Structural and heat-insulating foam concrete for individual monolithic housing construction

Автор: Steshenko A.B., Kudyakov A.I., Inozemtcev A.S., Inozemtcev S.S.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The article presents the results of studies of structural and heat-insulating cement-based foam concrete for monolithic individual housing construction using porous aggregates sand and superplasticizers. The relevance of the study is to improve the technological properties of foam concrete mixtures to enhance their transportation and laying in formwork, as well as to increase the strength and thermal insulation parameters of wall materials used in individual housing construction. A synergistic effect is ensured and increased stability of the foam concrete mixture is achieved, resulting in an increase in the grade of compressive strength of foam concrete and a decrease in thermal conductivity by partially replacing quartz sand with expanded clay or slag sand in the amount of 25% by volume and introducing the superplasticizer “Steinberg MP-4”. Materials and methods. The study of foam concrete mixture and foam concrete was carried out in the accredited laboratory of TSUAB in accordance with the requirements of national standards. Results. The use of combined additives, including a superplasticizer and a mineral porous aggregate, leads to increase the grade of compressive strength of foam concrete from B1 to B2 while maintaining the average density grade D600, and also allows reducing the thermal conductivity coefficient of foam concrete to 17% compared to the basic composition. Conclusion. The developed compositions for the production of monolithic structural and heat-insulating foam concrete of natural hardening with a combined additive, including mineral porous aggregate and current plasticizers, are recommended for individual housing construction of low-rise buildings.

Cement foam concrete of natural hardening, porous aggregates, expanded clay and slag sand, diameter of the mixture flow, compressive strength, average density, thermal conductivity coefficient

Короткий адрес: https://sciup.org/142242260

IDR: 142242260 | DOI: 10.15828/2075-8545-2024-16-4-320-328

Текст научной статьи Structural and heat-insulating foam concrete for individual monolithic housing construction

Review article

I n 2024 the volume of individual housing construction

(IHC) will reach 40 million sq. m in accordance with the program of the Ministry of Construction of Russia [1]. The main structural and heat-insulating element of a low-rise residential building is the wall. Much attention is paid to material’s quality, cost and technology of construction work for choosing a wall material for your own home. The quality of the wall material means high strength and heat-insulating characteristics, durability

(frost resistance), as well as reliability in their production during housing construction [2]. One of the important factors in ensuring the quality of construction work is the ability to erect walls from hardening porous mixtures prepared directly at the construction site (monolithic construction) [2, 3].

Monolithic individual housing construction is developing dynamically in Russia. Currently, various options for monolithic individual housing construction technologies are used, and each method requires naturally hardening foam concrete mixtures of the appropriate quality [4, 1].

CONSTRUCTION MATERIALS SCIENCE

The quality of monolithic foam concrete intended for the construction of wall structures is regulated by standards for two main parameters: the grade of compressive strength, assessed taking into account homogeneity, and thermal conductivity coefficient. Based on the analysis of the cellular concrete market in the Russian Federation [4], the most popular are structural and heatinsulating foam concretes with the average density grade D500-D700. According to the requirements of Russian State Standards GOST 25485-2019 the grade of compressive strength of foam concrete must be at least B1, and the thermal conductivity coefficient in a dry state is 0.15–0.17 W/m•°C.

It is necessary to take into account the technological complexities of ensuring the homogeneity of the structure for managing the processes to ensure compliance or improve the quality of foam concrete according to the above parameters during monolithic construction of wall structures [1, 3, 5]. This is due to the need for uniform mixing of the components and obtaining a homogeneous structure of the mixture due to the large difference in the average density of the quartz filler grains and the porous cement matrix. The construction of enclosing structures with monolithic technology in many cases needs to fill with a mixture at an increased height, exceeding the standard size of the wall blocks. It leads to segregation of the components, a decrease in the homogeneity and strength of the frame-forming base of foam concrete [6, 7]. It is necessary to develop technological principles for obtaining more stable foam concrete mixtures while maintaining the required mobility and density. Increased stability of the mixture is achieved by strengthening the cementsand matrix, increasing the average density, which leads to a decrease in the thermal insulation characteristics of the enclosing structures of buildings. Ensuring high strength of foam concrete without increasing the average density is possible by introducing porous active mineral components into the mixture [8–12]. Low values of the thermal conductivity coefficient of foam concrete are also achieved with the maximum possible content of air pores in the cement-sand matrix without loss of strength of the interpore partitions. This effect is achieved by saturating the cement-sand matrix with porous aggregates commensurate with the macropores of foam concrete, while simultaneously increasing the strength of the matrix [10–14]. However, porous aggregates have greater water absorption, compared to quartz sand, which leads to an increase in the water demand of the foam concrete mixture. To ensure a high degree of hydration of the cement-sand matrix, taking into account the technological features of monolithic construction technology, it will be necessary to optimize the content of mixing water. An important component of the mixture in this case can be an effective plasticizing additive, which allows for the required mobility of the mixture and the strength of foam concrete [15–17].

