Raw materials in the paste of ceramics of the Kulaika culture Surgut variant (based on samples from Barsova Gora)

Автор: Selin D.V., Maksimova A.A., Chemyakin Y.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.52, 2024 года.

Бесплатный доступ

A multidisciplinary analysis of ceramics from six sites of the Surgut variant of the Kulaika culture at Barsova Gora was made. Technology was assessed using traceological, petrographic, and X-ray phase analyses. At all the sites, the potters used ferruginous clays tempered with grus, grog, sand, and organic material. Fragments in the clay were either rounded, as in sand, or coarse, as in grus. The sand was mainly represented by feldspar and quartz, suggesting that this type of raw material was extracted from nearby non-metallic mineral deposits. The grus consisted of fragments of basaltoids, amphiboles, and pyroxenes, evidencing that it came from igneous common rocks associated with the Surgut volcanic fi eld and spread over a large area. Rocks were probably mined near settlements, perhaps on the floodplain of the Ob. Grog in all the samples was similar to the basic clay in terms of its composition. Three groups of sites were identified, differing in the composition of the clay of which the ceramics were made. This may indicate the presence of several groups within the Iron Age Kulaika population, utilizing various sources of clay.

Короткий адрес: https://sciup.org/145147218

IDR: 145147218 | DOI: 10.17746/1563-0110.2024.52.3.067-074

Текст научной статьи Raw materials in the paste of ceramics of the Kulaika culture Surgut variant (based on samples from Barsova Gora)

The Barsova Gora group of sites is located on the right bank of the Ob River, 8–15 km west of the present-day boundary of the city of Surgut. To date, approximately 400 archaeological sites from the Neolithic to the Modern Age have been discovered over an area of less than 6 km2 (Chemyakin, Zykov, 2004: 9, 164). Over 60 of them can be attributed to the Surgut variant of the Kulaika culture or cultural-historical community (Ibid.: 182–184; Chemyakin, 2008: 78–79). Pottery fragments are the most common category of finds at the sites of this community. Analysis of the pottery production technology has made it possible to establish the contents of the craftsmanship and provides sources for reconstructing cultural and historical processes among the carriers of the Surgut variant of the Kulaika culture (see, e.g., (Bobrinsky, 1978, 1999; Tsetlin, 2012; Zhushchikhovskaya, Mylnikova, 2020;

Molodin et al., 2020)). Pottery-making technology at sites within a single closed landscape (microregion) reveals the specific skills of potters at different stages and levels of production, as well as their transformation over time.

Previously, one of the authors of this article analyzed the ceramics technology of the Surgut variant of the Kulaika culture using evidence from the fortified settlements of Barsov Gorodok (hereafter, BG) I/4, BG I/5, BG I/7, BG I/20, BG I/32, BG III/6 and settlement of Barsova Gora III/2 (Selin, Chemyakin, Mylnikova, 2021; Selin, Chemyakin, 2021, 2022a, b, c). It was established that ferruginous clays were used and the main recipe for the paste was unmixed, consisting of clay and grus. At some settlements this paste was used for 2/3 of the total number of vessels. The selection of artificial additives was wide and included grus, grog, sand, and various organic materials. In addition, a specific feature of the pottery-making technology in the Surgut variant of the Kulaika culture was variability in the composition of pastes at the same settlement. For example, at the BG I/5 site, nine recipes were identified. Hollow forms were constructed primarily using patch and sometimes also coil technique. A distinctive feature was the additional decoration of the vessel’s rim with a rounded band up to 1 cm in diameter. Pottery of this variant also revealed a variety of combinations of devices used for processing the vessels’ surfaces. For example, 39 methods of combination were identified at BG I/4. In addition, at all the studied sites, a specific technique for processing the internal surface was observed: smoothing the transition area from shoulder to body with a serrated tool.

