The development of new method for producing dry kumis powder

Автор: Sarsekova F., Saparbekova A., Konarbayeva Z., Mamayeva L., Aytkulova R.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 5 (101), 2013 года.

Бесплатный доступ

Kumis is a fermented dairy product traditionally made from mare's milk. Kumis is widely known as medical and highly nourishing beverage received during lactic and ethanol fermentation of mare's milk. But the kumis is still a seasonal product, in winter the mares are not milked. Lactation of mares usually lasts 5-7 months. At the same time it can not be stored for a long period, during 3-4 days sours and becomes unfit for consumption. Therefore, one of the major problems in kumis production is obtaining kumis with extended shelf life. The objects of study are mare's milk and kumis.

Мare's milk, kumis, yeast, lactic acid bacteria, sublimates drying

Короткий адрес: https://sciup.org/140205015

IDR: 140205015 | УДК: 613.3

Текст научной статьи The development of new method for producing dry kumis powder

Kumis is a fermented dairy product traditionally made from mare's milk. The drink remains important to the peoples of the Central Asian steppes, of Turkic and Mongol origin: Bashkirs, Kalmyks, Kazakhs, Kyrgyz, Mongols, Uyghurs, and Yakuts [1]. Kumis literally "water of life" is a product of microbial. Kumis enhances oxidative processes, improves interstitial exchange, normalizes the blood and, most characteristically, increases levels of hemoglobin in the blood and contributes to the disappearance of hypovitaminosis. There is the beneficial effect of kumis on the nervous system. It is also Improves the functional combination of respiratory and cardiovascular systems. Reduced acid processes in the colon and, consequently, decreases autoinintoxication of the organism; in addition, kumis increases the body's defenses. Kumis prevents premature aging and development of many diseases [2]. It is known that the kumis is only useful in the process of fermentation. Substances produced with the "kumis" microorganisms, increase the resistance of the microorganism to infections. Therapeutic value has the full range of products of kumis fermentation (alcohol, lactic acid, amino acids, B vitamins, and ascorbic acid and antibiotic compounds).

Kumis is a dairy product similar to kefir, but is produced from a liquid starter culture, in contrast to the solid kefir "grains". Because mare's milk contains more sugars than cow's or goat's milk, when fermented, kumis has a higher, though still mild, alcohol content compared to kefir.

Even in the areas of the world where kumis is popular today, mare's milk remains a very limited commodity. Industrial-scale production, therefore, generally uses cow's milk, which is richer in fat and protein, but lower in lactose than the milk from a horse. Before fermentation, the cow's milk is fortified in one of several ways. Sucrose may be added to allow a comparable fermentation. Another technique adds modified whey to better approximate the composition of mare's milk [3].

In modern controlled production, the initial fermentation takes two to five hours at a temperature of around 27 °C (81 °F); this may be followed by a cooler aging period. The finished product contains between 0.7 and 2.5% alcohol [4].

Object and methods

Sources of bacteria and yeasts, LAB were isolated from lactic acid-containing foods such as kumis, airan, katyk, susbe, sour cream, cottage cheese whey, plant substrates (grain of wheat), yeasts were isolated from different kind of kumis.

A number of media are recommended for isolating LAB from various sources. These include liquid and solid media that contain amino acids and vitamins, yeast extracts (Yeastrel) and autolysates, and protein hydrolysates. Yeast autolysate – 5 g, peptone - 10 g, glucose – 20 g, ammonium citrate – 2 g, sodium acetate – 5 g, MgSO 4 x 7H 2 O – 200 mL, MnSO 4 x 4H 2 O – 500 mg, K 2 НPO 4 – 2 g, twin 80 – 1 g, agar-agar – 20 g, water – 1 L, рН 6.2-6.6 Hydrolyzed milk (on Bogdanov) for preparing of it to 1L boiled and chilled sterile defatted milk (рН =7.4-7.6) added 1 g pancreatic, 5 mL chloroform [5].

