Small blade and bladelet production in Central Asia at the turn of MIS 7 and 6: cores from Kulbulak layer 23

Автор: Pavlenok G.D., Kogai S.A., Mukhtarov G.A., Pavlenok K.K.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 3 т.52, 2024 года.

Бесплатный доступ

We describe 27 parallel, narrow-faced, and burin-cores for small blades and bladelets from Kulbulak layer 23, Western Tien Shan, excavated in 2016 and 2017. In terms of typology, flat-faced (longitudinal and transverse), prismatic (carinated, subconical, and subcylindrical), and narrow-faced cores (including burin[1]cores) were identified. Scar pattern analysis suggests that regardless of the typological affiliation of cores, a uniform technological scheme was used—staggered sequence of blanks. This Middle Paleolithic non-prismatic pattern probably indicates the initial steps in the formation of a technology that would subsequently influence the Middle Paleolithic blade industries in western Central Asia and become one of the sources for the regional Upper Paleolithic in the second half of MIS 3. It is concluded that small blade technology emerged within Middle Paleolithic industries of western Central Asia at the turn of MIS 7 and 6. In the Obi-Rakhmat industry (MIS 5a), this technology is represented in its fully developed form.

Короткий адрес: https://sciup.org/145147214

IDR: 145147214 | DOI: 10.17746/1563-0110.2024.52.3.030-039

Текст научной статьи Small blade and bladelet production in Central Asia at the turn of MIS 7 and 6: cores from Kulbulak layer 23

Studies of key Stone Age sites in western Central Asia in the 21st century revealed early signs of the most important technological innovations dating back to the Middle Paleolithic. In particular, traces of systematic use of a developed small-blade technique of stone knapping were noted in the archaeological collections of the Obi-Rakhmat cultural affinity from the period of not younger than 80–70 ka BP (Krivoshapkin, 2012). According to the published data, among the Middle Paleolithic complexes from this broad region, the Obi-Rakhmat lithic industry is the only probable basis for developing local Upper Paleolithic industries focused on production of small blades and bladelets (Kolobova, 2014; Kolobova, Krivoshapkin, Pavlenok, 2014; Kolobova et al., 2013; Krivoshapkin et al., 2012).

The data of recent comprehensive geomorphological, sedimentological, and stratigraphic studies (Taratunina et al., 2020) provide the reasonable grounds to classify

the lithic industry of layer 23 at Kulbulak (the period corresponding to the turn of MIS 6 and 7) as the oldest evidence of small-blade production in western Central Asia. This article presents the results of a comprehensive analysis of the small-blade component of the lithic industry of layer 23 (excavations of 2016–2017). The study includes typological analysis, scar pattern analysis, and statistical procedures. The scar pattern analysis was based on the principles described and substantiated by A. Pastoors (Pastoors, Schäfer, 1999; Pastoors, 2000), J. Richter (2001), E. Boёda (2001), M. Kot (2013, 2014), as well as K.A. Kolobova and A.V. Kharevich (Shalagina) (Shalagina, Kolobova, Krivoshapkin, 2019; Kolobova et al., 2019). This method makes it possible to reconstruct the process of preparation of a lithic artifact on the basis of negative scars of removals noticeable on the artifact surfaces, and to determine the sequence of these removals (Kolobova et al., 2022).

