Water purification from oil and petrol products by means of nano-porous super-hydrophilic materials

Автор: Kuligin S.V., Kosyakov A.V., Belov P.V., Lapenko A.A., Ishkov A.D.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The study of the properties of nanomaterials

Статья в выпуске: 2 Vol.13, 2021 года.

Бесплатный доступ

Introduction. This article reveals the research results of physical and chemical properties of the new filtering material, evaluation of its hydrophilic and oleophobic features as well as the efficiency of oil-in-water emulsions separation in laboratory conditions and in production. Methods and materials. As the base for creation of new filtering material a natural mixture of minerals with good prevalence of silicon earth also including some small amounts of fissile hydrous silicates (mica, clay) was chosen, which provide the durability of granulated end product at reservation of porosity and hydrophilic properties of the material surface. The research used spherical shape granules of various particle size obtained by drying, granulation and firing. Prior to filtration the granules are being impregnated with water aiming to obtain a water shell around each granule, which provides granules protection from oil and petrol products contamination as well as an easy filter cleaning by backwashing in fluidization mode. For the lab testing of oil-in-water emulsions separation parameters a test rig was built. In process a set of various tool methods of physical and chemical research was used. Results. The chemical and mineral composition of the developed filtering material and the results of its X-ray-structural analysis, photomicrography of ground substrate obtained with SEM are given as well as the porous structure data (pores size distribution and aggregate pores of granules material) obtained by the method of low-temperature nitrogen adsorption. The results of laboratory and pilot testing of separating and accumulating ability of the filtering material are presented. Interpretation. The obtained data prove the fact that the developed material possesses over the prominent hydrophilic properties, while after water shell creation also over the oleophobic properties. Upon exploration of the two liquid immiscible phases separation during the filtering through the granules obtained, a significant efficiency growth of the filter after attaining the special amount of oil and petrol products retained by the filter was detected. The efficiency increase of the filter is connected with formation of a prolonged structure, which was named by the authors a “fluid net”, created by the oil and petrol products entrapped. The strings of that “fluid net” being formed in the gaps between the granules are decreasing the sizes of the passages which lets the entrapping efficiency of finer oil and petrol products droplets grow. Conclusion. The obtained nano-porous granules of the filtering material exhibit super-hydrophilic properties and based on the water shell created around them provide the following: protection of granules from contamination with oil and petrol products contained in water to be purified; effective and not decreasing over the course of time filter regeneration by means of backwashing in fluidization mode; quality of water purification from oil and petrol products at the level of the most expensive purification methods. Prospective fields of applications. The “OreFilter” technology developed has passed the pilot scale validation on the basis of more than fifty industrial objects of different industrial branches (mainly on those connected with oil production and oil refining) in Russia and abroad. The technology is now being tested on industrial objects in the Near East, Canada, US, Brazil and Australia. The industrial filtering units using “OreFilter” technology are already in operation on Russian enterprises as well as in Sweden and Germany. The experimental-industrial tests have proved the application efficiency of the technology developed: in food industry; at the detergents and soaps manufacturing plants; at mining and processing plants; at purification of ballast and bilge water at ports; at purification of polluted water after oil tankers washing; in fish farming; in seaquariums and dolphinariums.

Water purification, filtering, emulsions separation, filtering materials, petrol, petrol products, oil and petrol products, open-porous granules

Короткий адрес: https://sciup.org/142226915

IDR: 142226915 | DOI: 10.15828/2075-8545-2021-13-2-63-72

Текст научной статьи Water purification from oil and petrol products by means of nano-porous super-hydrophilic materials

T he petrol products are the most common pollutants of the waste water, whereas the hydrocarbon group of petrol, fuel oil, kerosene, oils and impurities thereof due to their high toxicity are among the top ten most dangerous pollutants of the environment acc. to UNESCO [1]. Therefore, the water purification from oil and petrol products refer to the highly important and public relevant environmental problems, which however are being solved insufficiently effective, since the creation of modern treatment systems requires implementation of new technologies and, as a result, considerable financial expenditures.

At present, the following methods of water cleaning from oil and petrol products are in practical work [2]:

-

• mechanical methods (screening, centrifugal separation, sedimentation, filtering);

-

• physical-chemical methods (floatation, sorption, extracting, coagulation, flocculation);

-

• chemical methods (ion exchange, neutralization, oxidation);

-

• biological methods (natural and artificial conditions).

