Potential of technogenic mineral raw materials in Russia and the issues of its rational use

Автор: Goncharova Larisa Ivanovna, Larichkin Fedor Dmitrievich, Perein Vladimir Nikolaevich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Branch-wise economy

Статья в выпуске: 5 (41) т.8, 2015 года.

Бесплатный доступ

The increasing negative impact of mining waste on natural ecosystems often leads to their irreversible destruction, a trend that is gradually becoming global. The particular relevance of the research is explained, on the one hand, by the possibilities of minimization of specific volumes of formation of mining waste in all types of industries; on the other hand, by the possibilities of maximization of comprehensive use of their valuable components as secondary material resources on an economically rational basis and the possibilities of restoring the disturbed natural environment. The rational use of natural and technogenic mineral raw materials is greatly facilitated by the geological exploration and geological-economic evaluation of the resources, which requires the development of specific methodological approaches to the economic justification of resource estimation parameters for outlining and calculating the multicomponent commercial reserves of raw materials and separate valuable components in them...

Mining waste, organizational and economic mechanism for waste management, price valuation methods, evaluation of economic effectiveness, rational nature management, integrated use of raw materials

Короткий адрес: https://sciup.org/147223757

IDR: 147223757 | УДК: 338.45:622,17:504.062 | DOI: 10.15838/esc/2015.5.41.7

Текст научной статьи Potential of technogenic mineral raw materials in Russia and the issues of its rational use

Global production of minerals during the latest century is increasing by nearly 10% per year, and is now about 500 billion tons; at that, more than 800 billion tons of host rock is removed from the depths each year. Due to the priority development of the most accessible and richest deposits and since there is a need to use raw materials of worse quality, the rate of accumulation of mining waste (MW) tends to exceed the growth rate of industrial production.

The growing negative impact of MW on natural ecosystems often leads to their irreversible destruction and this trend is gradually becoming global. This explains the particular relevance of the search for opportunities to minimize specific volumes of formation of mining waste in all types of industries, the search for opportunities to maximize the comprehensive use of their valuable components as secondary material resources (SMR) on an economically rational basis, and the possibilities of restoring the disturbed natural environment.

Developed countries of the world and Europe have achieved high levels of using mining waste as SMR, and in the short term they plan to abandon the practice of waste burial completely. There is a transition from the concept of safe handling of the MW to the concept of the so-called “industrial metabolism”. This concept is based on the comprehensive assessment of economic effectiveness of measures to protect the environment at all the stages of production and consumption of products, from mining operations up to the liquidation of the manufactured materials and products after their life cycle has expired.

The use of any kind of SMR is a multifaceted issue that covers all sectors of material production, services sector, exports and imports, resource consumption, resource conservation, protection and restoration of the environment.

In Russia, the low level of using mining waste as secondary material resources proceeds not from the lack of technological developments, but from flaws in the organizational and economic mechanism of waste management, inefficient methods of their cost estimate, and methodology for assessing the economic effectiveness of the comprehensive utilization of their valuable components, and also from the fact that enterprises have no real economic incentives for the processing of mining waste.

The scientific basis for exploration, technology, economics of rational comprehensive development and utilization of natural and technogenic resources was developed by the following domestic scientists and experts: M.I. Agoshkov, A.S. Astakhov, N.P. Bannyi, A.Kh. Benuni, S.N. Bobylev, A.M. Bybochkin, V.I. Vernadskii, A.D. Verkhoturov, V.N. Vinogradov, T.A. Gatov, E.V. Girusov, I.M. Gratsershtein, V.T. Kalinnikov, Yu.A. Kiperman, M.A. Komarov, G.D. Kuznetsov, V.N. Leksin, N.V. Mel’nikov, B.K. Mikhailov, S.A. Pervushin, V.A. Reznichenko, A.M. Sechevitsa, K.N. Trubetskoi, V.A. Fedoseev, A.E. Fersman, V.A. Chanturiya and others [1].

