Types of construction nails from Markul, Abkhazia (based on metallographic analysis)

Автор: Trebeleva G.V., Konushkin S.V., Sevostyanov M.A., Yurkov G.Y.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 1 т.52, 2024 года.

Бесплатный доступ

During excavations at the Markul fortified settlement, Republic of Abkhazia, a cluster of iron items, including nails, was found. Nails usually draw little attention as they cannot serve as chronological indicators. Several attempts at constructing a typology of nails have proved unsuccessful. The quality of metal of which they were forged has not been studied purposefully, although it can be relevant to the use of nails and construction practices. Here, we present the results of a metallographic analysis of 19 nails from Markul (13 spec. from a simultaneously formed cluster of iron items, and six spec. found elsewhere at the site). The findings suggest that they can be subdivided into three types in terms of metal structure and, accordingly, of properties of nails: those with a ferrite structure ("soft"), those with a ferrite-pearlite structure ("strong"), and those with a cementite structure ("extra strong"). These types correlate with three types of construction materials used in Abkhazia in the Late Classic and Medieval period. Lack of correlation between metric properties of nails and metal structure suggests that the latter was intentionally formed for specific tasks, depending on the characteristics of the details joined by nails.

Короткий адрес: https://sciup.org/145146974

IDR: 145146974 | DOI: 10.17746/1563-0110.2024.52.1.109-116

Текст научной статьи Types of construction nails from Markul, Abkhazia (based on metallographic analysis)

Metallography is a traditional method for analyzing metal artifacts discovered during research into historical and cultural heritage (Kolchin, 1953: 10–15; Ryndina, 1965, 2006: 6; Zinyakov, 1989: 76–79; 1997: 26, 69–70; Chindina, Zinyakov, 2020; Zavyalov, Terekhova, 2021; Zavyalov, 2021; Vodyasov et al., 2021; and others).

Although this method was used for studying weaponry, jewelry, and other important and unique items from the archaeological sites of Abkhazia (Bgazhba, 1983; Terekhova, Rozanova, Bgazhba, 1987), mass-produced and ordinary items, such as forged iron nails, have hardly attracted any attention from scholars, largely because throughout almost their entire history the shape of nails has remained unchanged. Their manufacturing

technology had also remained the same from the turn of the Common Era until the 20th century, and was as follows: the blacksmith heated an iron rod, sharpened one end, made a thickening in the place of the future head, and chopped off the rod; the resulting blank was inserted into the hole of a special nail header iron plate where the thick end was flattened with a hammer thus forming the head.

Some attempts to systematize the evidence were made in the studies on the nails of the Russian Middle Ages and Modern Age. For his systematization of nails, P.A. Korchagin used the categories of length, thickness, and weight, but did not analyze the metal. He wrote: “It is possible to determine the function based on the data on the

50 m

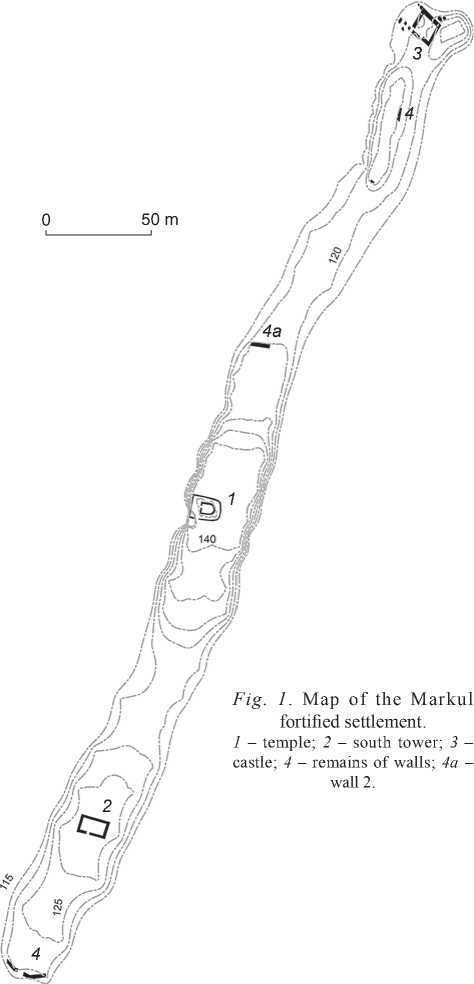

Fi g. 1 . Map of the Markul fortified settlement.