An effective way to control the porous structure and strength of the cement-sand matrix of foam concrete is the combined introduction of structure-regulating and plasticizing additives into the mixture [1, 6, 12]. It is necessary to ensure a synergistic effect or the possibility of implementing an emergent first-order structure for the rational choice of active mineral and plasticizing additives. It will positively affect the optimization of the structure and performance properties of foam concrete [18–20].

During the study it is proposed to use the positive properties of plasticizing and mineral additives by introducing them together into the mixture in the form of a combined additive selectively influencing the processes of structure formation of foam concrete.

The scientific hypothesis: by introducing combined additives during the preparation of foam concrete mixtures that form microporosity (porous aggregates with an active surface) and maintain mobility (water-reducing additives). It is possible to ensure the stability of the mixture during the period of laying in the formwork, homogeneity during the formation of the structure and the required parameters characterizing the quality of foam concrete [15, 16, 21, 22].

It is recommended to use porous expanded clay sand and ash and slag sand from the Severskaya TPP (Tomsk Region) as mineral porous additives for the production of foam concrete of the required level and stability of quality. In the concrete mixture, the mineral porous aggregates act as not only an active mineral additive that actively influences the processes of structure formation and increasing the strength of foam concrete, but also a filler with micropores that increases the thermal resistance of the wall material [21–24].

It is proposed to introduce microporous filler into the composition of the foam concrete mixture instead of 25, 50 or 75% quartz sand by volume, taking into account the bulk density, with subsequent adjustment of the recommended compositions according to the values of the actual average density of the foam concrete mixture.

The aim of the research is to establish the patterns of influence of porous aggregates and water-reducing additives on the processes of structure formation of cement based foam concrete, as well as to develop scientifically based formulation and technological solutions for the production of cement based structural and heat-insulating foam concrete of natural hardening with a combined additive for individual housing construction.

MARERIALS AND METHODS

The following raw materials were used in the research: - portland cement from Topkinsky cement plant, type

CEM1, strength grade – 42.5B (Russian State Standards GOST 31108-2020);

CONSTRUCTION MATERIALS SCIENCE

-

- quartz-feldspar sand from Kudrovskoye deposit, Tomsk region (Russian State Standards GOST 87362014). The physical and mechanical properties of sand are given in table 1;

-

- expanded clay sand from Large-Panel Housing Construction Plant, Tomsk (Russian State Standards GOST 9757-90). The physical and mechanical properties of expanded clay sand are presented in table 2;

-

- porous slag sand from Severskaya TPP, Tomsk region (Russian State Standards GOST 26644 85). The physical and mechanical characteristics of slag sand are given in [13]. Slag sand belongs to class 1 in terms of the content of natural radionuclides and is suitable for the production of building materials. Bulk density of slag sand is 850 kg/m3;

-

- tap water (Russian State Standards GOST 23732– 2011);

-

- superplasticizer “Steinberg MR-4” is a product based on the condensation of naphthalene sulfonic acid and formaldehyde (Technical Specifications 20.59.59-00145419370-2018);

-

- superplasticizer “Steinberg GROS-63 MR” (Technical Specifications 20.59.59-001-45419370-2018).

-

- superplasticizer “Relamix T2” is a mixture of inorganic (thiocyanates, thiosulfates) and organic (polymethylene naphthalene sulfonates) sodium salts (Technical Specifications 5745-070-58042865-2012).