A widely used wastewater treatment which is aimed at removing petrol products includes the following stages [3]:

-

• settlement – for removal of coarse free oil and petrol products followed by floatation to remove the finely dispersed and bound petrol products; this stage makes it possible to reduce the amount of petrol products in water to 20 mg/l;

-

• filtering – for the removal of finely dispersed and especially emulsified petrol products; this stage decreases the amount thereof in water to 10 mg/l;

-

• sorptive aftertreatment – brings the amount of petrol products in water down to 0.5–1.0 mg/l.

The more high-scale purification of water provides the method, the more expensive it comes accordingly. The mechanical water cleaning of petrol products using sedimentation and filtering is the most cost saving method of water treatment [4]. Whereas the filtering through various screens and cloths is used to remove coarse particles, the filters containing the material entrapping petrol products (quartz sand, expanded clay, foamed polystyrene, foamed polyurethane, anthracite, slags, porous granulated materials, fibrous materials etc.) as the filter bed allow oil containing water purification at higher scale. Thus, developing a filter bed of quality provides the possibility of higher quality of water purification from petrol products, which can be obtained only with more expensive (not mechanical) methods, reserving the main advantage of the mechanical method – low cost of the cleaning process.

LLC “Voronezhpenosteklo” has developed the innovative material – open-porous granules for demulsification [5–18], which surface cannot be wetted by petrol products since granules have a water shell around them.

This shell formed due to the preliminary impregnation of granules with water, provides the protection thereof from pollution with oil and petrol products as well as an easy filter cleaning by backwashing in fluidization mode.

The goal of the present work has been the exploration of physical-chemical properties of the new filtering material, evaluation of its hydrophilic and oleophobic features as well as the effectiveness of oil-in-water emulsions separation in the laboratory and industrial conditions.

METHODS AND MATERIALS

At the core of the functional properties of the filtering material is the principle first described in the works of Kim P. and Wong T. [19]. It concerns creation of new super-hydrophobic SLIPS-coatings: to obtain a surface with wetting contact angle more than 120 degrees, one should use a nano-structured porous material impregnated with a fluid which wets the solid matrix well and is insolvable in the second (outer) fluid phase. However, the authors used a polymer nano-structured material (polypyrrole) impregnated with fluororganic agent (Kry-tox 100) to obtain the super-hydrophobic surface nonwettable by liquid water and having low adhesion to ice.

To reach the objectives of the present work it was necessary to find a material which could form the solid porous matrix possessing good wettability with water and which had sufficient mechanical strength. Some materials on the basis of amorphous silicon earth meet this requirement. Finally, a natural mixture of minerals with significant amorphous silica prevalence was chosen (see table 2) including among all some small amounts of fissile hydrous silicates (mica, clay) providing the durability of granulated end product at reservation of porosity and hydrophilic properties of the material surface. The researches have used spherical shape granules of various particle size obtained by drying, granulation and firing.