Upon undertaking technical and technological analysis of pottery from different sites of the Kulaika culture Surgut variant, only binocular microscopy has been used to determine the specific features of the raw materials and artificial additives. Scientific methods could provide the data that are not available through binocular microscopy. Identification of the mineral composition of the plastic raw material makes it possible to establish its

Ttr 12 | ★ I 3[ ’ ]4 5 0 6 Й 7±8

similarity or difference at the same site, determine the region of clay extraction, and detect pottery made of nonlocal raw materials.

The Barsova Gora microregion is located in the CentralWestern Siberian fold system. It crosses the Western Siberian plate from northwest to southeast, from the Kara Sea to the spurs of the Altai-Sayan, and connects with the structures of the Altai-Sayan fold belt. The structure of the system was faulted and complicated during the Triassic rifting stage, when the Surgut volcanic field emerged in this region. For example, the area where the sites under study are located shows Triassic deposits of the Turinsk series (Fig. 1), consisting of sandstones, basalts, basaltic andesites, siltstones, tuffaceous-sedimentary rocks, andesites, and their tuffs. Around Barsova Gora, deposits of non-metallic minerals have been found (Fig. 1). For instance, at a distance of 7–10 km north of the sites, there are deposits of sand and gravel. About 8 km to the east, there are deposits of construction sand, and to the south deposits of brick clays can be found (Gosudarstvennaya geologicheskaya karta…, 2012).

Pottery from the BG I/5, BG I/7, BG I/8, BG I/15, and BG I/30 bank fortified settlements, located on the terrace of the Utoplaya channel, was analyzed. For comparison, evidence from Barsova Gora III/2 was used. In the Kulaika period over this relatively small area, there might have been a single fortified settlement, which was moved by its inhabitants along the terrace (the distance between the outermost fortified settlements is no more than 0.55 km). Therefore, the mineral composition of clays used in pottery-making from these settlements is of particular interest; it may reveal similarities or differences in the skills of selecting raw materials. For the first time, this pottery was studied using a set of interdisciplinary methods. The purpose was to describe the plastic raw material and artificial additives used by the carriers of the Surgut variant of the Kulaika culture for the manufacture of pottery at different settlements of the Barsova Gora locality.

Methods and materials

This study was carried out using interdisciplinary synthesis, where methods from different sciences and digital technologies complement one other (see, e.g., (Fiziko-khimicheskoye issledovaniye…, 2006; Drebushchak V.A., Mylnikova, Drebushchak T.N., 2018; Molodin et al., 2019; Zhushchikhovskaya, 2022; Karasik,

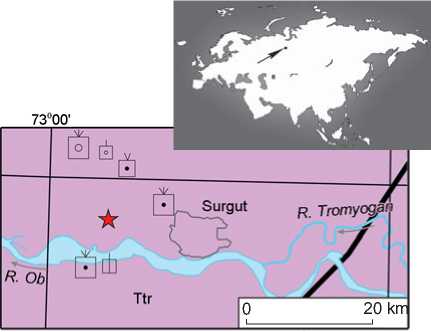

Fig. 1 . Location of the Barsova Gora locality.

1 – Tura series; 2 – fault; 3 – location of sites; 4–8 – mineral deposits: 4 , 5 – construction sand ( 4 – large; 5 – medium); 6 , 7 – sand and gravel ( 6 – large; 7 – small); 8 – small deposit of brick clays.

Harush, Smilansky, 2020; Chistyakov, Bocharova, Kolobova, 2021)). The potterymaking technology was analyzed using the methodology elaborated by A.A. Bobrinsky (1978, 1999). Surfaces and fresh fractures of shards were examined using a binocular microscope (Leica M51). The traces identified were compared to the experimental base of technological traces on pottery. When identifying and interpreting the specific features of the technology, scholarly literature and the “Catalogue of Standards for Ceramic Trace Analysis” by I.N. Vasilieva and N.P. Salugina were also used (see, e.g., (Bobrinsky, 1978, 1999; Tsetlin, 2012, 2017; Vasilieva, Salugina, 2020)).