The foam concrete mixture was prepared in a turbulent mixer using single-stage technology [25]. Testing and quality assessment of foam concrete were carried out according to Russian State Standards GOST 254852019.

The design of the composition of the foam concrete mixture was carried out in accordance with the requirements of Russian Standard SN 277-80 “Instructions for the production of cellular concrete products”. The designed basic (control) composition of structural and heat-insulating foam concrete with an average density grade D600, used in conducting studies of the effect of microporous and plasticizing additives on the quality parameters of foam concrete, is presented in table 3.

RESULTS AND DISCUSSION

The results of the studies on the influence of porous aggregates on the properties of foam concrete mixture are presented in table 4. The volume of quartz sand was

Table 1

Physical and mechanical properties of quartz-feldspar sand

|

Partial (total) residues, %, on sieves, mm |

Module size |

Density, kg/m3 |

Content of dust and clay particles,% |

||||||

|

2.5 |

1.25 |

0.63 |

0.315 |

0.16 |

< 0.16 |

bulk |

true |

0.1 |

|

|

0.5 (0.5) |

1.0 (1.5) |

4.5 (6.0) |

35.0 (41.4) |

53.5 (94.5) |

5.5 (100) |

1.8 |

1400 |

2550 |

|

Table 2

Physical and mechanical properties of expanded clay sand

|

Partial (total) residues, %, on sieves, mm |

Module size |

Density, kg/m3 |

Thermal conductivity coefficient, W/m • °С |

||||||

|

2.5 |

1.25 |

0.63 |

0.315 |

0.16 |

< 0.16 |

bulk |

true |

0.1099 |

|

|

70.7 (70.7) |

19.0 (89.7) |

7.7 (97.4) |

1.0 (98.4) |

0.7 (99.1) |

0.9 (100) |

4.6 |

650 |

2315 |

|

Table 3

Basic (control) composition of foam concrete grade D600

|

Consumption of raw materials per 1 m3 |

|||

|

cement, kg |

quartz-feldspar sand, kg |

water, l |

foaming agent, l |

|

333 |

166 |

250 |

1.66 |

CONSTRUCTION MATERIALS SCIENCE

Table 4

The influence of porous fillers on the properties of foam concrete mixture

It has been established that the increase of the proportion of expanded clay sand and slag sand in the filler leads to decrease the density of the foam concrete mixture in all compositions. At the same time, an increase in the mobility of the foam concrete mixture is observed. The mobility of the foam concrete mixture increases from 13 cm to 14 cm due to the replacing 25% of quartz sand by volume with expanded clay sand, and replacing it with slag sand – from 13 cm to 13.5 cm. In compositions with slag sand in a volume of 50%, the mobility of the mix- ture increases from 13 cm to 16.5 cm, and in a volume of 75% – up to 17.5 cm compared to the basic composition. The increase in the mobility of the mixture is explained by a decrease in the density of the cement matrix at the contact with the vitrified surface of the slag sand grains. The density of the mixture decreases due to the porous structure of the aggregates, the colmatation of the open pores of the grains with cement paste and the lower true density of the grains compared to quartz-feldspar sand [11, 23, 26].

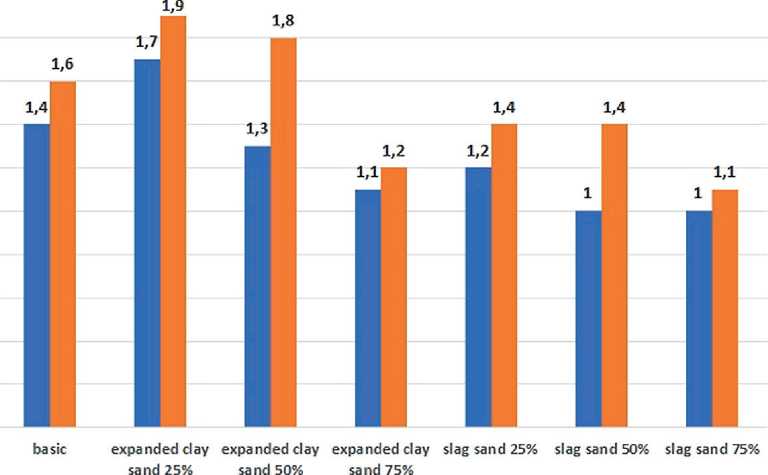

The results of the studies on the influence of expanded clay and slag sand on the strength properties of foam concrete are presented in fig. 1.

