The effectiveness of using fibre-reinforced concrete in underground construction: experience and prospects

Автор: Rusanov V.E., Maslov P.S., Alekseev V.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 3 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The article discusses the current state of the possibilities to improve the efficiency of construction processes by using fibre-reinforced concrete in the construction of transport and utility tunnels, as well as other critical building structures. The authors present foreign experience with widespread use of fibre-reinforced concrete in transport construction, as well as few such cases for domestic practice. The inconsistency of domestic experience with the modern state of art has been noted. The main blockers in the development of the issue are under consideration, the theoretical approach and practical application are presented. Materials and methods. The principal aspects of the current approach to the quality indicators of fibre-reinforced concrete and the classification principles of fibre-reinforced concrete based on quality criteria, which are the basis for the normalization of material characteristics, are described. The continuity of domestic and European regulatory documents is shown. Results. Illustrated examples of the possibilities of an optimization approach to the selection of structural solutions in the design of transport construction facilities used in international practice are described. Conclusion. The argumentation in favor of technology development is shown. This opens up possibilities for significant cost reduction justified by a scientific approach. In conclusion, the authors provide recommendations on the general application of the promising material in the domestic practice.

Fibre-reinforced concrete, dispersed reinforced concretes, composite materials, high-strength concrete, calculation methods, stress-strain state, fibre, modified binders, tunnel, lining, load-bearing structures of underground construction facilities

Короткий адрес: https://sciup.org/142240873

IDR: 142240873 | DOI: 10.15828/2075-8545-2024-16-3-276-287

Текст научной статьи The effectiveness of using fibre-reinforced concrete in underground construction: experience and prospects

Review article

M odern construction has been constantly improving, materials and their properties are optimized, more modern technologies are used, a fundamental analysis allows us to apply more advanced methods of structural calculations. One of the development vectors combined with the latest achievements of science and technology is the wider use of composite materials such as fibre-reinforced concrete (FRC) [1, 2, 3]. These materials are a special type of concrete in the volume of which metal or polymer fibres of different geometries and characteristics [6, 7] can be distributed by the method of dispersed reinforcement [4, 5], i.e. the entire thickness of the concrete structure

during construction will be permeated with fibres located in different directions and setting special properties of the material.

At the present time a large number of different types of fibres are used in fibre-reinforced concrete, the range of which is constantly increasing and the properties of already known fibres are being optimized [8]. The main materials for fibre used in the dispersed reinforcement of concrete include steel, glass, polymers (acrylic, aramid, nylon, polypropylene, etc.), ceramics, asbestos, carbon, and even natural fibres (wood, coconut, bamboo, etc.) [9].

However steel fibre is most often used in structural concretes that take the main load in buildings and constructions. Although studies have been conducted on the

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION use of polymer fibres with characteristics close to steel [2, 8, 10]. Structural fibre should have increased strength to loads, have no shrinkage deformations and contribute to increased crack resistance and wear resistance.

From the point of view of properties for concretes of the most common classes B20–B40 the FRC is an effective substitute for standard reinforced concrete and allows to achieve the required physical and mechanical properties of concrete structures giving at the same time a number of positive properties:

-

– elimination of reinforcement work and reduction in construction costs;

-

– eduction to shrinkage;

-

– resistance to cracking;

-

– high tear and tensile strength comparable to reinforced concrete;

-

– increased modulus of elasticity;

-

– resistance to weathering influences and chemicals;

-

– high plasticity;

-

– impact resistance.

The use of FRC as load-bearing elements of precast and monolithic structures and sprayed shells in underground constructions looks especially promising.

It should also be noted that the properties of the final material – FRC – are significantly influenced by the characteristics of the binder and fillers used. On the basis of the Department of Technology of Binders and Concretes of the National Research University of MGSU the authors conducted tests on the modification of the binder for FRC with fillers having independent hydraulic activity and a high degree of dispersion (microparticles of selected mineral components with particle diameters d95 = 6 and 9 microns with a content of nanoparticles with average diameters of less than 0.1 microns to 10 and 5% respectively).

The introduction of micro- and nanoparticles with specified grain granulometric parameters allows filling the intergranular space of the standard Portland cement fraction granules with particles comparable in size to the volume of the formed pores, as well as contributing to the sealing of capillary pores. When selecting the composition of a composite binder, the maximum filling of the intergranular space with a micron filler in a given volume without exceeding it, with the exception of the effect of wedging large particles, should also be taken into account. The nanoparticles in the filler, in their turn, fill the smallest pores and contribute to the compaction of the cement paste structure at the micro level. When fibre is introduced into the modified concrete mixture, a more dense contact arrangement of the “fibre – cement stone – grains of inert aggregate” system occurs, which encourages a more active involvement of fibre work in the operation of the concrete structure during operation.

However, today there are no unambiguous regulatory documents prescribing the cost of materials to obtain a number of required characteristics of FRC, which is especially true for complex work structures such as the lining of underground constructions. Experiments on the selection of compounds and some experimental data have not been continued in the form of a completed document that allows designing fibre-reinforced concrete structures and establishing certain costs of the required components for it. One of the goals of the intended scientific research is to develop a regulatory framework for calculations and standard technological maps in order to obtain FRC, in particular for use in underground structures.

LLC Scientific and Engineering Center Tunnel Association and Scientific and educational Center Underground Construction of the National Research University (MGSU) undertake scientific research on the use of fibre-reinforced concrete in underground structures and have their own developments in the calculation and design of fibre-reinforced concrete structures, confirmed by construction and operation practices. In addition, it should be noted that global progress, constantly developing industry and the introduction of innovations in the chemical industry make it possible to increase dramatically the effectiveness of such technologies in the future.

THE SUBJECT OF THE STUDY

Tunnel linings constructed in a closed manner (circular and vaulted outlines) from the standpoint of structural mechanics are statically indeterminate structural systems operating overwhelmingly in conditions of off-center compression with predominance of compression stress. In such conditions, the strength and stress-strain properties of fibre-reinforced concrete (FRC) are realized most effectively due to their special characteristics.

