the external end of a ceramic nozzle was found in the monolith of leaked slag and conglomerate. After reaching the required temperature and uniform combustion over the entire area of the furnace, upper air-blasting was initiated from the outside of the

Fig. 2 . Ground plan and cross-section of complex P1-10 at the Tolcheya site. Iron furnaces. Excavations of 2015 by the author.

a – nozzle fragment; b – direction and names of profiles; c – outline of the pit; d – estimated level of the buried surface; e – charcoal;

f – virgin soil; g – direction of slag streaks; h – filling of the pit; i – slag; j – vitrified fragment of soil; k – ceramic nozzle; l – undecorated pottery fragment.

Fig. 3 . Ground plan of complex of objects in excavation 2 at the Tolcheya site. Iron-smelting furnaces. Excavations of 2015 by the author.

a – nozzle fragment; b – direction and names of profiles; c – outline of the pit; d – stone; e – filling of the pit; f – estimated level of the buried surface; g – charcoal; h – virgin soil; i – outline of the air-blowing tunnel; j – slag; k – vitrified fragment of soil.

Fig. 4 . Complex of objects in excavation 2 at the Tolcheya site. Iron-smelting furnaces.

Excavations of 2015 by the author.

Fig. 5 . Reconstructed iron-smelting furnace. Experiment of 2017 by the author.

Fig. 6 . Processes of warming up the furnace ( 1 ), loading furnace charge ( 2 ) and upper air-blasting ( 3 ). Experiment of 2017 by the author.

* я^»

and slag either (with a positive angle) accumulated in the outlet of the tunnel and, after cooling down, blocked it; or (with a negative angle) flowed along the tunnel towards the production pit. In any case, air-blasting from below stopped at this stage, and air was further blown only from above (Fig. 6, 3). The presence of molten conglomerate and slag at the base of the furnace had a positive effect on the stability of the smelting temperature. Although a large amount of ore was lost on conglomerate that did not react and did not yield iron. The process of smelting was furnace, and charcoal and burden layers of crushed iron ore were loaded* (Fig. 6, 2).

Smelted slag and conglomerate with a main concentration of fayalite (2 FeO·SiO2 and Fe2SiO4) and wustite (FeO) with smelt ore flowed to the bottom of the furnace and reached the yield of the air-blowing tunnel. Depending on the tunnel’s angle of inclination, the liquid fraction of the conglomerate finished when the level of slag masses reached the level of the nozzles. After that, blooming iron formed under the nozzles was extracted from the furnace (Fig. 7). With rare exceptions (the sorting ground of object P1-12 at Tolcheya), there is no evidence for additional systematic sorting-out of conglomerateslag masses, despite the presence of layers and grains of blooming iron therein.

After extracting blooming iron and slag from the furnace, the production process was repeated. In the radial objects of the Tolcheya site (with a central production pit and oppositely located furnaces), it could have occurred sequentially, almost without pauses.