Average density in dry condition, kg/m3

576 570 506 482 539 504 481

28642186420 LLIL aaaa Eds £,①占 S ф>^^ф^-п-ЕО0

28 days

Fig. 1. The influence of porous sands on the properties of foam concrete

CONSTRUCTION MATERIALS SCIENCE

It has been established that replacing 25% by volume of quartz-feldspar sand in the foam concrete mixture with expanded clay sand leads to increase the compressive strength of foam concrete at the age of 7 days by 18%, and at the age of 28 days by 16% compared to the basic composition of foam concrete. This effect is explained by the colmatation of open pores of the grains of the porous filler by the cement-sand mixture, an increase in contact strength. That contributes to the strengthening of the foam concrete matrix [12, 23, 26]. It was shown that introducing 25% slag sand into the foam concrete mixture promotes decrease in the compressive strength of foam concrete at the age of 7 days by 12%, at the age of 28 days by 11% compared to the basic composition.

The use of expanded clay sand and slag sand in the amount of 50% and 75% by volume, instead of quartz sand in the foam concrete mixture, leads to a decrease in the strength characteristics of foam concrete.

Expanded clay sand and slag sand in the amount of 25% by volume are recommended, instead of quartzfeldspar sand for further research on improving the quality of foam concrete mixture and foam concrete.

Preservation of the primary pore structure during transportation of the finished mixture and laying in the formwork of wall structures depends on the rheological characteristics of the foam concrete mixture [1, 25]. Evaluation of the rheological properties of foam concrete mixtures is necessary when managing technological processes for the production of monolithic building structures.

To achieve the required mobility of the foam concrete mixture during transportation, pouring the mixture into formwork (removable or permanent), and implementing the principles of emergence in managing structure formation, it is proposed to introduce effective plasticizers into the mixture [25, 27]. Several types of superplasticizers used in the production of building materials were used in the study to achieve the required mobility (flow diameter) of the foam concrete mixture. The recommended dosage of superplasticizers is 0.5% of the cement mass. The results of studies of the effect of plasticizing additives on the properties of cement foam concrete mixture and foam concrete with expanded clay sand are given in table 5.

It has been established that the use of plasticizing additives leads to increase the diameter of the spread (mobility), while the strength of foam concrete decreases. The use of the plasticizer “Shtayberg MP-4” ensures the best mobility of the foam concrete mixture of 18 cm, while the least decrease in strength characteristics is observed.

Experimentally was shown that the use of the plasticizer “Relamix T2” leads to the spread of the foam concrete mixture almost doubled, the mixture is unstable, the formed pores collapse. It promotes a decrease in the volume of the finished mixture, a decrease in the average density of the mixture by 18% and a decrease in the compressive strength of foam concrete at 28 days of age by 3 times compared to the basic composition.

The greatest decrease in average density by 23% compared to the basic composition is observed in the foam concrete mixture with the addition of “GROS 63 MR”. Some water is released in the foam concrete mixture (water-reducing effect) and the foaming capacity of the mixture increases.

The plasticizer “Steinberg MP-4” was used in an amount of 0.5% of the cement mass for further studies to improve the quality of foam concrete.

The studies were conducted with combined additives in order to predict the possibility of selectively increasing the quality of foam concrete mixture and concrete by simultaneously introducing a plasticizing additive and the porous aggregates. Combined additives include the superplasticizer “Steinberg MP-4” and porous aggregates in an amount of 25% by volume instead of quartz sand, taking into account it’s bulk density.