Chronostratigraphic position of Kulbulak layer 23

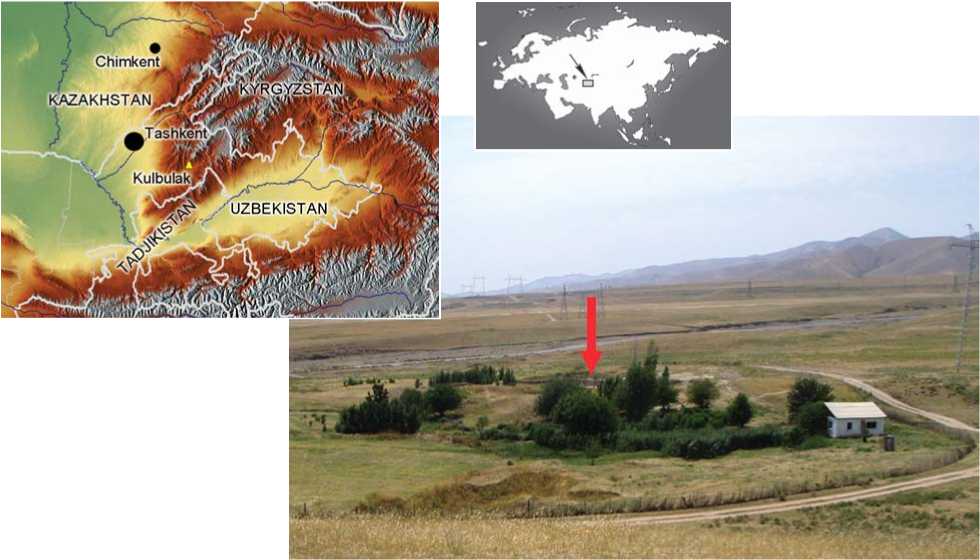

The open-air site of Kulbulak in Eastern Uzbekistan is located near the spring of the same name, on the terraced surface of the left bank of the Kyzyl-Alma sai, a right tributary of the Akhangaran River, at the foot of the southeastern slope of the Chatkal Range (Western Tien Shan) (Fig. 1). In 2007–2019, excavations unearthed the undisturbed deposits in the northwestern corner of pit 3, made during the previous works headed by M.R. Kasymov

(Kasymov, Godin, 1984; Kasymov, Tetyukhin, 1981). Owing to the paucity of data, when determining the age of the oldest cultural strata (layers 24 and 23), we relied on the TL-date of 111 ± 19 ka BP for the closest dated layer 16, which corresponds to MIS 5e (UG-7094) (the date was derived by S. Fedorovich, Department of Geomorphology and Quaternary Geology, University of Gdańsk, Poland) (Pavlenok K.K., Pavlenok G.D., Kurbanov, 2020). Based on the age determinations made for layer 16 and the paleogeographic reconstruction (Taratunina et al., 2020), layers 24 and 25 in the lowermost part of the profile were tentatively attributed to a pronounced warming stage corresponding to the second half of MIS 7 (Pavlenok G.D. et al., 2023).

The deposits of layer 23, overlying layer 24, are composed of light-brown sandy loam, which turns into the gray loam of layer 22 (Fig. 2). These layers correspond to the stage of increasing climatic contrast as compared to the stable conditions characteristic of the period of accumulation of layers 24 and 25. Heavy showers, which were the main cause of erosion of sediments in the area under study, became frequent. This assumption is supported, in particular, by the erosion area between layers 23 and 22 (Fig. 2). The overlying layers 21–18 are alternating proluvial-mudflow sediments with thin interlayers of lacustrine loams of gray and grayish colors. This period of catastrophic mudflow processes can apparently be correlated with the cooling stage corresponding to MIS 6 (Taratunina et al., 2020). Judging by the data of paleogeographic reconstructions, layer 23 can be tentatively correlated to the period of the turn of MIS 7 and 6.

Chimkent

KAZAKHSTAN,

UZBEKISTAN ьй^жЖ//

Fig. 1. Location of the site of Kulbulak.

11.25

“10

11.50

11.75

12.00

12.25

12.50

Fig. 2. Stratigraphic column of the Kulbulak southern profile wall.

a – clay ; b – loam; c – sandy loam; d – loess-like loam; e – carbonate concretions; f – charcoal; g – rubble/crushed stone; h – erosion boundary.