Fibre-reinforced concrete structures are able to be loaded and resist deformation after the formation of cracks in them without brittle destruction, while the tensile strength of the FRC (marginal relative tensile deformations) can exceed the compressibility limit.

At the moment regulatory documents have been developed and are in force on the territory of the Russian Federation that allow you to design effective tunnel structures made from FRC: SP 2971, SP 3602, STO NOSTROY 2.27.1253. Moreover, there are regulatory guidance manuals, for example, “Guidelines for the design of concrete

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION and reinforced concrete tunnel linings using composite materials”, approved by the construction complex of the city of Moscow. Technical specifications and quality control requirements for heavy and fine-grained steel FRC are given in GOST R 595354. The codes of Rules SP 360 and SP 297 are entered into the List of documents in the field of standardization, as a result of which, on a voluntary basis, compliance with the requirements of Federal Law No. 384-FZ dated December 30, 2009 “Technical Regulations on the safety of buildings and structures” is ensured. With all the possibilities, the use of fibre-reinforced concrete for load-bearing structures of transport, utility tunnels, as well as other critical building structures of urban infrastructure isn’t widely spread in the domestic construction practice.

ANALYSIS OF APPLICATION EXPERIENCEAND DEVELOPMENT PROSPECTS IN THE RUSSIAN FEDERATION

FRC is used to a much greater extent in European countries where Spain [11, 12, 13], Italy [14, 15, 16, 17], Portugal [18], Great Britain, Germany [19, 20, 21, 22], Norway, Switzerland have the leading positions. Outside Europe, fibroblast is widely used in Australia [23, 24], Brazil, Peru, the USA [25, 26], Ecuador, and Japan. Recently. The use of FRC for the fastening of transport tunnels by shotcrete has become widespread in Turkey [27, 28].

The widespread use of FRC is due to the high level of scientific and technological progress in this field for the past twenty years. The state-of-the-art technology allows you to get significant advantages when using the material. The resistance to the transverse force in the structure increases to 57% depending on various parameters, while the crack opening width decreases to 70% with delayed crack formation in the area of action of the transverse forces [29].

According to the Bulletin of the International Tunnel Association for 2016 [30, 31], about 40 large projects were implemented in the Italian metro until 2016 only for the shield method of tunnel construction since the introduction of fibre-reinforced concrete in transport tunneling in 1982 (see Table 1). Lining structures with diameters from 4.8 to 14.3 m with reinforcement were used with only steel fibre in 58% of cases, with combined reinforcement “steel fibre + steel reinforcement” in 39% of cases. One project was implemented using polymer fibre reinforcement in combination with steel reinforcement.

The wide practice of using fibre-reinforced concrete also initiates the scientific and technical basis/arguments of the applied selected technical solutions. As a result of these works, it becomes possible to significantly reduce the costs and refine the calculation methods. For example, during the construction of the ninth metro line in Barcelona, a technical solution (65 kg of fibre per 1 m3 of concrete), adopted on the basis of the calculation method fib Model Code 2010 [32], which looked effective, was refined according to the results of scientific work [33] with a decrease in the amount of fibre reinforcement to 45 kg/m3.

The extensive experience of foreign colleagues demonstrates the technical and economic efficiency of fibre-reinforced concrete, especially in the tunnel construction industry, which is achieved by:

-

• reduction in labor costs for the manufacturing prefabricated linings of the shield method of work and monolithic linings of the mining method of work;

-

• increasing productivity (production speed with the inline method) in the production of prefabricated blocks of linings for the shield method of work and reducing the manufacturing time for monolithic linings with the mining method of work;

-

• reduction in defect rate during production of prefabricated blocks, as well as their transportation and installation by a block loader.

To date, however, there has been no precedent in the domestic tunneling industry in using fibre-reinforced concrete tunnel linings at transport and even municipal facilities.

Fibre-reinforced concrete tunnel structures were applied in the framework of experimental metro sections in Moscow (fibre-reinforced shotcrete jacket of the distillation tunnel and lock blocks made of FRC) and St. Petersburg (3 rings of lining) [34, 35, 36, 37]. It is worth noting that at the time of the construction of the experimental sections, steel fibre was used, which, as of today, is not suitable for load-bearing structures operating under stress with off-center compression.

At the same time, it is noteworthy that the leadership in the use of FRC belongs to Russian engineers [38]. Vladimir Pavlovich Nekrasov at the beginning of the 20th century (1907–1909) studied and patented the composition of concrete reinforced with wire segments (1925 monograph “The method of indirect concrete armament”).

The main problems of FRC implementation in underground construction and in particular for the construction of tunnel linings for various purposes are:

-

• the lack of a precedent for using FRC structures on real objects in the Russian Federation, and the presence of two or three experimental sites carried out in the 90s – 2000s does not provide correct information on the technical and economic efficiency of the material;

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

Table 1

International experience in the use of prefabricated SFRC linings for transport tunnels [30]

