Pottery from the Barsov Gorodok III/6 Early Iron Age fortified settlement in the Surgut stretch of the Ob: a technological analysis

Автор: Selin D.V., Mylnikova L.N., Chemyakin Y.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 2 т.49, 2021 года.

Бесплатный доступ

This article outlines the findings of a technological study of the Kulai ceramics from Barsov Gorodok III/6 near Barsova Gora, on the right bank of the Ob River, Tyumen Region, Khanty-Mansi Autonomous Okrug. We describe the site, its stratigraphic sequence and planigraphy, and the layout of the dwellings. The analysis was performed using binocular microscopy of traces in fresh transverse and longitudinal fractures of potsherds. Results were compared with those relating to the experimental sample. The examination of 50 specimens revealed a conservative tradition typical of the potters’ substrate skills. Its characteristics included the use of homogeneous clay mined near reservoirs in one and the same area, and the technology was based on bottom-to-body or body-to-bottom coiling. The body was constructed by side coiling. Adaptive skills were variable. Four mixed recipes for clay paste are described, making up one-fifth of the total number of recipes: clay + broken stone + chamotte; clay + broken stone + liquid organics; clay + + chamotte + sand; clay + broken stone + sand; and two unmixed recipes: clay + broken stone; and clay + chamotte. The mechanical processing of surface is variable, being based on 16 techniques and their combinations. Techniques used at various stages of pottery manufacture are listed. Simple paste recipes indicate groups of potters representing various traditions. Mixed recipes attest to a blend of traditions. Those using them might have been monocultural or multicultural groups of potters using different techniques and skills.

Early Iron Age, Surgut, Ob River, Kulai culture, pottery, technological analysis

Короткий адрес: https://sciup.org/145146269

IDR: 145146269 | DOI: 10.17746/1563-0110.2021.49.2.072-083

Текст научной статьи Pottery from the Barsov Gorodok III/6 Early Iron Age fortified settlement in the Surgut stretch of the Ob: a technological analysis

Barsova Gora is located on the high right bank of the Ob, between the Bartsevka and Kalinka (Kalinina) rivers, near the city of Surgut, Khanty-Mansi Autonomous Okrug, Tyumen Region (Fig. 1). The area of 6 km2 contains a great number of archaeological sites dating from the Neolithic to the Late Middle Ages (Chemyakin, Zykov, 2004: 6). The abundance of finds, ceramics in particular (Chemyakin, 2008), makes it possible to trace the features of pottery-manufacturing within a single landscape in various times. Of particular interest are the ceramic collections from the Kulai culture sites: these contain the greatest amount of

Until recently, the Surgut region of the Ob has been a “blank spot” on the archaeological map of Russia. In the late 19th century, V.F. Kazakov and F. Martin carried out excavations at Barsova Gora (Arne, 1935; Arne, 2005; Zykov, 2008). In 1925, S.A. Kuklin and N.Y. Pavlov headed a topographic survey of the ancient fortified settlements, among which there could have been the settlement of Barsov Gorodok III/6.

Large-scale archaeological works at Barsova Gora began in 1971 in connection with the construction of a railway bridge across the Ob River. In 1973–1974, students of the Physics Department of Ural State University under the supervision of Y.P. Chemyakin carried out a topographic survey of the Barsova Gora site allocated for the railway bridge’s construction, including the settlement of Barsov Gorodok III/6. In 1974, M.V. Elkina excavated this site. The excavation area of 525 m2 contained the inner area of the fortified settlement; some parts of the defensive system were also explored. The rampart was subjected to excavations “in some areas, because it did not contain finds and was covered with trees” (Elkina, 1975: 3).

To date, a series of works describing the ancient pottery of the Late Bronze to Early Iron Ages at Barsova Gora has been published (Barsova Gora…, 2008; Dubovtseva, Yudina, 2010, 2011; Zykov, 2008, 2012; Serikov, Chemyakin, 1998; Chemyakin, Zykov, 2004; Chemyakin, 2008; Chemyakin, Koksharov, 1984, 1991; Posrednikov, 1969; and others).

The purpose of this study is to present a reconstruction of the clay pastes, vessel design, and surface processing techniques. The analysis of the stages of pottery manufacture was carried out via binocular microscopy (Leica M80), with a subsequent comparison of technological traces noted on the artifacts under study and on the experimental sample.

The number of artifacts recovered at Barsova Gora provides solid grounds for reconstruction of almost all stages of pottery manufacture (see (Bobrinsky, 1978, 1994, 1999; Tsetlin, 2012)) and for tracing its development over time. The fortified settlement of Barsov Gorodok III/6 is one of the earliest Kulai sites in the Surgut stretch of the Ob; therefore, its ceramics collection was chosen for the technical and technological analysis: the results of its study will make it possible to consider the pottery from this site as a reference sample, and then to compare other ceramic assemblages from this region and adjacent territories with it (for example, from the Novosibirsk region of the Ob (Troitskaya, 1979)).

Fig. 1. Location of the fortified settlement of Barsov Gorodok III/6.

