Production of fermented milk from reconstituted skimmed milk

Автор: Shingisov A. U., Khamitova B. M., Tastemirova U. U.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 2 (127), 2020 года.

Бесплатный доступ

Fermented milk products produce with application of different lactic acid bacteria, these products are widely used by millions in the world. The consumption of milk products has decreased during last years; this tendency has caused the development of new generation dairy products with reduced energy value and increased functionality. The majority of fermented milk products has high-energy value as many ingredients (sugar, fruit additives, grains, seed sand nuts, chocolate, etc.) are added during production. The study results revealed that higher milk solids non-fat positively contributed to strengthening the organoleptic and structural properties of fermented milk. Skimmed milk powder should be a suitable alternative to raw skimmed milk in reconstituted dairy products production.

Dairy products, fermented milk, reconstituted, skimmed milk

Короткий адрес: https://sciup.org/140250870

IDR: 140250870 | УДК: 637.146.2:664.762

Текст научной статьи Production of fermented milk from reconstituted skimmed milk

Dairy products are essential foods in human diet. They are protein and fatsource in nutrition, providing 20 percent ofthe protein and over 30 percent of the fatsdaily [1].

In recent years, there has been an overall growth in demand for healthy food products. Consumers prefer products whose main charac-terristics are not only appropriate appearance and pleasant taste, but also functionality and high nutritional value [3].

They represent a great source of bioactive compounds, as well viable lactic acid bacteria compete with undesirable microorganisms and metabolites that contribute to consumer healthand well-being [5].Products have pleasant, slightly fresh, acidic taste, they stimulate appetite and improve the microbiota of the organism, as well as products enhance digestion and appetite, they have antitumor activity and LDL cholesterol reduction potential, etc.

Recently the volume of milk products produced using skimmed milk powder (SMP) is increased [4] .It is caused by seasonal variation of milk production or lack of raw milk in some world regions. The fortification of milk products produced from skimmed milk powder andstarter cultures allowsexpandingthe variety of functional products and strengthening the immunity of organism, and reduce the risk of environmentally harmful factors.Application of skimmed milk powder in fermented milk products production helps to regulate such sensory attributes as texture and viscosity [6]. The aim of the present study was to develop the technology of fermented milk using skimmed milk powder, lactic acid bacteria culture and plant oils.

Objects and methods of research

This study investigated the structural characteristics of fermented milk samples with various milk solids non-fat and plan oils.

Characteristics of materials

Skimmed milk powder (Kirgizstan) with the following indices in 100 g of product: proteins 33.2 g, fats 1 g, carbohydrates 52.6 g, energy value 362 kcal was used for the study.

Yoghurt starter culture (Каприна, Russia) with following composition Streptococcus thermophillus and Lactobacillus delbrueckii subsp. Bulgaricus was used for the experiments.

Fat improves the sensory perception offermented dairy products, therefor plant oils (olive, palm, wheat sprouts and walnuts) were used for fermented milk production in such concentrations 6.2 mg g-1 (olive), 2.9 mg g-1 (palm), 6.1 mg g-1 (wheat sprouts), 3.7 mg g-1 (walnuts).

Fermented milk preparation

Reconstituted skimmed milk was prepared with different milk solids non-fat concentration – 9, 12, 15% (w/w) at 45 + 5oC 15 min. After complete solubility of skimmed milk powder, plant oils were added in quantity of 1.5 to 2.5% (w/w). Samples were pasteurized at 94oC for 6 min, cooled to 45oC and inoculated with liquid starter (5%, v/v). Samples were fermented at 45oC at least 7 hours until reached 80-85oTh acidity, followed by gently mixing and coolingup to 20oC.

Methods of analysis

Milk solids non-fatconcentration was measured in reconstituted skimmed milk samples, as well as fermented milk samples were tested, analysing dynamic viscosity, whey separation, water-holding capacity (WHC) andorganoleptic properties.

Titratable acidity was determined by titration of sample with 0.1 M NOH at the presence of 1% (w/v) phenolphthalein till stable slightly pink colour (Walstra, Wouters, Geurts, 2006). Acidity was expressed in Therner degree.

Dynamic viscosity was analysed using capillary viscosimeter VPZh (Russia).

Milk solids non-fatwas evaluated at 20oC using refractometer.