|

Tunnel Name |

Year |

Countiy |

Function |

%т |

11, ш |

Fibre |

Rebars |

|

Metiosud |

1982 |

Italy |

Subway |

6.40 |

0.30 |

Steel |

No |

|

Heathrow Express |

1994 |

England |

Railway |

6.14 |

0.22 |

Steel |

No |

|

Napoli metio |

1995 |

Italy |

Subway |

6.40 |

0.30 |

Steel |

No |

|

2nd Heiiienoord |

1999 |

Netherlands |

Road |

8.30 |

0.35 |

Steel |

No |

|

Jubilee Line Extension |

1999 |

England |

Subway |

4.90 |

0.20 |

Steel |

No |

|

Essen |

2001 |

Gennaiiy |

Subway |

8.00 |

0.35 |

Steel |

No |

|

Oeiizberg tiumel |

2003 |

Switzerland |

Railway |

11.40 |

0.30 |

Steel |

No |

|

Oeiizberg-TBM |

2003 |

Switzerland |

Railway |

12.20 |

0.40 |

Steel |

Yes |

|

Oeiizberg-Shield |

2003 |

Switzerland |

Railway |

12.20 |

0.40 |

Steel |

No |

|

Baicelona Metro Line 9 - Cail Zain Stretch |

2003 |

Spain |

Subway |

11.60 |

0.35 |

Steel |

No |

|

Channel Tiumel Rail Link (CTRL) |

2004 |

Eng. - Frail. |

Railway |

7.90 |

0.35 |

Steel |

No |

|

Heathrow Express Extension (HexEx) |

2005 |

England |

Railway |

6.14 |

0.22 |

Steel |

No |

|

Metropolitan Expressway CCSR tiumel |

2005 |

Japan |

Road |

11.80 |

0.45 |

Steel |

Yes |

|

Baicelona Metro Line 9 - Stretch I |

2006 |

Spain |

Subway |

9.04 |

0.32 |

Steel |

Yes |

|

Lotschberg |

2007 |

Switzerland |

Railway |

4.94 |

0.22 |

Steel |

No |

|

Beacon Hill Tmuiels |

2007 |

USA |

Road |

7.30 |

0.30 |

Steel |

No |

|

Madrid Metio |

2007 |

Spain |

Subway |

9.00 |

0.30 |

Steel |

Yes |

|

Line 1 of the Valencia Metro |

2007 |

Spain |

Subway |

9.20 |

0.40 |

Steel |

Yes |

|

Heathrow - PiccEx |

2008 |

England |

Subway |

4.80 |

0.15 |

Steel |

No |

|

Heathrow Express Ext. Tiumel to T5 |

2008 |

England |

Railway |

6.14 |

0.22 |

Steel |

No |

|

Sao Paulo Metro Line 4 |

2009 |

Brazil |

Subway |

9.10 |

0.35 |

Steel |

No |

|

Docklands Liglit Railway (DLR) Extension |

2009 |

England |

Railway |

5.80 |

0.25 |

Steel |

No |

|

Malaga Rail Tiumel |

2009 |

Spain |

Railway |

9.04 |

0.32 |

Synth. |

Yes |

|

The Clem Jones Tinuiel - Clem 7 |

2010 |

Australia |

Road |

12.00 |

0.40 |

Steel |

Yes |

|

Extension of the FGC ill Ten'assa |

2010 |

Spain |

Railway |

6.60 |

0.30 |

Steel |

Yes |

|

Keio line |

2010 |

Japan |

Railway |

7.30 |

0.30 |

Steel |

Yes |

|

Metropolitan Expressway |

2011 |

Japan |

Road |

14.30 |

0.45 |

Steel |

Yes |

|

Aiipoit Link |

2012 |

Austialia |

Road |

12.20 |

0.40 |

Steel |

No |

|

Sagami Line |

2012 |

Japan |

Road |

12.80 |

0.50 |

Steel |

Yes |

|

Koisliikawa Kasen |

2013 |

Japan |

Railway |

7.30 |

0.30 |

Steel |

Yes |

|

The Welniialm Line |

2014 |

Gennaiiy |

Subway |

8.90 |

0.30 |

Steel |

No |

|

Sail Francisco Central Subway |

2014 |

USA |

Railway |

5.96 |

0.28 |

Steel |

Yes |

|

Legacy Way |

2015 |

Austialia |

Road |

12.00 |

0.35 |

Steel |

No |

|

Metropolitan Expressway |

2015 |

Japan |

Road |

13.10 |

0.40 |

Steel |

Yes |

|

Doha Meti'o Red North Line |

2016 |

Qatar |

Subway |

6.77 |

0.30 |

Steel |

No |

|

Downtown Line 3 |

u.c. |

Singapore |

Subway |

6.36 |

0.28 |

Steel |

No |

|

Thomson Line |

uc |

Singapore |

Subway |

6.36 |

0.28 |

Steel |

No |

|

Crossrail |

u.c. |

England |

Railway |

6.80 |

0.30 |

Steel |

No |

|

Вгешіег Base Tumiel |

u.c. |

Italy-Austi'ia |

Road |

6.00 |

0.20 |

Steel |

Yes |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

-

• poor awareness of design organizations and state evaluation bodies of the possibilities, prospects and conditions for the effective use of FRC, as well as the lack of methodological developments in the design and calculation of structures made of FRC;

-

• the lack of equipment of the reinforced concrete plants (dispensers, dispersants, special mixers), including absence of special equipment for testing fibre-reinforced concrete samples in quality control laboratories;

-

• the absence of accumulated statistics on testing of FRC samples in the Russian Federation for various classes of FRC; absence of practical base of lining designs in conjunction with FRC classes;

-

• the lack of specialized courses (lectures) on the FRC construction of underground structures and tunnels in universities.

Currently, structural fibre-reinforced concrete can be classified as follows:

-

• by type of concrete-matrix – made from concrete of normal strength (up to B60); high-strength concrete – HSC/HPC (B60-B100[150]); ultra-high-strength concrete – UHSC/UHPC (above B150);

-

• according to the type of fibre used – made of steel (wire with bends R > 1200 MPa); polymer (straight R > 800 MPa); a combination of microfibre and structural fibre;

-

• by the type of reinforcement in the structure – fibre of the same type; a combination of fibre of the same type and rod reinforcement without prestressing; fibre of two types (hybrid) and rod reinforcement without pre-

stressing; fibre of two types (hybrid) and prestressed reinforcement;

-

• by the nature of the work with cracks – with softening (conventional FRC); with hardening (high fibre content in both normal strength FRC and HSC/HPC or UHSC/UHPC).

Therefore, in connection with the peculiarities of the nature of the work, the rationing of FRC by physical and mechanical characteristics is carried out in two classes – the concrete (matrix concrete) class in compressive strength B and the FRC class in residual tensile strength BF.