0 800 m

Barsov GorodokJII/6

■urgut

Ba rsovo

Description of Barsov Gorodok III/6

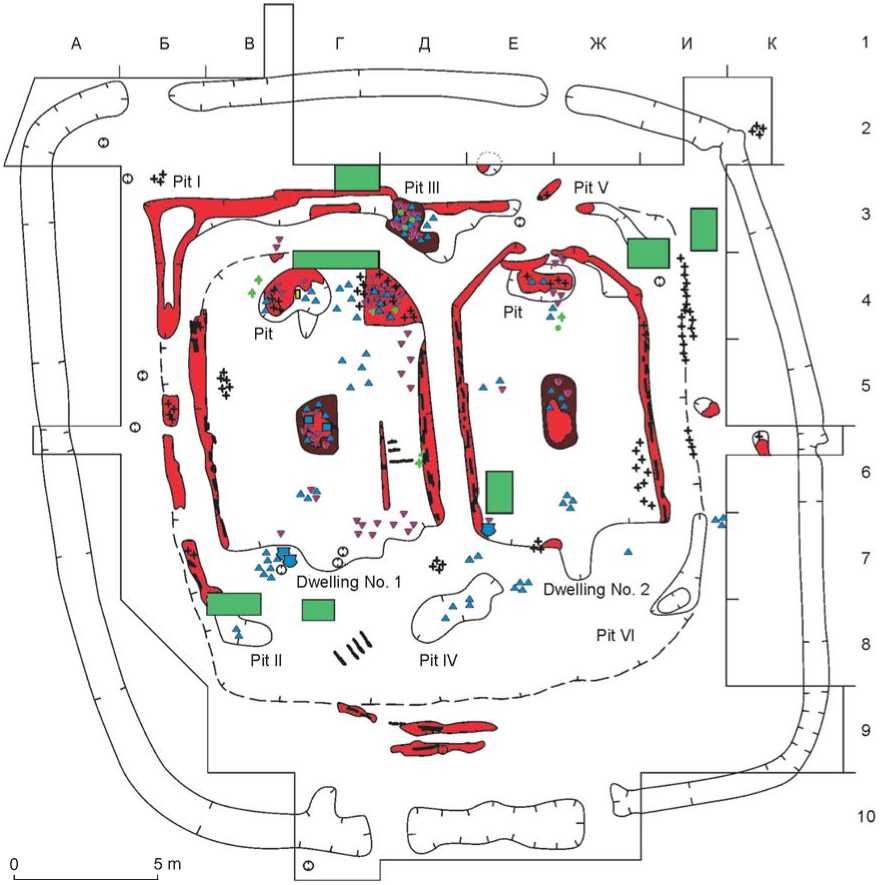

The site is located on a flat forested area, 460 m from the edge of the bank of the Utoplaya channel, 33.5 m above the level of the Ob. The area with dimensions of 27 × 27 m, of parallelogram shape, was oriented almost to the cardinal points (with a deviation of 10° to the west) (Fig. 2). The settlement was surrounded by a ditch 1 m wide and 0.3–0.5 m deep, as well as with a rampart up to 3 m wide and 0.4–0.6 m high. On the southern side, the rampart was slightly smoothed. A narrow (0.5 m) and shallow (5–10 cm) groove ran along the inner side of the rampart. In the corners of the settlement, the groove formed subtriangular pits 0.2–0.4 m deep. The exit from the fortified settlement was located in its southern part. In the interior zone, there were two embanked depressions, 12 × 8 to 9 m, surrounded by grooves. The research was carried out at an area of 525 m2; both dwellings were excavated to the virgin layer, and the defensive system was excavated partly.

The stratigraphic sequence is the following:

-

1. Modern soil layer contains forest mulch and podzol; thickness 0.05–0.15 m.

-

2. Cultural layer is yellow and grayish-yellow sandy loam of varying shades; at the bottoms of dwellings it varies in color from gray to brown; this sandy loam fills the dwelling’s foundation trenches and some pits; average thickness 0.2–0.6 m.

-

3. Redeposited yellow sand is the remains of dwellings and rampart strew; thickness 0.05–0.3 m; sterile.

-

4. Buried soil is leached light gray sand (podzol); thickness 0.05–0.2 m; separated by yellow sand strew.

-

5. Virgin soil is yellow sand.

-

6. Spots of burnt soil contain red sand.

-

7. The hearth layer is a loose humic brown sandy loam, with inclusions of charcoal pieces and burnt bones; thickness 0.05–0.35 m.

а и b c

— —■d

+++ e

оf

.* g

^ ▼h

□k

□ l

m

Fig. 2. General plan of the fortified settlement of Barsov Gorodok III/6.

a – unexcavated area; b – hearth; c – spot of burnt soil; d – burnt wooden boards; e – charcoal pieces; f – hole; g – scarp and a bronze item; h – crucible; i – ceramics; j – disintegrated vessels; k – pebble; l – horse-tooth; m – strew residual; earth mounds.

The ditch surrounding the settlement was filled with light gray podzol. Elkina reported that it was 0.7– 0.9 m wide on average, 0.5–0.75 m deep from the ancient surface; the walls were gently sloping, the bottom was rounded*. The rampart consisted of yellow sand with thin layers of buried podzol. The rampart was 3.0–3.5 m wide and 0.2–0.3 m high above the level of the buried soil.

Two parallel stripes of red calcined sand, with remains of charcoal from burnt structures, were recorded in the southern part of the rampart surrounding the settlement (sq. Г–Е/9) (Fig. 2). The stripes are about 3 m long and 0.3–0.4 m wide. Several pits, possibly from pillars, were revealed below the rampart.

A shallow discontinuous groove, 0.5–0.7 m wide and 0.1–0.4 m deep, with a fired bottom, filled with podzolic soil, was noted along the inner border of the northern and western sides of the rampart. The greatest depth was recorded in the northern part of the groove. In the interior zone, the remains of two sub-rectangular dwellings, slightly dug into the ground and with long walls almost adjoining each other (the distance between being about 0.5 m) and oriented along the N-S line, were uncovered.

The foundation pit of dwelling No. 1 is 10.0 × 8.0 m, the depth is 0.25–0.3 m below the ancient surface level. The exit, in the form of a short corridor, measuring 3 × 1 m, deepened to the floor level, faced south. In the middle of the exit, two pits, possibly remaining from the pillars, were noted. One meter to the west of the exit, there was another pit, near which two vessels were standing upside down. The walls of the dwelling pit are slightly sloping, the bottom is even. Near the walls, a layer of dark gray sandy loam 0.05–0.08 m thick covered the bottom. In the center, around the hearth, this layer was absent. Traces of the burnt wooden walls in the form of stripes of bright-red calcined sand with charcoal pieces were recorded along the western and eastern walls of the foundation pit. These were 0.5–0.7 m wide and 0.1–0.3 m thick.

The corners of the foundation pit in its southern part are almost straight. The northern boundary of the pit had been partially destroyed by the growing trees; the corners in this part were probably rounded or beveled. In the northeastern corner, a triangular ledge protruding with its right angle inside the dwelling was uncovered. A layer of intensely burnt, buried podzolic soil, with inclusions of charcoal pieces and fragments of crucibles (sq. Г–Д/4) (Fig. 2), covered the ledge. The foundation pit was filled with grayish-yellow sand, which was not very different from the virgin land. In the middle of the foundation pit, there was a subrectangular hearth, elongated along the long axis of the dwelling (sq. Г/5–6), lenticular in crosssection. Its size is 2.0 × 1.25 × 0.1 m. The hearth is filled with brown humic sandy loam, with inclusions of calcined bones and pieces of charcoal. It contained fragments of crucibles, small charred pottery fragments, and cracked and smoked pebbles. The sandy loam layer overlay a layer of burnt soil 0.05–0.1 m thick.

At the northern wall of the foundation (sq. В–Г/4), a pit 2.2 × 1.6 × 0.5 m was uncovered. Its walls are slightly sloping, the bottom is even. An interlayer of charcoal 0.03–0.05 m thick was found at the pit bottom. The filling of the pit is heterogeneous: a light gray calcinated podzol in the upper part, and grayish brown sandy loam, with inclusions of charcoal, in the middle and lower part. The filling contained horse teeth, fragments of crucibles and potsherds. Near the pit (sq. В/4), a bronze plate bearing contour images of two animals in high relief and a bronze arrowhead of the Kulai type were found (Chemyakin, 2008: Fig. 79, 12 , 37 ).

