Stone Age Ivory Points from the Arctic Zone of Northeast Asia

Автор: Kandyba A.V., Zotkina L.V., Grigoriev S.E., Fedorov S.E., Cheprasov M.Y., Novgorodov G.P., Petrozhitskiy A.V., Kuleshov D.V., Parkhomchuk V.V.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 4 т.51, 2023 года.

Бесплатный доступ

We give a technological and typological description of two well-preserved points (one fragmented rod-shaped, the other double-slotted), made of mammoth ivory and found in the Ust-Yansky District of Sakha-Yakutia in 2016. Traces evidencing various stages of manufacture are described in detail. A succession of technological operations is reconstructed, from the preparation of preforms and further processing by planing and abrasion to final polishing. Spall negatives on artifacts are interpreted as post-depositional damage that could have occurred from the effect of cryogenic processes in sediments. The slotted specimen is decorated with five finely engraved arrows. The discovery context and the morphology of the rod-shaped specimen are similar to those of ivory points from the Yana sites, whereas the slotted one resembles those from Zhokhovo and other Northeast Asian sites of the same age. Radiocarbon analysis of the points supports these findings. The following conclusions are reached: the rod-shaped point dates to MIS 3, and the slotted one, to MIS 2; such points evidence an elaborate technology of ivory processing during the Late Pleistocene and Early Holocene in the high latitudes of Northeast Asia and an adaptation to the scarcity of lithic raw material in the region.

Northeast Asia, Pleistocene, Holocene, mammoth ivory, ivory points, traceological analysis

Короткий адрес: https://sciup.org/145146952

IDR: 145146952 | DOI: 10.17746/1563-0110.2023.51.4.025-034

Текст научной статьи Stone Age Ivory Points from the Arctic Zone of Northeast Asia

Mammoth tusks have been used as a raw material in the manufacture of tools, weapons, personal ornaments, and symbolic items since remote antiquity; this is one of the striking examples of human adaptation strategies, and one of the important components of the material culture of ancient humans. The manufacture of hunting tools from tusk points not only to the availability of bone resources, but also to the fact that this material was stronger than stone or wood, which were rare in the tundra-steppe landscapes of the Arctic zone of Northeast Asia (Albrecht, 1977; Basilyan et al., 2011). Among other ways, osseous raw materials were obtained through hunting (Nikolskiy, Pitulko, 2013). Getting mammoth ivory, which was used to make weapons, was one of the main goals of hunting (Pitulko, Pavlova, Nikolskiy, 2015). Therefore, the sites evidencing human habitation during the Paleolithic are usually associated with large clusters of faunal remains, the most famous of which are Berelekhskoye (Vereshchagin, 1977; Pitulko, Basilyan, Pavlova, 2014; Pitulko, Pavlova, Basilyan, 2014) and one of the localities of the Yana complex (Basilyan et al., 2011). In recent decades, several paleontological sites have been discovered, including those containing archaeological materials (Cheprasov et al., 2015; Dyakonov et al., 2020; Kandyba, Dyakonov, Pavlov et al., 2020; Kandyba, Zotkina, Pavlov et al., 2022; Pavlov, Suzuki, 2020). In general, in the Arctic zone of Northeast Asia, relatively few Stone Age sites of the Late Pleistocene and Early Holocene have been found (Pitulko et al., 2015; Pitulko, Pavlova, Nikolskiy, 2017; Pitulko, Pavlova, 2019). For that reason, isolated indicative finds from this region—animal bones with traces of anthropogenic impact—are important for science, and provide solid grounds for establishing the earliest evidence of ancient human habitation in this region (Pitulko et al., 2015; Pitulko, Pavlova, Nikolskiy, 2017; Pitulko, Pavlova, 2019); the same is true for solitary artifacts marking the zone of human activity in the region during the periods corresponding to MIS 3 and 2 (Kandyba, Grigoriev, Tikhonov et al., 2015; Kandyba, Fedorov, Dmitriev et al., 2015).

