The adaptation of the Seima-Turbino tradition to the Bronze Age cultures in the south of the West Siberian plain

Автор: Molodin V.I., Durakov I.A., Mylnikova L.N., Nesterova M.S.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.46, 2018 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145382

IDR: 145145382 | DOI: 10.17746/1563-0110.2018.46.3.003-058

Текст обзорной статьи The adaptation of the Seima-Turbino tradition to the Bronze Age cultures in the south of the West Siberian plain

Despite a significant number of studies of the Seima-Turbino bronzes, certain issues are still unclear. The sites with the Seima-Turbino bronze artifacts have been recorded from a vast region; but no distinct archaeological culture has been identified, because neither have any boundaries of their occurrence been established, nor any settlements with traces of their manufacturing been found, and every burial site shows specific features. E.N. Chernykh and S.V. Kuzminykh (1989) proposed a term “Seima-Turbino transcultural phenomenon” for the sites containing such artifacts. Up to now, the dispersal of the Seima-Turbino objects has been attributed to migrants who moved from east to west, in the direction opposite to that of the representatives of the Andronovo timber-grave tradition (Chernykh, Navarrete, 2011: 20–21).

During the last decade, the total number of the Seima-Turbino objects has grown, as new artifacts have been found in the Irtysh basin. In this region, the cemeteries of the Odinovo and Krotovo cultures (Preobrazhenka-6 (Molodin, 2013), Sopka-2/4B, C (Molodin, Grishin, 2016: 81–82, fig. 137, 139, 1, 25), Tartas-1 (Molodin et al., 2009), and Rostovka (Matyushchenko, Sinitsyna, 1988)) have revealed five burials containing not only standard Seima-Turbino objects, but also casting molds. However, local manufacture of the Seima-Turbino bronzes was not confirmed until the traces of such manufacture were found at the settlements.

Casting molds and manufacturing areas at Krotovo settlements

Casting molds were found at several settlements of the Krotovo culture: Chernoozerye VI (Kondratiev, 1974: 18; Stefanova, 1988: Fig. 6, 3 ), Vengerovo-2 (Molodin, Mylnikova, Durakov et al., 2015: 323–324, fig. 1, 2 ), and Abramovo-10 (Fig. 1). These finds are significant for establishing reliable correlations between the Seima-Turbino bronzes and particular areas and cultures.

The settlement of Chernoozerye VI is situated on a fluvial terrace on the left bank of the Irtysh River, 1 km to the northeast from the village of Chernoozerye in the Sargatsky District, Omsk Region. The site yielded a spear mold-fragment: a part of a ceramic mold with a cavity and parting. The fragment was found in the casting workshop’s waste, at the edge of the terrace (Kondratiev, 1974: 18). Since the site is multilayered (Stefanova, Stefanov, 2007), the mold can be attributed to the Krotovo culture.