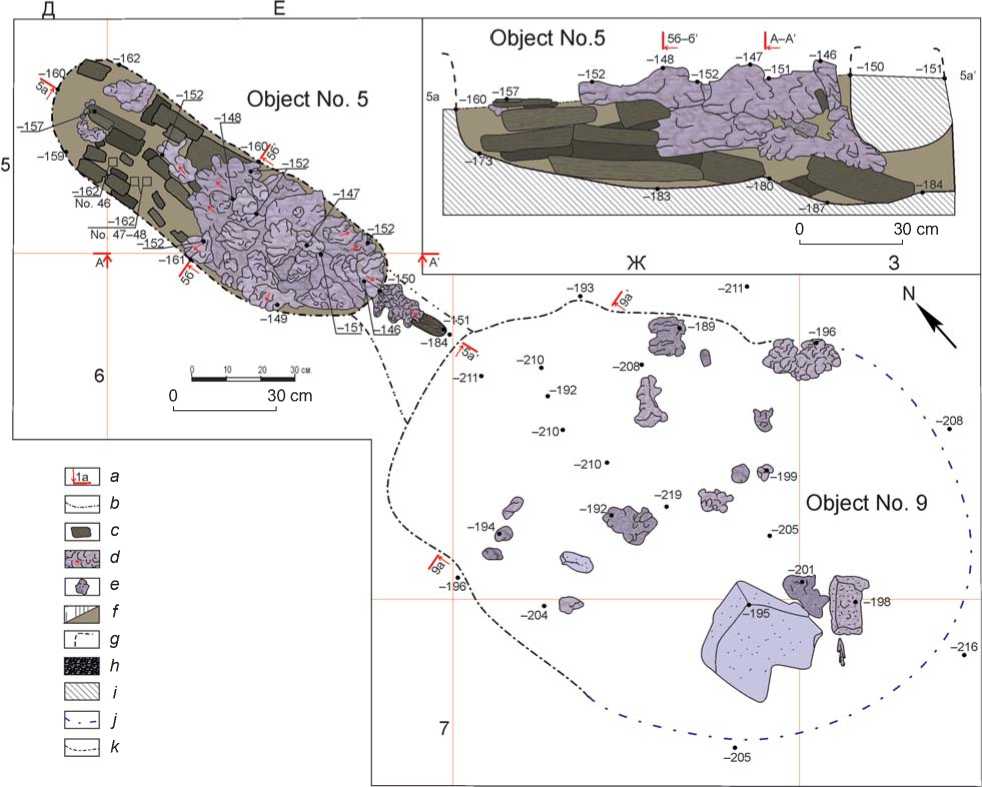

Type 2 (Fig. 8, 9) includes furnaces P1-5, P1-27, P1-30, and P1-33 at Tolcheya. The basic technological process was identical to type 1, but the smelters tried to reduce the volume of ore lost to wustite and fayalite, and increase the percentage of the resulting iron relative to ore spent. This was achieved in two main ways: early termination of lower air-blasting by closing the mouth of the underground tunnel, and purposeful filling the lower part of the furnace with tightly stacked firewood. The latter method reduced the volume that could be filled with conglomerate, since the smelting

Fig. 7 . Monolith of a conglomerate with inclusions of bloomery iron. Experiment of 2017 by the author.

Fig. 8 . Ground plan and cross-section of complex P1-5 at the Tolcheya site. Iron-smelting furnaces. Excavations of 2015 by the author.

a – direction and names of profiles; b – outline of the pit; c – burnt wood; d – direction of slag streaks; e – slag; f – filling of the pit; g – estimated level of the buried surface; h – charcoal; i – virgin soil; j – estimated outline of the pit; k – circuit of air-blowing tunnel.

Fig. 9 . Physical section of object P1-30 at the Tolcheya site. Iron-smelting furnaces. Excavations of 2018 by the author.

Fig. 10 . Charred firewood in the lower part of iron-smelting furnace near the village of Balyktuyul, in the Altai Mountains (after (Bogdanov et al., 2018)).

process took place only opposite the upper nozzles, where the temperature and chemical environment ensured the necessary conditions. In this case, most of the ore was subjected to the process of

chemical transformation (deoxidizing). Without lower air-blasting and powerful padding of the slag conglomerate, it would become more difficult to maintain the temperature conditions, which demanded a higher quality of upper air-blasting. A similar technological approach—reduction in the volume of the smelting chamber by tightly stacking the lower part with firewood—has also been observed at the Balyktuyul site in the Altai Mountains (Fig. 10) (Bogdanov et al., 2018: 226).