At the eastern foundation wall, on the floor, sooty black stripes and areas of calcined sand from burnt structures were recorded. These ran parallel and perpendicular to the dwelling wall. Two bronze plates were found in sq. Д/6.

The foundation pit of dwelling No. 2 is almost identical to that of dwelling No. 1. It is 10.0 × 6.5 ×

× 0.2–0.3 m in size, the walls are slightly sloping, and the bottom is even. A corridor-shaped exit (1.0 × 1.2 m) was placed in the southern wall and had been deepened to the level of the pit. At a distance of 1 m to the west from the exit, a hole for a pillar was found. A patch of calcined sand 0.06 m thick was noted near the exit. On the floor, near the pit walls, an interlayer of gray sandy loam 0.03–0.05 m thick was revealed, which was colored less intensely than in dwelling No. 1. Along the western and eastern foundation walls, remnants of burnt walls in the form of stripes of calcined sand with charcoal pieces were noted; the stripes were 0.5–0.7 m wide and 0.1– 0.3 m thick. In the southwestern corner of the dwelling, a crushed vessel was found overlain by a layer of calcined sand with charcoal pieces.

The southern corners of the pit are almost straight. The top of a semicircular (or with beveled corners) northern wall was identified through a calcined stripe 0.3 m wide and 0.1–0.2 m thick on the surface of the buried soil, and the lowermost part of the wall was determined through a layer of gray sandy loam at the bottom of the pit. In the center of the dwelling, there was a sub-rectangular hearth dug into the ground to 0.1 m (sq. Е–Ж/5–6), measuring 2.5 × 1.1 × 0.15 m and stretching along the long axis of the dwelling. The hearth layer was lenticular in cross-section; it consisted of brown, humic loose sandy loam, with inclusions of burnt bones and charcoal pieces. Below, a layer of burnt soil 0.06–0.08 m thick was uncovered. The filling of the hearth contained fragments of crucibles, small charred potsherds, and split pebbles.

Near the northern foundation wall, a pit was found (sq. Е–Ж/4), similar to the pit in dwelling No. 1. It was sub-oval in shape, measuring 2.3 × 1.3 × 0.35 m. The pit was semicircular in cross-section and filled with grayish-yellow sandy loam and burnt sand; a black carbonaceous interlayer 0.05–0.07 m thick was traced at the bottom. Fragments of crucibles and potsherds were found in the filling of the pit. In sq. Ж/4, close to the pit, bronze ornitho- and zoomorphic figurines in the style of flat single-sided castings were found (Chemyakin, 2008: Fig. 79, 2 , 24 ), and a fragment of a flat bronze ring. In the southern part of the dwelling, next to the eastern wall, on the floor, small inclusions of charcoal were located—the remains of burnt wooden structures.

The exterior surfaces of the walls of both dwellings were strewn with sand, which led to the formation of grooves and external pits on the outside. Elkina noted that “the base of the rampart was reinforced with wood from the inside; this is suggested by a surviving groove with burnt soil and pieces of charcoal” (1975: 18)*. In front of the dwellings on the southern side, i.e. opposite the exits, there was a free area 4.5–5.0 m wide. The pits at the northern walls of the dwellings could be used both in the process of bronze casting and during ritual activities. This assumption is confirmed by the presence of spots of burnt soil, pieces of charcoal, and fragments of crucibles in the filling of the pits, as well as cast cult objects, an arrowhead, and pieces of bronze next to them. The area where the metal-working production was located seems to have included also the ledge in the northeastern corner of dwelling No. 1. About 150 fragments of crucibles and a thick layer of burnt soil with charcoal inclusions were noted in that area. Over 70 fragments of crucibles were found in or near the central hearth in dwelling No. 1.

Another bronze casting area may have been associated with the outer pit III located between the dwellings in the northern part (sq. Д/3). In this pit, a thick (up to 0.45 m) lens of the hearth layer overlying a layer of burnt soil was revealed. The filling yielded more than 200 potsherds, 200 fragments, and two intact crucibles with droplets of bronze, splashes of bronze, fragments of clay figurine, fish bones, and split charred pebbles. In dwelling No. 2, there were much fewer traces of metalworking; these were noted in and around the pit near the northern wall, as well as in the central hearth.

In the outer pits II at the corner of dwelling No. 1 (sq. В/8) and IV between the buildings (sq. Д–Е/7–8), a large number of pottery fragments and fish bones were

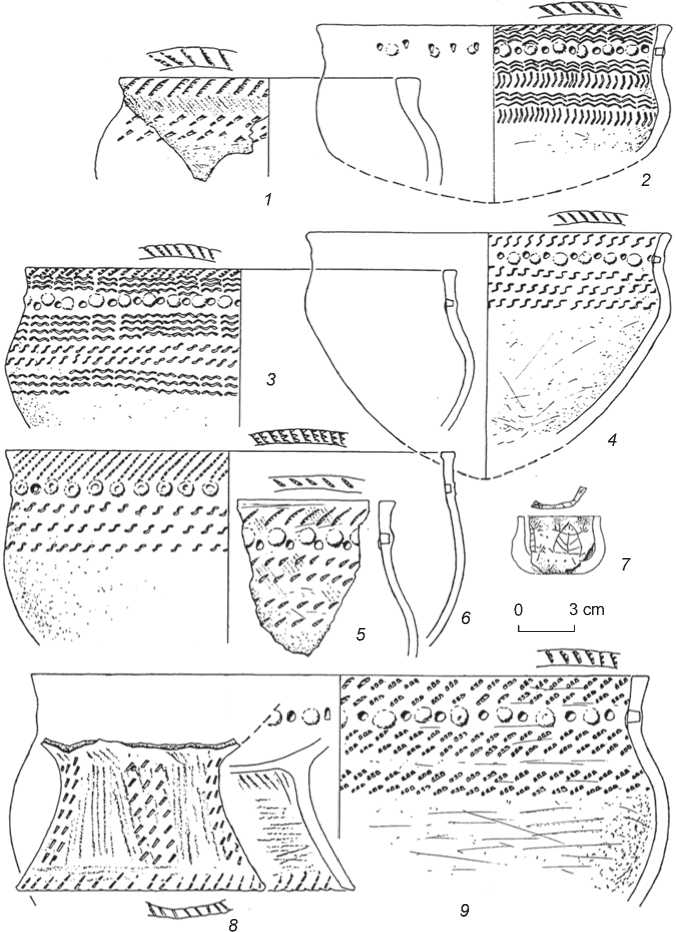

Fig. 3. Pottery of the Kulai culture.