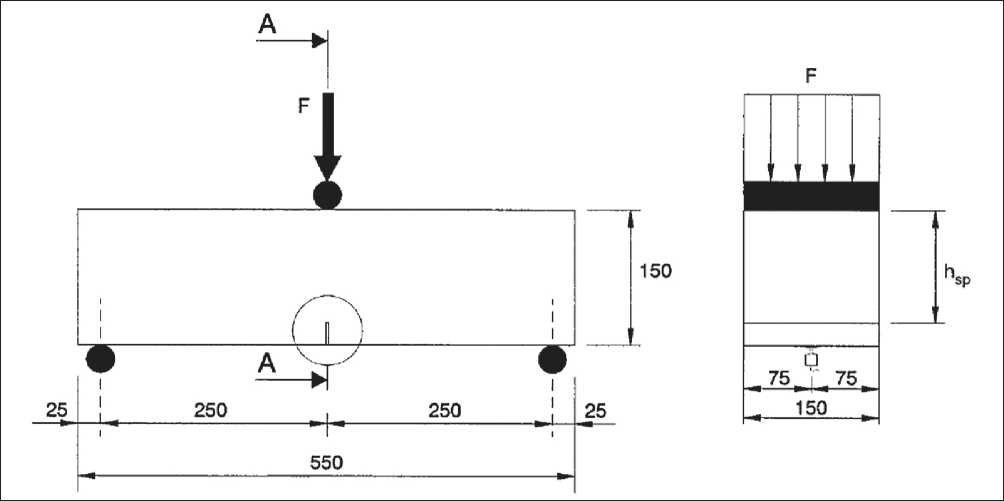

The class of FRC in terms of residual tensile strength BF is determined by testing samples-prisms with a cross section of 150×150 mm, a length of 550...600 mm with an incision in the center (see Fig. 1) either without incision, or round plates with diameter of 800 mm, thickness of 75 mm [39]. During the tests, the applied load and the opening width of the incision (in the case of a sample-a prism with an incision) or the deflection of the sample in the center (in the case of a sample-a prism without an incision and a round plate) are recorded.

A special aspect of the tests is the use of special servo– hydraulic equipment for loading and monitoring deformations of samples, which has an almost instantaneous response to changes in the stiffness of the sample due to the formation of micro and macro cracks, which allows you to record the descending sections (the softening stage) in the Load-Strain graphs.

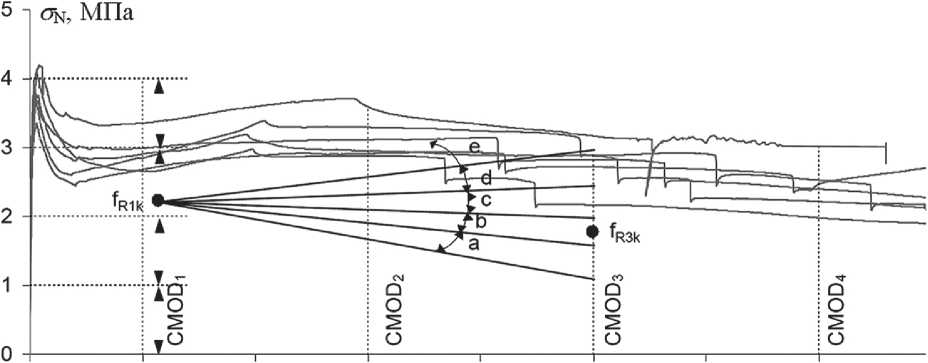

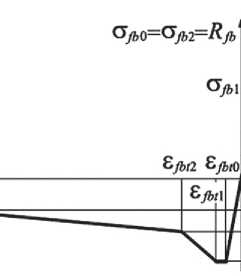

The diagram (Fig. 2) shows the test results of incised prism samples, while the concentrated load scale F is re-

Fig. 1. Example of a test scheme for a prism sample with an incision to determine the class of FRC in terms of residual tensile strength BF

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

Fig. 2. Scheme for determining the class of FRC by residual tensile strength BF based on test results of samples-prisms with an incision

placed by the normal stress scale in the central section of the sample σN, the CMOD scale (Crack Mouth Opening Displacement) indicates linear deformations of the incision lower edge of the sample (modeling crack growth). The strength corresponding to a small deformation (the second group of limiting states) at CMOD1 = 0.5 mm is indicated in the diagram as fR1. The strength corresponding to the limit deformations (the first group of limit states) at CMOD3 = 2.5 mm is indicated in the diagram as fR3. Two indicators are used to normalize the FRC class in terms of residual tensile strength BF: fR1, which is recorded in the designation with a number rounded down to the nearest normalized class; the ratio fR3/ fR1 with range ranking and designation in Latin letters:

a – at 0,5 ≤ fR3/ fR1 < 0,7;

b – at 0,7 ≤ fR3/ fR1 < 0,9;

c – at 0,9 ≤ fR3/ fR1 < 1,1;

d – at 1,1 ≤ fR3/ fR1 < 1,3;

e – at 1,3 ≤ fR3/ fR1.

For example, in the diagram in Fig. 2, for the designated points fR1 and fR3, the class of FRC in terms of residual tensile strength should be written as BF2.0b (taking into account statistical processing of test results for fR1 and fR3).

It should be noted that in SP 297, SP 360, with the concept of European regulatory documents adopted by the authors of the Joint Venture regarding the classification of fibre-reinforced concrete, a typo was made in the letter designation of the fR3/fR1 ratio ranges.

Thus, the full designation of the FRC class (without specifying the brands for water resistance and frost resistance) looks, for example, as follows:

SFRC B40 BF3.0b is a steel fibre-reinforced concrete based on concrete B40 with a class of fibre-reinforced concrete in terms of residual tensile strength BF3.0b;

PFRC B40 BF3.0b is a fibre-reinforced concrete based on concrete B40 and polymer fibre, with a class of fibre-reinforced concrete in terms of residual tensile strength BF3.0b.

The advantage of this classification of FRC is the clearly defined physical and mechanical characteristics of FRC (before its manufacture) for a certain class, which can be selected during the design and calculation of the FRC structure. In this case, designers do not need to decide what type and dosage of fibre will be required to achieve the calculated class of FRC, similar to the situation when designers do not ask themselves what kind of crushed stone and sand must be used to obtain concrete of a particular class.