12.75

13.00

13.25

-13.50

13.75

14 00

14.25

14 50

14.75

-15.00

15.25

15.50

15.75

16.00

16.25

ООН

16.50

16.75

17.00

17.25

1 17.50

18 00

18 50

20 J

-18.75

19.75

20 00

24.1

20.25

20 50

20 75

а

b

c

d

e

f

21 00

21.25

g

21.50

h

21.75

22.00 m

Technological context of lithic industry in layer 23

Formerly, the lithic industry of Kulbulak layer 23 (collection 2010; 4997 spec.) was attributed to the early stage of the Obi-Rakhmat cultural tradition (Krivoshapkin, 2012; Krivoshapkin et al., 2010; Kolobova et al., 2018). The technological analysis of the lithic collection 2016–2017 (21,884 spec.) has shown that the primary reduction was based on the Levallois sequence (Pavlenok K.K., Pavlenok G.D., Kurbanov, 2020; Pavlenok et al., 2018). This technology proposes various techniques of preparation of the working surface of cores, which is evidenced by the direction of the negative scars of modifying flakes and facets (Shea, 2013). The industry of layer 23 demonstrates the use of mainly Levallois recurrent centripetal method. Discoidal and orthogonal core reduction techniques were also used for the production of flakes. The Nahr Ibrahim technique was used to obtain truncated-faceted products (Shalagina, Krivoshapkin, Kolobova, 2015). The industry also contains narrow- and wide-faced cores showing signs of simple parallel flaking; the removed blanks include bladelets.

The well-developed Middle Paleolithic complex contains an impressive small-blade component. The objectives of the present study are: examination of blades and bladelets for technological differences; scar pattern analysis of the cores targeted at the production of small blades and bladelets by parallel, narrow-faced, and burin knapping; comprehensive characterization of the smallblade component of the lithic industry.

Description of archaeological materials

The total of 739 lithic artifacts was analyzed from the assemblage of flake found in 2016–2017 in Kulbulak layer 23 (ca 3200 spec.): 589 blades and bladelets (less than 12 mm wide) and 132 core-trimming elements with proportions of blades and bladelets. From the collection of typologically definable cores (173 spec.), all the cores aimed at the production of small blades and bladelets by parallel, narrow-faced, and burin knapping (27 spec.) were analyzed. The rest 146 cores demonstrate the Levallois, orthogonal, or discoidal reduction patterns; longitudinal and transverse flake cores are also present.