1 – temple; 2 – south tower; 3 – castle; 4 – remains of walls; 4a – wall 2.

length of the nail, the shapes of its shank and head, etc., and thereby draw conclusions as to what kind of production (shipping, carpentry, shoemaking) was practiced in ancient times at the excavation site” (Korchagin, 2011: 62). S.F. Tataurov also left metal analysis aside, arguing that it was not possible to subdivide nails typologically and they could not serve as chronological markers (2001, 2004). The latter statement may be true; this was precisely the main reason for the lack of interest in nails despite their widespread use.

Notably, in addition to metric parameters, metallographic analysis of nails may indicate the scope of their application and the variety of construction technologies. It helps to determine the quality of raw materials, forging technology, and level of its development, which generally characterizes the level of technical and economic development of society.

Science-based methods were applied to studying nails used for decorating and padding shoes (17th– 18th centuries), which were discovered in Tara. The results of X-ray fluorescence analysis revealed that metal of the nail heads that decorated the vertical bar of the heel contained tin remaining from their tinning. However, a detailed analysis of the structure of the iron-containing base has not been carried out (Osipov et al., 2017). The only study that analyzed the metal of nails was a collective monograph on the blacksmithing of Northeastern Semirechye (Kazakhstan) (Savelieva, Zinyakov, Voyakin, 1998), although unfortunately its authors did not draw any conclusions based on its results.

During excavations of the Markul fortified settlement, located in the Ochamchirsky District of the Republic of Abkhazia (Trebeleva, 2019), a joint expedition from the Institute of Archaeology of the Russian Academy of Sciences and the Abkhazian Institute for Research in the Humanities of the Academy of Sciences of Abkhazia accumulated a large collection of iron nails of various sizes and degree of preservation, coming mostly from different layers and locations in that site. During the excavations in 2021, a large pile of metal fasteners (clamps, nails, onlays) from the same structure was found near wall 2. The thirteen nails discovered there became the main object of this research. Nails from two other areas of the settlement—temple and castle (Fig. 1)—were used as comparative evidence.

Material and methods

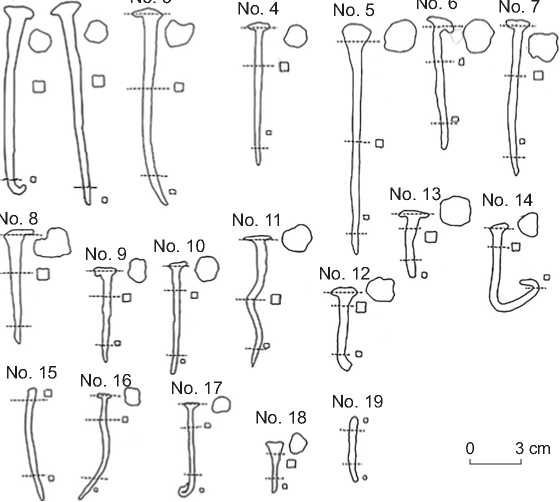

Nineteen nails (Fig. 2) were examined from three areas of the settlement, which were designated as “wall 2”, “temple”, and “castle” (see Table ). Wall 2, near which the excavations were carried out, was a part of the remaining stonework on the northern edge of the first plateau. Its maximum height above the ground surface

Fig. 2 . Images of nails, indicating sampling locations.