For antagonistic activity determining of bacterium and yeast used the diffusion method for agar. As test-culture used B. subtilis, S.

typhimurium, E. сoli, P. aеruginosa, S. aureus. Test-culture grown in media with the optimal composition for each kind: mash-agar mixed with meat-peptone agar at a ratio of 1:1. Into molten and chill medium brought 0.1 mL of suspension, mixed and poured into Petri dish. In the layer of medium cut holes in which it paid a liquid suspension cultures studied daily LAB and placed in an incubator for 24 hours. After a day measured the inhibition of growth of test cultures of lactic acid bacteria [6].

Result and discussion

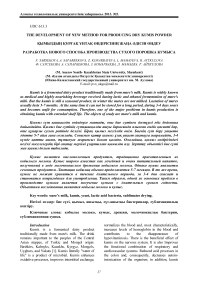

The technology preparation of kumis in an industrial environment includes the preparation of milk. Mare's milk must be obtained from healthy animals under the supervision of veterinary staff. Milk should not have off-flavors and odors, contain toxic chemicals and pathogens. Kumis prepared by the fermentation of mare's milk with special starter cultures consisting of lactic acid bacteria, yeast and milk. The technological scheme of the dry kumis powder production is illustrated in the figure 1.

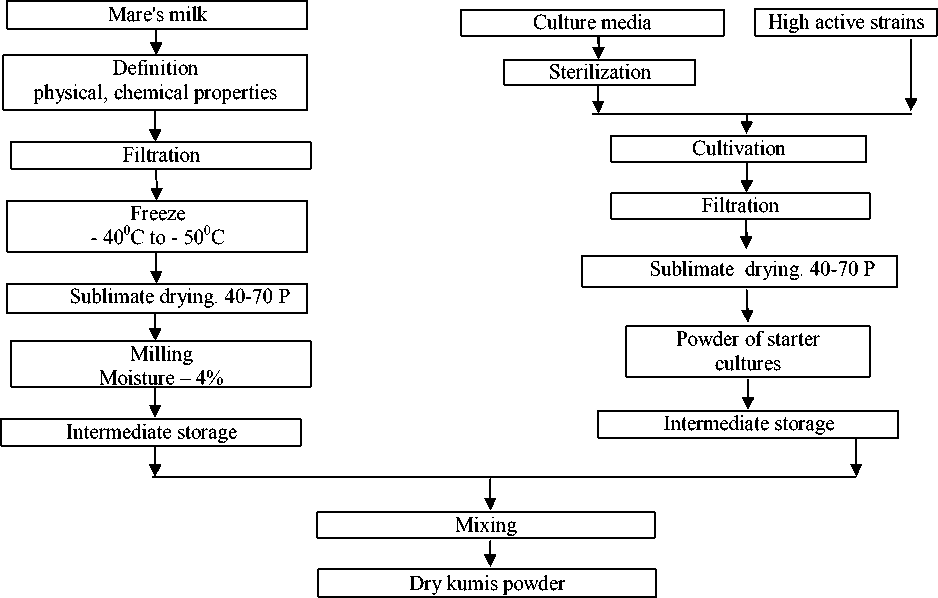

Liter of kumis contains about 20 grams of fat and protein, 70 grams of milk sugar, 800 milligrams of calcium and 500 milligrams of phosphorus, a large amount of vitamin C, vitamin A, B 1 , B 2 , PP 1 , D, E. Vitamin C in the mare's milk approximately is ten times more than in the cow milk. The uniqueness of recreational and therapeutic activities of kumis is the chemical composition of mare's milk, and substances that are produced during fermentation of milk with the aid of bacterial and yeast leaven. Mare's milk contains biologically active proteins lactoferrin, angiogenin, immunoglobulins, lysozyme, essential fatty acids, and ascorbic acid. Based on the results obtained in the investigation of the mare's milk with a milk horse farm, we obtain Figure 1, which reflects the chemical composition of mare's milk.

As seen from figure 2, milk served as material for conducting a research activity, characterized by the main chemical and physicochemical parameters: the content of protein, fat, lactose, density, titratable and active acidity.