Mineralogical and petrographic study of thin sections involved the polarization microscopy (Zeiss Axio Scope A1 microscope). Ceramic petrography was used to establish the mineral composition of the plastic raw material and artificial additives. In the descriptions, the “matrix” refers to the plastic raw material (clay). The clastic material included mineral grains that were unevenly distributed throughout the clay and were predominantly of artificial origin. X-ray phase analysis was used for the determination of the mineral phases of the raw material with a Stadi MP (Stoe) X-ray powder diffractometer.

Technical and technological analysis was carried out for the pottery from five fortified settlements of the Surgut variant of the Kulaika culture: BG I/5 (33 spec.), BG I/7 (5 spec.), BG I/8 (19 spec.), BG I/15 (26 spec.), BG I/30 (12 spec.), and one settlement Barsova Gora III/2 (50 spec.). Samples from BG I/5 (15 spec.), BG I/7 (3 spec.), BG I/8 (7 spec.), BG I/15 (10 spec.), BG I /30 (5 spec.), and Barsova Gora III/2 (10 spec.) were subjected to petrographic study and X-ray phase analysis.

Study results

Technical and technological analysis of the vessels from BG I/5 has revealed that they were manufactured with the use of ferruginous clays tempered with grus, grog, sand, and organic material. Nine recipes for pastes have been identified: 1) clay + grus (13 spec.); 2) clay + grog (8 spec.); 3) clay + grus + grog (3 spec.); 4) clay + grus + + sand (3 spec.); 5) clay + grog + sand (1 spec.); 6) clay + + grog + sand + organic material (1 spec.); 7) clay + sand +

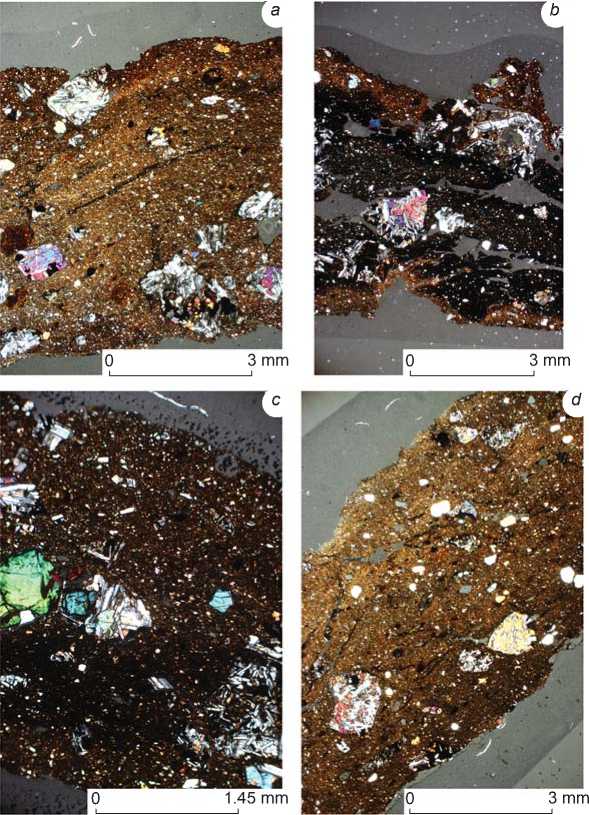

Fig. 2 . Thin sections of pottery from the sites of the first group.

a – BG I/5 site, sample No. 5; b – BG I/8 site, sample No. 25; c – BG I/15 site, sample No. 32; d – Barsova Gora III/2 site, sample No. 41.

+ organic material (2 spec.); 8) clay + grus + organic material (1 spec.); 9) clay + grus + grog + organic material (1 spec.) (Selin, Chemyakin, 2022b). The pottery from this site demonstrated a large amount of matrix (from 69 to 97 %) and up to 30 % of clastic material. The grog content reached 10 % (Fig. 2, a ). The matrix predominantly consisted of silty micaceous clay with fragments of pyroxenes, feldspars, and muscovite. The clastic material included plagioclases, gabbroids, and pyroxenes. Six samples contained rounded grains of potassium feldspars. The grog contained rounded grains with rare inclusions of feldspars, and was mostly dark. In two thin sections, the matrix of the main ceramic body appeared to be similar in mineral composition to the grog. The mineral composition of clays was similar in all analyzed pottery samples from that site, which indicates that the raw materials were procured in the same area.