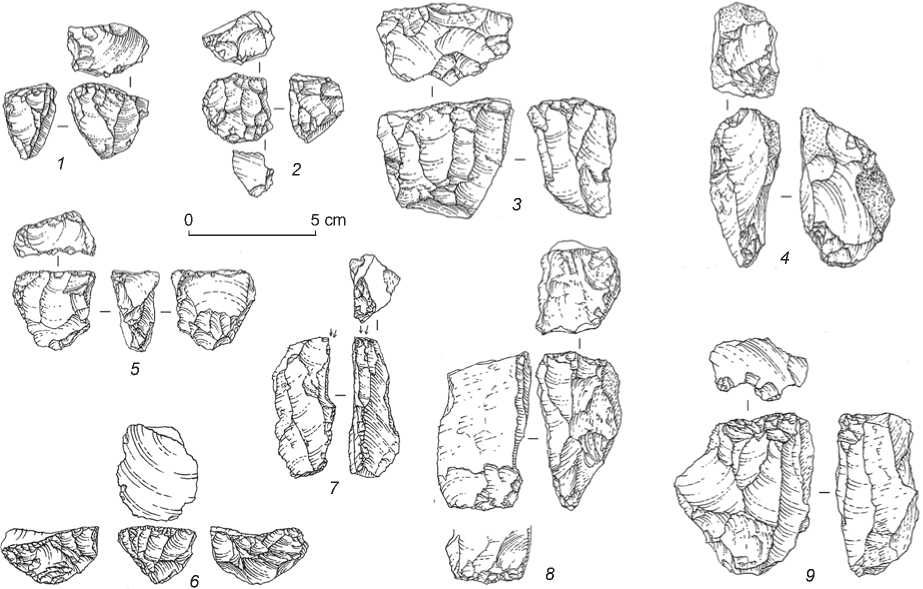

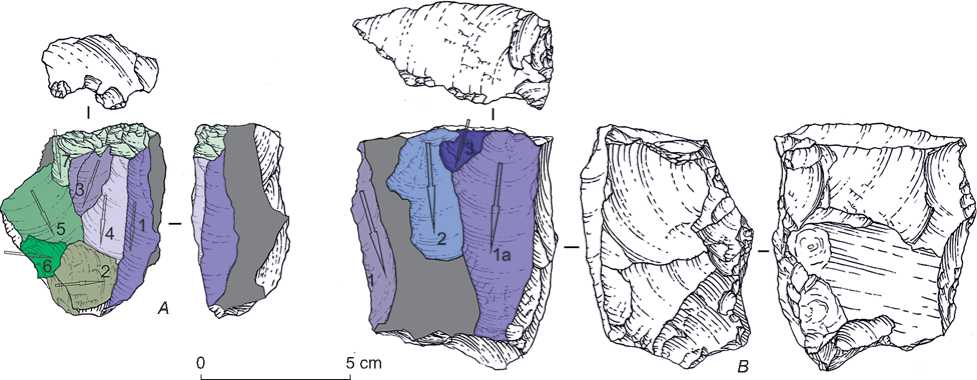

The typological analysis of the sample of 27 cores under study has shown the following varieties: longitudinal (13 spec.), transverse (2 spec.), narrow-faced (6 spec.), subconical (2 spec.), subcylindrical (1 spec.), burin-cores (2 spec.), and carinated (1 spec.). Only one core was made of effusive rock, the other were made of flint.

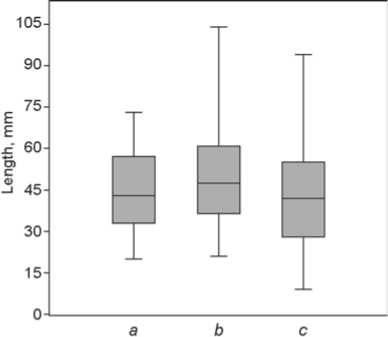

The box plot of the length of cores (27 spec.), complete core-trimming elements with proportions of blades and bladelets (66 spec.), and complete flake-blanks with proportions of blades and bladelets (126 spec.) shows that the ranges of length values of the items in these three categories overlap to a significant extent (Fig. 3). At the same time, the cores (residual product of reduction) are slightly smaller than target and core-trimming elements. This allows the assumption to be made that exactly variously-sized elongated blanks were the target products; bladelets were not a by-product of knapping the cores intended to obtain larger elongated flakes.

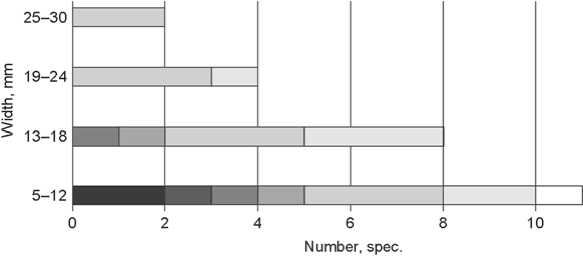

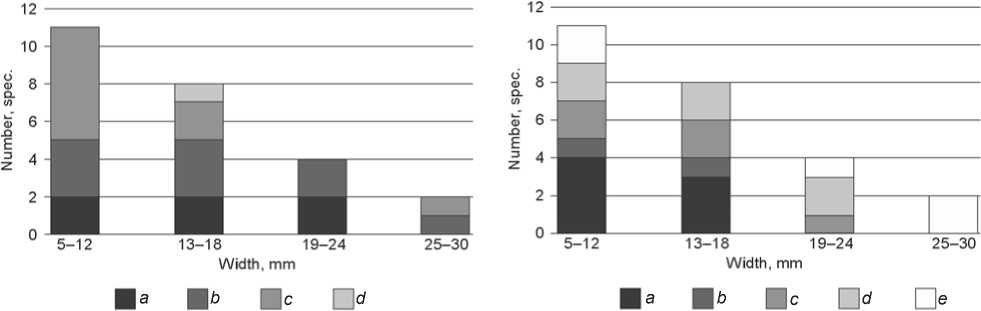

In order to determine whether specialized lithic flaking strategies focused on bladelet production were used, a histogram of the distribution of core types by widths of the latest negative scars was constructed. The category of cores with bladelet negative scars (less than 12 mm wide) and small blades (13–18 mm wide) (Fig. 4) shows the greatest variability in the types of artifacts. A few artifacts—subconical, subcylindrical, carinated, and burin-cores—bear traces of flaking aimed exclusively at bladelet production (Fig. 5).