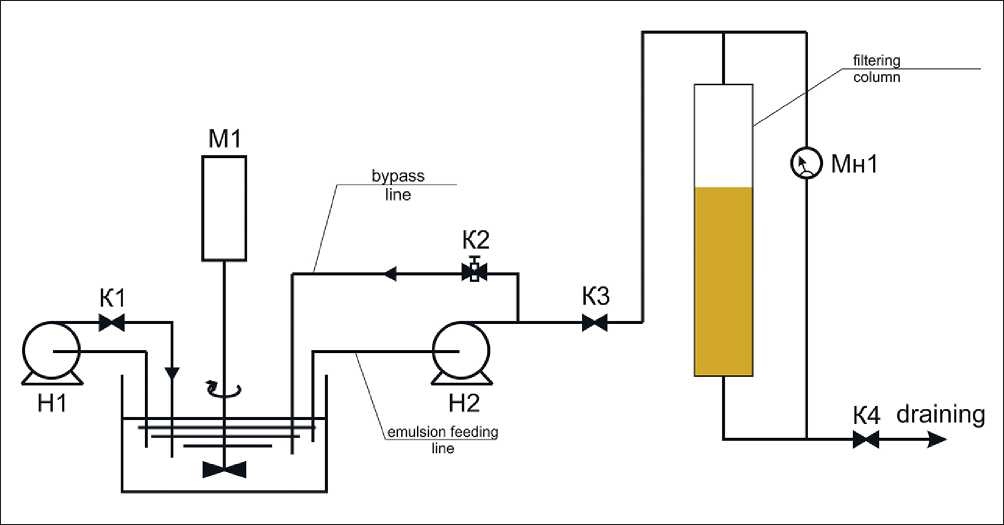

For the lab testing of oil-in-water emulsions separation parameters a test rig was built. The layout of the test rig is presented on Fig. 1.

For the practical implementation a design of the classic pressure filter for granulated filter bed was chosen. The system is represented by vertical cylindrical filter with distribution system below and above and with necessary fittings of pipes and shutoff valves.

The centrifugal emulsifier used allowed to obtain the oil emulsion with drops size in the range of 5 to 80 µm with max. content of drops sized 20 µm.

The petrol concentration (density 0.984 g/cm3) at filter inlet equaled 1 g/l. The filter was filled with granulated bed of the grade 0.7–1.7 mm, preliminary impregnated with water. Filter bed thickness made 200 mm.

For verification of the method and filtering mechanism described a pilot testing on cleaning of bottom water on heavy oil producing sites (density 0.984 g/cm3) was

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 1. Hydraulic layout of the test rig for oil-in-water emulsions separation parameters study:

Н1 – emulsifier, М1 – paddle mixer for emulsion homogenization in the volume,

Н2 – gear pump for emulsion feeding to the filter, К1, К3, К4 – ball valves, К2 – bypass line valve

also performed. For the test the analogous granules of the filtering material with equivalent diameter 0.7–1.7 mm obtained with “OreFilter” technology at manufacturing facility of OOO “LightOre” were used. Filter bed height made 1.5 m at inner diameter of the filter 200 mm. After completion of the filtering cycle (at pressure difference over 1.2 bar) the material cleaning by water backwashing in fluidization mode was made during which the filtering bed expanded by 0.8 m.

During the work a set of various instrumental physical-chemical research techniques was used.

Definition of elementary composition was made by the method of X-ray fluorescence spectrometry (XRF) on “Axios” sequential spectrometer of the company PANalytical (Netherlands). The analysis was done using the method 439-RS (Scientific Council for Analytical Procedures, All-Russian Scientific-Research Institute of Mineral Resources 2000), providing the results quality of III accuracy degree of quantitative analysis acc. to OST RF 41-08-205-99 (analysis of mineral substance).

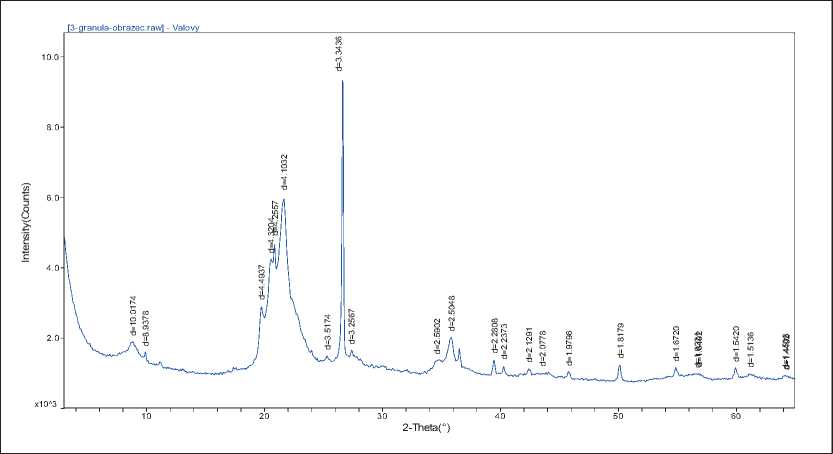

The diagnostics of phase composition was done by the method of X-ray difffraction comparing the experimental and reference spectrums of the database PDF-2 from the software pack Jade 6.5, of the company MDI. The quantitative analysis was performed by the method of full-profile treatment of X-ray patterns of unoriented specimen by Rietveld in BGMN software program (www. . The XRD analysis was done using ULTIMA-IV X-ray diffractometer by the company Rigaku (Japan).