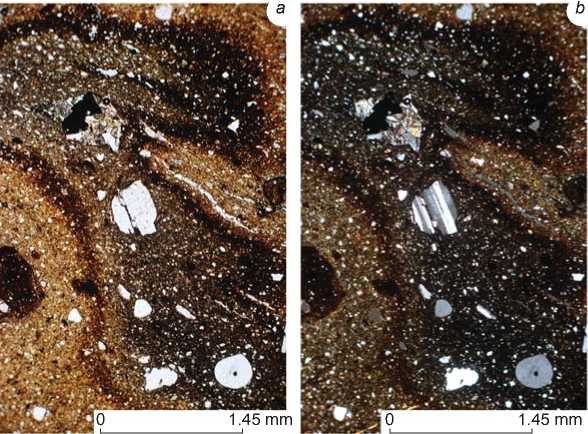

Fig. 3 . Sample No. 18 from BG I/7, the site of the third group. a – in transmitted light; b – in crossed nicols.

Pottery from BG I/7 was made of ferruginous clays tempered with grus, grog, and organic material. Three recipes for the paste were identified: 1) clay + grus + + organic material (2 spec.); 2) clay + grog (2 spec.); 3) clay + grus + grog (1 spec.) (Selin, Chemyakin, 2022b). Pottery from that site was distinguished by a predominance of matrix (75–93 %), and a smaller amount of clastic material as compared to the ceramics described above (up to 10 %), and a slightly higher content of grog (up to 20 %) (Fig. 3). The matrix was mostly aleuropelite micaceous clay with grains of muscovite and feldspars. The composition of the clastic material was plagioclase, gabbroids, and pyroxenes. Rounded grains with inclusions of feldspar were identified in the grog. In one thin section, the grog matrix was micaceous and similar in mineral composition to the main ceramic body. In all the analyzed samples, the mineral composition of the clays was similar, which indicates that raw materials were procured in the same area.

At the BG I/8 fortified settlement, ferruginous clays tempered with grus, grog, sand, and organic material were used. Six recipes were identified: 1) clay + grus (12 spec.); 2) clay + grog (1 spec.); 3) clay + grus + grog (1 spec.); 4) clay + grus + sand (2 spec.); 5) clay + grog + + organic material (1 spec.); 6) clay + grus + sand + organic material (2 spec.). The ceramics demonstrated a high matrix content (63–94 %). The share of clastic material was 5–30 %. The content of grog reached 10 % (see Fig. 2, b). The matrix was predominantly silty micaceous clay with fragments of pyroxenes, feldspars, and muscovite. The clastic material included gabbroids (predominantly), pyroxenes, and plagioclases. Elongated voids were observed, which indicated the use of an organic material. This additive was also identified by technical and technological analysis. Almost all grog inclusions were dark, which complicates the determination of the similarity or difference between the matrix of grog and the main ceramic body. The mineral composition of the clays was similar in all pottery samples analyzed, which indicates that raw materials were extracted from the same area.

Pottery from BG I/15 was also made of ferruginous clays tempered with grus, grog, sand, and organic material. Five recipes were identified: 1) clay + grus (18 spec.); 2) clay + grog (2 spec.); 3) clay + grus + + grog (3 spec.); 4) clay + sand (1 spec.); 5) clay + sand + grog (1 spec.); 6) clay + grog + organic material (1 spec.). A large amount of matrix (65–92 %) was observed in thin sections of the pottery. The proportion of clastic material was 5–30 % (see Fig. 2, c ). As compared to pottery from the three fortified settlements described above, the grog content was lower (under 5 %). The matrix was mainly silty micaceous or silty clay, with fragments of pyroxenes, feldspars, and muscovite. The clastic material consisted of gabbroids (predominantly), pyroxenes, and plagioclases. The grog contained small rounded dark grains, with rare inclusions of plagioclase. The grog matrix was similar in mineral composition to the main ceramic body. The mineral composition of the clay was similar in all the pottery samples analyzed from that site, which indicates the same area of extracting raw materials.