Fat content is 1.74. This is a good indicator for the mare's milk. This suggests that the milking mares are chosen properly and provided good fodder.

The fat content of milk depends largely on the quality of the diet. Relatively high content of total proteins (2,45), characterized investigated milk. It is a measure of milk depends largely on animal breeds, as well as forage conditions.

Figure 1 - Diagram of the process of a dry kumis powder production.

Figure 2 - The chemical composition of mare's milk.

High concentration of lactose in different mammal mare. Individual mares produce milk with a lactose content of 8%. In our case, the milk is determined 5.27% lactose. High proportion of lactose in milk can produce from it a good quality mare, with ethanol content of up to 3%. While the milk of other animals, since a low concentration of milk sugar, can not make product similar kumis.

As is well known mare is a product of lactic acid and alcoholic fermentation of mare's milk under the influence of special ferment. As a result of fermentation is obtained by lightly foaming milky drink, refreshing, slightly heady, sweet-sour taste and distinctive aroma. All this gives, along with nutritious, easy digestibility and more particularly pleasant taste and aroma.

The work of many scientists will make sure that important components of milk are lactose, protein, fat, vitamins, enzymes, and minerals. Lactose is the most strongly varies during maturation of kumis, because it is a source of energy needed to achieve energy cost of microorganisms in kumis. But the kumis is still a seasonal product: in winter the mares are not milked. Lactation mares usually lasts 5-7 months. At the same time, it can not be stored for a long period, 3-4 days sours and becomes unfit for consumption. Therefore, one of the major problems in kumis production is obtaining kumis with extended shelf life. Therefore, our main task was - to develop a method for producing a dry kumis powder, providing improved quality and healing properties of milk beverages, as well as increase the shelf life of finished product.

Yeasts for a long time have been applied in fermented beverages, because they can improve nutritional, organoleptic, technological and shelf-life characteristics. The presence of yeasts, particularly in dairy products, offers potential advantages due to the production of flavour components, acceleration of ripening, by metabolizing milk constituents [7].

We selected five strain Torulopsis sphaerica, two strains Torulopsis kefir var. kumis and one strain Candida mycoderma having strong antagonistic properties against to saprophytic conditionally-pathogenic and pathogenic bacteria. For the development of the kumis leaven from 8 active strains only 1 strains were chosen. It is Torulopsis sphaerica TR 3 having high antagonistic activity.

Viable microorganisms such as LAB present in food and nutritional supplements can produce antibiotics that can suppress undesirable microflora present in the gastrointestinal tract. Table 1 presents studies of antagonistic activities of LAB. L. аcidophilus SHА-2, S. thermophilus IТ-2, S. lactis SS-2, S. lactis SSа-1, S. cremoris K-3, and S. lactis Tuz-2 showed the highest levels of antagonistic activities, suggesting that they may be useful in the manufacture of sour milk products as dietary supplements and therapeutics.

The optimum temperature for culturing LAB differs from that required for fermentation and can vary depending on conditions. The activity of ripening process depends on the length of the lag phase of growth, and the activity of acid formation is the compulsory criterion for determining the activity of LAB. L. аcidophilus SHА-2, S. lactis SSа-1were used to study the rate of acid production

Lactobacillus acidophilus (L. acidophilus) is the most commonly used probiotic, or "friendly" bacteria. Many healthy bacteria live in the intestines and vagina, where they protect against "bad" bacteria that can cause disease. They do this is a couple of ways: for example, when L. acidophilus breaks down food in the intestine, several substances are formed (such as lactic acid and hydrogen peroxide) that create an unfriendly environment for “bad” bacteria [8].