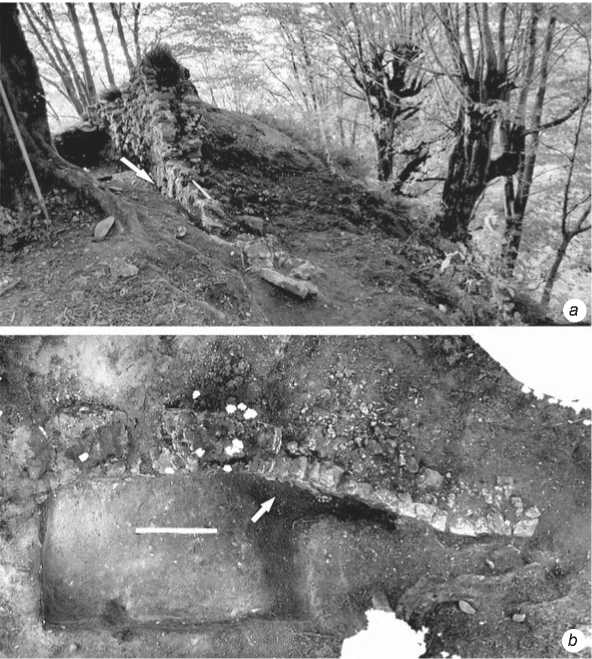

was 1.5 m, length 4 m, and thickness 1.3 m. The excavation pit was made on the southern side of the wall along its visible section, and later a small trench was added in the eastern direction, revealing the continuation of the wall below the level of the daylight surface. Its total length was 6.68 m. The wall did not run along a straight line, but bent along the edge of the plateau almost going into a cliff, where robust tree roots, possibly destroying a part of the wall, came close to it (Fig. 3).

A pile of metal items, mainly fastenings (nails, clamps, hooks, plates), was discovered in the northeastern corner of the excavation pit. The pile was located under a rectangular hole (25 × 30 cm) in the wall, in a place where the wall dropped sharply. There was

No. 1 No. 2

No. 3

Nails analyzed

|

No. |

Place of discovery |

Length, cm |

Head size, cm |

Thickness, mm |

State of preservation |

|

|

under the head |

2 cm from the end |

|||||

|

1 |

Castle, sq. 3В, level 11 |

10.5 |

1.5 × 1.5 |

8 × 8 |

3 × 3 |

Curved |

|

2 |

Castle, sq. 5В, level 3 |

12.0 |

1.4 × 1.3 |

8 × 8 |

2.7 × 3.0 |

Straight |

|

3 |

Temple, sq. 5, sector 3, level 6 |

11.5 |

1.5 × 1.3 |

6 × 5 |

3 × 4 |

ʺ |

|

4 |

Temple, sq. 6, sector 1, level 5, 6 |

8.5 |

1.5 × 1.4 |

5 × 5 |

3 × 3 |

ʺ |

|

5 |

ʺ |

14.0 |

2 × 2 |

4 × 4 |

3 × 3 |

ʺ |

|

6 |

Temple, sq. 6, sector 2, level 5 |

7.5 |

2 × 2 |

4 × 4 |

3 × 3 |

ʺ |

|

7 |

Wall 2, sq. А2, level 3 |

9.5 |

1.8 × 1.5 |

5 × 5 |

3 × 3 |

ʺ |

|

8 |

ʺ |

6.5 |

1 × 1 |

4 × 4 |

4 × 4 |

ʺ |

|

9 |

ʺ |

6.5 |

1.5 × 1.5 |

5 × 5 |

3 × 3 |

ʺ |

|

10 |

ʺ |

7.3 |

2 × 2 |

4 × 4 |

3 × 2 |

ʺ |

|

11 |

ʺ |

8.0 |

2 × 2 |

6 × 6 |

3 × 3 |

Curved |

|

12 |

ʺ |

5.5 |

2.0 × 1.5 |

4 × 4 |

4 × 4 |

ʺ |

|

13 |

ʺ |

4.5 |

2 × 2 |

7 × 7 |

3 × 3 |

ʺ |

|

14 |

ʺ |

5.5 |

1.5 × 1.5 |

5 × 5 |

3 × 3 |

ʺ |

|

15 |

ʺ |

7.0 |

3 × 3 |

Fragment |

||

|

16 |

ʺ |

8.0 |

2 × 2 |

4 × 4 |

2 × 2 |

Curved |

|

17. |

ʺ |

6.0 |

2 × 2 |

7 × 7 |

2 × 2 |

Bent |

|

18 |

ʺ |

4.5 |

5 × 5 |

3 × 3 |

Fragment |

|

|

19 |

ʺ |

4.0 |

1.5 × 1.5 |

Fragment |

||

Fig. 3 . Excavation site “wall 2”.

a – view from the east; b – orthophotomap. The arrows indicate the location where the pile of iron items was discovered.

probably some kind of a wooden structure, and the hole was the place of a fastening beam. The fasteners obviously belonged to this structure, which suggested their simultaneity.