Water-holding capacity was measured using centrifugation.Fermented milk samples (10

g) were centrifuged (Laboratory centrifuge for the dairy industry Laboratory centrifuge for the dairy industry LCDI 12) for 30 min at 4500 rpm at 35oC. Precipitated whey (PW) was removed and weighed. The WHC was calculated as:

WHC (%) = 100 (S-PW)/S, where:

PW – precipitated whey, g;

S – sample weight, g (Akilin et al., 2021).

Organoleptic evaluation of samples of fermented milk products was carried out at the Department of Technology of food and animal products.

Data analysis

Data analyses were performed in two replications and results are showed as an average of two measurements.

Results and their discussion

The chemical composition, mainly total solids non-fat, protein, fat content and coagulum acidity affect textural properties of fermented milk products [8]. Nevertheless, skimmed milk powder can be a suitable alternative to raw skimmed milk, especially in countries with reduced milk production capacity. Organoleptic properties of developed fermented milk are presented in Table 1.

Table 1 - Organoleptic properties of developed fermented milk

|

Indices |

Characteristics |

|

Appearance |

Firm without whey separation |

|

Aroma and taste |

Slightly acid taste and mild lactic acid aroma |

|

Consistence |

Firm, homogenous consistence |

|

Colour |

White with slightly bluish tone |

The study results revealed that addition of plant oils from 1.5 to 2.5% does not cause changes in organoleptic properties. It is interesting to observe that addition of plant oilsdoes not differ in the acceptance of final product.

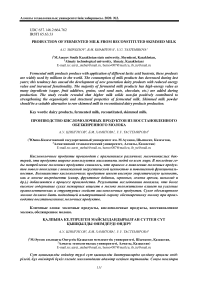

The structural properties of fermented milk samples are crucial in overall consumer acceptance of developed products [2]. The influence of milk solids non-faton dynamic viscosity of samples is shown in Figure 1.

Figure 1. The influence of milk solids non-fat on fermented milk samples viscosity

The variations on dynamic viscosity were observed in the study. Differences in total solids content among analysed samples affect coagulum firmness, demonstrating that total solids and proteins have close relationship tothe final product textural characteristics.

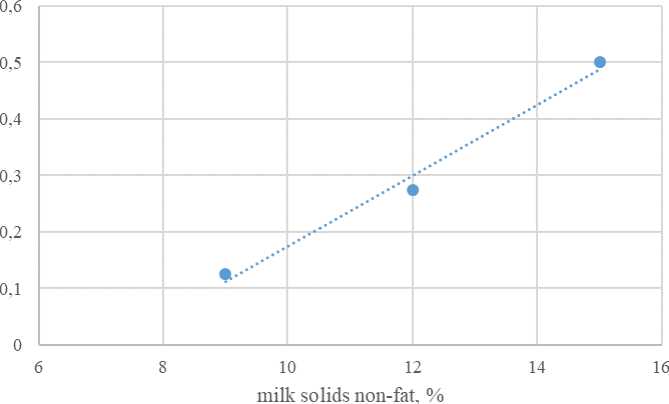

Figure 2. The influence of milk solids non-fat on whey separation in fermented milk samples

The syneresis of evaluated samples decreased when the milk solids non-fat were increased. Whey separation negatively affects consumer perception. Different approaches have been used to maintain fermented milk structural characteristics using stabilisers and thickeners, as well as increasing the total solids non-fat content in milk [11]. The separation of whey relates to an unstable coagulum, which we observed in sample with 9% of milk solids non-fat. The increased solids content also requires an additional acidity development by lactic acid bacteria starter to achieve a targetacidity; therefore 12% of milk solids non-fat in samples were set as more appropriate.

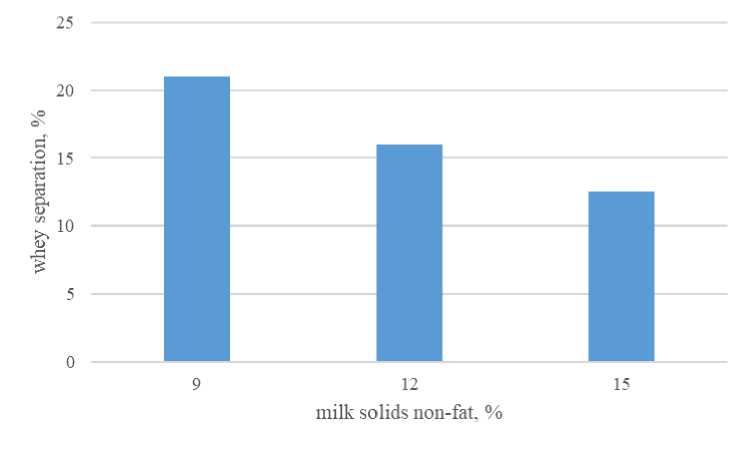

Figure 3. The influence of milk solids non-fat on water-holding capacity of developed product

Total solids and protein content also affects WHC; the higher milk protein content increases gel firmness, and consequently the WHC.