Table 1 - Antagonistic activity of lactic acid bacteria

|

Strain |

Diameter of zones of growth suppression (mm) |

||||

|

Salmonella typhimurium |

Escherichia coli |

Pseudomonas aeruginosa |

Staphylococ cus aureus |

Bacillus subtilis |

|

|

S. cremoris SL-12 |

6 ± 0.5 |

10.7 ± 0.5 |

13.5 ± 0.5 |

14.6 ± 0.5 |

6.3 ± 0.5 |

|

S. lactis SH-4 |

9.2 ± 0.5 |

6 ± 0.5 |

12.6 ± 0.5 |

16.6 ± 0.5 |

7.4 ± 0.5 |

|

L. аcidophilus SHА-2 |

18.9 ± 0.5 |

20.2 ± 0.5 |

14.4 ± 0.5 |

21.6 ± 0.5 |

13.4 ± 0.5 |

|

S. lactis SN-1 |

12.3 ± 0.5 |

4.7 ± 0.5 |

8.5 ± 0.5 |

14.6 ± 0.5 |

8.6 ± 0.5 |

|

S. thermophilus IТ-2 |

14.4 ± 0.5 |

11.6 ± 0.5 |

14.4 ± 0.5 |

15.6 ± 0.5 |

18.4 ± 0.5 |

|

L. аcidophilus Тr-2 |

11.0 ± 0.5 |

12.6 ± 0.5 |

7.3 ± 0.5 |

24.6 ± 0.5 |

11.5 ± 0.5 |

|

S. thermophilus Тr-3 |

18.7 ± 0.5 |

4.7 ± 0.5 |

8.5 ± 0.5 |

14.6 ± 0.5 |

8.6 ± 0.5 |

|

S. lactis Тr-4 |

8.4 ± 0.5 |

11.6 ± 0.5 |

14.4 ± 0.5 |

8.6 ± 0.5 |

18.4 ± 0.5 |

|

S. lactis SS -2 |

11.7 ± 0.5 |

19.8 ± 0.5 |

11.3 ± 0.5 |

24.6 ± 0.5 |

11.5 ± 0.5 |

|

S. cremoris SSp-3 |

8.4 ± 0.5 |

10.7 ± 0.5 |

12.5 ± 0.5 |

14.6 ± 0.5 |

6.3 ± 0.5 |

|

S. lactis SSа-1 |

19.2 ± 0.5 |

17.6 ± 0.5 |

16.2 ± 0.5 |

15.1 ± 0.5 |

17.7 ± 0.5 |

|

S. thermophilus SPа-1 |

9.2 ± 0.5 |

6 ± 0.5 |

12.6 ± 0.5 |

16.6 ± 0.5 |

7.4 ± 0.5 |

|

L. bulgaricus SPm-2 |

4.0 ± 0.5 |

11.6 ± 0.5 |

6.3 ± 0.5 |

10.8 ± 0.5 |

6.2 ± 0.5 |

|

S. lactis SPz-1 |

12.3 ± 0.5 |

4.4 ± 0.5 |

9.5 ± 0.5 |

14.7 ± 0.5 |

8.6 ± 0.5 |

|

L. plantarum SPz-2 |

10.5 ± 0.5 |

13.8 ± 0.5 |

10.4 ± 0.5 |

8.9 ± 0.5 |

9.4 ± 0.5 |

|

S. lactis K-1 |

12.7 ± 0.5 |

8.7 ± 0.5 |

9.5 ± 0.5 |

14.6 ± 0.5 |

8.6 ± 0.5 |

|

S. cremoris K-3 |

16.9 ± 0.5 |

18.2 ± 0.5 |

14.4 ± 0.5 |

14.6 ± 0.5 |

13.4 ± 0.5 |

|

S. lactis ТU-5 |

15.0 ± 0.5 |

21.6 ± 0.5 |

6.8 ± 0.5 |

10.8 ± 0.5 |

6.2 ± 0.5 |

|

S. lactis Тuz-2 |

10.7 ± 0.5 |

12.7 ± 0.5 |

11.5 ± 0.5 |

14.7 ± 0.5 |

11.6 ± 0.5 |

Probiotics are often suggested as a supplement when you take antibiotics. Antibiotics kill bacteria, but don' t discriminate between “friendly” and “unfriendly” organisms, so the balance between good and bad bacteria in the intestines can be upset. It is thought that taking probiotics helps restore the healthy balance of bacteria. Microbial associations which contain Lactic acid bacteria and yeast are the principal organisms involved in the manufacture of a lot of dairy products. In some fermented dairy products, additional bacteria, referred to as secondary microflora, are added to produce carbon dioxide, which influences the flavor and alters the texture of the final product.