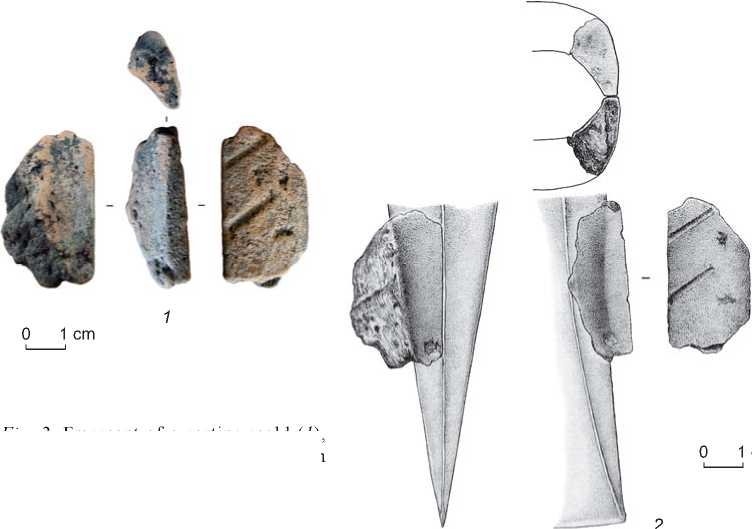

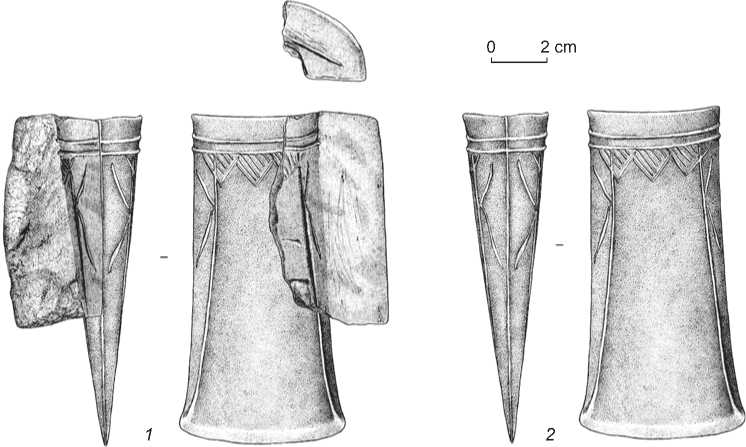

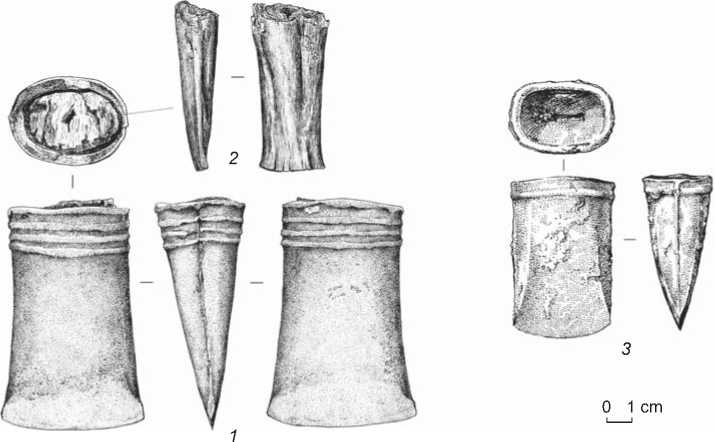

The settlement of Abramovo-10 yielded two fragments of clay celt-casting molds. The site is located on the second fluvial terrace on the left bank of the Om River, 5 km southwest of Kuibyshev, in the Kuibyshevsky District of the Novosibirsk Region (Molodin, 1985: 35) (Fig. 1). One of the finds is a fragment of the middle portion of a mold retaining the cavity side-wall and the parting (Fig. 2, 1 ). The mold was made of a mixture of clay with well-calibrated medium-sized sand. The mold was made using a bottom board, which left an impression on the surface of the parting of the mold. Judging by the mold cavity’s shape, the celt had a hexagonal cross-section in its middle part, and was wedge-shaped in side view (Fig. 2, 2 ). The mold also showed traces of stiffening ribs at the line of convergence of the lateral and front faces of the celt. Judging by the size and converging of walls of the mold cavity and the parting of the mold, the celt’s

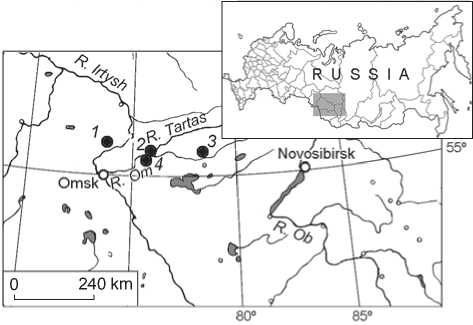

Fig. 1. Krotovo settlements yielding Seima-Turbino bronzecasting molds.