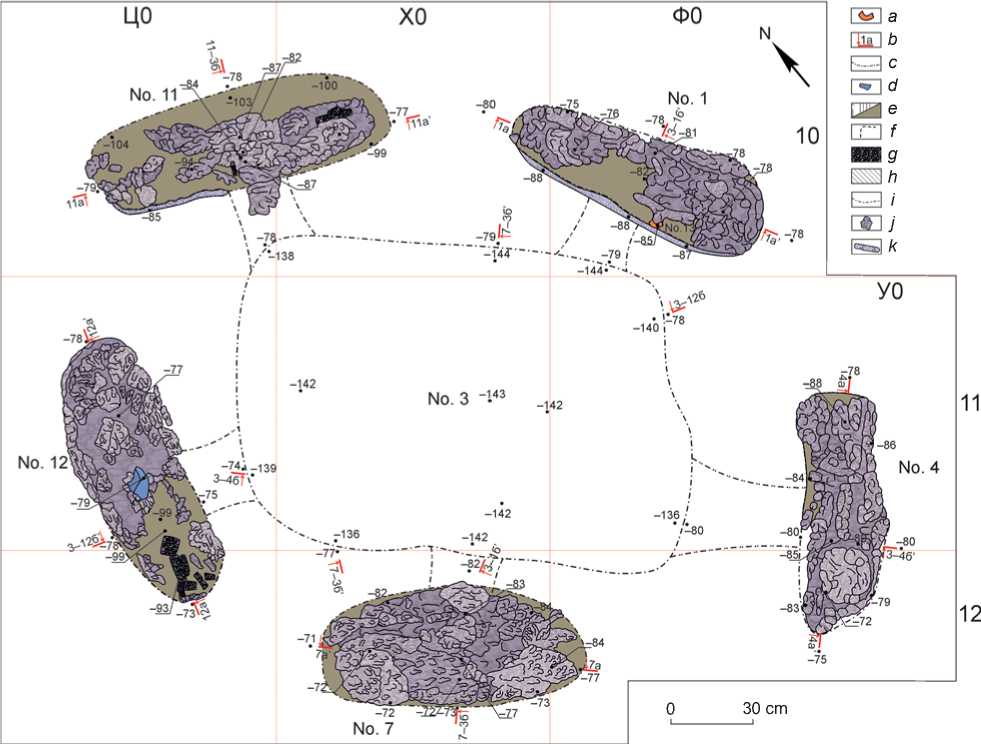

Type 3 (Fig. 11, 12) includes almost all the studied furnaces at the Troshkino-Iyus site (except No. 10–11). The main parameters of the smelting process were similar to those of type 1. The furnaces had an underground structure. They are relatively small: from 0.8 × 0.4 to 0.9 × 0.5 m, and up to 0.7–0.8 m in depth. A rounded production pit measuring from

Fig. 11 . Object No. 5 at the Troshkino-Iyus site. Ground plan and cross-section. Excavations of 2012 by the author.

Fig. 12 . Ground plan and cross-section of object No. 7 at the Troshkino-Iyus site. Excavations of 2012 by the author.

a – outline of pit surface; b – slagged fragment of furnace wall; c – slag fragment; d – layer of dark gray calcined soil; e – outline of pit bottom; f – fragment of gray-black coating on the furnace wall; g – filling of the object; h – whitish loam; i – slag fragment; j – charcoal; k – layer of humified dark brown sandy loam.

-

1.1 × 1.2 to 1.7 × 1.8 m was also nearby. However, unlike types 1 and 2, the production pit was not connected to the furnace pit by the underground tunnel. It shows horizontal layers of slag, ore, and vitrified walls of the furnace. Air-blasting was carried out only from above, through the nozzles inserted into the furnace from the level of the ancient surface. Their locations and remains of ceramic nozzles have been repeatedly recorded. After the process of smelting was finished, the earthen wall between the furnace and the production pit was immediately destroyed and liquid slag was poured down into the production pit, which facilitated the removal of blooming iron formed under the nozzles.

Conclusions

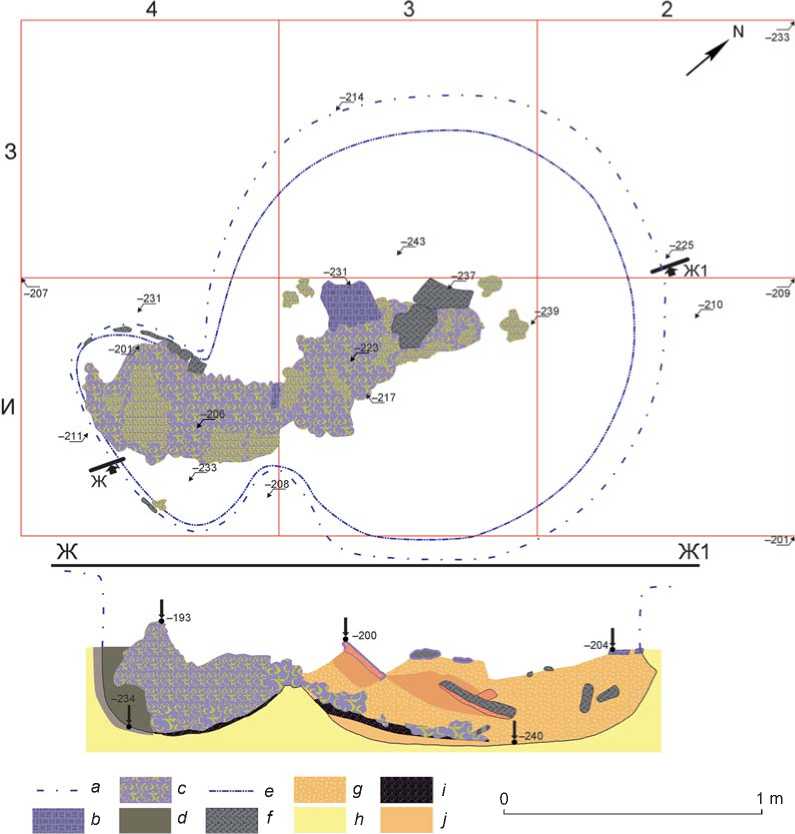

On the basis of the types of furnaces described above, the following evolutionary and technological theory can be proposed.