Operation mode: 40 kW – 40 mA, copper radiation, nickel filter, measuring range: 3–65о 2θ, scanning angle pitch 0.02о 2θ, fixed system of focusing gaps. For shooting acceleration and quality increase of experimental data a new gen solid state detector DTex/Ultra was used: scanning speed – 10о 2θ/minute.

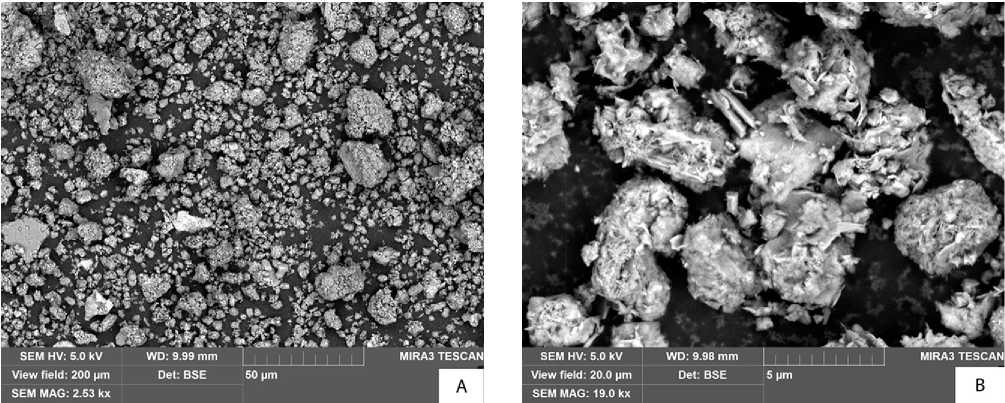

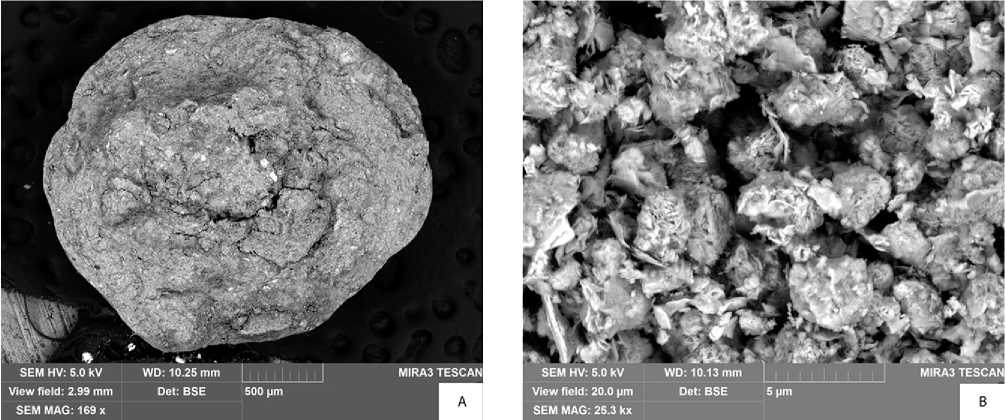

The figures of materials specimen microstructure were obtained using the scanning electronic microscope MIRA3 by the company TESCAN (Czech Republic).