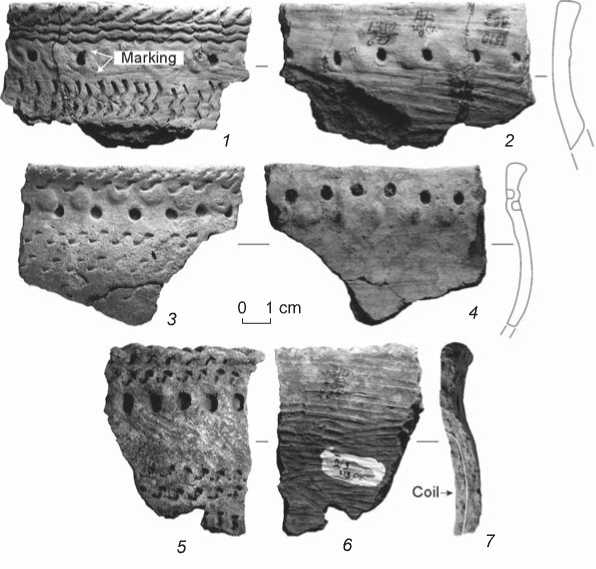

Fig. 4. Ceramic fragments showing signs of surface processing and construction of a hollow body.

1 – traces of smoothing with fingers, polishing, and horizontal marking on the exterior surface; 2 – interior surface smoothing with a comb tool; 3 , 4 – smoothing with soft material; 5 , 6 – smoothing with a comb tool; 7 – side coiling technique.

found. Elkina reported two gates to the settlement in the southern wall, where the rampart was almost untraceable (1975: 18). The gates were 1.0 and 1.2 m wide.

The finds recovered from the settlement include pottery (Fig. 3–5), fragments, and intact crucibles (Chemyakin, 2008: Fig. 78, 1–4 ), fragments of clay figurines, and stone and bronze items, including cast cult objects.

A preliminary generalized description of the ceramics of the Surgut version of the Kulai culture has been previously published by one of the co-authors in a summarizing monograph (Ibid.: 84–86).

Study results

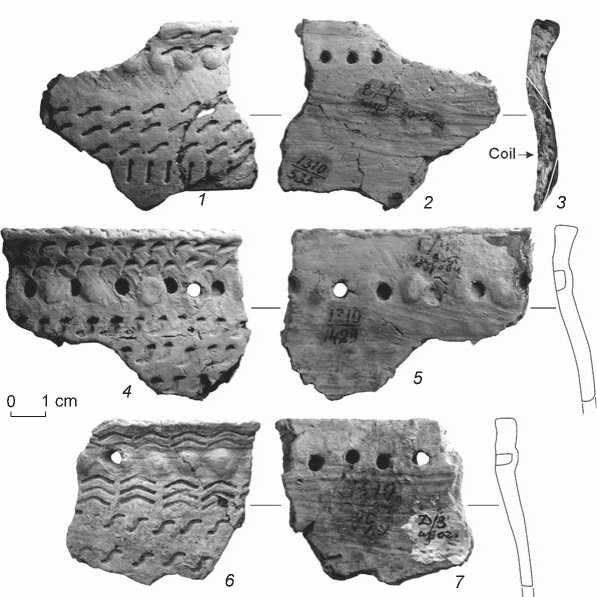

A total of 1853 fragments of various vessels was uncovered at the site. Samples for technical and technological analysis were collected from 50 vessels retaining traces of technological features. Surfaces and fractures of the artifacts were analyzed through binocular microscopy of the products’ (Fig. 6, 7).

The clay pastes of pottery from Barsov Gorodok III/6 consist of ferruginous clays with low (70 %) and medium (30 %) sand content. Natural impurities in the raw material are brown iron ore – 54 % of the total number of the samples (see Fig. 6, 3 ), solitary small plates of mica – 10 %, rare inclusions of vegetative organic matter – 4 %, small rounded limestone pieces – 2 %, large rounded sand grains – 2 %, and solitary fish bones – 2 %. In 38 % of the samples, the clay paste has not revealed any natural impurities. Fractions of brown iron ore are rounded (96 %) and angular (4 %). These are subdivided into small (38.5 %), small and medium (19.2 %), various-sized (34.6 %), and large (7.7 %). The degree of sand content

Fig. 5 . Ceramic fragments showing signs of surface processing and construction of a hollow body.

1 – exterior surface smoothing with a comb tool and burnishing; 2 – interior surface smoothing with a comb tool; 3 – side coiling; 4 , 5 – smoothing with a comb tool;

6 – smoothing with fingers; 7 – interior surface smoothing with a comb tool.

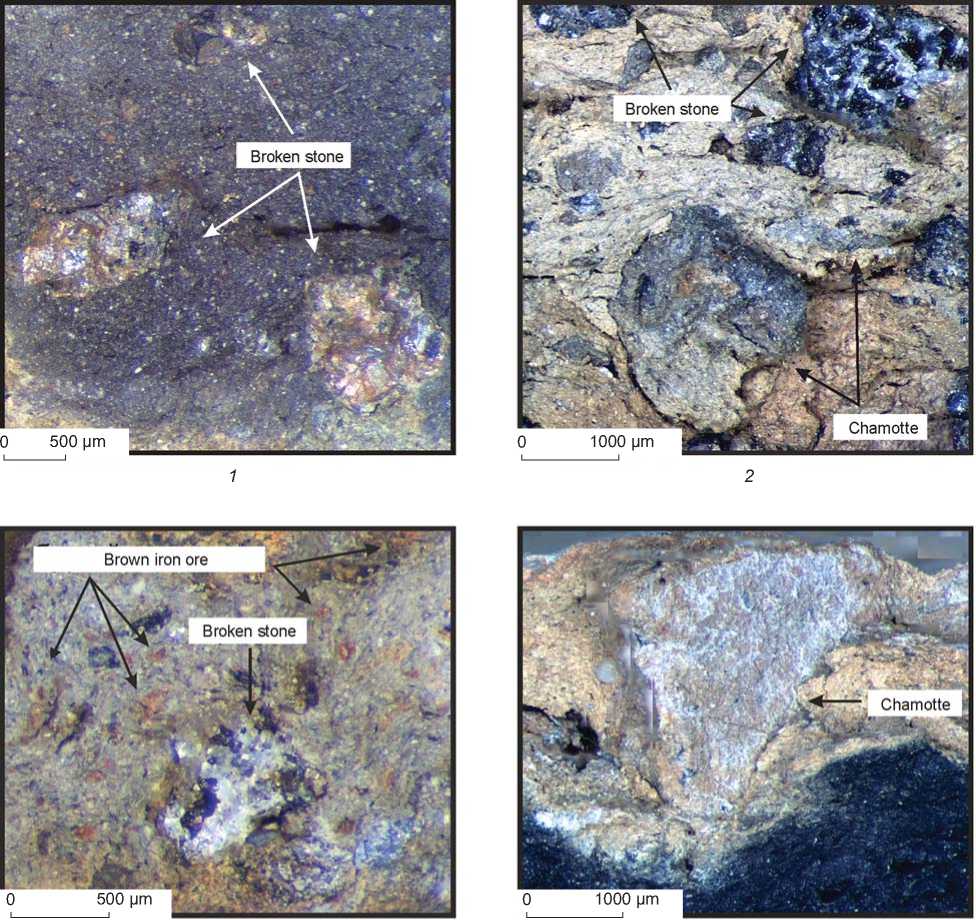

Fig. 6 . Microphotographs of the areas of clay paste.