1 – Chernoozerye VI; 2 – Vengerovo-2; 3 – Abramovo-10; 4 – Stary Tartas-1.

height did not exceed 8.7 cm. The external surface of the mold showed two deeply cut oblique lines, adjoining the parting, that served as guide-marks during the centering of the mold when connecting the mold’s halves. Such cuts were typical of the Krotovo molds. These were noted on the molds from Tartas-1 and Sopka-2 (Ibid.: Fig. 28, 1 , 5 ) and on the molds of other contemporaneous cultures of Siberia (Koksharov, Chemyakin, 1991: 46–47, fig. 2, 1 , d ; 3, 1 , c , f ).

Another fragment is a part of the upper mold-half with a sprue and a cavity (Fig. 3, 1 ). The mold was made of a mixture of clay with well-calibrated sand and crushed calcined bones. The mold’s cavity retains a fragment of the relief ornamentation: a band of oblique lines between two horizontal lines forming a kind of staircase. This ornamental pattern is typical of the Seima-Turbino celts (Chernykh, Kuzminykh, 1989: 46).

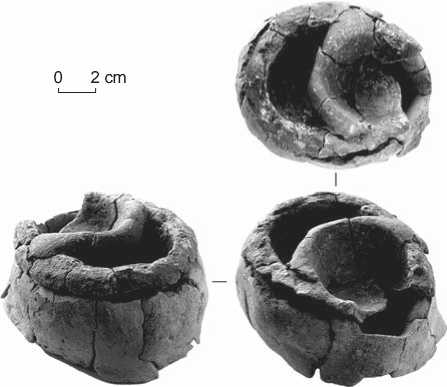

The above-mentioned mold fragments were found in the bronze-casting area between the houses at the settlement of Abramovo-10. The area contained a hearth (Fig. 3, 2 ) and a utility pit. The hearth (structure B) was a rectangular pit 2.0 × 0.89 m in size and 0.47 m deep, oriented with its long axis along the NW-SE line (Sobolev, 1984). The vertical walls and the bottom of the pit were coated with a layer of fired clay up to 0.14 m thick. The filling consisted of dark gray loam with inclusions of soot, ash, and pieces of calcined clay. In the immediate vicinity of the hearth and in its filling, fragments of at least seven crucibles were found (Fig. 3, 3 , 4 ), one of which we restored (Fig. 3, 3 ). The utility pit (No. 124) was located 0.8 m to the northeast from the hearth. It is ovoid, with vertical walls and a plain bottom; the size is 1.7 × 0.9 m, and the depth 0.24 m. The filling revealed fragments of pottery and bones, and slagged fragments of crucible.

One of the most impressive finds is a fragment of a celt casting mold of the Seima-Turbino type, from the settlement of Vengerovo-2 (Molodin et al., 2015: Fig. 1), located at the edge of the second fluvial terrace on the left bank of the Tartas River, in the Vengerovsky District, Novosibirsk Region (Molodin, Polosmak, 1978; Troitskaya, Molodin, Sobolev, 1980). This object was found at floor level in dwelling 7 (Molodin et al., 2015: 323–324, fig. 1, 2 ) (Fig. 4). It was a fragment of a stone mold for celt-casting (Fig. 5). The mold was made of dark gray soft marl (class 2 in the Mohs scale of hardness). Only a part of the mold cavity and a parting of mold halves survived. Judging by the traces on the mold, all its main cavities were initially outlined on the leveled blank surface, and were then cut with a knife with the technique similar to wood carving. For example, the surfaces of all depressions forming the relief ornamentation show traces of bilateral trimming made with the tip of the blade. The back of the mold half was first given a rounded shape with a knife, and then additionally fashioned with a coarse-grained abrader. This technique of mold

cm

Fig. 2. Fragment of a casting mold ( 1 ), reconstruction of a celt ( 2 ) cast in it, from Abramovo-10.

0 1 cm

0 40 cm

0 1 cm

0 1 cm

-50 fA

■а ■ b

ш c ш d

Fig. 3. Fragment of a casting mold ( 1 ), plan and section of the hearth (structure B) ( 2 ), and crucibles ( 3 , 4 ) from Abramovo-10.

