Rheological behavior of mixtures used in 3d-printing: ex-perimental evaluation of the effectiveness of criteria requirements for filler

Автор: Slavcheva G.S., Solonina V.A., Razov I.O., Filipenko P.V., Orlov V.S.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.16, 2024 года.

Бесплатный доступ

Introduction. For handling the problem of mixtures design for additive construction technologies, the paper presents the results of experimental studies of rheological behavior and production characteristics (plasticity and shape stability) of cement mixtures based on various types of fillers with different size, shape, and grade. Methods and materials. Rheological properties of 3Dprintable mixtures were investigated using squeezing rheometry methods. The constant strain rate mode of 5 mm/s was used to evaluate plasticity and the constant load rate of 5 N/s was used to evaluate form stability. Scanning electron microscopy method (Phenom XL) was used to evaluate the size-geometry characteristics of cement and filler particles. Image processing to determine particle length and width was performed using ParticleMetric software. The size and gradation of the cement and filler particles were evaluated using a laser particle size analyser “Analyzette 22”. Results and discussion. It was found that a necessary condition for the plasticity and stability of mixtures is the creation of dense spatial packing of disperse phase particles. The values of the plasticity limit rational for extrusion are ensured if the filler particles have a size comparable to cement particles and multi-size gradation. The characteristics of the fillers are not decisive for the shape stability of the mixtures. Conclusion. The numerical criteria of fillers for design of 3D-printable mixtures have been substantiated, including mean average particle diameter, particle shape factor, particle distribution constant as a characteristic of the particle size gradation.

Additive technologies, cement mixture, fillers, rheology, workability

Короткий адрес: https://sciup.org/142242259

IDR: 142242259 | DOI: 10.15828/2075-8545-2024-16-4-310-319

Текст научной статьи Rheological behavior of mixtures used in 3d-printing: ex-perimental evaluation of the effectiveness of criteria requirements for filler

Review article

INTRODUCTION development of 3D-build printing creates the need a wide range of mixtures on the market that meet

the requirements of this technology. The efficiency of 3D-build printing is determined by a number of critical properties of mixtures such as plasticity for implementation of extrusion (extrudability), shape stability in multilayer casting (buildability), structural build up [1–4].

As a result of the accumulation of a number of experimental data, e.g. [5–19], a lot of different types of mixtures with the necessary technological properties for printing have been developed and successfully tested. The obtained mixtures are characterised by their multicomponent mix design, their compositions simultaneously using superplasticisers, viscosity modifiers, hydration process regulators, fillers and aggregates of different chemical and mineralogical composition and particle size.

CONSTRUCTION MATERIALS SCIENCE

When designing mixtures, the role of binders, plasticisers and viscosity modifiers in regulating technological properties is theoretically justified and established experimentally [6–8, 10–11]. At the same time, the choice of fillers and the regulation of their concentration in the mixture compositions is based on an empirical approach [12–18]. When developing compositions, the filler content of a certain type is selected without defining the general requirements for their properties, which are necessary for a priori (before experience) determination of the applicability of a particular filler in 3D build printing and for determining the limits of its rational content.

The author’s approach to the modelling and control of the rheological behavior of visco-plastic mixtures in 3D printing processes and the optimization of their mix design is based on the provisions of the structural rheology of disperse systems, the priority of whose theoretical foundation belongs to the Soviet school of physico-chemical mechanics [19–20]. On this basis, the main means of controlling the rheological behavior of viscoplastic mixtures considered as heterogeneous systems “disperse phase + dispersion medium” have been substantiated by author team [21]. The criteria requirements for the properties of fillers are theoretically justified and numerical criteria for their evaluation are proposed [22]. These criteria include average particle diameter dc, particle shape factor ks, particle distribution constant Gpc, which are proposed to be used for preliminary complex evaluation of fillers in the problems of mixture design.

This paper discusses the results of experimental evaluation of the effect of numerical filler criteria on the rheological behavior and properties of 3D printable mixtures.

MATERIALS AND METHODS

Five types of mixtures were investigated (Table 1). The parameters of mix composition such as cement: filler mass ratio, concentration and type of additives, fiber, W/C-ratio were kept constant because this parameters were established according to the results of the previous studies [23–24]. The variable factor in the mix composi- tion was the size-geometry characteristics of the fillers. The mixtures on 4 types of fillers were studied such as al-europelite (Al), fly ash (FA), crushed sand (CS), crushed limestone (CL). The characteristics of the mixture initial components are presented in Table 2.