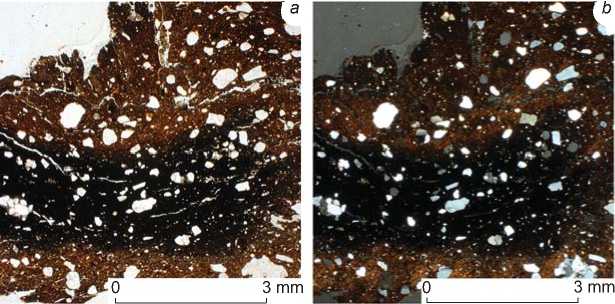

Pottery from BGI/30 was made of ferruginous clays tempered with grus, grog, and sand. Three recipes have been identified: 1) clay + grus (4 spec.); 2) clay + grog (7 spec.); 3) clay + sand + grog (1 spec.). Pottery from that site was characterized by a high matrix content (68– 94 %) and a small amount of clastic material (1–2 %) as compared to other sites. In only one sample was the proportion of clastic material 30 %. The grog content was small, under 8 % (Fig. 4). The matrix was predominantly aleuropelite micaceous clay, with the predominance of feldspars; muscovite and pyroxenes were also present. The clastic material consisted mainly of the rounded grains of feldspars. Small rounded grains with a micaceous matrix and feldspar fractions were identified in grog. The grog matrix was similar in mineral composition to the main ceramic body. The mineral composition of the clay was similar in all the pottery samples analyzed from the site, which indicates the same area of raw material extraction.

Pottery from Barsova Gora III/2 was made of ferruginous clays tempered with grus, grog, and organic material. Four paste recipes were identified: 1) clay + + grus (32 spec.); 2) clay + grus + grog (14 spec.); 3) clay + grus + organic material (3 spec.); 4) clay +

Fig. 4 . Sample No. 37 from BG I/30, the site of the second group.

a – in transmitted light; b – in crossed nicols.

+ grus + grog + organic material (1 spec.) (Selin, Chemyakin, 2022a). The matrix content in the samples was 63–97 %; the clastic material content was 2–25 % (see Fig. 2, d ), and the grog content was under 5 %. The matrix consisted predominantly of aleuropelite, micaceous, silty clay, with a predominance of feldspars; muscovite, biotite, and pyroxenes were also present. The clastic material was represented by gabbroids, pyroxenes, and feldspars. Some samples contained rounded feldspar grains. The grog showed the presence of predominantly rounded fractions with micaceous matrix and feldspar grains. The inclusion of grog in the grog was detected. In both cases, the matrix was similar in mineral composition to the main ceramic body. The mineral composition of the clay was similar in all the pottery samples analyzed from the settlement, which indicates that raw materials were extracted from the same area.

Fragmental material artificially added to the clay can be divided into two types: rounded (sand) and coarse (grus). The sand consisted predominantly of feldspars and quartz, which indicates that the raw material might have been extracted from nearby non-metallic mineral deposits (see Fig. 1). The second type of fragmental material was represented by basaltoids, amphiboles, and pyroxenes. This grus could have resulted from igneous rocks of basic composition that are associated with the Surgut volcanic field and are spread over a large area. Raw materials for the grus might have been procured in the Barsova Gora locality, near the sites under discussion, probably on the

floodplain of the Ob River. The matrix of grog and of grog in grog was similar in mineral composition to that of the main ceramic body, which indicates that potters of the Surgut variant of the Kulaika culture had stable skills in selecting plastic raw materials.