-

1. At first, ancient metallurgists used the technology of a pit iron-smelting hearth with double synchronous air-blasting: from above—the level of the present-day surface, and from below—the tunnel. As a result, large quantities of molten conglomerate and slag flowed down the bottom of the furnace, which created temperature conditions favorable for smelting. This simplified the smelting process,

-

2. The next step was the attempts to save the ore by filling the bottom of the furnace with firewood and charcoal, as well as by early cessation of air-blasting from below. This could increase the amount of iron produced relative to ore spent, but complicated the process and required the development of technology or air-blasting technique. The increased amount of iron in the bodies of furnaces of type 2 implies violation of temperature conditions.

-

3. Finally, the metallurgists abandoned the technology of lower air-blasting through the tunnel. Now, air-blasting was carried out only from the level of the present-day surface. It was difficult to ensure the required amount of air and its uniform supply. Apparently, this became possible after changing the technique and technology of airblowing. Given the decrease in the diameter of the nozzles in this type of furnace, as confirmed by material evidence, bellows with a hard frame might have been used, which could provide higher pressure of the supplied air.

but led to a low percentage of the resulting iron as compared to the ore used.

These conclusions must be additionally confirmed by new experiments, focusing on type 3 technology with different varieties of bellows and different conditions. Experimental method is important for studying ancient technologies.

Thus, briefly summarizing all the above, the following conclusions can be made.

-

1. The first products made of bloomery iron appeared in the Khakass-Minusinsk Basin in the Tagar period (5th–3rd centuries BC).

-

2. Iron items, typologically related to the Tagar culture, were most likely imported.

-

3. To date, the existence in the Khakass-Minusinsk Basin of iron production earlier than the Tes archaeological culture (2nd–1st centuries BC) has not been reliably established.

-

4. The technology of ferrous metallurgy emerged in the region spontaneously and at a fairly high level, which may suggest its appearance together with carriers of these metallurgical traditions.

-

5. Further development of iron production in the Khakass-Minusinsk Basin was associated with the search for effective technological solutions aimed at production optimization and increasing the ratio of the resulting product to resources consumed.

Список литературы Origin and evolution of the earliest iron-smelting technologies in the Khakass-Minusinsk basin

- Amzarakov P.B. 2008 Tesinskiy perekhodniy period. Tagaro-tashtykskoye vremya (II v. do n.e. - I v. n.e.). In Ocherki istorii Khakasii (s drevneishikh vremen do sovremennosti), V.Y. Butanaev, V.I. Molodin (eds.). Abakan: Izd. Khak. Gos. Univ., pp. 65-68.

- Amzarakov P.B. 2014 Raskopki drevnego metallurgicheskogo kompleksa tashtykskogo vremeni v rayone sela Troshkino Shirinskogo rayona Respubliki Khakasii. In Narody i kultury Yuzhnoy Sibiri i sopredelnykh territoriy. Abakan: Khak. kn. izd., pp. 26-38.

- Amzarakov P.B. 2015a Predvaritelniye itogi issledovaniya pamyatnika drevney metallurgii zheleza tashtykskoy epokhi “Tolcheya”. In Drevnyaya metallurgiya Sayano-Altaya i Vostochnoy Azii = Ancient Metallurgy of the Sayan-Altai and East Asia: Materialy I Mezhdunar. nauch. konf., posvyashch. pamyati doktorara ist. nauk, prof. Y.I. Sunchugasheva (Abakan, 23-27 sentyabrya 2015 g.). Abakan, Ekhime: Univ. Ekhime, pp. 98-106.

- Amzarakov P. 2015b Early iron production in South Siberia. In The Present-Day Research on Ancient Iron Production in the World. Matsuyama: Ehime Univ., pp. 39-46.

- Belokobylsky Y.G. 1986 Bronzoviy i ranniy zhelezniy vek Yuzhnoy Sibiri: Istoriya idey i issledovaniy (XVIII - pervaya tret XX v.). Novosibirsk: Nauka.

- Bogdanov E.S., Murakami Y., Solovyev A.I., Grishin A.E., Solovyeva E.A., Gnezdilova I.S. 2018 Issledovaniye syrodutnykh pechey okolo sela Balyktuyul (Respublika Altai) v 2018 godu. In Problemy arkheologii, etnografii, antropologii Sibiri i sopredelnykh territoriy, vol. XXIV. Novosibirsk: Izd. IAET SO RAN, pp. 224-228.

- Bokovenko N.A. 2014 Arkheologicheskiye pamyatniki skifskoy epokhi Usinskoy kotloviny v Zapadnom Sayane: Kulturno-khronologicheskaya interpretatsiya. In Arkheologiya drevnikh obshchestv Yevrazii: Khronologiya, kulturogenez, religiozniye vozzreniya. St. Petersburg: IIMK RAN, pp. 372-392.