The first step in preparing dry kumis powder was a definition physical, chemical properties, dry solids, fat, protein and minerals, milk sugar

The second step was milk filtration. We offer deep filter media in various levels of stability and stiffness especially for milk filtration: Viledon nutritexx nonwoven fabrics can be processed into suitable sacs or hoses by sewing, welding or pressing – whatever the application calls for. The high percentage of natural cellulose causes an optimal purification of the milk without sacrificing valuable fats or proteins.

Simultaneously microbial associations which contain Lactic acid bacteria and yeast were chosen. Cultures of lactic acid bacteria Lb. acidophilus, Str. lactis and yeast Torulopsis sphaerica grown separately and mixed in a ratio of 1: 1: 0.5 immediately before fermentation kumis (table 2).

Thereby among of all tested yeasts the best starter kumis were Lb. acidophilus, + Str. lactis, + T. Sphaerica. Ratio of the different combinations LAB and yeast 1: 1: 0,5 is №2. We investigated the effect of the leaven to intensity of the fermenting mare's milk, the quality kumis, acid-and aromatic formation in kumis. The results of the experiment are also re- confirmed the high quality of this product.

Table 2 - Influence of the different combinations lactic acid bacteria and yeast on quality of the kumis

|

Ratio of the different combinations LAB and yeast |

Organoleptic factors |

|

|

1 |

1:1:0,25 |

Kumis pleasing, sour milk taste, fermented, little carbonated. |

|

2 |

1: 1: 0,5 |

Kumis pleasing, refreshing, carbonated, homogeneous, fermented. |

|

3 |

0,5:0,5:0,5 |

Kumis little carbonated, water taste. |

|

4 |

0,5:0,5:1 |

Kumis pleasing, weak sour milk taste, fermented, powerfully carbonated. |

|

5 |

1:0,5:0,5 |

Kumis sour milk taste, little carbonated, homogeneous. |

|

6 |

0,5:1:0,5 |

Kumis sour milk taste, little carbonated, pleasing, homogeneous. |

|

7 |

0,5:1:1 |

Kumis sour milk taste, weakly fermented, homogeneous. |

|

8 |

1:1:1 |

Kumis fermented, carbonated, pleasing. |

|

9 |

2:1:0,5 |

Kumis sour milk taste, little carbonated, pleasing. |

|

10 |

1:2:0,5 |

Kumis strong sour milk taste, fermented, little carbonated. |

The next step in preparation of dried powder is freeze wherein the primary parameter influencing the quality of the subsequently finished product is freezing temperature. Based on the experimental study of the optimum temperature of freezing of condensed - 40ºC

Freeze-drying (also known as lyophilization or cryodesiccation) is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublime directly from the solid phase to the gas phase.

Milling (grinding), the process of grinding dry milk or other materials in a powder by milling machine, a cutting and shaping equipment or hand by mortar

After drying, the mare's milk powder is mixed with the dried starter and probiotic cultures. A mixture of dry mare's milk powder and dried leaven cultures is form kumis powder.

In the capacity of the mixer water is poured an amount of 1 / 3 to 1 / 2 required for the recipe and dry kumis powder is added.

The mixing proceeds until the mixture gets a uniform consistency. Then remaining water is added, reaching the overall ratio of dry kumis powder and water 1:5. The resulting mixture was stirred during 20-25 min with simultaneous aeration, kept for 2 h. Then maturation of the mixture is bottling, tight sealing and cooling it at a temperature from 2 to 8oC. Thus, as a result of the proposed method was obtained kumis with increased antibiotic activity, and also has preventive properties against conditionally-pathogenic and pathogenic bacteria.