Discussion

Pottery from the sites of the Surgut variant of the Kulaika culture differs in the mineral composition of the raw materials. Yet they all were procured in the region confined to the Surgut volcanic field. Not a single site contains vessels made of imported plastic raw materials. The potters who lived in these settlements extracted clay in the same area, but from different outcrops.

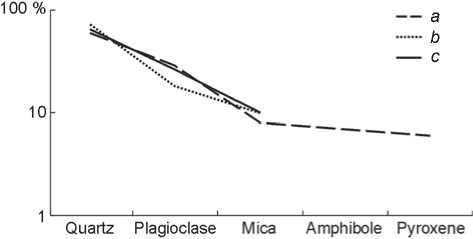

X-ray phase analysis (Table 1, Fig. 5) was carried out for all the pottery studied by the petrographic method. The results of the comprehensive study made it possible to identify three groups of sites with pottery differing in mineral composition of the plastic raw materials. The first group includes the fortified settlements of BG I/5, BG I/8, BG I/15, and Barsova Gora III/2. The samples

Table 1. Results of X-ray phase analysis of pottery samples, wt%

|

Site |

Quartz |

Plagioclase |

Mica |

Amphibole |

Pyroxene |

|

BG I/5 |

49–78 |

16–36 |

2–16 |

5–8 |

10 |

|

65 |

25 |

9 |

6 |

||

|

BG I/7 |

63–65 |

20–27 |

9–15 |

||

|

64 |

24 |

11 |

|||

|

BG I/8 |

39–69 |

20–38 |

3–9 |

8–14 |

4–7 |

|

58 |

30 |

6 |

11 |

6 |

|

|

BG I/15 |

45–67 |

22–42 |

3–12 |

6 |

5–11 |

|

56 |

32 |

6 |

9 |

||

|

BG I/30 |

67–76 |

17–23 |

7–11 |

||

|

72 |

19 |

10 |

|||

|

Barsova Gora III/2 |

52–72 |

18–37 |

5–13 |

5–7 |

2–5 |

|

60 |

29 |

9 |

6 |

4 |

Note. The numerator is the range; denominator is the average value.

Fig. 5 . XRF graphs of pottery samples from the sites of the first ( a ), second ( b ), and third ( c ) groups.

show a quartz content of 39–78 wt%, a plagioclase content of 16–42 wt%, a mica content of 2–16 wt%, an amphibole content of 5–14 wt%, and a pyroxene content of 2–11 wt%. Notably, only in this group were darkcolored minerals (amphiboles and pyroxenes) identified using X-ray diffraction data. Plastic raw materials that were used for the pottery manufacture at these sites had a micaceous siltstone composition with fragments of pyroxenes, feldspars, and muscovite.

The second group is represented at BG I/30. These ceramics demonstrate a higher quartz content (67– 76 wt%), smaller content of plagioclase (17–23 wt%), and comparable content of mica (7–11 wt%) as compared to pottery of the first group. The matrix is predominantly aleuropelite micaceous clay, with a predominance of feldspar fragments and inclusions of muscovite and pyroxenes. It differs from the raw materials used at other settlements by a higher content of feldspars and lower content of plagioclases, which could have been due to the raw material having been extracted from a different outcrop of clay.

The third group is associated with BG I/7. The quartz content in the samples is in the range of 63– 65 wt%, the plagioclase content is 20–27 wt%, and the mica content is 9–15 wt%. The raw material is mainly aleuropelite micaceous clay, with inclusions of feldspars and muscovite. This group differs from the first group by the absence of pyroxenes and amphiboles, and from the second group by a greater amount of plagioclase and mica, which indicates a different place of clay extraction.

The analysis of paste recipes has also shown some differences between these groups (Table 2). Pottery from the sites of the first group has a wide range of artificial additives. However, up to 2/3 of the vessels were made using the unmixed recipe of clay + grus. At all sites of this group, the recipe clay + grus + grog was identified, which indicates the beginning of mixing different pottery skills. The use of organic materials was also observed.