The relationship between the shape of core flaking surface and the parameters of target spalls (width of the final negative scar) were analyzed. Most of the artifacts (cores with final negative scars from 5 to 24 mm wide) show similarities in the number of oval and rectangular flaking surfaces (Fig. 6, a , b ), and differ in the number of subtriangular flaking surfaces (Fig. 6, c ). More than 50 % of the bladelet cores (≤ 12 mm) bear subtriangular flaking surfaces. In the next size category (13–18 mm), the share of such cores decreases to 25 %. Among the cores with final negative scars 19–24 mm wide, those with the subtriangular flaking surfaces are absent.

The sub-triangular shape of the flaking surface was prepared through rejuvenation of the tip and lateral sides (see Fig. 4, 3–6 , 8 ); only in few cases was it determined by the choice of the blank. The most indicative category is narrow-faced cores: the base was additionally narrowed and sharpened by bifacial retouch on four of the six specimens (see Fig. 4, 4–6 , 8 ). Retouch was observed both over the base zone and lateral zones. The carinated and two longitudinal cores demonstrate similar processing by lateral flaking on both sides (see Fig. 4, 1 , 3 , 6 ).

Fig. 3. Distribution by length of cores for the production of laminar flakes ( a ), core-trimming elements ( b ), and target blade spalls ( c ).

The analysis of distribution of striking platform types has shown that the bladelet cores (5–12 mm) and small blade cores (13–18 mm) bear smooth and natural platforms (Fig. 7). In larger cores, platforms were formed through several removals, or the natural surface was used.

The examination of the preservation stage of the working edge (between the striking platform and the flaking surface) has shown that 7 of 27 cores (26 %) have no traces of rejuvenation. No connection of this feature with the typology of cores and the platform design has

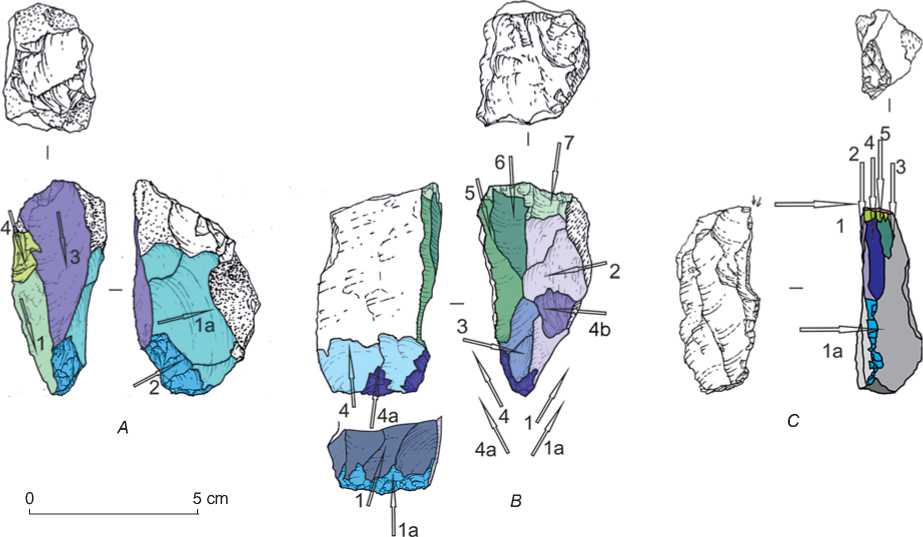

Fig. 4. Small blade and bladelet cores.

с а

□b

□c

d

□e f

g

Fig. 5. Distribution of cores by the width of the final negative scar.

a – subconical; b – subcylindrical; c – burin-cores; d – transverse; e – longitudinal; f – narrowfaced; g – carinated.

Fig. 6. Distribution of cores by the shape of the flaking surface with respect to the final negative scar. a – oval; b – rectangular; c – subtriangular; d – angular.

Fig. 7. Distribution of cores by the type of the striking platform with respect to the width of the final negative scar. a – smooth; b – natural; c – polyhedral; d – faceted; e – fragmented.

been established; therefore, a similar index (lack of rejuvenation of the striking platform edge) was derived for the target spalls; it was 55 %. This allows us to assume that the reduction of core edge was not an integral part of the technological scheme.

Scar pattern analysis

The cores used to obtain small blades and bladelets by parallel, narrow-faced, burin and prismatic (carinated) flaking were analyzed. Scar patterns were reconstructed for two of 13 longitudinal cores, two of 6 narrow-faced cores, two subconical, one subcylindrical, one carinated core, and one of 2 burin-cores.