The technology of production of ivory implements is quite specific. S.A. Semenov (1957: 180–184, fig. 74– 76), a Soviet scholar, was among the first archaeologists to pay special attention to this aspect. Experts studied the sequences of chaîne opératoire in preparing tool blanks (Gerasimov, 1941; Filippov, 1978; Khlopachev, 2006; Khlopachev, Girya, 2010; Tartar, White, 2013), and techniques of the manufacture of personal ornaments (Otte, 1974; Poplin, 1995; White, 1993, 1997). The most amazing collection of ivory artifacts from the Arctic zone of Northeast Asia has been reported from the Yana sites (Pitulko, Nikolskiy, Girya et al., 2004; Pitulko et al., 2012;

Pitulko, Nikolskiy, Basilyan et al., 2013; Pitulko, Pavlova, Nikolskiy, 2015). Some objects discovered outside the stratigraphic context provide information about the cultural and chronological range of their manufacture and use. These artifacts are studied in terms of mammoth tusk processing techniques and use-wear.

The points found in 2016 in the Ust-Yansky District of the Republic of Sakha (Yakutia) (hereinafter RS(Y)) (Grigoriev et al., 2017) were subjected to use-wear analysis. A double-slotted point was discovered by local residents of the Tumat village, Ust-Yansky District RS(Y), in the tundra zone, on the bank of the Krestyakh River (a tributary of the Syalakh River) (71°14′10.86′′ N, 140°1′39.68′′ E). A fragmented rod-shaped point was found by local residents of the Kazachiye village, Ust-Yansky District RS(Y), at the Yana mammoth cemetery in the lower reaches of the Yana River (70°43′25.25′′ N, 135°24′47.62′′ E). In 2017, the artifacts were deposited at the Mammoth Museum of the Research Institute of Applied Ecology of the North of the Ammosov NorthEastern Federal University, where they are recorded as MM-A18 and MM-A19.

This article provides the results of the cultural and chronological attribution of the mammoth ivory artifacts found outside the stratigraphic context, carried out using an integrated approach.

Methods

The ivory points have been subjected to technical-typological, experimental-traceological*, and radiocarbon analyses. The manufacturing techniques and types of the items—the main characteristics for cultural attribution— have been analyzed by technical-typological methods. This reveals deviations in behavior and raw material selection that emerged during adaptation to a particular environment by convergence, or due to migration flows. Points with specific technical and typological characteristics should occur in stratified sites that are close (or supposedly close) in age and similar in cultural and technological features.

The basic technical operations involved in the manufacture of the items have been reconstructed by the experimental-traceological method (Semenov, 1957; Keeley, 1980).

The study of artifacts was carried out in stages and involved an assessment of the state of preservation of the items, a preliminary examination using a stereoscopic microscope to identify use-wear signs, their comparison with published data, and a small series of experiments aimed at identification of basic techniques of tusk processing with stone tools. The final stage of the work involved a detailed study of artifacts using a microscope at low (up to ×50) and high (from ×50 to ×300) magnifications in order to interpret the use-wear traces on the artifacts.

The analysis was carried out using an Olympus SZX7 stereoscopic microscope (×8 to ×56) and an Olympus BHMJ metallographic microscope (×50 to ×300). Photographic recording of artifacts and use-wear signs on their surfaces was carried out by a Nikon D750 full-matrix camera; macro- and microfeatures were recorded remotely from microscopes using Nikon Pro Camera Control software. To obtain the best resolution photographs, the stacking technique was used (taking multiple images at different focus distances); combining of stacks was carried out using the Helicon Focus software.

For a proper interpretation of the traces on the ivory points, we used the published findings (Villa, d’Errico, 2001; Maigrot, 2003; Mazza et al., 2014; Haynes, 2017; Augustin et al., 2019; Thun Hohenstein, Gargani, Bertolini, 2020). The monograph by G.A. Khlopachev and E.Y. Girya “Secrets of Ancient Bone Cutters of Eastern Europe and Siberia: Techniques for Processing Mammoth Tusk and Reindeer Antlers in the Stone Age (Based on Archaeological and Experimental Data)” (2010) was taken as a main reference publication.

Notably, the traces of processing can be reliably classified into three main categories (technological, functional, and post-depositional), but not on all the artifacts. This concerns the objects with an unknown context of occurrence. Therefore, the origins of some traces can only be hypothesized.