Foreign researchers C. Drury, Hahn Dietger, C. Fontain, H. Court, H. Culmann, M. De Narbonn, L. Lawrence, C. Schlatter, K. Slater, C. Wootton and others [2] virtually do not use the terminology and concept of integrated use of raw materials, they examine only the distribution of the total costs of integrated production between the primary (targeted) product and the so-called byproducts (incidental, attendant products/ components).

The fundamental theory of noosphere developed by Academician. V. I. Vernadskii [3] is of key importance for the socio-ecological-economic effectiveness of rational nature management. The aim of the theory is rational scientific transformation of biosphere into “noosphere” – the sphere of reason – in accordance with the laws of conservation and maintenance of life for the harmonious coexistence of society and nature. Academician A.E. Fersman’s theory of the integrated use of all the valuable components of mineral raw materials on the principles of environmental and economic efficiency [4] forms the basis of the majority of concrete projects in the field of subsoil use.

Various types of mining waste, as well as natural mineral raw materials, have a complicated multicomponent structure; the issues of their sustainable use are considered as part of comprehensive subsoil use and nature management (M.I. Agoshkov, A.Kh. Benuni, V.I. Vernadskii, I.M. Gratsershtein, V.T. Kalinnikov, Yu.A. Kiperman, M.A. Komarov, G.D. Kuznetsov, V.N. Leksin, N.V. Mel’nikov, B.K. Mikhailov, V.A. Reznichenko, V.A. Fedoseev, A.E. Fersman [1, 5]).

The modern concept of rational nature management attaches special importance to environmental issues; due to this fact, it is necessary to take into account the environmental effects that are achieved as a result of a more full use of integrated natural and technogenic raw materials.

The rational use of natural and technogenic mineral raw materials is greatly facilitated by the geological exploration and geological-economic evaluation of the resources, which requires the development of specific methodological approaches to the economic justification of resource estimation parameters for outlining and calculating the multicomponent commercial reserves of raw materials and separate valuable components in them [6, 7].

The problem of secondary material resources processing is regarded as an important part of the overall socio-ecological-economic system for rational nature management. The analysis of the existing practice of mining waste usage should be based on the system approach and take into consideration geological, technological, economic, environmental and social characteristics throughout the cycle of production, combined processing and treatment of secondary waste according to the principle “from the earth to the earth”.

The expediency of including production and consumption waste in economic circulation as secondary raw materials is proven by a long-term experience in many countries. For example, the proportion of waste is 26% in the balance of source materials in the USA and Japan; this indicator ranges from 16 to 20% in the majority of developed countries; it was 15% in the USSR, and it is about 10% in modern Russia.

It will be useful to consider the development of legislation, practical achievements and positive experience of waste management in the European Union (EU). The EU takes comprehensive measures to promote three interrelated areas: a) prevention or reduction of waste generation and their hazardous properties; b) involvement of waste in economic circulation; c) reduction of waste intended for final disposal.

Since 1973, the EU has adopted six medium-term programs for environmental protection, each of which is a political and legal document that defines specific goals, objectives and priority actions for the near future. For example, the main targets of the Sixth Program provide for the reduction of waste disposal by 20% by 2010 and by 50% by 2050 as compared to the 2000 level; the same can be said about the volume of hazardous waste generation in the EU [5].

Directive 96/61/EU introduced the concept of “best available techniques” (BAT) in the European law. Since 1996, 33 European BAT reference documents (BREFs) on various industries were prepared, every 5–7 years they are revised. The copyright of the BREFs allow their free translation into other languages and use [5].

The annual global volume of mineral production is approaching 500 billion tons, and the volume of simultaneously extracted host rocks is over 800 billion tons. Thus, the annual volume of mining waste in the world already exceeds 1,000 billion tons.

To date, according to various estimates, Russia has accumulated approximately from 40 to 100 billion tons of mining waste and more.