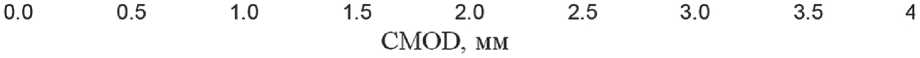

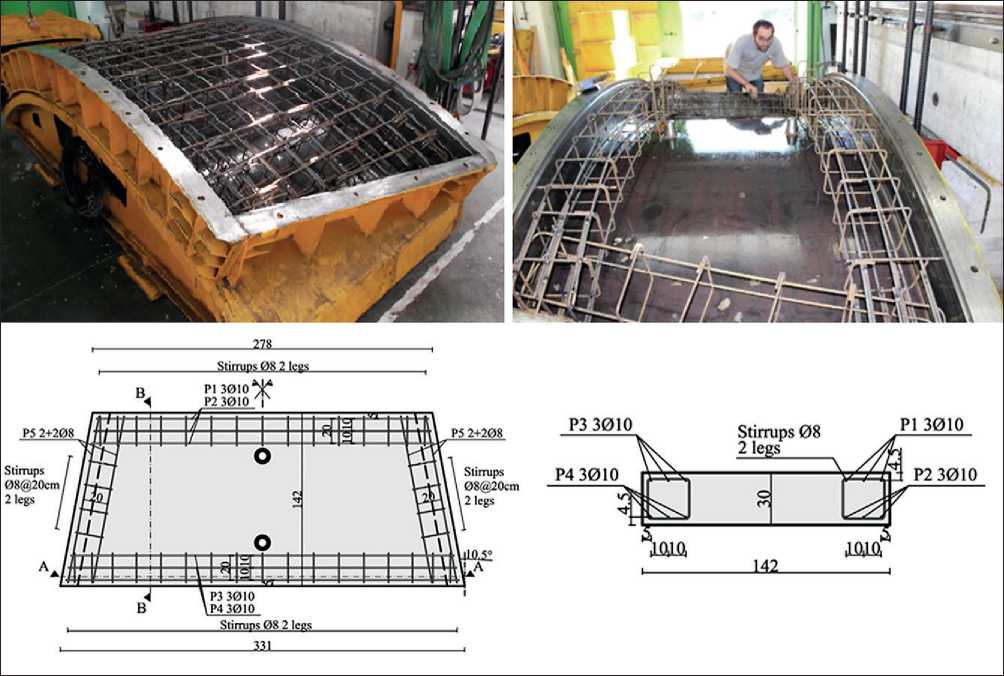

Each class of FRC in terms of residual tensile strength BF will correspond to a state diagram (material deformation diagram) (see Fig. 3, 4), which can be constructed according to normalized strength and deformation parameters (Table 2).

Thus, when developing a statistical database for testing fibre-reinforced concrete samples (in the conditions of the Russian Federation), manufacturers of fibre-reinforced concrete structures will understand which fibre and how much of it is required to provide a particular class of fibre-reinforced concrete.

In the world practice of using fibre-reinforced concrete in tunneling and other areas of construction the following areas are actively developed:

• production of lightweight tunnel lining structures (reduction in the thickness of lining)[40];

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

Fig. 3. Example of a diagram of the stress-strain state of

FRC (STO NOSTROY 2.27.125-2013)

-

• reduction or elimination/exclusion of bar/core reinforcement for precast/prefabricated and monolithic linings (significant reduction or complete exclusion of the main longitudinal reinforcement, transverse reinforcement, exclusion of structural reinforcement) [41, 42];

-

• production of high-strength and ultra-high-strength FRC structures (hybrid FRC using two types of fibre – microfibre and structural fibre) [43, 44];

-

• production of bending structures (beams, slabs of large spans) [42];

-

• studies on the stress state of the elements in fibre-reinforced concrete structures working on torsion [45];

-

• research and development of effective anchoring devices for steel wire fibre;

-

• development of methods and techniques of fibre orientation in structures in order to increase the effectiveness of reinforcement [46];

-

• development of new and improvement of existing methods of FRC structures quality control;

-

• improvement of FRC test methods for samples in order to reduce the percentage of rejection, decrease the

Fig. 4. Example of a diagram of the stress-strain state of FRC (SP 360.1325800.2017)

Table 2

Values of regulatory resistances (Table 5.2.1. STO NOSTROY 2.27.125-2013)