The chronological position was established through the radiocarbon analysis of the samples that were drilled out from the inside of the points. Chemical preparation of the samples was carried out in the Laboratory for Isotope Research of the Institute of Archaeology and Ethnography SB RAS. Fragments of bone samples were washed with distilled water, dried at room temperature, and ground into powder using a FreezerMill cryogenic homogenizer. After this, the powder of each sample was placed into the cell of an ASE350 automatic extractor, washed with methylene chloride at room temperature once, and then dried. At the following stage, the bone powder was demineralized by treating it with a 0.5 M aqueous solution of HCl at room temperature and washing with water up to pH = 7, then the powder was treated with a 0.05 M aqueous solution of NaOH at room temperature for 15 minutes, washed with distilled water up to pH = 7, and was re-treated with a 0.5 M HCl solution at room temperature for 30 min. After this, the powder was washed with distilled water up to pH = 3 and kept at this acidity and 70 °C for 12 hours. Then the solution was separated from the sediment by centrifugation on an LMC-3000 device at a speed of 3000 rpm for 3 minutes; the solution was placed into test tubes, centrifuged again at 14,500 rpm for 70 min, separated from the sediment, and dried at 70 °C to get collagen powder.

The next stage was the procedure of graphitization of collagen at AGE-3, pressing each 1 mg of carbon into targets, which were subjected to radiocarbon analysis at the unique scientific device “Accelerator Mass Spectrometer of the Institute of Nuclear Physics SB RAS”. In addition to research samples, standard samples of oxalic acid OxI and sucrose ANU were also subjected to the graphitization procedure. The relative content of 14C/13C radiocarbon in research samples was calculated as the average of two parallel graphite targets, and normalized by the 14C/13C content in the standards.

Materials

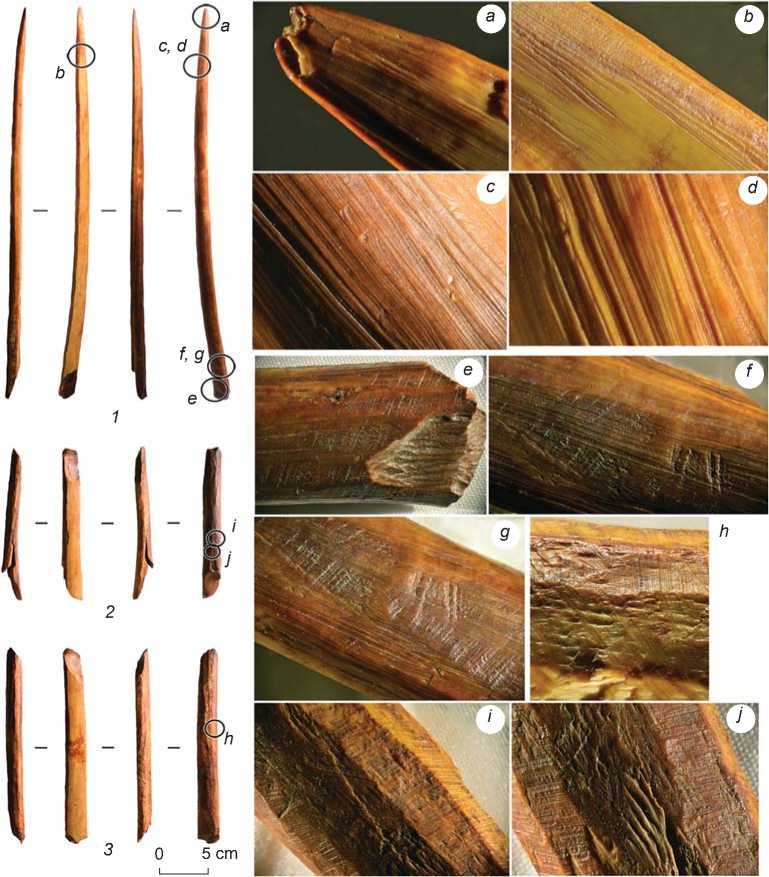

Artifact 1 is a fragmented, slightly curved rod-shaped head of a spear or dart, with a total length of 75 cm. Three fragments of the item were found; two of them (2, 3) can be refitted (Fig. 1). The fragment between parts 1 and 2 is missing.