Conclusion

Production of dry kumis powder is a new technology that allows exporting national product over long distances, while maintaining all its nutritional and medicinal qualities.

Experiments have shown chemical composition of mare's milk, kumis and changes in the fermentation process, reviewed the technologies of kumis production. The study revealed the optimum method of mare’s milk and starter culture drying. Technological scheme for dry kumis powder production based on high active culture was developed.

Result of scientific work the chemical composition of mare's milk were indicated. In the result were selected specific active strains of microorganisms which can be used in kumis fermentation. The best starter kumis were L. аcidophilus SHА-2, S. lactis SSа-1 + T. Sphaerica TR 3. Ratio of the different combinations LAB and yeast 1: 1: 0,5. Also were investigated methods for drying of kumis and choose sublimate drying.

REFFENCES

-

1. Zeder, Melinda A. ed. (2006). Documenting Domestication: New Genetic and Archaeological Paradigms. University of California Press. -P. 264.

-

2. Lozovich S. Medical use of whole and fermented mare milk in Russia. - Cultured Dairy Products Journal. 31, 1995. - Р. 18-21.

-

3. Kurmann, Joseph A. et al. (1992). Encyclopedia of Fermented Fresh Milk Products. Springer. -Р. 174.

-

4. Outram, A. K.; Stear, N. A.; Bendrey, R.; Olsen, S.; Kasparov, A.; Zaibert, V.; Thorpe, N.; Evershed, R. P. (6 March 2009). "The Earliest Horse Harnessing and Milking". Science 323 (5919): 1332–1335.

-

5. Merkulova, N.G., Merkulov, M.Y., Merkulov, I.Y., 2009. Production control in the dairy industry. St. Petersburg, - Professiya. - 340 p.

-

6. Technical specifications 10-02-02-789-6597, 1991.

-

7. Kozhahmetova Z.A., Tolysbaev B.T., Duysembaev K.I. - Physiological characteristic yeast of the kumis fermentation //Material international scientifically-practical conference "Condition and prospects of the development of the veterinary science and practical persons" denoted State program "Aul -an EXECUTION- VI. - Almaty, 2003. - Р.143-148.

-

8. Reddy, G.C., K.M. Shahani, B.A. Friend and R.C. Chandan, 1984. Natural antibiotic activity of Lactobacillus acidophilus and bulgaricus, production and partial purification of Bulgaricus cultured. J. Dairy Products, 8: 15-19.

Список литературы The development of new method for producing dry kumis powder

- Zeder, Melinda A. ed. (2006). Documenting Domestication: New Genetic and Archaeological Paradigms. University of California Press. -P. 264.

- Lozovich S. Medical use of whole and fermented mare milk in Russia. -Cultured Dairy Products Journal. 31, 1995. -Р. 18-21.

- Kurmann, Joseph A. et al. (1992). Encyclopedia of Fermented Fresh Milk Products. Springer. -Р. 174.

- Outram, A. K.; Stear, N. A.; Bendrey, R.; Olsen, S.; Kasparov, A.; Zaibert, V.; Thorpe, N.; Evershed, R. P. (6 March 2009). "The Earliest Horse Harnessing and Milking". Science 323 (5919): 1332-1335.

- Merkulova, N.G., Merkulov, M.Y., Merkulov, I.Y., 2009. Production control in the dairy industry. St. Petersburg, -Professiya. -340 p.

- Technical specifications 10-02-02-789-65-97, 1991.

- Kozhahmetova Z.A., Tolysbaev B.T., Duysembaev K.I. -Physiological characteristic yeast of the kumis fermentation//Material international scientifically-practical conference "Condition and prospects of the development of the veterinary science and practical persons" denoted State program "Aul -an EXECUTION-VI. -Almaty, 2003. -Р.143-148.

- Reddy, G.C., K.M. Shahani, B.A. Friend and R.C. Chandan, 1984. Natural antibiotic activity of Lactobacillus acidophilus and bulgaricus, production and partial purification of Bulgaricus cultured. J. Dairy Products, 8: 15-19.