|

В 『 |

0,5 |

1,0 |

1,5 |

2,0 |

2,5 |

3,0 |

3,5 |

4,0 |

4,5 |

5,0 |

5,5 |

6,0 |

6,5 |

7,0 |

7,5 |

8,0 |

|

拝 F06” и KfCr |

0,50 |

1,00 |

1,50 |

2,00 |

2,50 |

3,00 |

3,50 |

4,00 |

4,50 |

5,00 |

5,50 |

6,00 |

6,50 |

7,00 |

7,50 |

8,00 |

|

а |

0,25 |

0.50 |

0,75 |

1,00 |

1,25 |

1,50 |

1,75 |

2,00 |

2,25 |

2,50 |

2,75 |

3,00 |

3,25 |

3,50 |

3,75 |

4,00 |

|

b |

0,35 |

0,70 |

1,05 |

1,40 |

1,75 |

2,10 |

2,45 |

2,80 |

3,15 |

3,50 |

3,85 |

4,20 |

4,55 |

4,90 |

5,25 |

5,60 |

|

^Ғ2.5.л И Rn.5^er С |

0,45 |

0,90 |

1,35 |

1,80 |

2,25 |

2,70 |

3,15 |

3,60 |

4,05 |

4,50 |

4,95 |

5,40 |

5,85 |

6,30 |

6,75 |

7,20 |

|

d |

0,55 |

1,10 |

1,65 |

2,20 |

2,75 |

3,30 |

3,85 |

4,40 |

4,95 |

5,50 |

6,05 |

6,60 |

7 』 5 |

7,70 |

8,25 |

8,80 |

|

е |

0,65 |

1,30 |

1,95 |

2,60 |

3,25 |

3,90 |

4,55 |

5,20 |

5,85 |

6,50 |

7,15 |

7,80 |

8,45 |

9,10 |

9,75 |

10,40 |

|

0.33 |

0,67 |

1,00 |

1,33 |

1,67 |

2,00 |

2,33 |

2,67 |

3,00 |

3,33 |

3,67 |

4,00 |

4,33 |

4,67 |

5,00 |

5,33 |

|

|

л |

0,17 |

0,33 |

0,50 |

0,67 |

0,83 |

1,00 |

M7 |

1,33 |

1,50 |

1,67 |

1,83 |

2,00 |

2,17 |

2,33 |

2,50 |

2,67 |

|

b |

0,23 |

0,47 |

0,70 |

0,93 |

1,17 |

1,40 |

1,63 |

1,87 |

2,10 |

2,33 |

2,57 |

2,80 |

3,03 |

3,27 |

3,50 |

3,73 |

|

Rf2J C |

0,30 |

0,60 |

0,90 |

1,20 |

1,50 |

1,80 |

2,10 |

2,40 |

2.70 |

3,00 |

3,30 |

3,60 |

3,90 |

4,20 |

4,50 |

4,80 |

|

0.37 |

0,73 |

1,10 |

1,47 |

1,83 |

2,20 |

2,57 |

2,93 |

3,30 |

3,67 |

4,03 |

4,40 |

4,77 |

5,13 |

5,50 |

5,87 |

|

|

£ |

0,43 |

0,87 |

1,30 |

1,73 |

2,17 |

2,60 |

3,03 |

3,47 |

3,90 |

4,33 |

4,77 |

5,20 |

5,63 |

6,07 |

6,50 |

6,93 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION coefficient of variation, and improve measurement accuracy [47].

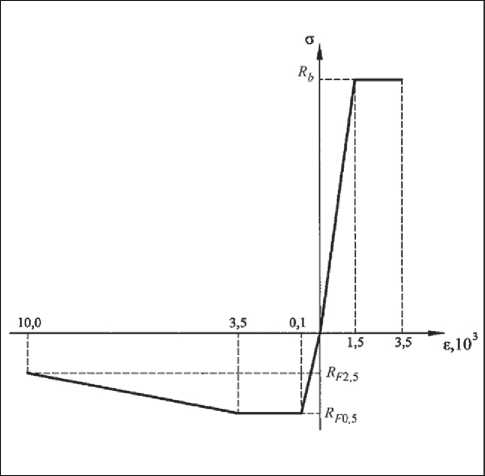

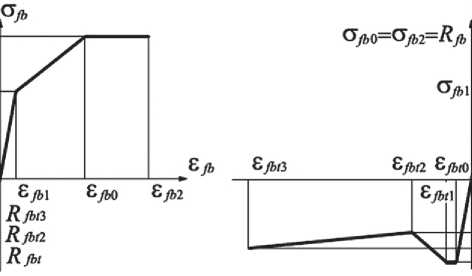

As illustrative examples of the implementation of research results in transport tunnels, the experience of Spanish [41] and Italian [42] specialists in the “optimization” of reinforcement in prefabricated and monolithic tunnel linings should be noted (see Fig. 5, 6).

In the case shown in Fig. 5, there is a prefabricated lining of a subway running tunnel in Spain. In the basic version of traditional reinforcement, the amount of rebars was approximately 150 kg/m3. The engineers offered to use fibre-reinforced concrete based on class B45 concrete and steel wire fibre in an amount of 45 kg/m3 together with rebars made of non-metallic reinforcement arranged locally along the transverse/annular and longitudinal/radial faces of the blocks to perceive the thrust forces from the jacks during shield moving and perception compressive stresses formed in blocks from rock pressure (longitudi-nal/radial faces).

The proposed technical solution made it possible to eliminate the use of steel reinforcement with a simplification of the shape of the core frames and by reducing financial costs and labor resources in the manufacture of rebar frames, achieve savings of up to 12% in the production of blocks.

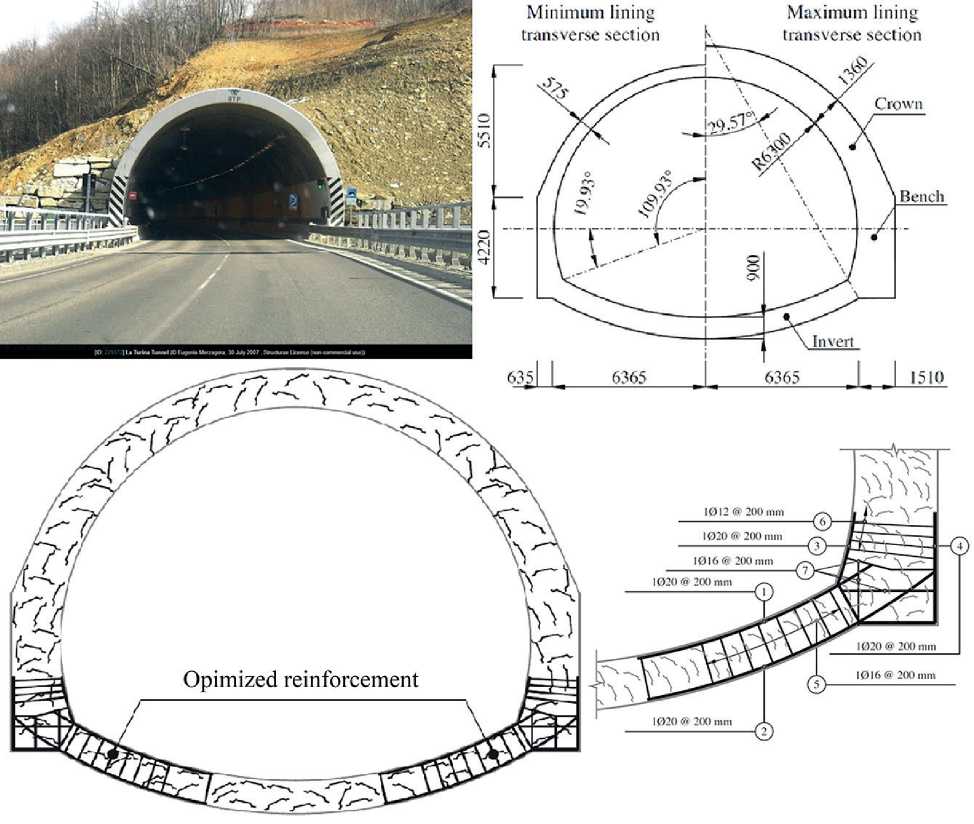

In the case shown in Fig. 6, there is a monolithic lining of a road tunnel in Turin (Italy). The basic version assumed the conventional reinforcement of the lining with discrete rebars, which is a labor intensive process at the stage of a monolithic lining construction. After the feasibility study/ calculated justification of the “optimized” reinforcement, a solution was proposed to exclude core reinforcement from the arch and walls of the tunnel to the stress concentration zone at the corners of the wall interface with the reverse arch, as well as to exclude the core reinforcement in the middle third of the reverse arch of the lining.