Artificial additives: 1 – broken granitoid stone; 2 – chamotte and broken stone; 3 – broken quartzite stone and brown iron ore grains as a natural additive in clay; 4 – chamotte.

and the nature of natural impurities indicate the use of raw ductile materials from various sources. The absence of any specific impurities and the sufficient homogeneity of the clay suggest that these clay deposits were situated within one and the same region; judging by the inclusions of vegetative organic matter, solitary large sand grains, and fish bones, the clay sources were located near water bodies.

Different preferences in the choice of raw materials are indicated by inclusions of variously shaped fractions of brown iron ore in the clay paste, or their complete absence. Since the Neolithic, the bearers of the Barsova

Gora archaeological cultures preferred ferruginous clays with low sand content and a natural admixture of brown iron ore (Dubovtseva et al., 2016: 63). Various sizes of the brown iron ore fractions may be associated with the tradition of preparation and purification of clay before mixing the paste, which led to crushing of large inclusions into smaller ones. This assumption is supported by the potsherds whose paste yielded no natural impurities; this category makes up 38 % of the analyzed samples.

The clay paste included organic and mineral components (see Fig. 6, 7). Organic components (traces of liquid organic matter, noted in 4 % of the samples) are

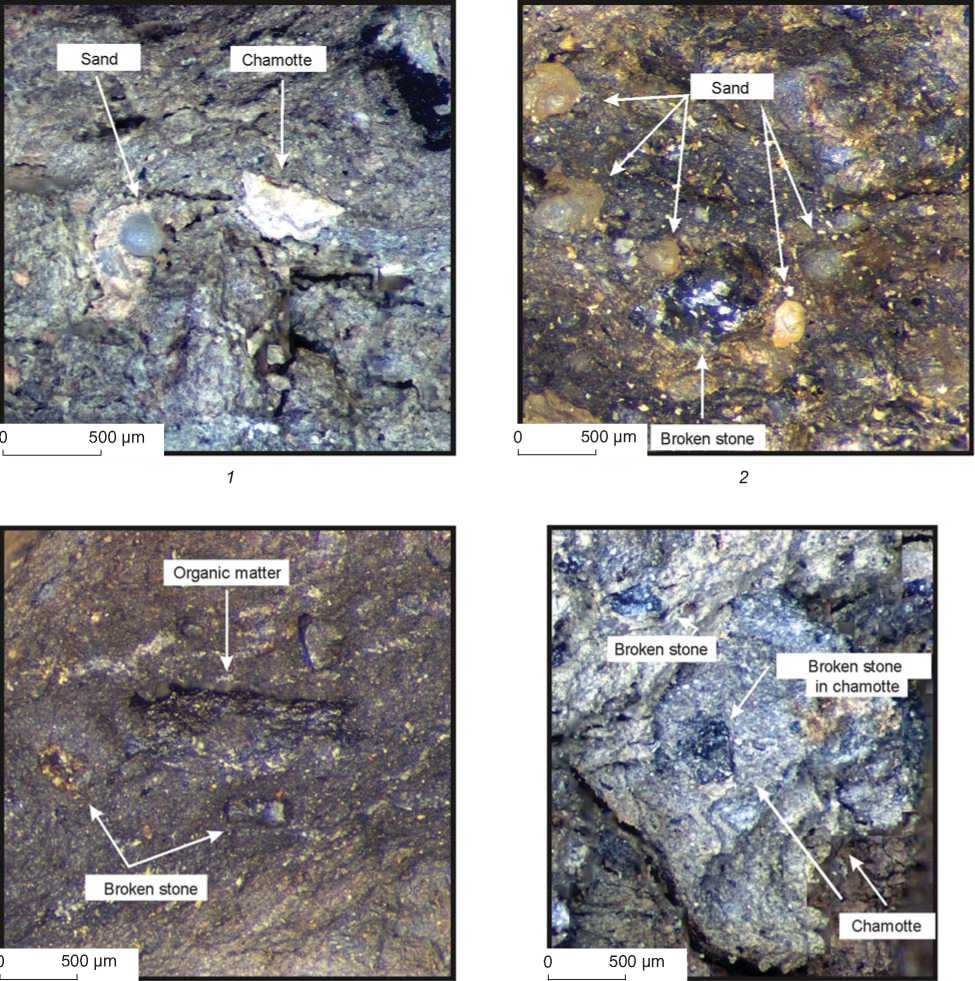

Fig. 7 . Microphotographs of the areas of clay paste.

Artificial additives: 1 – sand and chamotte; 2 – sand and broken stone; 3 – organic matter and broken stone; 4 – broken stone, chamotte, and broken stone in chamotte.

represented on the fracture surfaces in the form of cavities filled with a black glossy coating (see Fig. 7, 3 ).

Mineral additives (broken stone, chamotte, and sand) were noted in the clay paste of all the samples under consideration (see Fig. 6; 7, 1, 2, 4). Broken stone as an additive in the raw material was noted in 62 % of the samples (see Fig. 6, 1, 3), in combination with chamotte in 14 % (Fig. 6, 2), and in combination with sand in 2 % (see Fig. 7, 2). Fired igneous rocks were used for crushing: granitoids – 76 % (see Fig. 6, 1) and quartzite – 4 % (see Fig. 6, 3). In 78.5 % of the detected cases, the fragments were not calibrated before being introduced into the clay paste; in 16.6 % they were calibrated up to the upper limit (≤1.9 mm), in 4.9 % to the lower limit (≥1 mm). The following concentration rates were recorded: 1 : 2 (2.4 %), 1 : 3–4 (4.9 %), 1 : 4 (36.6 %), 1 : 4–5 (9.8 %), 1 : 5 (14.6 %), 1 : 6 (4.9 %), 1 : 6–7 (9.8 %), 1 : 7 (4.9 %), 1 : 7–8 (4,9 %), 1 : 8–9