The analysis of the longitudinal core used for small blade production (see Fig. 4, 9 ; 8, A ) has shown that the main flaking zone was located at the corner between the wide and narrow faces. Most of the narrow-faced surface retains natural crust. The general pattern of negative scars on the flaking surface represents the centripetal reduction strategy; but flaking was carried out from the prepared striking platform only in the longitudinal direction (series of scars 1, 3, 4 in Fig. 8, A ). Flaking directed from the back surface to the left lateral side

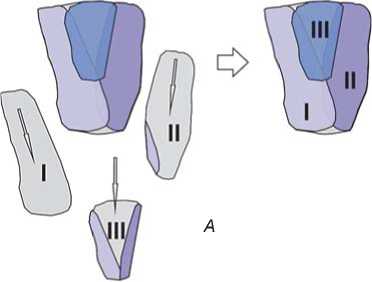

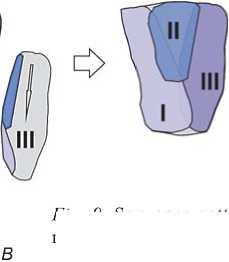

(2, 6, 5, in Fig. 8, A ) was an auxiliary technique, since it was made from situational platforms—negatives of previously removed spalls. The identified location of flaking zone and the orientation of auxiliary spalls show a significant similarity of this scheme to that of asymmetric reduction of blade cores reconstructed on the basis of archaeological materials from the sites in the Tien Shan lowlands dating to the period of MIS 3 and 4 (Kot et al., 2022, 2024). The target laminar removals from the core were made not sequentially (I–II–III), with a gradual shift of the percussion point along the working edge of the core (Fig. 9, B ), but in a staggered sequence (I–III–II). Owing to this strategy, extreme negative scars (series of negatives) I and II formed a central bulge, which was later detached by final removal III (Fig. 9, A ).

A similar scar pattern has been noted on the other longitudinal blade core (see Fig. 8, B ): extreme scars I and Ia form a bulge on the flaking surface, scar II partially removes it.

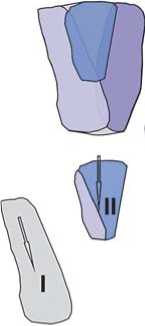

The scar pattern analysis of the narrow-faced cores (see Figs. 4, 4 , 8 ) indicates a similar staggered sequence of blanks (see Fig. 9, A ). A distinctive feature of the reduction of these cores is the use of both transverse flake removals (Fig. 10, A , scars 1a, 2; B , scars 2, 4b) and longitudinal laminar removals (Fig. 10, A , scar 1; B ,

Fig. 8. Longitudinal core reduction schemes.

scar 5) to form the required shape of the flaking surface. The noted fragment of a retouched ridge in the terminal part of the flaking surface on both cores reveals the use of the technique of shaping and removing an initial crest spall (Fig. 10, A , scar series 2; B , scar series 1, 1a, 4, 4a).

The burin-core (see Fig. 4, 7 ; 10, B ) shows a staggered sequence of blanks: the ridge is formed by scar series 2 and scar 3, and then removed by scar 4, followed by rejuvenation of the edge of the striking platform (scar 5).