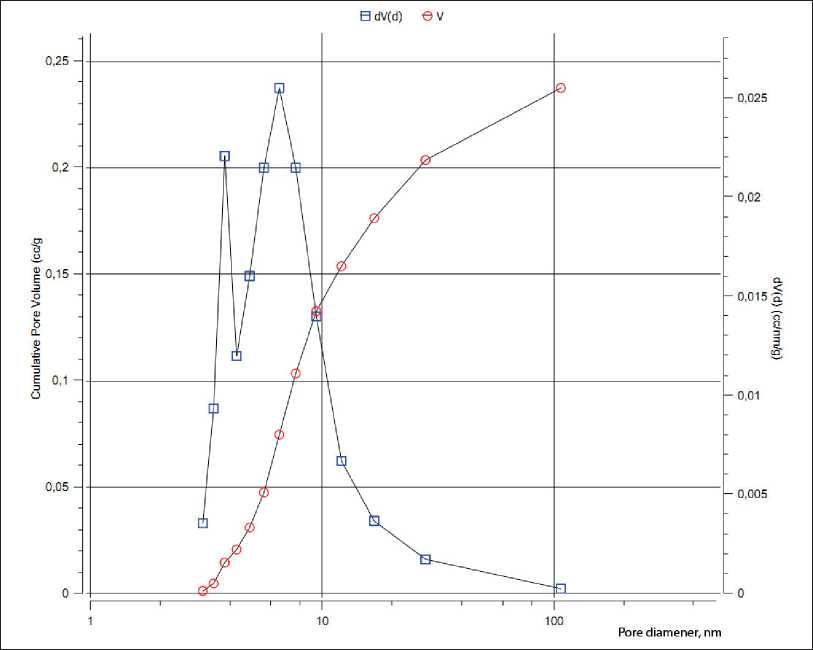

The analysis of specific surface and porous structure parameters was performed by BET method using NOVAtouch 2LX-1 analyzer by the company Quanto-chrome Instruments (U.S.).

Petrol products concentration in water was measured by fluorimetric method (Fluorat 02-5М).

RESULTS

To provide the quality consistency of material produced and to explain its physical-chemical properties the studies on definition of elementary, – and phase composition, of specific surface, porosity as well as surface morphology were performed.

The chemical composition of the material is presented in table 1, the mineral composition is given in table 2.

Results of XRD analysis are provided on Fig. 2.

The above results evidence that the main part of the material is represented by the nano-structured amorphous silica (Fig. 2, table 2). As main element the granules are

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 1

Chemical composition of granules

|

Na2O |

MgO |

Al 2 O 3 |

SiO2 |

K2O |

CaO |

TiO2 |

MnO |

Fe 2 O 3 |

P 2 O 5 |

SrO |

BaO |

|

|

Content, %-mass |

0.09 |

1.09 |

9.26 |

82.61 |

1.24 |

1.37 |

0.43 |

0.01 |

3.45 |

0.40 |

0.01 |

0.04 |

Table 2

Mineral composition of granules

|

Component |

Content, %-mass |

|

Quartz |

10.2 |

|

Illite |

17.8 |

|

Opal-MH |

58.0 |

|

Magnesium carbonate |

0.3 |

|

Clinoptilolite |

11.7 |

|

Feldspars |

2.0 |

Fig. 2. X-ray pattern of the filtering material after firing stage composed of acts silica. Aluminum, alkali metals and alkali-earth metals mainly form a part of fissile hydrosilicates (table 1).

The characteristics of the porous structure are given in table 3, while figure 3 shows pore size distribution and the cumulative pore volume of granulated material.

The results of materials comparative study by the method of scanning electronic microscopy show that the thin porous structure to be observed in the ground substrate for granules manufacturing (Fig. 4) remains in the end product even after processing (Fig. 5). This microstructure is formed by amorphous silica globules themselves having their own porosity as well as by in-terglobular space. Amorphous silica globules size is in the range of 3 to 5 µm. The presence of fissile hydrosilicates in composition of the material (illite, clinoptilolite) provides merging of separate silicon earth globules into a unified structure during the firing

Figure 5В shows the residues of fissile hydrosilicates as flakes in interglobular space.

The effectiveness of separating and accumulating features of the filtering material was studied during a series of laboratory and industrial tests. The parameters comparison of water phase cleaned of petrol products is given

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 3

Characteristics of the porous structure

|

Specific area of pores surface, m2/g |

Volume of pores with size less than 100 nm, cm3/g |

Pores average diameter, nm |

|

103.6 |

0.238 |

6.5 |

Fig. 3. Pore size distribution and cumulative pore volume of granulated material

Fig. 4. Microstructure of the ground silicate substrate at various magnifications: А – х2530, В – х19 000

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 5. Granules microstructure at various magnifications: А – х169, В – х25 300

in table 4. The data presented allow to reveal the fact that “OreFilter” technology applicability is rather broad: it is possible to perform the separation at a small bed thickness and filtering column diameter (20х200 mm) as well as at industrial scale (diameter 3200 mm, bed thickness 2500 mm).

Parameters and results of the filtering are given in table 4.