Methods for evaluating filler properties. Scanning electron microscopy (SEM) was used to evaluate the shape of the particles. Imaging was performed on a Phenom XL scanning electron microscope (vacc = 15 kV. P = 0.10 Pa). The images were processed using the ParticleMetric software in order to determine particle length l and width b. The average particle diameter and granulometric constant were calculated based on the data obtained on a laser particle size analyzer Analysette 22 Nano Tec.

The numerical filler criteria were calculated from the data obtained:

1) average particle diameter dc

where ci is partial residuals on sieves. %; d 1 is diameter taken as average for a certain interval (fraction). µm;

-

2) particle shape factor k s , calculated as the arithmetic average of two linear sizes (length l . width b ):

ks = ( l + b )/2.

-

3) particle distribution constant Gpc as characteristic of the particle size gradation:

G pc = d 60 / d 10 , (3)

where d 10( d 60) are diameters of particles. less than which the material contains 10% (60%) particles by weight. respectively.

Test parameters for evaluating the mixture rheological properties. The method of squeezing rheometry was used. The squeezing test were carried out on cylindrical samples of the fresh mixtures, the radius of which R, was equal to their height, h0 = 25 mm. The specimens were moulded and tested immediately after the preparation of

Table 1

Mix composition

|

System ID |

Viscosity modifier dosage, % mass cement |

Superplasticizer dosage, % mass cement |

Cement : filler mass ratio |

Fiber dosage, % mass cement |

|

|

XG |

SG |

||||

|

C (reference) |

0.2 |

0.2 |

0.2 |

1 : 1 |

0.3 |

|

C+Al |

0.2 |

0.2 |

|||

|

C+FA |

0.2 |

0.2 |

|||

|

C+CS |

0.2 |

0.2 |

|||

|

C+CL |

0.2 |

0.2 |

|||

CONSTRUCTION MATERIALS SCIENCE

Table 2

Materials characteristics

-

1) with a constant specimen deformation rate of 0.5 mm/s, modelling the visco-plastic flow of the mixture under dynamic conditions during extrusion (method of N. Roussel [26]);

-

2) with a constant load rate of 5 N/s, simulating the behavior of the mixure under static conditions of layer-by-layer casting (author's method). [22]).

As a result of squeezing tests, the rheological behavior of the mixtures was evaluated by analysis of experimental curves:

-

– “load N – relative change in specimen height hi/R” obtained from constant specimen deformation rate tests;

– “load P – displacement ∆” obtained from constant load rate tests.

The curves “N – hi/R” were obtained during the experiments were interpreted as influence curves of reduced compression load F* from a relative change of height of the sample hi/R: (“F* – hi/R”):

Fi* = Nhi/πR2, (1)

where hi = (h0–∆), h0 is the initial height of the sample, ∆ is transferred in the point of time, value R was taken as constant and equal to the radius of the sample at the beginning of the experiment.

The values of structural (σ0) and plastic strength (σpl) of mixtures at the moments corresponding to the beginning of deformation (∆ = 0.1 mm) and the beginning of cracking of specimens were calculated from the obtained experimental “P–∆” curves according to the formula:

σ = P/πR2. (2)

The following properties of the mixtures were determined to be suitable for 3D printing based on the test results:

‒ yield stress value Ki(I) was calculated at the inflection point of the “F* – hi/R” curves (hi/R = 0.9): 《(%) =等 ; (3)

– structural strength (σ0) as the ability of the mixture to withstand the load without deformation;

– plastic strength (σpl) and relative plastic strains (∆pl = ∆/h0) characterising the ability of the mixture to withstand load without cracking.

RESULTS

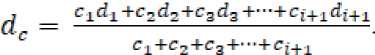

Size-geometry characteristics of the fillers. All types of fillers used are characterised by continuous gradation (Table 3, Fig. 1), which, as previously demonstrated [10, 27], is a necessary condition for ensuring the workability of 3D-printable mixtures according to the criteria of plasticity and shape stability. The particle distribution constant of the fillers is in the range of Gpc = 7.6–9.9.