а – dark gray loam with ash and soot inclusions; b – calcined clay; c – fragment of a crucible; d – fragment of a casting mold.

Fig. 4. General view ( 1 ) and plan ( 2 ) of dwelling No. 7 at Vengerovo-2.

а – hearth; b – furnaces; c – bronze drop; d – ash storage pit; e – utility pit; f – celt-casting stone mold; g – technical ceramics dispersal areas.

0 1 cm

manufacture is typical of the Seima-Turbino casting tradition. Signs of its use were traced on several objects made of soft stone; for example, on a talc mold from burial No. 282 at Sopka-2/4B, C (Molodin, Grishin, 2016: Fig. 397) and on a limestone mold from a concentration of artifacts associated with grave 21 at the cemetery of Rostovka, in Omsk (Matyushchenko, Sinitsyna, 1988: 30–31, fig. 36, 37).

The negative of the casting chamber makes it possible to reconstruct the object cast in it (Fig. 6). The celt had a hexagonal crosssection in its middle portion; its body was wedge-shaped in side view; its cutting edge was slightly wider than the main body; and the socket was flattened into an oval. Judging by the inclination of the mold cavity wall relative to the parting of the mold, the celt height did not exceed 12.5–12.7 cm. The socket edge was ornamented with a pair of thin relief fillets and a belt of shaded isosceles triangles. The lateral side of the celt, which survived in the mold, was ornamented with two deeply incised lines, forming an isosceles triangle oriented with its base towards the parting of the mold. The front surface of the celt is separated from the

Fig. 5. Fragment of a casting mold from dwelling No. 7 at Vengerovo-2.

0 2 cm

Fig. 6. Reconstruction of a celt cast from dwelling No. 7, Vengerovo-2.

lateral surfaces with an incised line simulating a stiffening rib, which feature is typical of the Seima-Turbino celts (Chernykh, Kuzminykh, 1989). In terms of construction and ornamentation, the Vengerovo-2 find is close to the celts of the Seima-Turbino-type (Kosarev, 1970: 124, fig. 1, 6, 7). According to the classification by Chernykh and Kuzminykh (1989: 46–55, fig. 10, 7 , 8 ; 15, 1 ; 16, 4 ), the object belongs to category K-12 or K-18.

The mold seems to have disintegrated owing to thermal effects. Its cavity has use-wear traces in the form of a dark gray layer of copper-scale. Experiments have shown that the stone mold can withstand more than

N

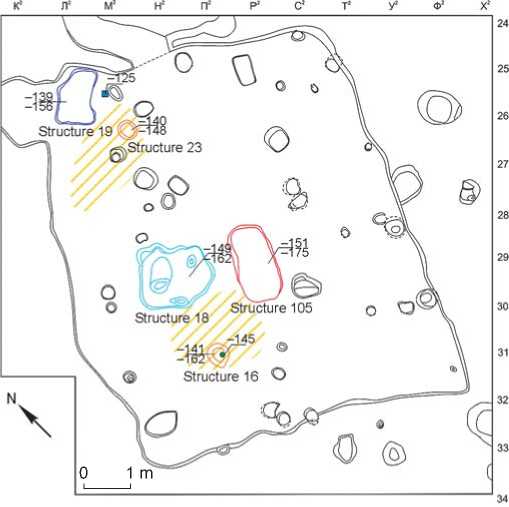

The hearth (structure No. 105) was a rectangular pit located in the center of the dwelling, 1.65 × 0.87 m in size and up to 0.21 m deep, filled with ash, burnt sandy loam, pieces of calcined bones, fragments of pottery, and pieces of burnt clay, containing a flake from some working tool and an abrader on a potsherd (see Fig. 7). Judging by the filling and the finds revealed from it, the hearth was used for cooking, heating, and lighting, as well as for production purposes. The hearth is shallower as compared to the similar central hearths in other

100 castings (Beltikova, 1993: 65; Coghlan, 1951: 73), which means that it could have been used in serial production. The bronze-casting workshop where the object was found reveals traces of long-lasting large-scale production. The production area occupies a major part of dwelling No. 7 (see Fig. 4, 2 ) and consists of a multifunctional hearth (Fig. 7), two specialized furnaces (Fig. 8, 9), and two ash utility and bone storage pits (Fig. 10).