It is very important that the BG I/30 fortified settlement, which was assigned to a separate group based on its plastic raw material, also differed in its paste recipes. The main recipe was clay + grog, which was atypical of the pottery of the Kulaika culture Surgut variant. The mixed recipe clay + grus + grog and organic material that were used by the potters from the sites of the first group, were not found at this site.

The main paste recipes for the pottery from BG I/7, assigned to the third group, were clay + grog and clay + + grus + organic material. The latter material did not appear in the second group, while the unmixed recipe clay + grus, typical of the first group, was not used by the potters from this settlement.

The similarity of plastic materials in the grog and in the main ceramic body was observed at almost all the sites (BG I/5, BG I/7, BG I/15, BG I/30, Barsova

Table 2. Correlation of paste recipes from the sites of the Kulaika culture Surgut variant

|

Recipe |

BG I/5 |

BG I/7 |

BG I/8 |

BG I/15 |

BG I/30 |

Barsova Gora III/2 |

|

clay + grus |

13 |

– |

12 |

18 |

4 |

32 |

|

clay + grog |

8 |

2 |

1 |

2 |

7 |

– |

|

clay + sand |

– |

– |

– |

1 |

– |

– |

|

clay + grus + grog |

3 |

1 |

1 |

3 |

– |

14 |

|

clay + grus + sand |

3 |

– |

2 |

– |

– |

– |

|

clay + grog + sand |

1 |

– |

– |

– |

1 |

– |

|

clay + grus + organic solution |

1 |

2 |

– |

– |

– |

1 |

|

clay + sand + organic solution |

2 |

– |

– |

– |

– |

– |

|

clay + grog + organic solution |

– |

– |

1 |

1 |

– |

– |

|

clay + grus + grog + organic solution |

1 |

– |

– |

– |

– |

1 |

|

clay + grog + sand + organic solution |

1 |

– |

– |

– |

– |

– |

|

clay + grus + sand + organic solution |

– |

– |

2 |

– |

– |

– |

Gora III/2), which indicates that clay selection skills were stable among the potters of each settlement.

Conclusions

This study has identified three groups of sites whose pottery differs not only in the mineral composition of the plastic raw materials, but also in recipes of paste. The chronology of the Kulaika artifacts from Barsova Gora was based on the evolution of pottery (Chemyakin, 2008: 90). The earliest site among those analyzed in this article is the fortified settlement of BG I/7. Its pottery was made from raw materials that have not been found at other settlements. This clay could have been procured from outcrops that became inaccessible to potters at a later time. There may be a chronological gap between the BG I/5, BG I/8, BG I/15 fortified settlements and the Barsova Gora III/2 settlement, which were placed in the first group, but their pottery was made of plastic raw materials similar in mineral composition. This suggests that it was procured from nearby outcrops. BG I/30 was chronologically close to the sites of the first group, but the potters from that settlement used clay of different mineral composition, which also points to a different extraction place of raw materials.

The difference in the mineral composition of plastic raw materials at different sites of the Kulaika culture Surgut variant, identified by multidisciplinary analysis, suggests that several different populations lived in the Barsova Gora locality, leaving fortified settlements and a village. Potters could have used various clay outcrops in the same area. Since Barsova Gora is a prominent object in the terrain, groups of the Kulaika population from neighboring territories would probably come there at different times. They had their own pottery skills, and various traditions mixed during the interaction of human groups, which led to variability in the selection of clays, variety of artificial additives, paste recipes, and combinations of devices for processing vessels’ surfaces.

Further comprehensive analysis of the Early Iron Age pottery in the Surgut Ob region will make it possible to reconstruct historical and cultural processes, identify migration routes of various populations, establish directions of trade relations, and determine patterns of interaction between different cultures.

Acknowledgments

This study was supported by the Russian Science Foundation: ceramics research (petrography, XRF, analysis of results) under Project No. 23-78-01192, analysis of specific features of the sites’ chronology under Project No. 24-28-00650.