Pottery from the layer where the pile of metal items was found was local, typical of the Tsebelda period (2nd– 7th centuries AD). In 2014, a fragment of a Roman red-glazed vessel was found in a test pit in the area next to this wall (Trebeleva et al., 2019). These facts allow the iron items, including 13 nails, to be attributed to the Tsebelda period.

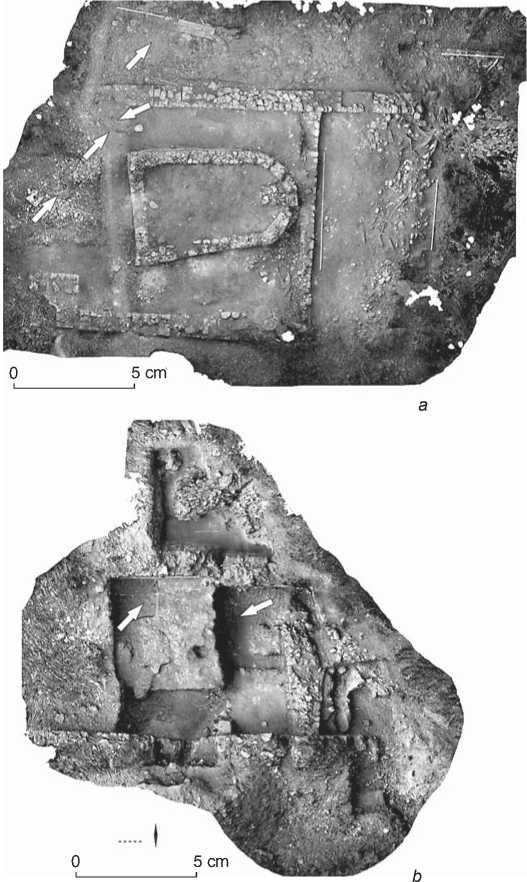

Four nails were taken for analysis from the temple area (Fig. 4, a ) (Trebeleva, Shvedchikova, 2019). They came from two different grids, but from the same level. Unfortunately, today, these items cannot be dated with certainty, because the layers near the temple were mixed. Generally, the temple dates back to the period from the turn of the 4th–5th centuries to the 14th century. Therefore, the nails might have belonged to both the Tsebelda period and the Middle Ages.

Since two nails from the castle area (Fig. 4, b) (Trebeleva, 2020) were found in different layers, they belonged to different periods. The castle, like the temple, was dated widely to the time from the second half of the 3rd century to the 14th century. One nail (No. 2) was found in the top layer near a narrow, pyramidal arrowhead, square in cross-section, with a waist at the tang (type 95 (Medvedev, 1966: 84)). Such points were widespread in Eastern Europe and Caucasus from the 8th to the 14th centuries. The second nail, discovered in the lower layer along with fragments of red-glazed pottery, may date back to the Late Classic and be contemporaneous with the nails from the excavation pit near wall 2.