In order to streamline the scope of production and consumption waste disposal in Russia, it is necessary to identify the main barriers to the large-scale comprehensive utilization of mining waste. The main ones are as follows: flaws in the legal framework; absence of economic mechanisms to encourage the collection, recycling and disposal of waste; limitations of traditional methods for economic evaluation and rational justification of prices of different (especially multi-component) waste; lack of economic incentives for enterprises. It is also necessary to clarify the scope of authority of the Russian Federation subjects and local self-government authorities in the field of waste management.

The problem of production and consumption waste disposal is one of the most pressing environmental and economic problems in the regions of the North and the Arctic, in particular, in the Murmansk Oblast.

Over 80 years of intensive subsoil resource use have significantly changed the topography of the region: there emerged manmade mountains of mining waste up to 60 m high, which, according to experts and statistics as of January 01, 2011 have accumulated more than 8 billion tons; there are open pits more than 500 m deep; 50-meters-high tailing and sludge dumps that cover several thousand hectares; besides, several mountains, lakes and rivers have disappeared from the face of the earth. The average annual volume of production and consumption waste generation in the oblast is about 100 million tons.

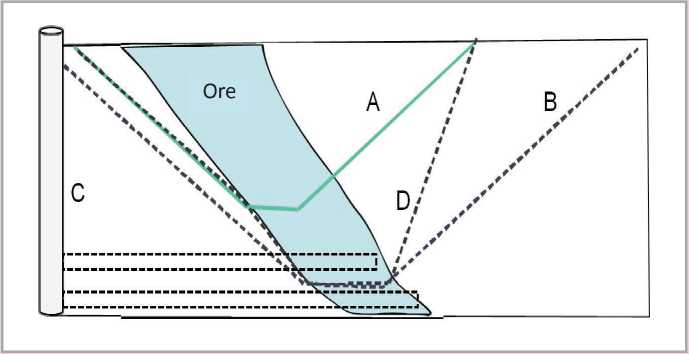

An effective way to solve the mining waste issue is to reduce its output and volume on all the stages and operations of production. In this regard, a methodology for pre-mining engineering-geological and geomechanical investigation of rock mass during the exploitation of deep open pits with the maximum angles of stable edges was developed in collaboration with the Kola Scientific Center of RAS and Inter-Industry Scientific Center VNIMI; this methodology helps minimize the risks of collapse of the edges and reduce the amount of overburden rock and the output of mining waste (fig. 1) .

In particular, for the open pits of JSC Kovdorsky GOK the increase in the slope of the end edge from 40 to 50° (depends on the parameters of specific rock type) reduces the amount of overburden rock and the output of mining waste by 40% (about 4% per 1° of increase in the angle), while preserving the previous size of its area on the surface and its depth.

A specific feature of using multicomponent mining raw materials is that the economic efficiency of using natural and technogenic

Figure 1. Model for the development of deep horizons:

D – option of the deep open pit with the maximum angles of stable edges

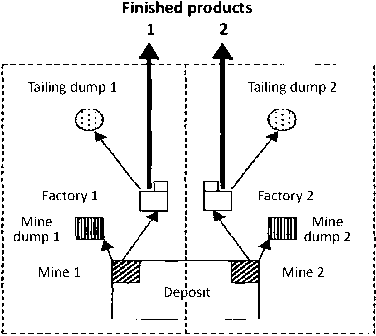

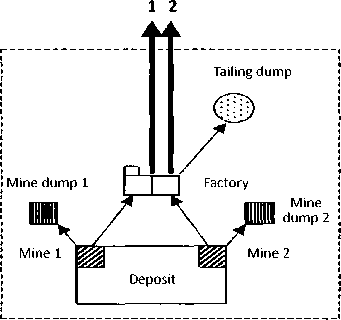

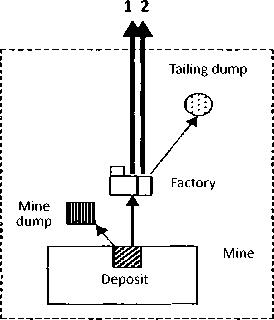

Figure 2. Varieties of production models when using the fields of multicomponent mining waste [1]

1. Individual production (single-product)

Finished products

2. Integrated production (conglomerate)

Finished products

3. Combined (complex) production

materials in general does not guarantee the efficiency of production of each of its valuable components and vice versa.