-152

-169

-177

-152'

-168

•167

-153

'В

Fig. 7. Plan ( 1 ) and section ( 2 ) of the hearth (structure No. 105) at dwelling No. 7, Vengerovo-2.

а – blackish-gray mixed sandy loam with inclusions of burnt clay; b – grayish-black mixed sandy loam; c – reddish-orange calcined sandy loam; d – light gray sandy loam; e – yellowish-gray mixed sandy loam; f – gray ashy sandy loam; g – virgin soil.

/-152

0 20 cm

а

bc

d

e Y777A fg

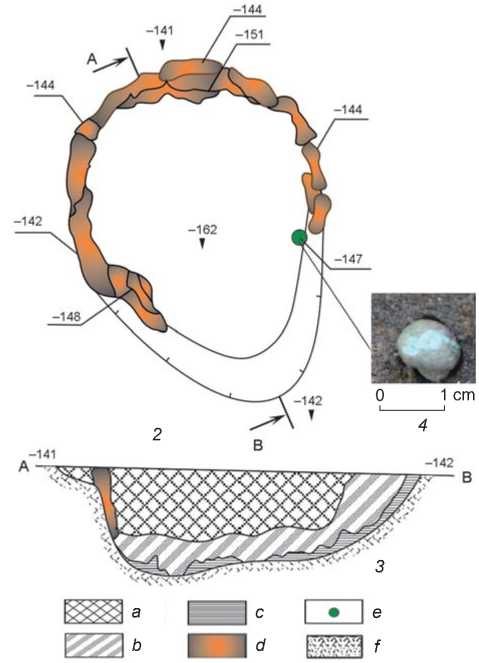

Fig. 8. General view ( 1 ), plan ( 2 ), and section ( 3 ) of furnace (structure No. 16) in dwelling No. 7 at Vengerovo-2, and a bronze drop from the furnace ( 4 ).

а – grayish-yellow mixed sandy loam; b – dark gray sandy loam with calcined inclusions; c – grayish-yellow mixed and dense sandy loam; d – clay coating; e – bronze drop; f – virgin soil.

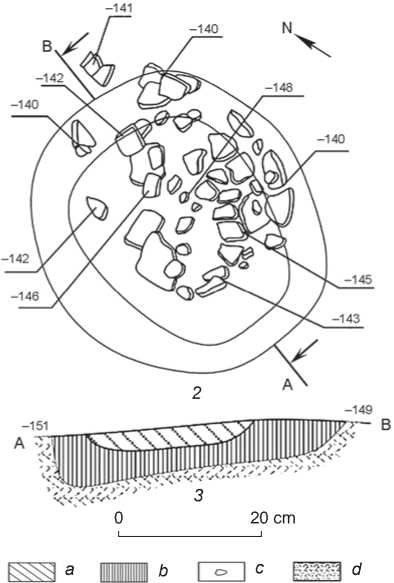

Fig. 9. General view ( 1 ), plan ( 2 ), and section ( 3 ) of the furnace (structure No. 23) in dwelling No. 7, Vengerovo-2. а – grayish-black sandy loam; b – yellowish-gray mixed sandy loam; c – ceramic fragment; d – virgin soil.

dwellings, and yields a smaller number of artifacts. According to stratigraphic features, only the western part of the hearth was used at the latest stage of its use.