CONSTRUCTION MATERIALS SCIENCE

Table 3

Particle size distribution

|

Particle size d, m |

ω of particles, % |

||||

|

Aleuropelite |

Fly ash |

Crushed sand |

Cement |

Crushed limestone |

|

|

≤ 4 |

16.8 |

9.1 |

11.3 |

11.8 |

11.5 |

|

8 |

14.6 |

8.2 |

6.3 |

9.0 |

6.8 |

|

15 |

17.5 |

14.6 |

10.2 |

13.9 |

15.2 |

|

30 |

28.7 |

28.1 |

29.0 |

27.5 |

27.4 |

|

55 |

20.1 |

29.0 |

33.6 |

28.2 |

16.8 |

|

100 |

2.3 |

10.9 |

9.6 |

9.6 |

9.8 |

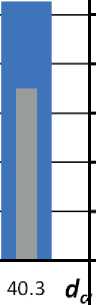

Fig. 1. SEM-images of filler particles: a) Aleuropelite; b) Fly ash; c) Crushed sand; d) Crushed limestone

Its value for Portland cement is in the same range (Gpc =

-

8.1 ) (Table 4). p

The fillers differ significantly in shape and size. Flat particles of aleuropelite (Fig. 1a) are characterised by the shape factor ks = 2.33. Spherical particles of fly ash (Fig. 1b) are characterised by the shape factor ks = 1.05, while cubic particles of crushed sand and crushed limestone (Figs. 1c, d) are characterised by the value of ks =

CONSTRUCTION MATERIALS SCIENCE

Table 4

Numerical criteria for the evaluation of fillers

|

Material type |

Average particle diameter dc, µm |

Particle shape factor, ks |

Particle distribution constant, Gpc |

|

Cement |

22.6 |

1.52 |

8.1 |

|

Aleuropelite |

17.5 |

2.33 |

8.1 |

|

Fly ash |

26.5 |

1.05 |

7.6 |

|

Crushed sand |

27.2 |

1.65 |

9.9 |

|

Crushed limestone |

40.3 |

1.46 |

8.9 |

-

1.46 –1.65, which is close to the value of the shape factor for Portland cement particles ks = 1.52.

The average particle diameter of crushed sand and limestone is correlated with its value for Portland cement (dc = 22.6 m). The average size particle of aleuropelite is 1.3 times smaller and average size particle of crushed limestone 2 times larger than size of Portland cement particle.