The existing methodological approach to assessing the efficiency of the development of multicomponent materials is based on the full reimbursement of production costs of the component at single-product enterprises. In practice, this leads to the increase in the cost of production of each individual component, and consequently, to the unjustifiable narrowing of the boundaries of cost-effective complex utilization of mining waste.

Environmental and economic advantages of the integrated use of raw materials and the emergence of synergetic effect are clearly represented in a comparative analysis of the models of individual (single-product), integrated and comprehensive productions that are organized on the basis of the same technogenic field of multicomponent industrial waste (fig. 2) .

It is necessary to note an important feature of mining waste usage: in comparison with the use of natural mineral raw materials, the relative volume of the total indirect costs of exploration and preparation of technogenic raw materials (washery refuse, in particular) for complex utilization is significantly lower.

In this regard, the methodology for assessing the economic effectiveness of integrated use of technogenic raw materials – mineral waste – is substantiated; it consists of two stages:

-

1) preliminary economic evaluation of extraction of each of the valuable components of the raw material, which is determined proceeding from the condition of reimbursement of only direct production costs related to the organization of extraction of the estimated component, excluding indirect costs;

-

2) final economic evaluation of integrated utilization of technogenic raw materials on the whole, which is determined proceeding from the condition of reimbursement of the total amount of direct and indirect costs of extraction and complex processing of raw materials taking into account only those components, the extraction of which is economically justified in accordance with the principle of stage 1.

These principles for the recommended methodology applied to multicomponent mining waste, taking into account the main provisions of the current methodological recommendations on the assessment of investment projects’ effectiveness are represented by the following system of inequations [9]:

⎧ T

-

2 ( Ци - 3nit - Knit ± Bit )(1 + E ) t a 0 ( 1)

-

t = 0

T

ЧДД = 2 ( Цt - 3t - Кt ± Bt )(1 + E ) t > 0 ( 2) t = 0

where Pit – the price of the i-th component in the finished product in year t ;

Cnit, Lnit – direct current and direct lump-sum costs of production of the i-th component in the finished product in year t ;

Eit – environmental component (taking into account benefits and costs) of extracting the i-th component from mining waste in year t (can be positive or negative);

Rt - economic result (total cost of sold products taking into account all the valuable components, the extraction of which satisfies the condition (1) in the t -th year;

Ct – total operating costs of extraction and complex processing of mining waste in the t -th year (excluding depreciation);

It – capital investments in the t -th year;

Et – total environmental result of the integrated processing of mining waste in year t ;

F – discount factor, the value of which is recommended to be taken on the basis of a bank’s interest rate (Russia’s National Reserves Committee recommends it to be 10–15% with regard to the development of deposits [11]);

-

t = 0 – year in which the exploitation (project) was launched;

T – year of completion of the investment project (exploitation of the field, total planning horizon does not exceed 20 years).

This method of economic valuation of the use of technogenic raw materials compared to a traditional one significantly expands the opportunities for the integrated use of mining waste.

The following was done as a practical example: the works on the study and use of industrial waste (tailings) and rock refuse at JSC Kovdorsky GOK were summarized and systematized; the work of the enterprise was analyzed, as well as the efforts of R&D organizations to develop and implement the technology for extraction and processing of the richest part of the mine tailings accumulated at the first field of the tailing dump; the exploration, technological and geological-economic assessment of the poorer tailings of the second field of the tailing dump were carried out; methodological approaches to the substantiation of condition parameters for outlining and calculating commercial reserves of multicomponent technogenic raw materials.