Fragment 1 (distal) (Fig. 1, A , 1 ) is the largest (ca 39 cm) in the set. The tip is slightly damaged, possibly owing to post-depositional processes, because this is the most fragile part (Fig. 1, B , a ). The proximal part is also damaged; the spalls are visible on both sides (Fig. 1, B , e ). The surface of the cementum layer of the tusk is well preserved (Fig. 1, B , b ).

Traces of planing are present on almost the entire surface of the fragment: long transverse, most often parallel or intersecting at an acute angle, overcuts of the tusk’s surface (Fig. 1, B , c , d ; 2, a , b ). Moreover, these grooves are considerably long and continuous, which indicates the use of a tool with a handle, possibly a two-handed tool (Khlopachev, Girya, 2010: 104, fig. 130–131). Starting from the medial part, the surface is “stepped” and overlapped by planing marks. In the proximal part, there are series of transverse, oblique, linear parallel traces, concentrated on several surfaces that form the round shape of the item (see Fig. 1, B , e ). This combination of signs suggests the hewing of small longitudinal sections and the subsequent abrasion of the surface. Since, near the proximal edge, there is an obvious overlap of these oblique marks by planing (see Fig. 1, B , f ), it can be concluded that the preform was first hewn, then the resulting faces were flattened by abrasion (see Fig. Fig. 2, c–f ); the final stage of smoothing involved planing (see Fig. 1, B , f , g ; 2, a , b ). Moreover, the final operation was carried out from the tip and continued in the medial part. The cementum layer shows planing marks mainly in the distal part, closer to the tip (see Fig. 1, B , b ).

АB

Fig. 1. Rod-shaped point.

A : 1–3 – general view of fragments; B: a – damage at the tip of fragment 1 (×20 magnification); b – traces of planing, partially extending to the area with cementum layer on fragment 1 (×20 magnification); c , d – traces of planing on fragment 1 (×20 and ×40 magnification, respectively); e – combination of traces of abrasion of the hewn surface and traces of planing, a negative scar in the proximal part of fragment 1 (×8 magnification); f , g – combination of traces of scraping and planing, including mutual overlaps in the proximal part of fragment 1 (×10 magnification), h – change in the orientation of traces of abrasion (scraping) of the hewn faces of fragment 3 due to a change in the position of the processed blank (×10 magnification); i , j – differently oriented traces of scraping of hewn sections of the blank on fragment 2 (×10 and ×20 magnification, respectively). Photo by L.V. Zotkina .

The boundaries of the cementum layer in other sections are very even and straight.

Fragment 2 (medial) (see Fig. 1, A , 2 ). Negative scars in the distal part are on the side of the cementum layer (do not refit with fragment 1), those in the proximal part are on the side of the prepared surface (refit with fragment 3).

The boundaries of the cementum layer are quite distinct, with the exception of the left edge in the medial part, damaged by two removals. The prepared surface shows characteristic longitudinally oriented faces, forming a rounded shape. The boundaries of almost all the faces are uneven, but well-flattened by abrasion, which is suggested by the transversely and diagonally oriented short parallel linear marks. Thus, the preform was hewn and then subjected to abrasion in order to flatten and smooth the surface. Linear marks along the entire length of the fragment, on each surface, are almost always oriented in the same direction. A change in the orientation of abrasion (scraping) marks is noted only in areas where the artisan, having completed the cutting off of one face, began to work on the other face; when the position of the item changed, the direction of the traces changed slightly (see Fig. 1, B, i, j). This suggests the use of a sufficiently large abrasive tool, which ensured contact of its active part with the processed surface along almost the entire length of each face, rather than along its particular parts.

Fragment 3 (proximal) (see Fig. 1, A , 3 ). Negative scars are observed in the proximal and distal parts. The distal part refits with fragment 2, although even in the section where the edges of the two fragments fit one another, a small facet of removal is visible on the side of the cementum layer, whose negative is recorded lower in the same section. In the distal part, the removal facet is on the side of the cementum layer; in the proximal part, on the treated side.