- Chlenova N.L. 1992 Tagarskaya kultura. In Stepnaya polosa Aziatskoy chasti SSSR v skifo-sarmatskoye vremya. Moscow: Nauka, pp. 206- 223. (Arkheologiya SSSR).

- Chugunov K.V., Parzinger H., Nagler A. 2017 Tsarskiy kurgan skifskogo vremeni Arzhan-2 v Tuve. Novosibirsk: Izd. IAET SO RAN.

- Kyzlasov L.R. 1962 Nachalo sibirskoy arkheologii. In Istoriko-arkheologicheskiy sbornik. Moscow: Izd. Mosk. Gos. Univ., pp. 43-52.

- Lurie V.M., Lazaretov I.P. 2021 Drevniye poseleniya Khakasii: Byrganov IV. In Tvorets kultury: Materialnaya kultura i dukhovnoye prostranstvo cheloveka v svete arkheologii, istorii, etnografi i: Sbornik nauch. statey, posvyashch. 80-letiyu prof. D.G. Savinova i 60-letiyu yego truda na nive otechestvennoy nauki, N.Y. Smirnov (ed.). St. Petersburg: IIMK RAN, pp. 188-198.

- Murakami Y. 2015 Nasha sovmestnaya deyatelnost v Respublike Khakasiya i yeyo znacheniye dlya issledovaniya istorii proizvodstva zheleza na Yevraziyskom kontinente. In Drevnyaya metallurgiya Sayano-Altaya i Vostochnoy Azii = Ancient Metallurgy of the Sayan-Altai and East Asia: Materialy I Mezhdunar. nauch. konf., posvyashch. pamyati doktora ist. nauk, prof. Y.I. Sunchugasheva (Abakan, 23-27 sentyabrya 2015 g.). Abakan, Ekhime: Univ. Ekhime, pp. 21-24.

- Polyakov A.V. 2022 Khronologiya i kulturogenez pamyatnikov epokhi paleometalla Minusinskikh kotlovin. St. Petersburg: IIMK RAN.

- Polyakov A.V., Marsadolov L.S., Lurie V.M. 2022 Poseleniye Kamenniy Log I na Srednem Yeniseye (po materialam raskopok M.P. Gryaznova i M.N. Komarovoy). St. Petersburg: IIMK RAN.

- Savinov D.G. 1996 Drevniye poseleniya Khakasii: Torgazhak. St. Petersburg: Peterburg. vostokovedeniye.

- Savinov D.G. 2009 Khakassko-Minusinskaya provintsiya khunnu. St. Petersburg: IIMK RAN.

- Sunchugashev Y.I. 1969 Gornoye delo i vyplavka metallov v drevney Tuve. Moscow: Nauka. (MIA; No. 49).

- Sunchugashev Y.I. 1975 Drevneishiye rudniki i pamyatniki ranney metallurgii v Khakassko-Minusinskoy kotlovine. Moscow: Nauka.

- Sunchugashev Y.I. 1979 Drevnyaya metallurgiya Khakasii: Epokha zheleza. Novosibirsk: Nauka.

- Sunchugashev Y.I. 1993 Pamyatniki gornogo dela i metallurgii drevney Khakasii. Abakan: Khak. kn. izd.

- Vadetskaya E.B. 1973 K istorii arkheologicheskogo izucheniya drevneishego proshlogo Sibiri. Izvestiya laboratorii arkheologicheskikh issledovaniy, iss. 6: 91-159.

- Vadetskaya E.B. 1986 Arkheologicheskiye pamyatniki v stepyakh Srednego Yeniseya. Leningrad: Nauka.

- Vodyasov E.V., Amzarakov P.B., Sadykov T.R., Shirin Y.V., Zaitceva O.V., Leipe C., Tarasov P.E. 2022 Nine Types of Iron Smelting Furnaces in Southern Siberia in the First Millennium AD: A Review of Archaeological and Chronological Data. URL: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4174729 or https://doi.org/10.2139/ssrn.4174729

- Zavyalov V.I., Terekhova N.N. 2015 K probleme stanovleniya zheleznoy industrii na Srednem Yeniseye (tekhnologicheskiy aspekt). KSIA, iss. 238: 212-228.

- Zinyakov V.M. 1980 K istorii osvoyeniya zheleza v Minusinskoy kotlovine. In Skifo-sibirskoye kulturno-istoricheskoye yedinstvo: Materialy I Vsesoyuz. arkheol. konf. Kemerovo: Kem. Gos. Univ., pp. 66-73.