Magnetite and apatite ore processing waste at the Kovdor Deposit are stored in the tailing dump: in first field – in 1962–1981, in the second field – from 1982 and up to the present. The main volume of the first field of the tailing dump was formed before the apatitebaddeleyite washing plant had been launched in 1975, and is represented by the tailings of wet magnetic separation, enriched in apatite and baddeleyite.

The extraction and transportation of raw materials of the technogenic deposit is carried out since 1995 with the help of the enterprise’s standard equipment. The results of the processing of mature tailings are presented in the table . As can be seen from the table, the content of valuable components in the tailings

Indicators of processing of mature tailings at the first field of the tailing dump at JSC Kovdorsky GOK

|

Indicators |

1995 |

1996 |

1997 |

1998 |

1999 |

2000 |

2001 |

2002 |

2003 |

2006 |

2007 |

2008 |

2009 |

2010 |

2011 |

2012 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

|

Processing of tailings, million tons |

0.364 |

3.06 |

3.21 |

3.96 |

3.41 |

3.83 |

3.28 |

2.99 |

1.19 |

1.09 |

5.00 |

5.45 |

5.70 |

4.68 10.88 |

4.56 11.3 |

3.44 11.3 |

|

Content of Р2О5, % ZrO2, % Cl. – 0.071 mm, % Moisture, % in tailings |

10.43 |

10.37 |

10.40 |

10.62 |

11.36 |

10.90 |

11.03 |

11.16 |

11.20 |

12.14 |

10.75 |

10.95 |

9.98 |

|||

|

0.258 |

0.38 |

0.36 |

0.36 |

0.36 |

0.35 |

0.32 |

0.33 |

0.29 |

0.30 |

0.26 |

0.30 |

0.27 |

0.28 |

0.286 |

0.277 |

|

|

13.5 |

14.0 |

19.2 |

17.0 |

21.0 |

25.9 |

29.8 |

||||||||||

|

7.2 |

7.2 |

7.5 |

7.6 |

8.4 |

9.4 |

9.7 |

10.25 |

10.12 |

8.88 |

11.34 |

14.71 |

14.48 |

16.43 |

17.1 |

19.0 |

|

|

Volume of apatite concentrate produced, thousand tons |

29.0 |

489.6 |

491.3 |

644.1 |

579.3 |

598.8 |

524.6 |

467.3 |

179.6 |

168.5 |

552.6 |

577.6 |

598.2 |

516.5 |

461.8 |

236.4 |

|

Р2О5 content in the concentrate, % |

38.3 |

38.2 |

38.0 |

38.1 |

38.1 |

38.2 |

38.2 |

38.2 |

38.1 |

38.0 |

37.88 |

37.74 |

37.79 |

37.72 |

37.26 |

37.27 |

|

Р2О5 extraction in the concentrate, % |

56.3 |

62.7 |

60.1 |

62.5 |

61.6 |

60.0 |

60.7 |

58.9 |

56.6 |

50.7 |

49.0 |

48.5 |

48.5 |

45.2 |

39.9 |

27.68 |

|

Volume of baddeleyite concentrate produced, thousand tons |

0.148 |

2.236 |

2.528 |

3.265 |

2.612 |

2.779 |

2.233 |

2.095 |

0.786 |

0.81 |

1.114 |

0.296 |

1.321 |

1.881 |

2.07 |

1.29 |

|

ZrО2 content in the concentrate, % |

98.3 |

98.1 |

98.0 |

98.3 |

98.2 |

98.4 |

98.5 |

98.6 |

98.53 |

98.58 |

98.56 |

98.41 |

98.58 |

98.54 |

98.55 |

98.46 |

|

ZrО2 extraction in the concentrate, % |

18.0 |

20.2 |

23.4 |

24.4 |

25.3 |

25.5 |

25.4 |

25.6 |

24.8 |

26.3 |

25.76 |

23.71 |

26.39 |

16.82 |

18.9 |

16.42 |

is higher than in the primary ore from the main open pit (in 2007–2008, the content of P2O5 was 7.12–7.19%, ZrO2 – 0.15–0.16%). Qualitative indicators of enrichment of mature tailings, except for the extraction of P2O5, in the initial period were practically at the same level as the processing indicators of the ores from the primary deposit; and the extraction of P2O5 in phosphate rock reduces significantly with the involvement of larger volumes of fine-grained tailings of the bottom levels in the processing.