Identical hewing scars flattened by scraping are noted. However, closer to the proximal end, more pronounced stepped effect and solitary negative hewing scars are recorded on the surface of the fragment (Ibid.: 119, fig. 153–155) (Fig. 1, B , h ). In addition, the right edge (from the side of the cementum layer) shows a stepped surface caused by hewing; the tool moved from the tip to the proximal end. Closer to the proximal part, a large and deep dent is noted on the prepared surface, which covers the signs of working; its edges were not flattened or smoothed during scraping. The dent occurred most likely accidentally and was not associated with deliberate working, although the shape of the dent resembles the trace from a chopping tool.

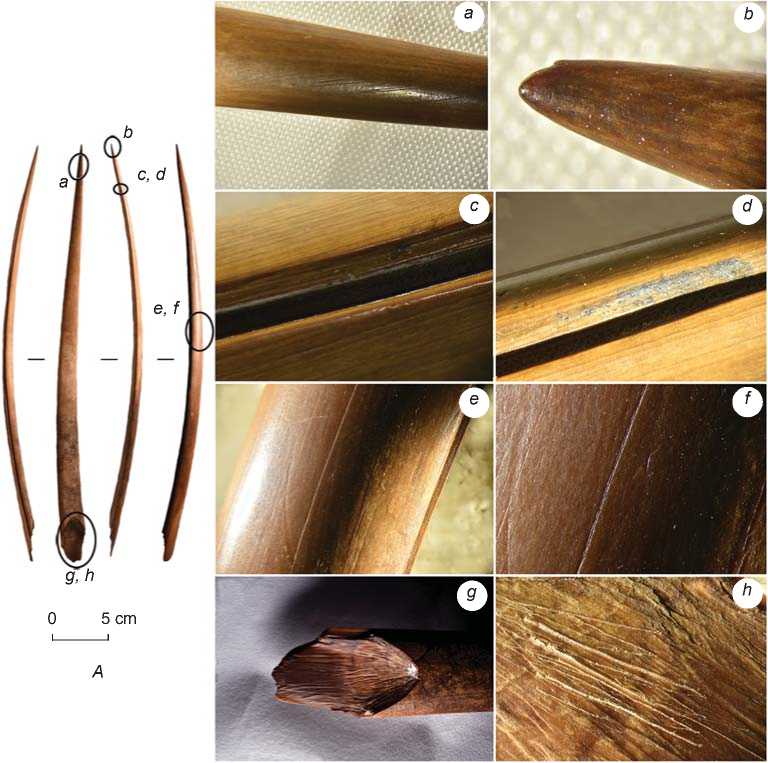

Artifact 2 is a well-preserved slotted point, 56 cm long (Fig. 3, A, 1). It shows rare and minor fresh scratches that may due to transportation. The proximal part is fragmented, a “tongued” negative scar is observed, which is most often interpreted as a breakage during tusk deposition in frozen soil (Ibid.: 96, fig. 115). The surface reveals a series of rather deep scratches, which may also be associated with post-depositional processes (Fig. 3, B, g, h). A bright polish with irregular linear traces of various sizes and directions (Fig. 4, a, b, e, f) is noted over almost the entire surface of the artifact and is a sign of intense polishing at the final stage of processing. An intense polish is also observed along the edges of the slots, but currently it is not possible to distinguish between the polishing at the final stage of the artifact’s processing and the use-wear traces. Two zones of black deposit are visible in one section along the edge of the point (see Fig. 3, B, c, d); perhaps these are the areas bearing the remains of the adhesive substance that fastened the microliths constituting the working edge.

A small damage was noted at the tip of the point; the damaged area was polished in the same way (see Fig. 3, B , b ) as the entire item (see Fig. 4). This slight unevenness could have appeared on the tip during manufacture or use.