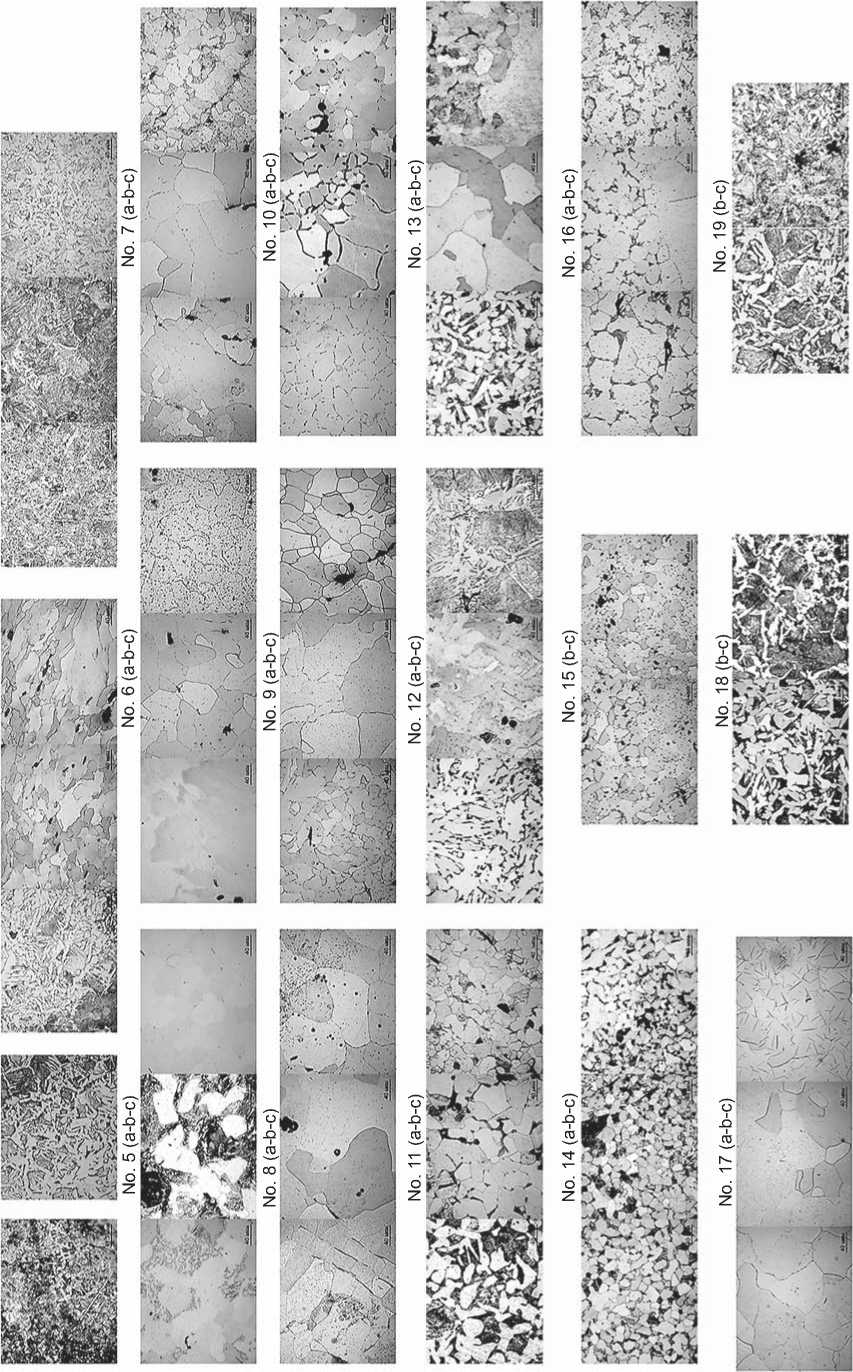

To study the structure of nails from the “temple” and “wall 2” areas, three thin sections were made from each sample: from the head (if it survived), from the middle part, and at a distance of 1.0–1.5 cm from the pointed end. In the nails from the “castle” area, only the latter fragment was studied (see Fig. 2). The samples were pressed into conductive resin with their end faces, and were prepared for metallographic analysis by sequential grinding on a Piatto diamond grinding disc with grit P220 (3–5 min), P600 and P1200 (3–5 min), polishing paper with grit P2500 and P4000 (5 min), Akasel Daran velvet with DiaMaxx Poly suspension with diamond particle sizes of 1 μm, and Akasel Chemal foamed neoprene with a colloidal suspension of silicon oxide with particle sizes of 0.05 μm (10 min). A Buehler Phoenix 4000 polishing machine (USA) was used for polishing the samples. The surface was etched with solution of HNO3 (3 parts) and C2H5OH (97 parts) for 10 sec. Then, the thin section was washed with running water and ethyl alcohol.

Thin sections were examined using an Altami MET 5C microscope with a built-in high-resolution video camera (14 megapixels), and special Altami Studio 4.0 software. The set of lenses has made it possible to obtain magnifications of 50 to 2000. Images were captured in unpolarized light at the highest brightness.