The analysis of organoleptic and structural properties have shown the possibility to maintain appropriate fermented milk consistence, taste and skimmed milk was developed. The technological aroma at 12% of milk solids non-fat concentration. flow is summarized in Table 2.

During the study the technology of fermented milk product from reconstituted

Table 2 Main processing steps in the manufacture of fermented milk

|

Operation |

Parameters |

|

Collection of raw materials and quality testing |

According to standards/requirements of legislation/quality certificates |

|

Reconstitution of skimmed milk powder |

t=45±5oC τ=15 min |

|

Addition of plant oils into reconstituted milk, emulsion formulation |

t=52±2oC τ=15 min |

|

Homogenisation |

t=75±5oC, p=12.5±2.5 MPa |

|

Pasteurisation |

t=94±2oC, τ=6±2 min |

|

Cooling to inoculation |

t=32±1oC |

|

Fermentation |

t=45±1oC, τ=8±0.5 h till 80-85oTh |

|

Mixing and cooling |

t=20±2oC, τ=30 min |

|

Packaging |

|

|

Cold store |

t=4±2oC, τ=5 days |

The results suggested that the structural characteristics of fermented milk products can be improved by milk solids non-fat concentration and by the use of appropriate starter culture. The developed technology allows to increase function-nality and nutritional value of fermented product and to extend fermented milk products diversity. Addition of plan oils to reconstituted skimmed milk helps to increase valuable polyunsaturated (ῼ=6) fatty acids which concentration in milk is insignificant.

Conclusions

-

1. The study results revealed that higher milk solids non-fat positively contributed to strengthening the organoleptic and structural properties of fermented milk.

-

2. Skimmed milk powder should be a suitable alternative to raw skimmed milk in reconstituted dairy products production.

Список литературы Production of fermented milk from reconstituted skimmed milk

- Akalin S., Unal G., Dinkci N. Havaloglu A. (2012) Microstructural, textural, and sensory characteristics of probiotic yoghurt fortified with sodium calcium caseinate or whey protein concentrate. // Journal of Dairy Science, 95 (7): 3617-3628.

- Delikanli B., Ozcan T. (2017) Improving the textural properties of yoghurt fortified with milk proteins. // Journal of Food Processing and Preservation, 41 (5): 1-8.

- Gabrielyan D.S. (2014) Resources saving technology of enriched fermented milk drinks. // Food industry, 8:12-14

- Overview of global dairy market developments in 2019 IDF The world dairy situation 2019. Bulletin of IDF 501/2019. Mode access: http://www.fao.org/3/ca8341en/CA8341EN. Date of application 18.02.2020

- Kryuchkova V.V., Evdokimov I.A. (2007) Functional fermented milk drin ks: technologies and health: monograph.- Stavropol: Sevkavgtuю- 108 p.

- Lee W.J. and Lucey J.A. (2010) Formation and Physical Properties of Yogurt. // Asian-Australian Journal of Animal Science 23(9):1127-1136

- Pakseresht S., Mazaheri Tehrani M., Razavi S.M.A. (2017) Optimization of low-fat-set-type yoghurt: effect of altered whey protein to casein ration, fat content and microbial transglutaminase on rheological and sensorial properties. // Journal of Food Science and Technology, 54(8): 2351-2360.

- Prasanna P.H.P., Ranadheera C.S., Vidanarachchi J.K. (2018) Microstructural aspects of yoghurt and fermented milk. In: Microstructure of dairy products. Eds. M.M. Abdel-Rahman El_Bakry, A.Sanchez. Wiley, 2018.-РР. 181-208.

- Skorina I.A., Tretyakova E.N., Sugareva T.N. (2014) Production of milk drinks of functional purpose with natural additives. // Food industry, 10: 8-12

- Walstra P., Wouters J.T., Geurts T.J. (2006) Dairy science and technology. 2 nd edit. Taylor & Francis Group.- 782 p.

- Yu H-Y., Wang L., McCarthy K.L. (2016) Characterization of yogurts made with milk solids non-fat by rheological behavior and nuclear magnetic resonance spectroscopy. // Journal of food and drug analysis, 24: 804-812