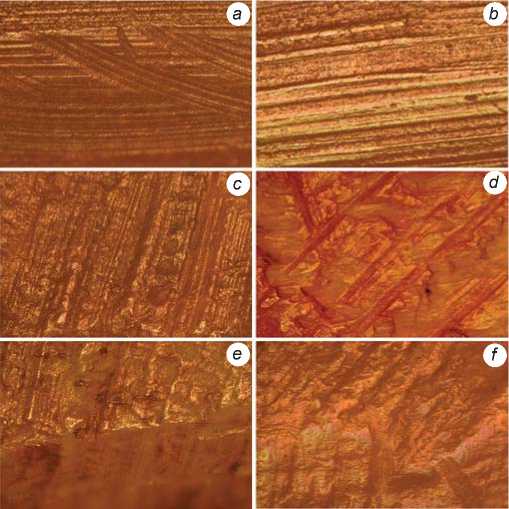

Fig. 2. Rod-shaped point.

a , b – traces of planing on fragment 1 (×50 magnification); c , d – traces of abrasion (scraping) of hewn sections on fragment 3 (×100 and ×50 magnification, respectively); e , f – traces of abrasion (scraping) of hewn sections on fragment 2 (×50 and ×100 magnification, respectively). Photo by L.V. Zotkina .

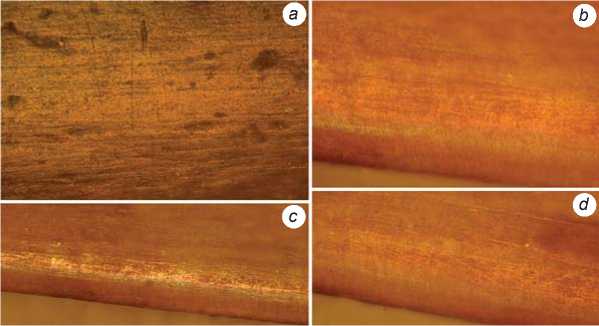

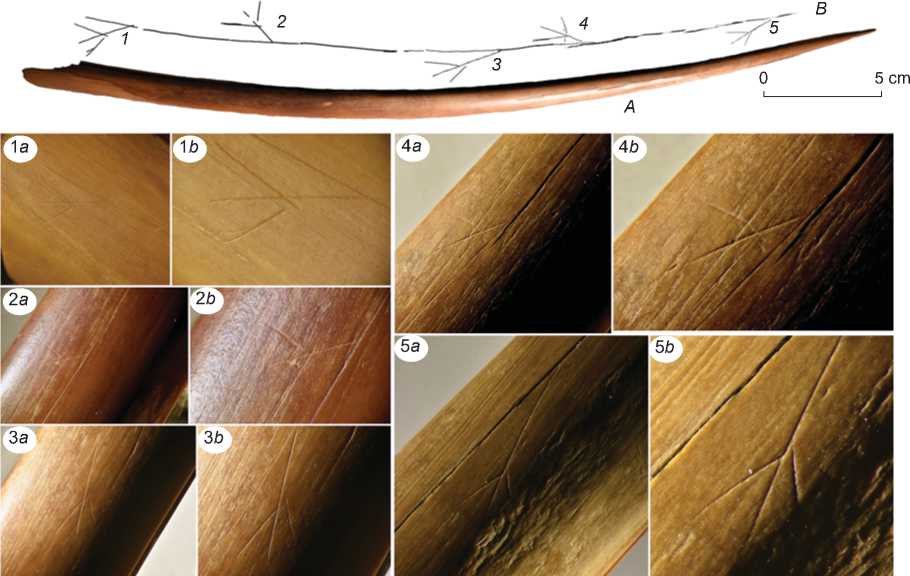

In addition to random minor scratches, there are some deliberate longitudinal engraved lines on the surface of the artifact (see Fig. 3, B, a). On the outer (convex) surface of the item, several thin lines made mostly with one reverse movement (cutting) are observed, forming an ornament of five “arrows” (Fig. 5, B); the arrows alternately extend to the right and left from the central line. In the area of “arrow” 4 (the second arrow from the tip), the central line turns into a crack (Fig. 5, B, 4a, 4b). Thus, the “arrow” closest to the tip runs from this crack rather than from the central line (Fig. 5, B, 5a, 5b). The “arrows” are formed by three lines (see, e.g., Fig. 5, 1b). First, a central line was engraved “running” from the main line stretching along the entire item; then two short notches were made, which were drawn from one point in opposite directions (longitudinally and transversely to the axis of the item), forming an arrow. The peculiarity of the ornament is due to the texture of the material. Longitudinal lines were drawn easily and did not change the trajectory planned by the artisan, because it followed the texture of the material. Transverse notches sometimes turned out with small fractures or parasite lines, which could occur owing to a greater resistance of the material, when the movement of the working part of the tool was directed against the fibers. This fine ornamentation was more visible on the fresh surface of the tusk than it is today.