It is offered to implement the remaining core reinforcement in areas with a concentration of tensile stresses in the form of flat frames, which can be prepared on the construction site and delivered for installation in a tunnel to the reinforcement site in order to minimize labor costs and terms of construction.

The results achieved in the implementation of this technical solution are as follows: 30% reduction in the number of fittings as a whole (in total by weight of steel – reinforcement + fibre); 75% reduction in core reinforcement; significant simplification of reinforcement; elimination of the most labor-intensive process of the arch reinforcement; reduction in the construction period of the tunnel.

Fig. 5. The experience of “optimizing” the reinforcement of the segmental lining (Spain)

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

职畤

Crown

Bunch

Invert

1012 @ 200 mm

1020 @200

1016® 200 mm

1020 @ 200 mm

1020® 200 mm

Opimized reinforcement

1020 @ 200

Minimum lining transverse section

Maximum lining transverse section

Fig. 6. The experience of “optimizing” the reinforcement of the prefabricated lining (Italy)

CONCLUSIONS

As the main conclusions, it should be noted:

-

• currently, in the conditions of the Russian Federation, there are no obstacles to design and produce FRC structures for tunnels and underground structures;

-

• steel fibre manufacturers are ready to supply the production with enough amount of fibre;

-

• the introduction of fibre-reinforced concrete in Russian conditions is hindered by the “fear of the new”, little experience in working with FRC, poorly developed production technology of FRC structures and their quality control;

-

• reinforced concrete plants need to invest in re-equipment for the FRC structures production – automatic dispensers integrated into the technological process;

-

• laboratories need special testing equipment with servo hydraulics for quality control;

-

• when using fibre-reinforced concrete structures, the expected effect is mainly associated with a reduction in labor costs for the manufacturing the reinforcement products and reaches: 5...20% for prefabricated FRC linings of the shield method; 10...30% for monolithic FRC linings of the mining method, as well as fibre-reinforced shotcrete supports and primary linings.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGY IN CONSTRUCTION

Список литературы The effectiveness of using fibre-reinforced concrete in underground construction: experience and prospects

- Ige Samuel Ayeni, Jamaludin Mohamad Yatim, Nor Hasanah. A review of hybridised use of fibres in shear behavior of fibre-reinforced concrete beams. ASEAN Engineering Journal. 2024. https://doi.org/10.11113/aej.V14.20314

- Kotha Hima Bindu, Mudigonda Rathna Chary, Jagadish Shrisaila Haranatti. Behavior of High Strength Reinforced Cement Concrete with Polypropylene and Steel Fibres.MATEC Web of Conferences 392. March 2024. https://doi.org/10.1051/matecconf/202439201011

- R. Lal, Surender Kumar Verma, Chander Sheikhar Singla. Fibre Reinforced Concrete: An Overview.Conference: International Conference on Emerging Trends in Engineering Innovations and Technology Management (ICET: EITM-2017) NIT Hamirpur, India. December 16–18. 2017.

- Rui Valente, Mário Pimentel. Fibre reinforced concrete under in-plane shear stresses. Engineering Structures. 2024; 307: 117890. https://doi.org/10.1016/j.engstruct.2024.117890

- Charankumar Ashok Kamble. Strength properties of hybrid fibre reinforced concrete using fly ash. Interantional journal of scientific research in engineering and management . 2023; 07(09). https://doi.org/10.55041/IJSREM25834

- Yazhini Ezhilarasan, R. Chithra. Performance study of fibre reinforced functionally graded concrete pipes. Construction and Building Materials. 2022; 344(1):128224. https://doi.org/10.1016/j.conbuildmat.2022.128224

- Florence More, Senthil Selvan. Impact of Fibres on the Mechanical and Durable Behaviour of Fibre-Reinforced Concrete. Buildings. 2022; 12(9):1436. https://doi.org/10.3390/buildings12091436

- Salahaldein Alsadey, Miftah Abdallateef, Muftah Mohamed, Abdalrhman Milad. Investigating Behaviour of Reinforced Concrete with Glass Fibre. Jurnal Kejuruteraan 2021; 33(3):559-577. https://doi.org/10.17576/jkukm-2021-33(3)-16

- Libo Yan, Nawawi Chouw. A comparative study of steel reinforced concrete and flax fibre reinforced polymer tube confined coconut fibre reinforced concrete beams. Journal of Reinforced Plastics and Composites. 2013; 32 (16):1155–1164. https://doi.org/10.1177/0731684413487092

- Abdullah O. Baarimah, Sharifah Maszura Syed Mohsin. Mechanical properties of steel/kenaf (hybrid) fibers added into concrete mixtures /IOP Conference Series Materials Science and Engineering. 2018; 342(1):012075. https://doi.org/10.1088/1757-899X/342/1/012075

- de la Fuente A., Lin L., Cavalaro S.H.P., Aguado de Cea A. Fibre reinforced precast concrete segments: design and applications. Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil.

- Liao L., de la Fuente A., Cavalaro S., Aguado A. Design of FRC tunnel segments considering the ductility requirements of the Model Code 2010. Tunnelling and Underground Space Technology. 2015; 47: 200-210.

- Serna P., Llano-Torre A., Martí-Vargas J., Navarro-Gregori J. Fibre Reinforced Concrete: Improvements and Innovations. RILEM-fib International Symposium on FRC (BEFIB) in 2020.

- di Prisco M., Plizzari G., Vandewalle L. Fibre reinforced concrete: new design perspectives. Materials and Structures. 2009; 42:1261–1281. https://doi.org/10.1617/s11527-009-9529-4

- di Prisco M., Tomba S., Bonalumi P., Meda A. On the use of macro synthetic fibres in precast tunnel segments. ITA WTC 2015 Congress and 41st General Assembly May 22–28, 2015. Lacroma Valamar Congress Center, Dubrovnik, Croatia.