When a new tailings processing plant was commissioned at JSC Kovdorsky GOK in 2007, there emerged an issue of supplying it with raw materials. Therefore, the decision was made to carry out a geological exploration of the tailings in the second field of the tailing dump for a feasibility study aimed at assessing the effectiveness of their industrial use.

After executing the complex of works described above, the assessment of the resources suitable for recycling was made and appropriate technical and technological solutions were developed; accordingly, it became possible to obtain saleable apatite, baddeleyite and iron ore concentrates from low-grade raw material containing on average 4.6% of P2O5, 4.26% of Feval. and 0.21% of ZrO2, when extracting, respectively, 27, 30 and 19%.

The current Methodological Recommendations of Russia’s National Reserves Committee [10, 11] were considered for the purpose of outlining (within identified resources) and assessing the commercial reserves of technogenic deposits and valuable components in them. In addition, several methodological approaches to the definition of resource estimation parameters for multicomponent raw materials of natural and technogenic origin were considered from the viewpoint of comprehensive utilization for the production of not one, but several valuable components on an economically rational basis.

At the same time, significant shortcomings of existing methodological guidelines for the substantiation of grade parameters of multicomponent natural and technogenic mineral raw materials were revealed; in practice, these shortcomings significantly limit, narrow, and in some cases completely exclude the possibility of integrated use of these raw materials.

In this regard, it is proved that the outlining and assessment of industrial reserves of multicomponent technogenic raw materials should be done on the basis of the marginal (rejection) content of each of the “primary” and “incidental” components that correspond to their cut-off grades, and a minimum industrial grade of a conditional component (in terms of all valuable components in the main target component) [6, 7].

A methodology for analytical determination of the limit (rejection, cut-off) content of each valuable component of mining waste is proposed for the purpose of substantiating the validity of the outlining and assessment of industrial reserves of multicomponent technogenic raw materials.

It is recommended to determine the limit (rejection, cut-off) contents under the condition of reimbursement of only direct production costs emerging in organizing the production of the component; and when determining the minimal industrial content of the conditional component, it is proposed to take into account only the valuable components, the content of which is higher than the corresponding limit (cut-off).

Thus, a scientifically grounded methodology for the quantitative calculation of the main parameters of condition for the outlining and calculation of industrial reserves of technogenic mineral raw materials is proposed for the first time. The methodology makes it possible to provide maximum economic efficiency of the integrated use of mining waste.

Current methodological approaches to the valuation of mining waste as secondary material resources were summarized; the methodology and technique for the substantiation and approval of a rational mutually acceptable level of contract prices for mining waste was developed [12], it ensures economic efficiency of acceptance and transfer for potential recyclers and enterprises that own mining waste.

The technique for determining future prices for products derived from technogenic raw materials [13, 14] was substantiated, as well as the technique for determining direct costs of producing each valuable component from industrial waste at JSC Kovdorsky GOK. The parameters of acceptable grades were estimated, and commercial reserves of mining waste were assessed in the second field of the tailing dump; technical and economic calculations of the efficiency of their industrial development were made.

There are many problems associated with mining waste utilization. Cost estimates and price negotiation concerning semi-finished products and intermediate products (sludge, slag, effluents, dust, sublimations, tailings and other types of current and accumulated waste from different production stages) are among the most acute issues and subjects of fierce disputes between producers and processors. This situation is manifest most clearly in the organization of recycling (disposal) of accumulated (mature) mining waste.