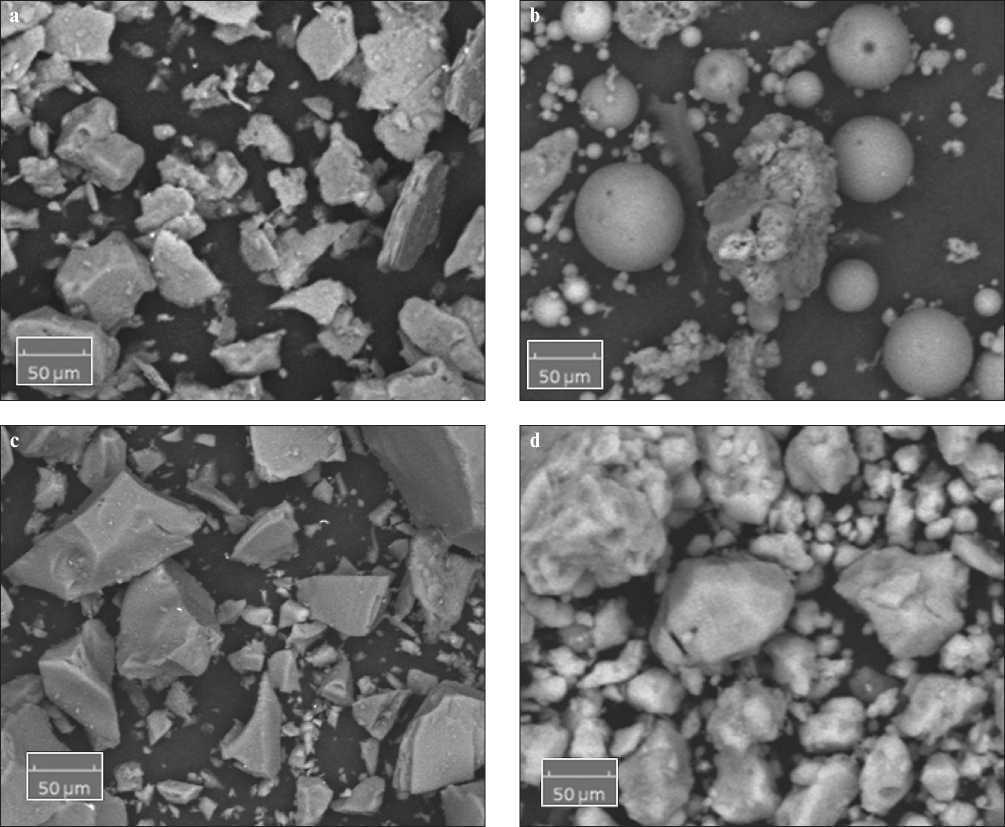

Rheological behavior of mixtures under squeezing. The plastic behavior of mixtures is characterised by the experimental curves “F* – hi/R” (Fig. 2). The experimental curves obtained can be divided into two types. The first type has a plastic deformation section between two inflection points in the range of relative strains of the sample 0.6 ≤ hi/R ≤ 0.9, but no pronounced transitions between the curve sections are recorded.

Under the action of low squeezing stress the structure of viscoplastic mixtures remains stable (“placing phase” [26]). That is the first section of the experimental curves “F* – hi/R” (0.9 ≤ hi/R ≤ 1.0). When the stresses increase at the second section 0.6 ≤ hi/R ≤ 0.9, the system deforms plastically (“perfect plastic response phase” [26]). An increase in stress and intensification of flow in the third section are associated with complete destruction

Fig. 2. Tested 3D-printable mixtures “F* – hi/R” curves

CONSTRUCTION MATERIALS SCIENCE

Table 5

Rheological properties of 3D-printable mixtures

The reference system without fillers is characterised by the lowest value of the Ki(I) = 2.14 kPa. When fillers are added, the yield stress value increases and the plasticity of the mixtures decreases. The system based on crashed limestone (C +CL) is characterised by the yield stress value Ki(I) = 5.27 kPa, i.e. it is the most rigid.

The second inflection point in the curve “F* – hi/R” at hi/R = 0.6 for the system with aleuropelite filler (C+Al) is not fixed. This means that the structure of the viscoplastic mixture is irreversibly destroyed at the first moment of loading. As a result, it loses stability and becomes fluid. Such systems do not have the necessary viscoplastic properties and stability for extrusion.