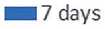

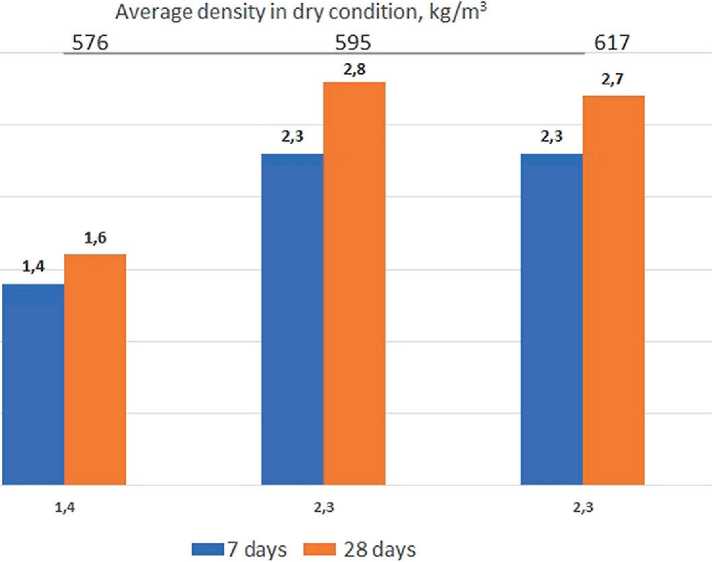

The introduction of aggregates into the composition of foam concrete mixture with plasticizer can provide the required rheological parameters and increase the aggregate stability of the mixture, increase the strength of hardened foam concrete [27]. The results of studies of the use of a combined additive in foam concrete mixture are presented in table 6 and fig. 2.

Table 5

The influence of plasticizing additives on the properties of foam concrete mixture and foam concrete

|

Type of additive |

Density of foam concrete mixture, kg/m3 |

Diameter of foam concrete mixture spread, cm |

Compressive strength of foam concrete at the age of 7 days, MPa |

Compressive strength of foam concrete at the age of 28 days, MPa |

|

Basic composition |

726 |

13.0 |

1. 37 |

1.60 |

|

Steinberg MP-4 |

617 |

18.0 |

1.03 |

1.38 |

|

GROS-63MR |

560 |

23.5 |

0.76 |

0.99 |

|

Relamix T2 |

596 |

20.0 |

0.21 |

0.52 |

CONSTRUCTION MATERIALS SCIENCE

3 5 2 5 1 5 0 z L a

BdzbMUES BABSBJdluoJ

Table 6

The influence of combined additives on the properties of foam concrete mixture

|

Type of additive |

Density of foam concrete mixture, kg/m3 |

Diameter of foam concrete mixture spread, cm |

|

Basic composition |

726 |

13 |

|

Expanded clay sand + MP-4 |

725 |

17.5 |

|

Slag sand + MP-4 |

733 |

16.5 |

Fig. 2. Effects of combined additives on the properties of foam concrete

Experimentally was shown that the use of combined additives into the foam concrete mixture made it possible to increase the spread diameter of the mixture by 1.5 times, without significantly changing the average density of the foam concrete mixture.

It has been established that the use of the “Steinberg MP-4” plasticizer together with expanded clay sand in the amount of 25% by volume instead of quartz sand leads to increase the strength of foam concrete samples by 40 and 85% compared to the basic sample, and by 40 and 79% with slag sand at 7 and 28 days of age, respectively. At the same time, the coefficient of variation in compressive strength decreases from 12.7 to 8.4 with expanded clay sand, 9.6 with slag sand, which characterizes an increase in the homogeneity of the foam concrete structure with a combined filler.

Thus, when using a combined additive with expanded clay sand, the grade of compressive strength of foam con- crete increases from B1 to B2, and slag sand – from B1 to B1.5, while maintaining the grade of average density D600.

The results of studies of the thermal conductivity of foam concrete with combined additives are presented in table 7.

The efficiency of thermal protection of enclosing structures of buildings made of foam concrete depends on the characteristics of the porous structure: the content, size and uniformity of distribution of pores and humidity [1]. Visual studies of the porous structure of the obtained samples with additives showed a fairly uniform structure of foam concrete. As follows from table 7, foam concrete with a combined additive with slag sand has the lowest thermal conductivity coefficient (0.086 W/m•°С). Analyzing the obtained results, we can conclude that the thermal conductivity coefficient of foam concrete with a combined additive is lower than the basic value and cor-

CONSTRUCTION MATERIALS SCIENCE

Table 7

Thermal conductivity coefficient of foam concrete with combined additives

|

Type of additive |

Thermal conductivity coefficient, W/m • °С |

|

|

at 25% humidity |

in dry condition |

|

|

Basic composition |

0.180 |

0.142 |

|

Expanded clay sand + MP-4 |

0.166 |

0.133 |

|

Slag sand + MP-4 |

0.108 |

0.086 |

Table 8

Foam concrete compositions with combined additives for industrial use

Compositions of cement foam concrete with combined additives have been developed for industrial application of scientific results in monolithic individual housing construction technologies (table 8).