B

Fig. 3. Slotted point.

A – general view of the artifact in four projections; B: a – polishing and a series of longitudinal linear marks at the tip (×12.5 magnification); b – smoothed tip of the point (×56 magnification); c , d – slot retaining the remains of black presumably organic substance (×40 magnification); e , f – polished surface in the medial part, typical of the entire item, and fine engravings on the outer side (×10 and ×32 magnification, respectively); g , h – negative scar in the proximal part of the item and macrophoto of scratches on the negative scar (×16 magnification). Photo by L.V. Zotkina.

Fig. 4. Polished sections on the slotted point.

a – at the tip (×100 magnification); b–d – along the edges of the slots in various areas of the item, on the inner and outer sides of the slots (×100, ×50 and ×50 magnification, respectively). Photo by L.V. Zotkina.

Results

Technological characteristics

The technique of cutting slots made it possible to produce a long blank for the rodshaped point and to retain the cementum layer surface (Ibid.: 120, fig. 97, 160); but in the region, the artisan most often used the wedging technique for such purpose (Pitulko, Pavlova, Nikolskiy, 2015). When the long longitudinal tusk-fragment was produced, the surface without a cementum layer was hewn out to round the shape in the cross-section; at that stage, a stepped relief was formed. To smooth it out, the surface was processed with an abrasive tool

C

Fig. 5. Photo of slotted point ( A ), tracing of the ornament ( B ), photos of the elements ( C ).

1 a , b – the first “arrow” from the bottom, consisting of three fine engraved lines connected to a central longitudinal engraved line running along the entire outer side of the point (×10 and ×25 magnification, respectively); 2 a , b – the second “arrow” from the bottom (×10 and ×25 magnification, respectively); 3 a , b – the third “arrow” from the bottom (×10 and ×16 magnification, respectively); 4 a , b – the fourth “arrow” from the bottom, connecting to the central engraved line running under the crack (×10 and ×25 magnification, respectively); 5 a , b – the fifth “arrow” from the bottom, running under the crack (×10 and ×32 magnification, respectively). Photo by L.V. Zotkina.

(see Fig. 2, c–f ). Grinding movements, most often oblique, were performed across the long axis of the workpiece. The abrasive surface was rather large, which ensured its contact with the treated faces simultaneously over almost the entire workpiece. The item was gradually rotated so as to smooth out each face. The final stage of processing was planing (see Fig. 2, a , b ): it was presumably carried out with a two-handed tool, which made it possible to work out fairly extended areas of the surface, from the tip to the medial part. The cementum layer was planed only at the tip. Judging by the fact that smoothing by scraping and planing of the hewn areas was not completed, the item is an unfinished blank. The final stage of processing probably involved polishing. Fragmentation of the point could have occurred as a result of cryogenic deformations in sediments, which assumption is supported by the transverse fracture that separated fragments 2 and 3.

The morphological features of the slotted point suggest wedging of the tusk or sawing through the slots, with the subsequent separation of the longitudinal fragment from the main body of the tusk. It is possible that the item was not unbended, but was used in its original curved form. However, available parallels suggest that the blank was most likely undended by soaking and fastening it in a log groove under pressure*. After that, the blank was flattened by planing, and the entire surface was smoothed. Two slots were cut at the sides. Traces of planing and, especially, of primary fragmentation to get a blank have not been recorded, because these processes preceded the polishing. At the final production stage, the item was polished, probably with a soft material, such as leather/hide with addition of fat.