(4.9 %), 1 : 10 (2.4 %). Thus, there are two main groups of rock debris proportions: 1 : 3–5 (65.9 %) and 1 : 6–8 (29.4 %). This may indicate that the potters (bearers of the Kulai culture) adhered to two traditions of mixing raw material and broken stone. The use of igneous rocks in manufacturing various tools at Barsova Gora was widespread both in the Early Iron Age and in earlier periods (Serikov, Chemyakin, 1998). However, no granite outcrops were found either at Barsova Gora or in its environs; granite intrusions were recorded only in deep drilling wells (in the ranges of 2992–3021 and 2920–2958 m deep) (Novikova et al., 2017: 38). Possibly, the raw materials were delivered from areas rich in rock outcrops, or from as yet unknown sources of igneous rocks in the area under study or the surrounding areas. It is known that broken stone was also added to the clay paste in the manufacture of Kulai ceramics in the Tomsk region of the Ob (Stepanova, Rybakov, 2016: 423; Rybakov, Stepanova, 2013: 89; 2017: 52). The stability of this tradition is evidenced by the presence of this admixture in chamotte (see Fig. 7, 4 ).

The second most common artificial mineral additive is chamotte: it was identified in 30 % of the samples (see Fig. 6, 2 , 4 ; 7, 1 , 4 ). In 16 % of the samples, it is included as the only additive (see Fig. 6, 4 ), in 14 % in combination with broken stone (see Fig. 6, 2 ), and in 2 % in combination with sand (see Fig. 7, 1 ). In terms of grain calibration, it can be subdivided into uncalibrated (60.1 %), calibrated up to the upper limit (≤1.9 mm, 33.3 %), and up the lower limit (≥2 mm, 6.7 %). The following chamotte concentration rates were recorded: 1 : 2 (6.7 %), 1 : 2–3 (6.7 %), 1 : 4 (6.7 %), 1 : 4–5 (6.7 %), 1 : 5 (6.7 %), 1 : 5–6 (13.3 %), 1 : 6 (13.3 %), 1 : 6–7 (13.3 %), 1 : 7 (6.7 %), 1 : 7–8 (6.7 %), 1 : 9 (6.7 %), 1 : 9–10 (6.7 %). The ratio of 1 : 5–7 can be regarded as a typical concentration; it accounts for more than half (53.3 %) of the cases detected. The variety of concentration ratios indicates the instability of the tradition of introducing chamotte into the clay paste. This conclusion is confirmed by the fact that in 14 % of the samples, chamotte is presented as a temper in combination with another mineral additive—broken stone. In the clay paste of the Kulai culture in the Tomsk region of the Ob and Altai, chamotte is rarely found; some researchers consider its use a non-local tradition (Stepanova, Rybakov, 2016: 423; Rybakov, Stepanova, 2017: 51; Stepanova, Bobrova, 2018; Kazakov, Stepanova, 2019; Pletneva, Ragimkhanova, Stepanova, 2019). We can hardly agree with this opinion, since the available information is incomplete: in some publications, the number of analyzed ceramics for each site is not indicated, or the data only on four to eight samples are provided (see, e.g., (Stepanova, Rybakov, 2019; Kazakov, Stepanova, 2020)), which does not make the samples representative.

Rounded sand as an artificial additive was noted in 4 % of the samples, along with rock debris (see Fig. 7, 2 ) or chamotte (see Fig. 7, 1 ). In one case, the sand was calibrated to the lower boundary (≥1 mm), in the second to the upper boundary (≤1 mm); the concentration was 1 : 4–5.

Thus, the following clay paste recipes have been identified: 1) clay + broken stone (62 %); 2) clay + + chamotte (16 %); 3) clay + broken stone + chamotte (14 %); 4) clay + broken stone + liquid organic matter (4 %); 5) clay + chamotte + sand (2 %); 6) clay + broken stone + sand (2 %).

The technology of pottery manufacture was based on bottom-to-body (possibly, body-to-bottom) coiling. The hollow bodies of vessels were also constructed by side coiling. The coils were 0.4–1.0 cm thick on average; the overlapping height could reach 3 cm. One sample shows the technique of rim formation through a separate coil up to 1.5 cm high. According to preliminary data, a similar technique was used in the manufacture of the Kulai ware uncovered at Barsov Gorodok I/4. The exterior surfaces of four fragments of the lower body part shows traces of stamping with a plain (3 spec.) or relief (1 spec.) beater.

Techniques of mechanical processing of surface are varied and occur in various combinations (see Fig. 4, 5). A zonation of surface processing was recorded on 30 % of the products: functionally different parts of the vessel were finished with different techniques and tools. Traces of horizontal marking for ornamentation (see Fig. 4, 1) were noted on the exterior surfaces of 6 % of the samples. The exterior and interior surfaces of the vessels had been processed differently. For example, the exterior side of 64 % of the vessels was smoothed in a wet state with a comb tool, which was probably used to make an ornament (see Fig. 4, 5, 6; 5, 1, 4). On five vessels, the smoothing lines form regular parallel rows without ornamentation, which suggests that these were a kind of technical decoration (see Fig. 5, 1, 4). The wet exterior surface of 22 % of the samples was smoothed with a soft material— cloth, leather (?) (see Fig. 4, 3). The surface of 12 % of the samples bear traces of smoothing with fingers (see Fig. 5, 7), 8 % traces of burnishing with a hard item (pebble?) over the dried surface after ornamenting (see Fig. 4, 1). On one vessel, the surface in the bottom part had been smoothed with a bunch of grass. In 80 % of cases, the interior surface of the items was smoothed in a wet state using a comb tool (see Fig. 4, 2, 6; 5, 5, 8). 14 % of the samples show signs of processing with a soft material (see Fig. 4, 4), 6 % of smoothing with fingers. In 28 % of cases, the rim was smoothed separately with fingers (26 %) or with a soft material (2 %) (see Fig. 5, 7). Perhaps this skill was developed as a result of the use of a swivel stand, when the upper part of the vessel was additionally smoothed in the course of rotation. The portion between the shoulder and the bottom part of the body was specially smoothed with a comb tool on the wet interior side; signs of the use of this technique are recorded on 20 % of the products (see Fig. 5, 2, 5, 8).

Various techniques of surface processing have been identified; one vessel can show the use of several techniques. In total, 16 processing techniques and their combinations have been noted:

Both surfaces are smoothed with a comb tool (30 %).

Both surfaces are smoothed with a comb tool + the rim with fingers (16 %).

The interior surface is smoothed with a comb tool, the exterior with a soft material (10 %).