Results

Sample 1. Its structure shows a band of hypoeutectoid low-carbon steel among two bands of softer iron. Iron with different carbon content was used to manufacture this nail, which is confirmed by the presence of purely ferrite, as well as ferrite-pearlite, areas in the structure (hereafter, Fig. 5).

Sample 2. It reveals the microstructure of hypereutectoid steel: pearlite and secondary cementite.

Fig. 4 . Orthophotomaps of the “temple” ( a ) and “castle” ( b ) excavation areas. Arrows indicate locations where the nails were found.

Sample 3. The structure of the head shows both ferrite areas with small and medium-sized grains, and ferrite-pearlite areas. In the middle part and the end of the nail, the structure is mainly ferrite. A small amount of slag inclusions is observed. Iron with different carbon content was used to manufacture this nail, which is confirmed by the presence of purely ferrite, as well as ferrite-pearlite, regions in the structure.

Sample 4. A uniform ferrite-pearlite structure with fine grains appears in the head and the end of the nail. Pearlite-cementite structure is in the middle part. Slag inclusions are almost absent. This nail was made of medium carbon steel.

Sample 5. In the head, the structure shows mainly ferrite, possibly with an admixture of granular pearlite with small amount of slag. In the middle part, the structure reveals ferrite and pearlite with numerous slag inclusions. The end of the nail has a ferrite structure with small grain sizes. A small amount of slag is observed. The nail was made of low-quality steel.

Sample 6. All parts of this nail have a uniform ferrite structure with medium and small grains, and slag inclusions. The nail was made of iron.

Sample 7. Its structure is similar to the previous one.

Sample 8. All parts of this nail have a ferrite structure with medium-sized and fairly large grains. Small number of banded slag inclusions are observed. The nail was made of iron.

Sample 9. The structure reveals ferrite with small and medium-sized grains in all parts of this nail. There is a fairly large number of slag inclusions. Alternating layers with small and medium grains are in the middle part. The nail was made of iron.

Sample 10. All parts of this nail have the ferrite structure with medium-sized and large grains, and a large amount of slag. Etched slag inclusions are observed along the grain boundaries. The nail was made of iron.

Sample 11. The head has the ferrite-pearlite structure with grains of various sizes. The amount of carbon is lower in the middle part and the end of the nail. The structure consists mainly of ferrite with small ferrite-pearlite areas with grains of different sizes and numerous slag inclusions. The nail was made of unevenly carburized hypoeutectoid steel.

Sample 12. The head has the uneven ferrite-pearlite structure. The areas of both pure ferrite and ferrite-pearlite with slag inclusions are present in the middle part and the end of the nail, which was made of unevenly carburized hypoeutectoid steel.

Sample 13. The structure of the head is ferrite-pearlite turning into ferrite with fine grains. It is ferritic with small ferrite-pearlite areas, medium-sized and large grains, and small amount of slag inclusions in the middle part and the end of the nail, which was made of hypoeutectoid steel.

Sample 14. All parts of this nail have the ferrite-pearlite structure with fine grains. Layering, which could have emerged during the forging process, is observed. Slag inclusions are insignificant. The nail was made of hypoeutectoid steel.

Sample 15. The structure is ferrite, with small grains and a large number of slag inclusions. The nail was made of iron.

Sample 16. The structure of the head consists of ferrite and ferrite-pearlite layers. Grains are small-sized. Slag inclusions are observed. The middle part and end of the

No. 1 No. 2 No. 3 (a-b-c) No. 4 (a-b-c)

Fig. 5 . Microphotographs of samples.

nail also have ferritic and ferrite-pearlite areas. The nail was made of unevenly carburized steel.

Sample 17. The structure of the head and middle part is ferrite, with large grains and a small amount of slag. Inclusions of banded defects are observed in the ferrite matrix at the end of the nail, which was made of iron.

Sample 18. A transition from the ferrite-pearlite structure to the pearlite-cementite structure with fine grains and small amount of slag inclusions is observed in thin sections from the middle and end of this nail, which was made of carburized steel.