1 m to the southwest of the central hearth, a special furnace was located, with the walls and floor coated with a clay layer (structure No. 16) (see Fig. 8). The furnace is a drop-shaped small pit (0.54 × 0.46 m, 0.16 m deep) oriented along the N-S line, with a minor eastward deviation. The northern, western, and eastern walls of the pit are vertical, the southern wall is sloping, the floor goes down gently from the south to the north. Clay coating (up to 3 cm thick) covers the walls and the floor except for the southern wall, which expands beyond a conventional circle (0.17 × 0.04 m). The northern wall was burnt more heavily than other wall portions. Near the southern end of the pit, bellows seem to have been mounted. These delivered the air stream, which reached the opposite wall, creating the area of highest temperature. The filling of the furnace pit yielded pieces of burnt clay and charcoal, as well as a bronze drop (see Fig. 8, 3 ). The practice of artificial airdelivery in Krotovo metallurgy is confirmed by the occurrence of nozzles in the graves of the Sopka-2/4B, C (Molodin, Grishin, 2016: 247, fig. 394). Furnaces of this sort have been reported from Preobrazhenka-3 (Molodin, 1985: 75) and other Krotovo sites.

Another furnace (structure No. 23) was located 1.5 m to the north of the abovementioned structure (see Fig. 9). It was a rounded pit, 0.4 × 0.38 m in size and 0.07 m deep. Its northern, western, and eastern walls were almost vertical, while the southern wall was sloping; the floor was uneven and slightly dipping to 5 cm from south to north. The floor and walls were paved with potsherds. A small fragment of a mold core for casting a socketed tool was found in the furnace filling. This furnace is almost identical to that described above. The only distinct feature is the pavement of the furnace inner surfaces with potsherds. A similar method of wall- and floor-

■a а EZO c EZO e [Ю g 0 20 cm b l~o~l d Шf

Fig. 10. General view ( 1 ), plan ( 2 ), and section ( 3 ) of the utility pit (structure No. 19) in dwelling No. 7, Vengerovo-2.

а – dark gray mixed sandy loam with inclusions of yellow loam; b – black calcined sandy loam; c – stone; d – animal bone fragment; e – fish bones and scales; f – ceramic fragment; g – virgin soil.

pavement was noted in the furnace structure in dwelling No. 10 (Molodin et al., 2017: 371). This technique was typical of the Krotovo and Odinovo cultures (Molodin, Nesterova, Mylnikova, 2014: Fig. 4).

The bronze-casting area also contained pits for ash utilization and bone storage. One of these pits

(structure No. 18) was irregularly pentagonal in shape, with uneven sloping walls and rounded corners. The pit’s size was 1.55 × 1.25–1.4 m, its depth was 0.13– 0.17 m. The floor was uneven, with a raised central part and a deepened western part. The pit was filled with ashy, sandy loam.

The other pit (structure No. 19) was sub-rectangular in shape, with a convex northern wall and a concave southern wall (see Fig. 10). The size of the pit was 1.20 × 0.69–0.85 m, its depth 0.06–0.1 m. The filling of the pit contained 57 pottery fragments: rims of at least four vessels; animal-bones, including those from fox (skulls, mandibles, and femurs) and horse (anterior splint bone); an operculum, scales and bones of a fish; and a pebble flake.

Traces of bronze-casting production were noted in almost all of the ten studied dwellings at Vengerovo-2. However, in terms of arrangement of the working areas, the number of furnaces, and the features of the recovered artifacts, dwelling No. 7 was the only specializing in bronze-casting.

0 2 cm

Fig. 11. Crucible from dwelling No. 3 at Vengerovo-2.

Conclusions

The currently available information on the Seima-Turbino bronzes (Kuzminykh, 2011) suggests that the Middle Irtysh basin is one of the regions most rich in such artifacts. Evidence of secondary metal-working at the Krotovo settlements of Vengerovo-2 and Abramovo-10, located more than 100 km from each other, points to the unification of the manufacturing process. These sites revealed similar types of casting areas, furnaces, and utility and waste pits, which were constructed following the standard technical tradition inherited from the preceding Odinovo culture of the Baraba foreststeppe (Stary Tartas-5 contained a furnace with one of the walls paved with large fragments of the ceramic vessel’s body (Molodin, Nesterova, Mylnikova, 2014)); similar crucibles (Fig. 11) demonstrating local traditions (Molodin, Durakov, Mylnikova et al., 2012; Durakov, Kobeleva, 2017: 23–24); and clear features of serial production (reusable molds designed for mass production, exceeding the needs of the site’s population).