Both surfaces were smoothed with a comb tool + the rim with fingers + the transition part from shoulder to body additionally smoothed with a comb tool (8 %).

Both surfaces are smoothed with a comb tool + the exterior side with a soft material (6 %).

Both surfaces are smoothed with a soft material + + the transition part from shoulder to neck additionally smoothed with a comb tool (6 %).

The interior surface is smoothed with a comb tool, the exterior with fingers (4 %).

Both surfaces are smoothed with a soft material (4 %).

The interior surface is smoothed with a comb tool, the exterior side is polished (2 %).

Both surfaces are smoothed with a comb tool + + the transition part from shoulder to neck additionally smoothed with a comb tool (2 %).

The exterior surface is smoothed with a comb tool, the interior surface with a soft material + the rim smoothed with fingers (2 %).

Both surfaces are smoothed with fingers + the transition part from shoulder to neck additionally smoothed with a comb tool (2 %).

Both surfaces are smoothed with fingers (2 %).

The interior surface is smoothed with a comb tool, the exterior with fingers (2 %).

Both surfaces are smoothed with a comb tool + the bottom part with grass (2 %).

The rim is smoothed with a soft material (2 %).

Thus, the surface processing of the vessels was carried out using various techniques and tools. The most common technique was smoothing with a comb tool (exterior surface 64 %, interior 80 %) or soft material (22 and 14 %, respectively). In some cases, smoothing with fingers, grass, or polishing with a hard item was performed. Notably, surface processing techniques are adaptive; when bearers of different traditions are mixed, these change very quickly, often during the life of one generation (Bobrinsky, 1978: 222; Tsetlin, 2017: 152). The total of 16 varieties of surface processing techniques suggests the instability of this technological skill among potters.

The vessels were fired at temperatures exceeding the incandescence temperature (from 550–650 to 900–

1100 °C), which is confirmed by the absence of the residual ductility characteristic of low-temperature firing, and traces of clay sintering to a glassy state. According to the color of the fracture, the products are subdivided into one-colored (brown 18 %, dark gray 16, gray 6 %), two-colored with light edges and a sharp transition to a dark center (50 %), and three-colored (10 %). The presence of dark gray and gray one-colored fractures is an indicator of firing in a neutral atmosphere. Two-colored fractures with a sharp border between colors and three-colored fractures indicate firing in a semi-reducing gas atmosphere, followed by rapid cooling of the fired products. In general, firing could have been carried out in fireplaces or hearths, as well as in special smelting furnaces (Volkova, Tsetlin, 2016).

Conclusions

The technical and technological analysis of the ceramics of the Kulai culture (Surgut version) from Barsov Gorodok III/6 suggests several main conclusions on the pottery technology:

The sources of the raw ductile materials were clay deposits located within the same area.

The main artificial additives in the clay paste were broken stone and chamotte.

The dominant recipes for clay pastes were: clay + + broken stone (64 %), clay + chamotte (16 %), and one mixed recipe: clay + broken stone + chamotte (12 %).

The bottoms and bodies of vessels were constructed by side coiling.

Up to 16 different techniques of surface processing and combinations thereof were recorded.

Firing of products could be carried out in fireplaces or hearths in a reducing or semi-reducing environment, with subsequent rapid cooling, as well as in special smelting furnaces.

The potters’ substrate skills, which are most stable under the conditions of mixing pottery traditions, demonstrate a conservative trend. The analyzed collection is characterized by the use of similar ductile raw materials and techniques of constructing the bottom and hollow body. Adaptive skills, which are subject to rapid change during the interaction of bearers of various pottery traditions, are more variable. Apart from two dominant unmixed recipes of clay pastes, four mixed recipes were identified, which constitute 1/5 of the total number of the samples under study. The methods of mechanical processing of surface also demonstrate instability: 16 combinations of various techniques have been identified. This is typical of the initial stages of mixing of pottery traditions, which led to the emergence of compromise techniques, often within the life of one generation (Tsetlin, 2012: 242).

Thus, the pottery technology of the Kulai population of Barsov Gorodok III/6 demonstrates a variety of methods of pottery manufacture at various stages of production. The revealed one-component recipes of clay paste suggest the activities of several groups of artisans, who adhered to different pottery traditions. Vessels with mixed recipes have also been identified, which makes it possible to draw a conclusion about the mixing of pottery traditions or of bearers of different traditions at this settlement. This population might have included the people of the same culture with various pottery traditions or the people of different cultures with different pottery traditions. However, this assumption requires a thorough review; it is necessary to carry out a comparative analysis of the examined materials with other collections of the Late Bronze to Early Iron Ages from Barsova Gora.

Acknowledgements

This study was supported by the Russian Science Foundation (Project No. 20-18-00111). The work was carried out with the equal participation of the authors.

Список литературы Pottery from the Barsov Gorodok III/6 Early Iron Age fortified settlement in the Surgut stretch of the Ob: a technological analysis

- Arne T.J. 1935 Barsoff Gorodok. Ein westsibirisches Gräberfeld aus der Jüngeren Eisenzeit. Stockholm.

- Arne T.J. 2005 Barsov Gorodok. Zapadnosibirskiy mogilnik zheleznogo veka. Yekaterinburg, Surgut: Ural. rabochiy.

- Barsova gora: Drevnosti tayezhnogo Priobya. 110 let arkheologicheskikh issledovaniy. 2008 Surgut: Barsova gora.

- Bobrinsky A.A. 1978 Goncharstvo Vostochnoy Yevropy. Istochniki i metody izucheniya. Moscow: Nauka.

- Bobrinsky A.A. 1994 Otrazheniye evolyutsionnykh i migratsionnykh protsessov v osobennostyakh drevney goncharnoy tekhnologii. In Paleodemografiya i migratsionniye protsessy v Zapadnoy Sibiri v drevnosti i srednevekovye. Barnaul: Izd. Alt. Gos. Univ., pp. 14-16.

- Bobrinsky A.A. 1999Goncharnaya tekhnologiya kak obyekt istoriko-kulturnogo izucheniya. In Aktualniye problemy izucheniya drevnego goncharstva. Samara: Izd. Samar. Gos. Ped. Univ., pp. 5-109.

- Chemyakin Y.P. 2008 Barsova Gora: Ocherki arkheologii Surgutskogo Priobya. Drevnost. Surgut, Omsk: Om. dom pechati.

- Chemyakin Y.P., Koksharov S.F. 1984 Poseleniye nachala I tysyacheletiya do n.e. na Barsovoy gore. In Drevniye poseleniya Urala i Zapadnoy Sibiri. Sverdlovsk: Ural. Gos. Univ., pp. 115-130.