Sample 19. In its middle and end parts, this nail has a uniform ferrite-pearlite structure with fine grains. Slag inclusions are observed. The nail was made of carburized steel.

Discussion

The results of the analysis show that, according to the structure of the metal, the nails can be classified into three types: 1) fairly hard, but ductile, made of carburized steel with the ferrite-pearlite structure (conventionally, “strong”); 2) soft and ductile, made of pure iron, intended for driving into fairly soft materials, since they most likely simply could not penetrate hard materials (conventionally, “soft”), and 3) very strong, but brittle, made of highly carburized steel with cementite in its structure (conventionally, “extra strong”). There were six nails of the first type, six nails of the second type, and one nail of the third type in the pile near the wall. Samples from the “castle” section were “strong” and “extra strong”. Among the nails from the temple area, two nails were “strong”, one was “extra strong”, and one was “soft”. All three types of nails were present in each area (with the exception of the “castle” where only two samples were taken for analysis).

Comparison with the analysis of 17 nails from the Northeastern Semirechye (Savelieva, Zinyakov, Voyakin, 1998: 71–74, 92, 99) has revealed that the absolute majority of them (15 spec.) were made of hypoeutectoid ferritic-pearlite steel corresponding to our “strong” group, and two were made of pure iron (“soft” group). There were no nails containing cementite (“extra strong”) in their structure.

An important issue is the presence/absence of correlation between the type of metal and the metric parameters of the nail. In this case, complete analysis is hampered by the fact that some of the nails were bent or fragmented. By reconstructing the lengths of the curved nails and averaging the parameters, it was established that the length ranged from 5 to 14 cm, with slight variability in thickness (from 4 to 8 mm under the head). There was no correlation between the structure of metal and the metric parameters. There was also no connection with the degree of preservation: three fragmented nails from the pile near wall 2 manifested all three types.

Conclusions

Abkhazia may rightly claim the role of a main center of iron metallurgy. Iron products appeared here as early as the 8th century BC; and in the 7th–6th centuries BC, local artisans mastered the methods of steel carburizing and hardening. The technology of metallurgy and blacksmithing in the region was highly developed and rich in its traditions. Sources of raw materials were also local (Bgazhba, 1983: 11–12).

The pile of iron items near wall 2, where the nails under discussion were found, was most likely the remains of fasteners (onlays, clamps, nails) of an unpreserved wooden structure. Assuming that the metal plates were parts of hinges with which this structure was attached to the wall, a set of nails would be needed to nail them both to the wooden structure and the stone wall. These different materials, into which the nails were to be driven, required different strengths for them. Most likely, this explains the presence of both “strong” and even “extra strong”, and “soft” nails in the excavation pit.

Three main types of material, i.e. wood of varying degrees of density, as well as stones of soft (such as spongy tuff, sandstone, and limestone) and very dense (sea and river pebbles) structure, may be observed in buildings of Abkhazia. These types of material may correlate with three types of iron nail, which suggests the targeted production of nails of different qualities, intended for driving into materials of different densities. Currently, this is only a hypothesis requiring further research. However, there is no direct correlation between the metric parameters of nails and the structure of the metal: “extra strong” nails could be both large (No. 2) and mediumsized (No. 4). The length of “strong” nails varies from 5.5 (No. 12) to almost 11.5 cm (No. 3), while the length of “soft” nails varies from 6.5 (No. 8 and 9) to 14 cm (No. 5). The situation is the same with nail thickness, which ranges from 5 (No. 4, 18) to 8 mm (No. 2) in “extra strong” nails, from 4 (No. 12, 16) to 8 mm (No. 1) in “strong” nails, and from 4 (No. 5, 6, and 8) to 7 mm (No. 17) in “soft” nails.

Thus, it may be concluded that the metric parameters of nails were determined by the sizes of the objects intended to be fastened, while the structure of metal was determined by the characteristics of the material with which it was supposed to provide fastening. This indicates the presence of a highly developed specialized production of nails in both the Tsebelda and Medieval periods.

Acknowledgments

This study was supported by the Russian Science Foundation, Project No. 22-18-00466.