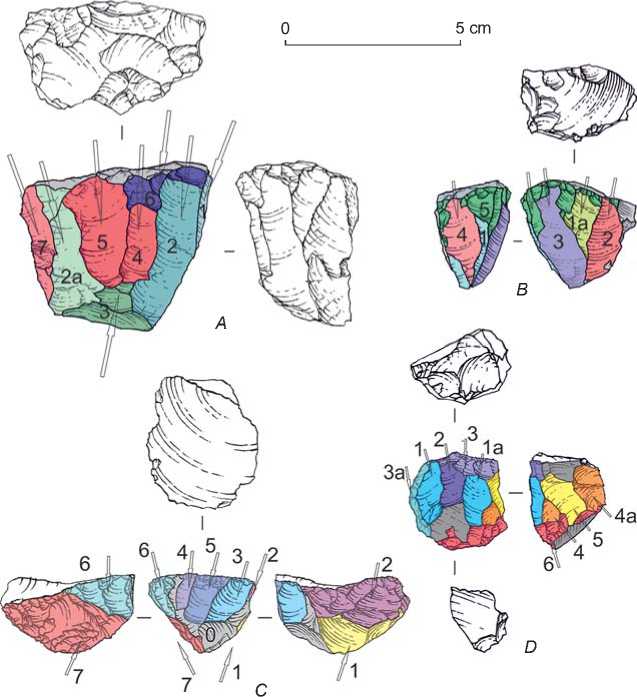

The subconical core (Fig. 11, A ) also shows a staggered sequence of blanks on the flaking surface; initially, the ridge was formed by scars 1, 2 and 2a, and removed by two successive scars (4 and 5) because of the formation of a conchoidal fracture. Scar 7 represents most likely the beginning of a new flaking cycle; at this stage, the ridge was formed by scars 5 and 7, and the final removal was not completed. The other subconical core (Fig. 11, B ) demonstrates a similar design—staggered sequence of blanks on a wide surface: preparatory scars 1 and 1a; medial scar 3; scar 2, which is slightly out of the pattern, at the edge of the flaking surface; and a longitudinal scar on the adjacent narrow surface (scar 4), which is not related to the others.

The examination of the subcylindrical blade core showing bidirectional knapping (Fig. 11, D ) has revealed that flaking was carried out in separate areas of a very long prepared working edge. Area 1 contains preparatory scars 1 and 1a, medial scar 2, modifying scars 3 and 3a. Area 2 on the adjacent surface in the opposite direction contains preparatory scars 4 and 4a, medial scar 5 and retouch 6. Both these areas show a staggered sequence of blanks (I– III–II) (see Fig. 9, B ). Thus, we have identified flaking zones shifted regarding one another, which were flaked from opposite platforms in stages. The use of a similar flaking pattern (semi-rotating bidirectional core) has been recorded in archaeological complexes of the Levant aged

Fig. 9. Sequence patterns of removal of target laminar flakes from cores.

А – staggered sequence; B – linear sequence.

~240–150 thousand years, marking the Early Middle Paleolithic of the regional Stone Age scale (Misliya Cave; layer F of Hayonim Cave, and others) (Meignen, Bar-Yosef, 2020; Zaidner, Weinstein-Evron, 2020).

Three stages can be traced in the knapping process of the carinated core (Fig. 11, B ). Initially, the right lateral side was prepared by scars of group 1 in the course of correction of the rear part and scars of group 2 executed from the striking platform. The next stage was the removal of bladelets from the flaking surface. Two separate

Fig. 10. Narrow-faced core reduction pattern ( A , B ), burin-core reduction pattern ( C ).

Fig. 11. Reduction patterns of subconical ( A , B ), carinated ( C ), and subcylindrical ( D ) cores.

working areas are noted on the flaking surface (area 1 – scars 3, 4 and 5; area 2 – scars of group 6), separated by a fragment of the negative scar related to the so-called zero stage (associated with the shaping of core preform). The first (main) area shows a staggered sequence of blanks (I-III-II): side scars 3 and 4 were detached, then scar 5 was removed between them. In the second area (scar series 6), the scar pattern can hardly be reconstructed. The final stage of reduction of this core included removals on the left lateral side directed from the base (scars 7).

Discussion

The analysis of cores with traces of simple parallel, narrow-faced, burin, and carinated reduction provides a generalized characteristics of non-Levallois blade and small blade production in the industry of Kulbulak layer 23 (2016–2017 collection).

The simple parallel and narrow-faced flaking patterns are most typical in the small blade and bladelet production. The size of the resulting blanks apparently depended on the initial dimensions of the used rocks, the longitudinal/transverse orientation of the core, and on the stage of core exhaustion. This assumption is confirmed by the presence of cores bearing negative scars of both blades and bladelets. It has been shown that the reduction of the working edge of core was not an integral part of the knapping scheme of these cores and other types of nuclei; it was associated with situational decisions in the course of rock knapping. The narrow-faced cores revealed the use of both longitudinal and transverse laminar flaking aimed at achieving the required shape of the flaking surface.