- Chemyakin Y.P., Koksharov S.F. 1991 Novoye poseleniye barsovskoy kultury (predvaritelnaya publikatsiya). In Zhilishcha narodov Zapadnoy Sibiri. Tomsk: Izd. Tom. Gos. Univ., pp. 106-114.

- Chemyakin Y.P., Zykov A.P. 2004 Barsova Gora: Arkheologicheskaya karta. Surgut, Omsk: Om. dom pechati.

- Dubovtseva E.N., Tonkushina M.O., Yudina E.A., Kosinskaya L.L., Ostroushko A.A., Kulesh N.A. 2016 Noviye danniye po pervomu pogrebeniyu Barsovskogo II mogilnika (opyt kompleksnogo analiza). In Sedmiye Bersovskiye chteniya. Yekaterinburg: KVADRAT, pp. 61-69.

- Dubovtseva E.N., Yudina E.A. 2010 Raskopki obyektov kulyoganskogo tipa selishcha Barsova Gora II/19. In Khanty-Mansiyskiy avtonomniy okrug v zerkale proshlogo, iss. 8. Tomsk, Khanty-Mansiysk: Izd. Tomsk. Gos. Univ., pp. 221-240.

- Dubovtseva E.N., Yudina E.A. 2011 Neoliticheskiye kompleksy selishcha Barsova Gora II/19. In Khanty-Mansiyskiy avtonomniy okrug v zerkale proshlogo, iss. 9. Tomsk, Khanty-Mansiysk: Izd. Tomsk. Gos. Univ., pp. 239-254.

- Elkina M.V. 1975 Otchet o raskopkakh poseleniy na Barsovoy gore v Surgutskom rayone Tyumenskoy oblasti, provedennykh v 1974 g. Sverdlovsk, 1975. Archives of the IA RAN. R-1, No. 5613.

- Kazakov A.A., Stepanova N.F. 2019 K voprosu o kulturno-khronologicheskikh osobennostyakh keramicheskogo kompleksa s poseleniya Ust-Chumysh. In Poleviye issledovaniya v Verkhnem Priobye, Priirtyshye i na Altaye (arkheologiya, etnografiya, ustnaya istoriya i muzeyevedeniye): Materialy XIV Mezhdunar. nauch.-praktich. konf. Barnaul: pp. 54-59.

- Kazakov A.A., Stepanova N.F. 2020 Keramicheskiy kompleks rannego zheleznogo veka gorodishcha Allak 1. Izvestiya Altaiskogo gosudarstvennogo universiteta, No. 5 (115): 113-119.

- Novikova L.P., Vlasov A.I., Zozulina T.I., Krivenkova G.G., Sukhanov A.I., Chistyakova A.I. 2017 Gosudarstvennaya geologicheskaya karta Rossiyskoy Federatsii. Masshtab 1 : 200 000. Ser. Zapadno-Sibirskaya. Podser. Tyumensko-Salekhardskaya: Obyasnitelnaya zapiska. Moscow: VSEGEI.

- Pletneva L.M., Ragimkhanova I.J., Stepanova N.F. 2019 Rezultaty tekhniko-tekhnologicheskogo analiza keramiki iz mogilnika Shelomok I, poseleniy Kizhirovo, Samus II. Tomskiy zhurnal lingvisticheskikh i antropologicheskikh issledovaniy, No. 4 (26): 120-127.

- Posrednikov V.A. 1969 Arkheologicheskiye raboty na r. Vakh. In Iz istorii Sibiri, iss. 2. Tomsk: Izd. Tom. Gos. Univ., pp. 76-85.

- Rybakov D.Y., Stepanova N.F. 2013 Rezultaty tekhniko-tekhnologicheskogo analiza kulaiskoy keramiki poselencheskogo kompleksa Ryuzakovo (Dukhovoye). Vestnik Tomskogo gosudarstvennogo universiteta. Istoriya, No. 2: 86-90.

- Rybakov D.Y., Stepanova N.F. 2017 Rezultaty tekhniko-tekhnologicheskogo analiza keramiki pamyatnikov kulaiskoy kulturno-istoricheskoy obshchnosti iz Tomskogo i Narymskogo Priobya. Vestnik Tomskogo gosudarstvennogo universiteta. Istoriya, No. 49: 46-53.

- Serikov Y.B., Chemyakin Y.P. 1998 Kamenniy inventar beloyarskogo poseleniya Barsova gora I/40. In Voprosy arkheologii Urala, iss. 23. Yekaterinburg: Izd. Ural. Gos. Univ., pp. 241-256.

- Stepanova N.F., Bobrova A.I. 2018 Osobennosti iskhodnogo syrya i sostava formovochnykh mass keramicheskikh kompleksov iz Tomskogo Priobya. In Problemy arkheologii, etnografii, antropologii Sibiri i sopredelnykh territoriy, vol. XXIV. Novosibirsk: Izd. IAET SO RAN, pp. 324-328.

- Stepanova N.F., Rybakov D.Y. 2016 Perviye rezultaty tekhniko-tekhnologicheskogo analiza keramiki gorodishcha Timiryazevo III kulaiskoy kulturno- istoricheskoy obshchnosti. In Problemy arkheologii, etnografii, antropologii Sibiri i sopredelnykh territoriy, vol. XXII. Novosibirsk: Izd. IAET SO RAN, pp. 420-423.

- Stepanova N.F., Rybakov D.Y. 2019 Osobennosti iskhodnogo syrya i formovochnykh mass drevney keramiki iz Tomskogo i Narymskogo Priobya. In Problemy arkheologii, etnografii, antropologii Sibiri i sopredelnykh territoriy, vol. XXV. Novosibirsk: Izd. IAET SO RAN, pp. 607-613.

- Troitskaya T.N. 1979 Kulaiskaya kultura v Novosibirskom Priobye. Novosibirsk: Nauka.

- Tsetlin Y.B. 2012 Drevnyaya keramika: Teoriya i metody istoriko-kulturnogo podkhoda. Moscow: Izd. IA RAN.

- Tsetlin Y.B. 2017 Keramika: Ponyatiya i terminy istoriko-kulturnogo podkhoda. Moscow: Izd. IA RAN.

- Volkova E.V., Tsetlin Y.B. 2016 O razrabotke metodiki opredeleniya temperatury obzhiga drevney keramiki. KSIA, No. 245-II: 254-264.

- Zykov A.P. 2008 Perviye issledovateli Barsovoy Gory. In Barsova Gora: Drevnosti tayezhnogo Priobya. Yekaterinburg, Surgut: Ural. kn. izd., pp. 6-15.

- Zykov A.P. 2012 Barsova Gora: Ocherki arkheologii Surgutskogo Priobya. Srednevekovye i Novoye vremya. Yekaterinburg: Ural. rabochiy.