Radiocarbon age and available parallels

The radiocarbon age of the rod-shaped point is 32,858– 32,143 BP (GV-03658), that of the slotted point, 14,236– 14,094 BP (GV-03659)**, i.e., the items belong to the periods of MIS 3 and 2. Long ivory blanks, as well as the evidence of their production at that time, occur widely in Arctic Siberia (Pitulko, Pavlova, Nikolskiy, 2015; 2017: 134–135, fig. 7). Among the finds, the most noteworthy is a series of the Yana osseous items revealing the chaîne opératoire from the initial processing of raw material to the final stages of tool shaping. This technology involves longitudinal splitting and unbending of the tusk, processing of the resulting blanks, and production of rods with rectangular cross-sections. The method of longitudinal wedging and, probably, the technology of extraction (groove-and-splinter technique), used in production of long blanks, can be considered the main techniques of longitudinal splitting of complete tusks. Long blanks for the manufacture of rods for spears and darts produced by these techniques are typologically close to the Yana and Berelekh ivory artifacts (Vereshchagin, 1977; Pitulko, Pavlova, Nikolskiy, 2015). Evidence of the use of the longitudinal splitting technique in blank production is recorded at the sites dating to the turn of the Pleistocene and Holocene, such as Urez-22, Ozero Nikita, Ilin-Syalakh (Pitulko, Basilyan, Pavlova, 2014). Parallels to the slotted point are recorded among the finds from Zhokhovo (Pitulko, 1998), which are close to the artifacts in question in their radiocarbon age, although the ivory resource at this site was insufficient owing to the reduction of the mammoth steppe biome at the turn of the Pleistocene and Holocene (Pitulko, Kasparov, Pavlova, 2018). Notably, the ornament in the form of a series of “arrows” noted on the slotted point has not yet been recorded on any other finds from the region.

The extensive use of mammoth ivory in the Arctic zone of Northeast Asia is evidenced not only by the artifacts from archaeological sites, but also by isolated significant finds. These are the cores made of mammoth tusk from the Novaya Sibir Island; a mammoth ivory debitage discovered near the village of Zyryanka on the Kolyma River (Pitulko, Pavlova, Nikolskiy, 2015); and mammoth ivory debitage, as well as bones of mammoth, bison, and horse, fragmented by humans, at the Irelyakh-Siene site (Cheprasov et al., 2015). Thus, we assume the existence during the Late Pleistocene and Early Holocene in Northeast Asia of a vast territory inhabited by ancient populations having technologically and typologically similar osseous industries and common raw-material preferences.

Conclusions

Many Upper Paleolithic sites in Northern Eurasia contain hunting osseous tools that suggest the emergence of an effective technology of making tools from mammoth ivory and the adaptation of this technology to various climatic fluctuations. For the ancient hunters settling in the mammoth steppe, this animal was one of the main vital resources, the effective use of which is confirmed by finds—animal bones with fragments of ivory weapons stuck therein (Pitulko, Nikolskiy, Basilyan et al., 2013) and fragments of stone points presented in osteological collections (Nikolskiy, Pitulko, 2013). The Upper Paleolithic archaeological sites are often situated near concentrations of faunal remains. The evidence of the hunting practices of ancient populations provided at such localities as Sopochnaya Karga (Pitulko, 2016) and Lugovskoye (Zenin et al., 2006) indicates the effective development of hunting tactics based on the use of projectile weapons, ensuring successful exploitation of the fauna of open landscapes of the former Holarctic tundra-steppe zone. Other archaeological complexes— Malta (Sitlivy, Medvedev, Lipnina, 1997), Afontova Gora (Astakhov, 1999), and Sungir (Bader, 1998; Soldatova, 2014)—have no concentrations of paleontological material, although the remains of the mammoth fauna and hunting tools, personal ornaments, and symbolic items made from ivory were found at the sites. These finds suggest widespread technologies of processing ivory, as well as antler and bones from other mammoth fauna species. In fact, interaction between humans and mammoths is a fundamental characteristic of a great part of the Upper Paleolithic in northern Eurasia. Therefore, studies of the features of initial settlement and the history of human paleopopulations in the changing paleoecological conditions of North Asia in the Late Pleistocene, as well as the use of mammoth megafauna as a resource base by Paleolithic hunters, provide important information on the development of the early human populations of this region; the subsistence strategies of Northeastern Asian hunters can be considered an almost global example of human adaptation to extreme conditions.

Acknowledgements

The study was carried out under State Assignment FWZG-2022-0003 “Northern Asia in the Stone Age: Cultural Dynamics and Environmental Context”.

The authors are grateful to K.A. Kolobova, Professor at the Russian Academy of Sciences, for consultations.