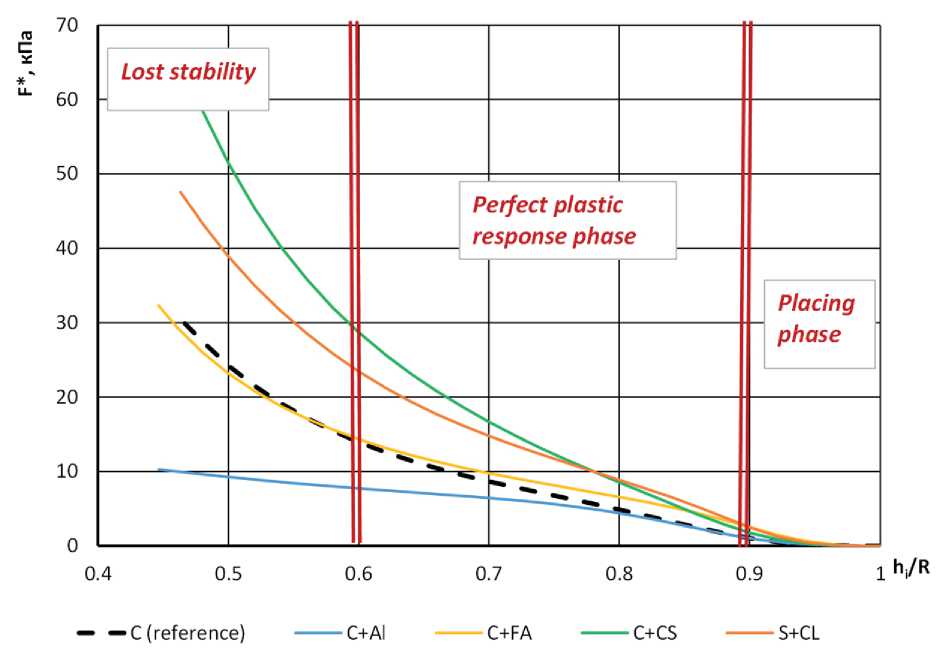

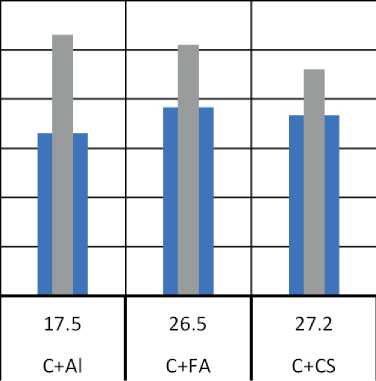

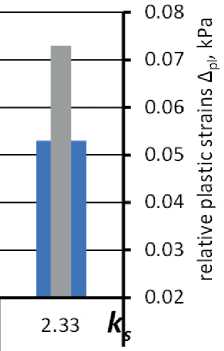

The shape stability of the mixtures was evaluated by the results of the analysis of the curves “load P – displacement ∆” (Fig. 3), which shows that all the investigated systems have similar values of structural strength σ0 = = 0.32–0.45 kPa and plastic strength σpl = 19.6– 23.1 kPa (see Table 5). All systems are characterised by minimal plastic deformation (∆pl < 0.07 mm/mm) under load.

C (reference)

-C+AI ----C+FA ----C+CS ----C+CL

Fig. 3. Tested 3D-printable mixtures “load P – displacement ∆” curves

CONSTRUCTION MATERIALS SCIENCE

The system C+CL shows the lowest values of structural σ0 and plastic σpl strength, and the lowest plastic strains ∆pl (see Table 3, Fig. 3). As a result, the interval between the first crack appearance and fracture is reduced, which indicates the lower stability of the system to the load.

DISCISSION

By evaluating the effectiveness of the influence of numerical filler criteria on the rheological behavior and properties of 3D printable mixtures, it was possible to establish that.

In experimental conditions modelling the visco-plastic flow of mixtures during extrusion (under dynamic conditions), the main factor in ensuring their necessary plastic- ity and aggregation stability is the kinetic factor, associated with the ability of the dispersed phase to float in the dispersion medium and counteract the kinetic energy of external forces and gravity. This requires maintaining a certain critical size of the dispersed phase particles and their high packing density.

This theoretical position is supported by the experimental results. It was found that the most significant factor in regulating the rheological behavior and plasticity parameters of the mixturess is the filler particles size (Fig. 4). The yield stress value Ki(I) increases by 1.7 times and the plastic deformations decrease by 1.4 times when the average size of the filler increases in the range dc = 17.5–40.3 µm. That is to say, there is a directly proportional dependence of the decrease in plasticity of the system with increasing filler

Ed*—dv SCB 匕 S --Is—d Ә--1—£

7 6 5 ООО o.o.o.

4 3 о о о.°-

C+CL Systems

1.05 1.46 1.65

C+AI C+FA C+CS

Fig. 4. Influence of filler particle size (a) and shape (b) on 3D-printable mixtures plasticity

CONSTRUCTION MATERIALS SCIENCE particle size. It is important to emphasise that the ratio of binder (cement) to filler particle size is the determining factor. The systems C+Al, C+FA, C+CS, in which the average filler particle diameter is smaller than or approximately equal to the average cement particle diameter (dc = 22.6 µm), are characterised by an increase in the yield stress value compared to the reference system without fillers was 1.5–1.7 times, and of 2.6 times for the system C+CL (dc = 40.3 µm) it was 2.6 times.

No clear patterns of filler shape influence on the rheological behavior and plasticity of the mixtures were found (see Fig. 4a).

From this it can be concluded that the rheological behavior of mixtures, their plasticity and structural stability under dynamic extrusion conditions is mainly determined by the size and shape of the dispersed phase particles. A necessary condition for the plasticity and aggregation stability of mixtures is the creation of a dense spatial packing of the dispersed phase particles. This is achieved when the filler particles are of a size and multi-size gradation comparable to that of the cement particles.

It has been shown that the rheological behavior and the shape stability of the mixtures are practically independent of the size and shape of the filler particles by simulating the behavior of the mixture under static conditions of layer-by-layer casting. The behavior of heterogeneous microdisperse systems (particle size d ~ 1 100 µm [21]) under static conditions, such as those studied, is determined by the action of gravitational forces (sedimentation factor) and forces of internal interactions (surface phenomena, contact interactions). Particles assemble into spatial structures when the field of action of these forces is equivalent to that of gravity.