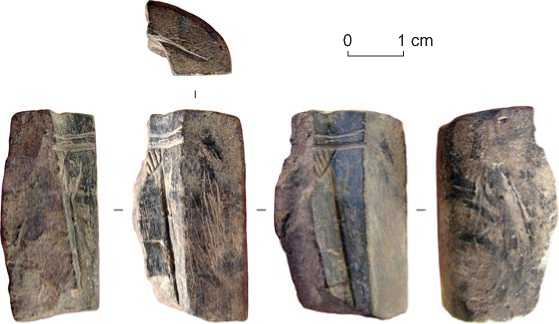

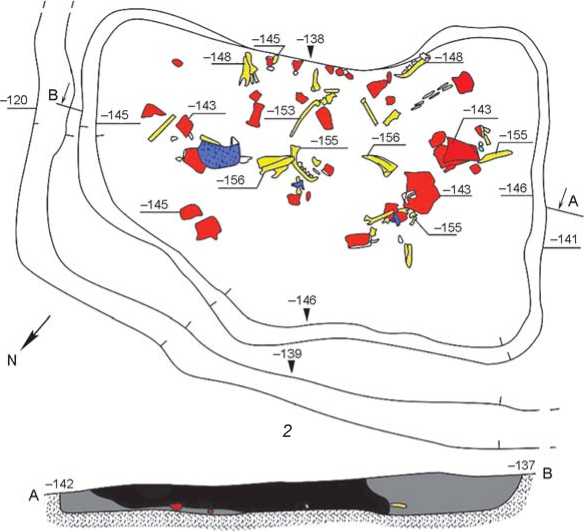

Traces of the well-developed bronze-casting production at the Middle Irtysh settlements point to the conclusion that the Seima-Turbino artifacts, which can be regarded an epochal phenomenon in this region, were undoubtedly manufactured by the indigenous Krotovo people, rather than by migrants. This inference is supported by the Seima-Turbino bronze artifacts discovered at the sites of the period under study. For instance, at Stary Tartas-1, in the cultural layer containing Odinovo and Krotovo ceramics (Molodin, Mylnikova, Grishin, 2005), two bronze celts were found, definitely belonging to the Seima-Turbino tradition. One of the celts, retaining a fragment of a wooden haft in the socket (Fig. 12, 1 , 2 ), was attributed to category K-4 or

Fig. 12. Celts ( 1 , 3 ) and fragment of a wooden haft ( 2 ) from Stary Tartas-1.

K-6 according to Chernykh and Kuzminykh’s classification (Molodin, Durakov, Sofeikov et al., 2012). The other celt, found in 2017 (Fig. 12, 3 ), is attributable to the same category. Unlike the first celt, this one is smaller, and displays the marked stiffening ribs and a relief fillet along the upper edge.

The Irtysh River and its tributaries apparently played an important role in the penetration, dispersal, and adaptation of the Seima-Turbino tradition. The tradition seems to have originated in the Upper Irtysh region. Indirect support for this assumption may be the discovery of artifacts of the Seima-Turbino-type in Xingjian (Molodin, 2017; Molodin, Komissarov, Wang Peng, 2017; Mei, 2009: Fig. 3, 1–3 ).

The Seima-Turbino artifacts, representing the best examples of the time’s advanced technologies, were imported to the Middle Irtysh region and became available to the local artisans of the Odinovo and Krotovo cultures. Indigenous metallurgists, using their own metallurgical traditions, began to produce similar items. Owing to the absence of ore reserves in the region, the West Siberian population imported raw materials from the deposits of the modern Eastern Kazakhstan, Rudny Altai, and possibly some southerner parts of Central Asia.

Acknowledgement

This study was supported by the Russian Foundation for Basic Research (Project No. 18-09-00406).