The analysis of waste management experience shows that along with the development of mining waste utilization technology and improvement of recycling process the quality of the resulting product increases: from a surrogate inferior substitute to a high-quality competitive product. Thus, the worthless waste that previously did not have any value becomes a valuable raw material and should be priced accordingly.

From the point of view of economic theory, non-recoverable losses and unused wastes are not subject to valuation because at the time of their formation they do not have value in use, therefore, they cannot have value in exchange.

However, since the beginning of industrial processing, mining waste becomes usable, it is included in the nomenclature of mineral raw materials suitable for complex processing, and it must be evaluated on the basis of general principles of pricing. Therefore, the exchange value (price) of a certain amount of mining waste must correspond to its value in use.

Such a qualitative transition of mining waste from the category of worthless unused waste at the time of its formation to the category of useful products after an effective technology for the utilization of mining waste was developed complicates its productive use. The problem is that the enterprises that own mining waste try to get considerable profit from its sales, and even the cheapest price of the waste that was useless not long ago would be a psychological disincentive for consumers.

Therefore, the basis for economic incentives and interest of potential recyclers and enterprises that own mining waste is a scientifically substantiated and mutually acceptable level of prices of mining waste, which ensures the profitability of the operations of reception and transfer of mining waste for each of the counterparties.

The solution to this problem, on the one hand, is to develop a scientifically based methodology for economic valuation of mining waste utilization that pays more attention to the accounting of all additional effects and costs of the enterprises-owners of mining waste and potential consumers; on the other hand, the solution is to develop a methodology for cost estimate of waste and the formation of mutually beneficial prices on a contractual basis through the coordination of opinions. In particular, the final contract price of mining waste should be determined from an agreed distribution of the general economic effect of a particular disposal project between the participants on the basis of assessing the contribution of each participant in the joint project [12, 13, 14].

It is proposed to set the prospective prices for the products produced from technogenic materials on the basis of the analysis of trends in the global situation. In particular, in relation to JSC Kovdorsky GOK, it is necessary to analyze these trends concerning phosphate raw materials and fertilizers, the prices of which, in turn, depend largely on the situation on the global agricultural market.

Thus, after the substantiation of the prices and direct costs of the production of each of the concentrates, the limit (rejection, cut-off) content of each of the valuable components and minimal industrial content of the conditional component (in terms of P2O5) was defined, and the calculation of industrial reserves and inferred resources (at the site near the sedimentation pond of existing tailing dump is not available for exploration).

On the basis of the calculations it is recommended to process the first and second grades together as the main option for treating the previously estimated and calculated reserves of waste (tailings) of the second field of the tailing dump; this will ensure the profitability of production [9]: a positive NPV, an acceptable profitability index, but a high payback period of investment and a small margin of safety (IRR slightly exceeds the minimum standard of the adopted discount rate).

Therefore, it is recommended to evaluate the following options for improvement of the efficiency of processing of waste (tailings) of the second field of the tailing dump:

-

1. To separate the richer part from the total reserves of mining waste on the basis of condition parameters of cut-off (rejected) content of useful components.

-

2. To determine the effectiveness of the use of dredges for recycling loose waste of the second field of the tailing dump, taking into

account the complexity of hydrogeological conditions for refining mining waste of the first and especially the second field, and also considerable expenses for the dewatering of the existing open pit at the first field. If a dredger is used, it is unnecessary to drain the deposit; a considerable part of the sludge can be discharged on the spot without its transportation to the beneficiation plant.

In general, the mining waste at the second field of the tailing dump is an additional resource base, which is considered in the longterm development strategy of JSC Kovdorsky GOK.

Список литературы Potential of technogenic mineral raw materials in Russia and the issues of its rational use

- Larichkin F.D. Nauchnye osnovy otsenki ekonomicheskoi effektivnosti kompleksnogo ispol’zovaniya mineral’nogo syr’ya . Apatity: KNTs RAN, 2004. 252 p.