The main factor in the stability of the visco-plastic structure under these conditions is hydrodynamic, which determines its dependence on the density and viscosity of the dispersion medium. Their increase reduces the mobility of the disperse phase particles in the dispersion medium and increases the stability of the system. These parameters for the investigated systems were optimised on the basis of previous studies by introducing a complex viscosity modifier “xanthan gum + liquid glass” in an optimal dosage. In this case, the liquid glass, due to its chemical nature, favours the modification of the ionic composition and the viscosity of the dispersion medium, while the xanthan gum particles increase its viscosity and density. As a result, the main factor determining the rheological behavior of mixtures and their shape stability under static conditions of layer-by-layer casting are the properties of the dispersion medium, regulated by the type and concentration of viscosity modifiers.

Therefore, within the design of 3D printable mixtures, the main criteria of fillers are the particle distribution constant Gpc, which characterises the filler particle size gradation, and the average particle diameter dc.

CONCLUSION

The workability of 3D-printable mixtures is determined by their plasticity and structural stability under load during extrusion and layer-by-layer casting.

It has been found that, the creation of a dense spatial packing of disperse phase particles is a necessary condition for the plasticity and aggregation stability of mixtures under dynamic extrusion conditions. Within the design of 3D printable mixtures, the most important properties of fillers have been established:

– the average diameter of filler particles dc, which should not exceed the average diameter of cement particles;

– the particle distribution constant Gpc, which characterises the particle size distribution. The rational range of it value Gpc = 7.5–10 corresponds to the multi-size gradation of the filler particle.

The properties of the fillers are not decisive for the shape stability of the mixtures under the static conditions of layer-by-layer casting. The primary factor is the properties of the liquid phase (dispersion medium), which is regulated by the type and dosage of viscosity modifiers.

Список литературы Rheological behavior of mixtures used in 3d-printing: ex-perimental evaluation of the effectiveness of criteria requirements for filler

- Perrot A. et al. From analytical methods to numerical simulations: A process engineering toolbox for 3D concrete printing. Cement and Concrete Composites. 2021; 122: 104164. https://doi.org/10.1016/j.cemconcomp.2021.104164

- Rehman A.U., Kim J. H.3d concrete printing: A systematic review of rheology. mix designs. mechanical. microstructural. and durability characteristics. Materials. 2021; 14(14): 3800. https://doi.org/10.3390/ma14143800

- Lu B., Weng Y., Li M., Qian Y. Leong K.F., Tan M. J. Qian S. A systematical review of 3D printable cementitious materials. Construction and Building Materials. 2019; 207: 477–490. https://doi.org/10.1016/j.conbuildmat.2019.02.1441

- Ngo T.D., Kashani A., Imbalzano G., et al. Additive manufacturing (3D printing): A review of materials. methods. applications and challenges. Composites Part B: Engineering. 2018; 143:103 – 110.

- Park C., Noh M., Park T. Rheological properties of cementitious materials containing mineral admixtures. Cement and Concrete Research. 2005; 35: 842 – 849.

- S.C., Tay Y.W.D., Panda.B., Tan M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Archives of Civil and Mechanical Engineering. 2018; 18(1): 311 – 319. https://doi.org/10.1016/j.acme.2017.02.008

- Varela H., Barluenga G., Palomar I. Rheology Evaluation of Cement Paste with Nanoclays. Nanosilica and Polymeric Admixtures for Digital Fabrication. RILEM Bookseries. 2020; 28: 144 – 152. 2020. https://doi.org/10.1007/978-3-030-49916-7_15

- Varela H., Barluenga G., Palomar I. Influence of nanoclays on flowability and rheology of SCC pastes. Construction and Building Materials. 2020; 243: 118285. https://doi.org/10.1016/j.conbuildmat.2020.118285

- Kawashima S., Chaouche M., Corr D.J., Shah S.P. Rate of thixotropic rebuilding of cement pastes modified with highly purified attapulgite clays. Cement and Concrete Research. 2013; 53: 112 – 118. https://doi.org/10.1016/j.cemconres.2013.05.019

- Liu Z., Li M., Weng Y., Wong T. N., Tan M. J. Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Construction and Building Materials. 2019; 198: 245 – 255. https://doi.org/10.1016/j.conbuildmat.2018.11.252

- Jiao D., Shi C., Yuan Q., An X., Liu Y., Li H. Effect of constituents on rheological properties of fresh concrete-A review. Construction and Building Materials. 2017; 83: 146–159.