Technological analysis of bladelet cores belonging typologically to the prismatic category (two sub-conical cores, a sub-cylindrical core, and a carinated core) has not revealed any grounds for distinguishing a specialized pattern of volumetric core technique (Boёda, 1988). Scar pattern analysis of the cores has identified small isolated areas on the wide core flaking surfaces of cores bearing three negative scars (or related groups of negatives). All the cores show a staggered sequence of blanks (scheme I-III-II) (see Fig. 9, A ). When choosing a place for staggered flaking on the core surface, preference was given to the most convex areas, on which the converging edges of previous flaking formed the most acute ridge. This algorithm finds parallels with the Levallois reduction sequence, which is one of the main techniques in this complex (Pavlenok K.K., Pavlenok G.D., Kurbanov, 2020; Pavlenok et al., 2018). The use of two flaking zones, offset from each other, was identified on the subcylindrical core; such a technique is known from the Early Middle Paleolithic materials of the Levant (~240–150 ka BP, Misliya Cave; layer F of the

Hayonim Cave, and others) (Meignen, Bar-Yosef, 2020; Zaidner, Weinstein-Evron, 2020).

Another specific feature in the reduction of carinated cores has been established during a recent study of the Upper Paleolithic carinated cores from Kulbulak (Kolobova et al., 2022; Kolobova at al., in press). The reduction sequence of some carinated cores included the multiple (up to three episodes) production of target blanks from the flaking surface: the spall removals alternated with rejuvenation of the surface by corrective flaking and/ or overhang trimming. The core under discussion from layer 23 (collection of 2016) reveals only one episode of bladelet removal from the core flaking surface.

Conclusions

The results of the analysis of blade and bladelet cores from Kulbulak layer 23 (2016–2017 excavations) indicate the existence of variable small-blade production in the Western Tien Shan during the period corresponding to the turn of MIS 7 and 6. Residual cores have been attributed to various types: longitudinal, narrow-faced, subcylindrical, subconical, as well as specific cores-burins and a carinated core. However, the noted scar pattern is based on the uniform staggered sequence of blanks (I– III–II). No traces of volumetric core technique has been identified, i.e. in terms of technology, subconical cores fell within the same category with longitudinal and narrowfaced cores, where the reduction strategy was targeted at detaching both small blades and bladelets. The use of the semi-rotating bidirectional core reduction strategy, which was represented on the exhausted subcylindrical core, makes it possible to draw parallels between the studied complex and the Early Middle Paleolithic complexes of the Levant, where similar cores were used to produce small blades and bladelets. Thus, the reduction of burincores and a carinated core, which demonstrate staggered sequence of blanks, was aimed exclusively at bladelets. This scar pattern is fully consistent with the general technological and chronological contexts of the studied industry. The noted Middle Paleolithic approach to removing small blades and bladelets characterizes the early stages of the development of small-blade technology in western Central Asia.

It should also be noted that the core reduction strategy involved the use of techniques typical of the Upper Paleolithic small blade technology: special rejuvenation of the rear parts, detachment of lateral spalls to control the width and shape of the flaking surfaces of cores. This observation is consistent with the previous assumptions that the Obi-Rakhmat industries aged ca 80 ka BP (MIS 5a) demonstrated the well-developed small blade reduction technology. Archaeological materials and the chronological position of Kulbulak layer 23 confirm that by that time (MIS 5a), the technique of removing bladelets from various forms of cores had already become widely used by the inhabitants of the region, and had undergone evolutionary changes, which resulted in the growing variability of the resulting products (cores, core-trimming elements, and bladelets). This technological tradition reached an important milestone in its development in the Upper Paleolithic (MIS 2 to the second half of MIS 3), when the small blade component took a dominant position in the structure of regional Stone Age industries.

Acknowledgments

This study was supported by the Russian Science Foundation, Project No. 22-18-00649 “Dispersal of Anatomically Modern Humans in Western Central Asia in the Middle to Upper Paleolithic: Chronology of Migration Processes” (analysis of archaeological materials), Project No. 22-18-00568 “Initial Human Dispersal Across Central Asia: Archaeology, Chronology, and Paleogeography of the Loess Paleolithic” (age assessment of the archaeological complex).