- di Prisco M., Colombo M., Dozio D. Fibre-reinforced concrete in fib Model Code 2010: principles, models and test validation. Structural Concrete. 2013. 14: 4. https://doi.org/10.1002/suco.201300021

- Caratelli A., Meda A., Rinaldi Z., Romualdi P. Structural behaviour of precast tunnel segments in fiber reinforced concrete. Tunnelling and Underground Space Technology. 2011; 26: 284-291.

- Barros J. Recent developments on the analysis and design of fibre reinforced concrete structures. 14th International Conference “Modern Building Materials, Structures and Techniques”, 5–6 October 2023. Lithuania.

- Winterberg R. Use of macro synthetic fibre in segmental tunnels. BEFIB2021, 096. v3.

- Plückelmann S., Breitenbücher R., Smarslik M., Mark P. Aufnehmbare Teilflächenspannung von hochfestem. Stahlfaserbeton Beton- und Stahlbetonbau 2019. 114: Heft 9.

- Hansel D., Guirguis P. Stahlfaserbeton-Tübbinge: Stand der Technik und realisierte Projekte (Steel-fibrereinforced segmental linings: State-of-the-art and completed projects). Tunnel. 2011; 1.

- Smarslik M., Mark P. Hybrid reinforcement design of longitudinal joints for segmental concrete linings. Structural Concrete. 2019; 1–15. https://doi.org/10.1002/suco.201900081

- Bernard E.S., Thomas A.H. Fibre reinforced sprayed concrete for ground support. Tunnelling and Underground Space Technology. 99 (2020) 103302.

- Bernard E.S., Clements M.J.K, Duffield S.B., Morgan D.R. Development of Macro-synthetic Fibre Reinforced Shotcrete in Australia. In: Seventh International Symposium on Sprayed Concrete for Underground Use, June 16–19, Sandefjord, Norway. 2014; 67–75.

- El-Helou R., Graybeal B. Flexural Behavior and Design of Ultrahigh-Performance Concrete Beams. Structural Engineering Journa. 2022.

- Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community. PUBLICATION NO. FHWA-HRT-13-060, JUNE 2013.

- Eryiğit H., Sayin A., Kocak B. An overview of the construction of turkey's longest road tunnel focusing on ground support using macro synthetic fibers as shotcrete reinforcement. Engineering, Environmental Science. 2014.

- Namli M. Evaluation of the effect of using fiber reinforcement in tunnel linings for metro projects. Underground Space 2021; 6 (6): 732-750.

- Abbood I., Faleh Al-Bayati A. Punching shear strength of steel fibre reinforced concrete flat slabs: a literature review and design codes evaluation, Kerbala, Iraq, 2021.

- Twenty years of FRC tunnel segments practice: lessons learnt and proposed design principles / ITA Report #16 / ISBN: 978-2-970 1013-5-2. April, 2016.

- Design guidance for precast fibre reinforced concrete segments / ITAtech Report #7 / ISBN: 978-2-9701013-2-1/ April, 2016.

- fib Model Code for Concrete Structures 2010, Ernst & Sohn, 2013 / ISBN:9783433030615 / https://doi.org/10.1002/9783433604090

- Design of FRC tunnel segments considering the ductility requirements of the Model Code 2010 / Tunneling and Underground Space Technology, № 47, p. 200–210, 2015.

- Matveev G., Kagan M. Key segments made of SFRC // Metrostroy. 1981. № 2. p. 10.

- Kagan M. Density of segment reinforced by steel fibre // Metrostroy. 1985. № 1. pp. 29-30.

- Cyvian B. Steel Fibre Reinforced Concrete linings // Metrostroy. 1986. № 4. pp. 30–31, № 6. pp. 29–32.

- Kagan M. Comparison of the actual compressive strength of concrete and steel fibre reinforced concrete segments // Metrostroy. 1987. № 3. pp. 19–22.

- Nekrasov V.P. The method of indirect reinforcing of concrete. M.: NKPS Transpechat, 1925.

- ASTM C 1550. Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel).

- Trabucchi I., Smarslik M., Tiberti G., Petraroia D.N., Plizzari G.A., Mark P. A hybrid solution proposal for precast tunnel segments. Structural Concrete. 2021;1–15. https://doi.org/10.1002/suco.202000629

- Meda A., Rinaldi Z., Spagnuolo S., De Rivaz B., Giamundo N. Experimental Behaviour of Precast Tunnel Segments in Steel Fiber Reinforcement with GFRP Rebars. FRC2018: Fibre Reinforced Concrete: from Design to Structural Applications Joint ACI-fib-RILEM International Workshop.

- Tiberti G., Minelli F., Plizzari P. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Composites. Part B 58. 2014; 199–207.

- Tengilimoglua O., Akyuzb U. Experimental study on hybrid precast tunnel segments reinforced by macrosynthetic fibres and glass fibre reinforced polymer bars. Tunnelling and Underground Space Technology 2020; 106.

- Conforti A., Trabucchi I., Tiberti G., Plizzari G., Caratelli A., Meda A. Precast tunnel segments for metro tunnel lining: A hybrid reinforcement solution using macro-synthetic fibers. Engineering Structures. 2019; 199: 109628, https://doi.org/10.1016/j.engstruct.2019.109628

- Facconi L., Amin A., Minelli F., Plizzari G. A unified approach for determining the strength of Frc members subjected to torsion—Part I: Experimental investigation. Structural Concrete.2021; 1–17. https://doi.org/10.1002/suco.202100161

- Medeghini F., Guhathakurta J., Tiberti G., Simon S., Plizzari G., Mark P. Steered fiber orientation: correlating orientation and residual tensile strength parameters of SFRC. Materials and Structures. 2022; 55:251. https://doi.org/10.1617/s11527-022-02082-9

- Carmona S., Molins C., García S. Application of Barcelona test for controlling energy absorption capacity of FRS in underground mining works. Construction and Building Materials 2020; 246.