CONCLUSION

leads to increase the grade of compressive strength of foam concrete from B1 to B2 (with expanded clay sand) and from B1 to B1.5 (with slag sand) while maintaining the average density grade of D600.

Список литературы Structural and heat-insulating foam concrete for individual monolithic housing construction

- Steshenko A.B., Kudyakov A.I., Inozemtcev A.S., Inozemtcev S.S. Controlling the structural formation of porized cement composites in the production of thermally efficient enclosure structures of enhanced quality. Nanotechnologies in Construction: A Scientific Internet-Journal. 2023; 15 (5): 408-417. https://doi.org/10.15828/2075-8545-2023-15-5-408-417

- Guanzheng Zh., Ray Kai L.S. A review on durability of foam concrete // Buildings. 2023; 13: 1880. https://doi.org/10.3390/buildings13071880

- Markin V., Nerella V.N., Schröfl C., Guseynova G. and Mechtcherine V. Material design and performance evaluation of foam concrete for digital fabrication. Materials. 2019; 12: 2433. https://doi.org/10.3390/ma12152433

- Telichenko V.I., Benuzh A.A., Rud N.S. Indoor air quality requirements for civil buildings in russian regulations in comparison with international green standards. International Journal for Computational Civil and Structural Engineering. 2021; 17 (1): 98-107. https://doi.org/10.22337/2587-9618-2021-17-1-98-107

- Gencel O., Bilir T., Bademler Z., Ozbakkaloglu T. A detailed review on foam concrete composites: ingredients, properties, and microstructure. Appl. Sci. 2022; 12: 5752. https://doi.org/10.3390/app12115752

- Eliseeva N., Eliseev N. Regulation of foam stability for non-autoclave foam concrete with additives of colloidal nature. International Scientific Siberian Transport Forum TransSiberia. Lecture Notes in Networks and System. 2021; 402. https://doi.org/10.1007/978-3-030-96380-4_15

- Guanzheng Zhou, Su R.K.L. A review on durability of foam concrete. Buildings. 2023; 13(7):1880. https://doi.org/10.3390/buildings13071880

- Oreshkin D.V., Chebotaev A.N., Perfilov V.A. Disposal of drilling sludge in the production of building materials. Procedia Engineering. 2015; 111: 607—611. https://doi.org/10.1016/j.proeng.2015.07.053

- Steshenko A.B., Kudyakov A.I., Kopanitsa N.O. Structural and heat insulating foam concrete made with drill cuttings. Journal Cement and its Applications. 2023; 6. https://doi.org/10.61907/cia.2023.53.63.001

- Kurmangalieva A.I., Anikanova L.A., Kudyakov A.I., Steshenko A.B., Inozemtcev A.S., Inozemtcev S.S., Buryanov A.F. Formation of porous structures in production technology of construction materials based on building gypsum plaster// Nanotechnologies in Construction: A Scientific Internet-Journal. 2023; 15 (4): 319-327. https://doi.org/10.15828/2075-8545-2023-15-4-319-327

- Kudyakov A.I., Prischepa I.A. Osipov S.P. Non-autoclaved cement foam concrete with thermal modified peat additive. Stroitel’nye materialy (Construction materials). 2022; 12 (1-2); 40-49. https://doi.org/10.31659/0585-430X-2022-799-1-2-40-49 (In Russian).

- Dien V.K., Ly N.C., Lam T.V., Bazhenova S.I. Foamed concrete containing various amounts of organicmineral additives. IOP Conf. Series: Journal of Physics: Conf. Series. 2019; 1425: 012199. https://doi.org/10.1088/1742-6596/1425/1/012199

- Kudyakov A.I., Steshenko A.B., Dushenin N.P., Ryabtseva N.E. Vestnik of Tomsk State University of Architecture and Building. 2021; 23 (5): 105−117. https://doi.org/ 10.31675/1607-1859-2021-23-5-105-117 (In Russian).