- Ma G., Li Z., Wang L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Construction and Building Materials. 2018. 16: 613 – 627. https://doi.org/10.1016/j.conbuildmat.2017.12.051

- Kazemian A., Yuan X., Cochran E. et al. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Construction and Building Materials. 2017;145: 639–647.

- Chen Y., Zhang Y., Pang B., Liu Z., Liu G. Extrusion-based 3D printing concrete with coarse aggregate: Printability and direction-dependent mechanical performance. Construction and Building Materials. 2021; 296: 123624. https://doi.org/10.1016/j.conbuildmat.2021.123624

- Bai G., Wang L., Ma G., Sanjayan J., Bai M. 3D printing eco-friendly concrete containing under-utilised and waste solids as aggregates. Cement and Concrete Composites. 2021; 120: 104037. https://doi.org/10.1016/j.cemconcomp.2021.104037

- Álvarez-Fernández M.I., Prendes-Gero M.B., González-Nicieza C., Guerrero-Miguel D. J., Martínez-Martínez J.E. Optimum mix design for 3D concrete printing using mining tailings: A case study in Spain. Sustainability. 2021; 13(3): 1 – 14. https://doi.org/10.3390/su13031568

- Ting G.H.A., Tay Y.W.D., Qian Y., Tan M.J. Utilization of recycled glass for 3D concrete printing: rheological and mechanical properties. Journal of Material Cycles and Waste Management. 2019; 29: 00857. https://doi.org/10.1007/s10163-019-00857-x

- Panda B., Ruan S., Unluer C., Tan M.J. Improving the 3D printability of high-volume fly ash mixtures via the use of nano attapulgite clay. Composites Part B Engineering. 2019; 165: 75 – 83.

- Kruglitsky N.N. Essays on physical and chemical mechanics. Naukova Dumka: Kyiv; 1988.

- Uriev N.B. Physico-chemical dynamics of structured nano-dispersed systems and nano-dispersed composite materials. Part 1. Physical chemistry of surfaces and protection of materials. 2010; 46(1): 3 – 23. (In Russian).

- Slavcheva G.S., Artamonova O.V. The rheological behavior of disperse systems for building 3D printing: the problem of management and possibility of «nano» tools // Nanotechnologies in Construction. 2018; 10(3):107 – 122. (In Russian).

- Slavcheva G.S., Razov I.O., Solonina V.A., Panchenko Y.F. Justification of the criteria requirements for fillers in mixtures for 3D construction printing. Nanotechnologies in construction. 2023; 15(4): 310–318. https://doi.org/10.15828/2075-8545-2023-15-4-310-318. – EDN: IFTQOV.

- Slavcheva G.S., Solonina V.A., Panchenko Yu.F., Orlov V.S., Filipenko P.V. Filler type influence on 3d-printable. mixtures fresh properties. Izvestiya vuzov. Stroitel’stvo [News of Higher Educational Institutions. Construction]. 2023; (12): 37–51. (In Russian).

- Slavcheva G.S., Solonina V.A., Panchenko Yu.F., Orlov V.S., Filipenko P.V. Effect of aleuropelite content on fresh and hardened properties of 3D-printable multi-binder composites. Construction of Unique Buildings and Structures. 2023; (109): 10909.

- Toutou Z., Roussel N., Lanos C. The squeezing test: A tool to identify firm cement-based material’s rheological behavior and evaluate their extrusion ability. Cement and Concrete Research. 2005: 35(10): 1891–1899. https://doi.org/10.1016/j.cemconres.2004.09.007

- Slavcheva G., Artamonova O., Babenko D., Ibryaeva A. Effect of Limestone Filler Dosage and Granulometry on the 3D printable Mixture Rheology. IOP Conf. Series: Materials Science and Engineering. V International Conference Safety Problems of Civil Engineering Critical Infrastructures. 2020; 972: 012042. https://doi.org/10.1088/1757-899X/972/1/012042