- Larichkin F.D., Vorob’ev A.G., Glushchenko Yu.G., Bloshenko T.A., Kovyrzina T.A. Spetsifika ucheta i upravleniya resursami i zatratami v kombinirovannykh gornopromyshlennykh proizvodstvakh . Ed. by F.D. Larichkin, A.G. Vorob’ev. Apatity: KNTs RAN, 2012. 285 p.

- Vernadskii V.I. Biosfera i noosfera . Moscow: Nauka, 1969. 262 p.

- Fersman A.E. Kompleksnoe ispol’zovanie iskopaemogo syr’ya . Leningrad: AN SSSR, 1932. 20 p.

- Mikhailov B.K., Kiperman Yu.A., Komarov M.A., Kotkin V.A., Kamenev E.A., Ashirmatov A.B. Tekhnogennye mineral’no-syr’evye resursy . Ed. by B.K. Mikhailov. Moscow: Nauchnyi mir, 2012. 236 p.

- Larichkin F.D., Ibrokhim Azim, Glushchenko Yu.G., Perein V.N., Khamzin B.S. O metodologii obosnovaniya parametrov konditsii na mestorozhdeniyakh mnogokomponentnykh rud: analiz normativno-metodicheskoi dokumentatsii . Gornyi zhurnal , 2011, no. 7, pp. 36-39.

- Larichkin F.D., Ibrokhim Azim, Glushchenko Yu.G., Perein V.N., Khamzin B.S. O metodologii obosnovaniya parametrov konditsii na mestorozhdeniyakh mnogokomponentnykh rud: uchet spetsifiki kompleksnogo ispol’zovaniya syr’ya pri obosnovanii parametrov konditsii . Gornyi zhurnal , 2011, no. 8, pp. 69-72.

- Melikhova G.S., Zhirov D.V., Perein V.N. New Structural Engineering Survey Method for Design and Operation of Deep Open Pit Mines. World Finance Review, 2012, March, pp. 10-11.

- Melik-Gaikazov I.V., Kovyrzina T.A., Larichkin F.D., Beloborodov V.I., Perein V.N. Ekonomicheskaya effektivnost’ utilizatsii otkhodov obogashcheniya i podgotovki rezervnoi syr’evoi bazy predpriyatiya . Trudy Karel’skogo nauchnogo tsentra RAN , 2012, no. 6, pp. 172-181.

- Metodicheskie rekomendatsii po kompleksnomu izucheniyu mestorozhdenii i podschetu zapasov poputnykh poleznykh iskopaemykh i komponentov: rekomendovany k ispol’zovaniyu protokolom MPR Rossii ot 03.04.2007 g. № 11-17/0044-pr. . Moscow: FGU GKZ, 2007. 16 p.

- Metodicheskie rekomendatsii po tekhniko-ekonomicheskomu obosnovaniyu konditsii dlya podscheta zapasov mestorozhdenii tverdykh poleznykh iskopaemykh (krome uglei i goryuchikh slantsev): utverzhdeny rasporyazheniem MPR Rossii ot 05.06.2007 g. № 37-r. . Moscow: NP NAEN, 2007. 60 p.

- Ganina L.I., Krasheninnikov O.N., Larichkin F.D. Effektivnost’ ispol’zovaniya otkhodov gornopromyshlennogo kompleksa Murmanskoi oblasti v stroitel’noi otrasli . Stroitel’nye materialy , 2006, no. 11 (623).

- Larichkin F.D., Vorob’ev A.G., Glushchenko Yu.G., Ibrokhim Azim, Perein V.N., Ivanov M.A. Teoriya i praktika tsenoobrazovaniya na produktsiyu kompleksnoi pererabotki mineral’nogo syr’ya . Natsional’nye interesy: prioritety i bezopasnost’ , 2010, no. 32 (89), pp. 24-30.

- Larichkin F.D. Teoriya i praktika stoimostnoi otsenki poleznykh komponentov v mineral’nom syr’e i produktakh ego kompleksnoi pererabotki . Moscow: NP NAEN, 2008. 88 p.