- Yakovlev G., Polyanskikh I., Pudov I., Saidova Z., Drochytka R., Skripkiunas G., Karpova E., Urkhanova L., Elrefai A.E.M.M. Effect of ultrafine additives on the morphology of cement hydration products. Crystals. 2021; 11 (8): 1002. https://doi.org/10.3390/cryst11081002

- Inozemtcev A., Korolev E., Duong T.Q. Conditions for selection of superabsorbent polymer hydrogel for cement compositions. Journal of Sol-Gel Science and Technology. 2023; 108 (2): 256-262. https://doi.org/10.1007/s10971-022-05803-2

- Song N., Li Zh., Yi W., Wang Sh. Properties of foam concrete with hydrophobic starch nanoparticles as foam stabilizer. Journal of Building Engineering. 2022; V. 56: 104811. https://doi.org/10.1016/j.jobe.2022.104811

- Urkhanova L.A., Lkhasaranov S.A., Buyantuev S.L., Khardaev P.K. The use of composite binders and nanomodifiers for fiber-reinforced concrete. Nanotechnologies in Construction. 2018; 10 (6): 91– 107. https://doi.org/10.15828/2075-8545-2018-10-6-91-107

- Li Hou, Jun Li, Zhongyuan Lu, Yunhui Niu, et al. Effect of nanoparticles on foaming agent and the foamed concrete. Construction and Building Materials. 2019; Vol. 227: 116698.

- Steshenko A.B., Kudyakov A.I., Ryabtseva N.E. Cement based foam concrete with hardening accelerators. IOP Conf. Ser.: Mater. Sci. Eng. 2020; 911: 012003. https://doi.org/10.1088/1757-899X/911/1/012003

- Obukhova S., Korolev E., Gladkikh V. The influence of single-walled carbon nanotubes on the aging performance of polymer-modified binders. Materials. 2023; (16) 24: 7534. https://doi.org/10.3390/ma16247534

- Hao Y., Yang G., Liang K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cement and Concrete Composites. 2022; V. 128: 104447. https://doi.org/10.1016/j.cemconcomp.2022.104447

- Stepanenko M.A., Markova I.Yu., Strokova V.V., Markov A.Y. Assessment of the activity of sol-entrainments of various compositions as mineral additives for cement systems. Proceedings of Higher Educational Institutions. Construction. 2023; 11 (779): 50-59. https://doi.org/10.32683/0536-1052-2023-779-11-50-59

- Kim D.V., Bazhenova S.I., Nguyen T.Ch., Tang V.L., Do M.Ch., Le V.L., Hoang M.Th. Insulation properties and performance of foam concrete using blast furnace slag. Structural integrity and life. 2022; Vol. 22 (1): 48–56.

- Steshenko A.B., Kudyakov A.I., Lukyanchikov S.A., Nasyrov V.A. Construction and heat-insulating foam concrete with the use of drilling sludge. AIP Conf. Proc. 2022; 2696: 020008-1–020008-5. https://doi.org/10.1063/5.0117016

- Steshenko A.B., Simakova A.S., Inozemtcev A.S., Inozemtcev S.S. Structural and heat insulating cement-based concrete with complex glyoxal based additive. Nanotechnologies in Construction. 2022; 14 (5): 353-362. https://doi.org/10.15828/2075-8545-2022-14-5-353-362

- Strokova V.V., Markova I.Yu., Markov A.Yu., Stepanenko M.A., Nerovnaya S.V., Bondarenko D.O., Botsman L.N. Properties of a composite cement binder using fuel ashes. Key Engineering Materials. 2022; 909 KEM: 184-190. https://doi.org/10.4028/p-tm4y4j

- Xiong Y., Pang B., Liu Zh., Liu Ch., Hu Zh, Liguo Ma L. Effect of foam temperature on foam stability of foamed concrete and stabilization mechanisms. Journal of Building Engineering. 2023; 77(6): 107492. https://doi.org/10.1016/j.jobe.2023.107492

- Ilina L., Kudyakov A., Rakov M. Aerated dry mix concrete for remote northern territories. Journal of Civil Engineering. 2022; 5 (113): 11310. https://doi.org/10.34910/MCE.113.10