At the end of the filtering cycle the material backwashing in fluidization mode was performed, during which more than 99% of the petrol products accumulated in filter were removed. At the filtering speed of 20 m/h and filter bed thickness of 2500 mm the pressure drop in filter at filtering start did not exceed 0,1 bar, whereas after major part of intergranular space was filled with petrol and just before backwashing start the pressure drop raised up to 1,2 bar.

The subsequent filtering cycles enable the obtaining of identical results in terms of quality of water cleaning from petrol as well as in terms of thoroughness of petrol products removal from the filtering bed by means of backwashing.

The capacity of the filtering material for crude oil depends on oil viscosity and accordingly on oil density but also on fractional distribution of the filtering material, filtration speed and the temperature. For instance, for the filtering material of 0.7–1.7 mm grade at the temperature 80oC and filtering speed of 20 m/h the material capacity on crude oil made 120 l/m3.

INTERPRETATION

The presence of nanodimentional open pores in the material possessing the prominent hydrophilic properties leads to the fact that when contacting with water, the entire pore space is filled with water along with simultaneous air displacement.

This process continues during an hour at the room temperature.

Any further interactions between the material and fluids with non-polar or low-polarity which are insoluble in water (and indecomposable by water) is hard to be performed. The macroscopic effect results in inadhesion of non-polar and low-polarity fluids to the granulated

Table 4

Laboratory and pilot testing results

|

Petrol density, kg/m3 |

Filtering bed height, mm |

Filtering speed, m/h |

t, оС |

Petrol products concentration initial, mg/l |

Petrol products concentration final, mg/l |

|

|

Lab testing |

984 |

200 |

20 |

60 |

280 |

6.6 |

|

15 |

4.1 |

|||||

|

Pilot testing |

2500 |

20 |

80 |

181 |

3.4 |

|

|

12 |

65 |

320 |

0.9 |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS filtering material over extended time intervals measured with decades. The availability of at least small amount of water phase in intergranular space is critical for maintaining the oleophobic properties.

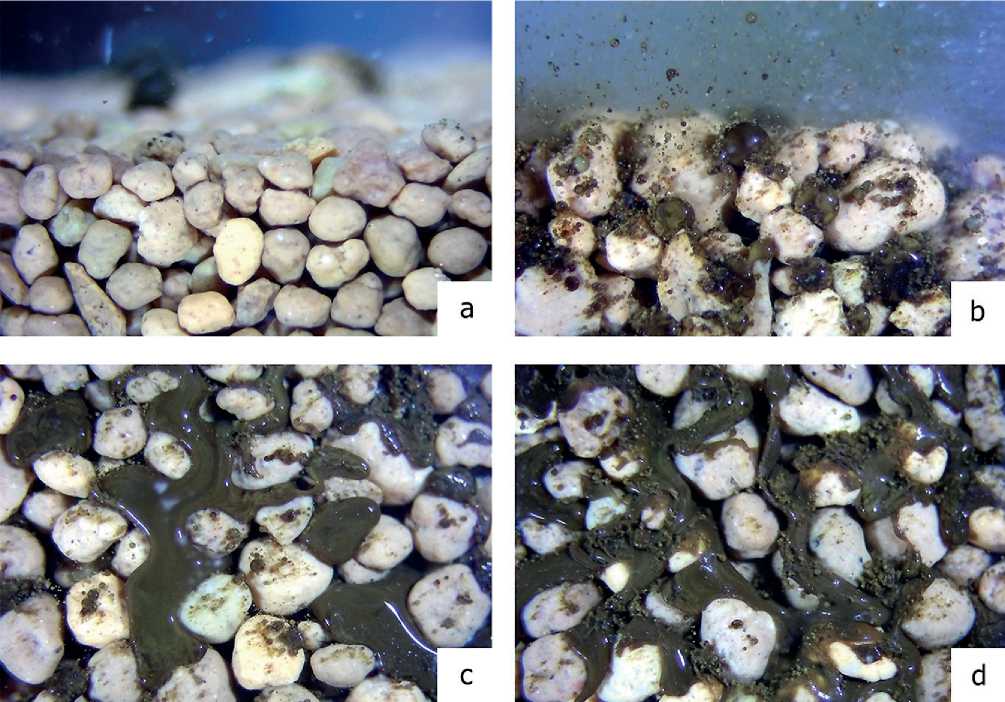

It appeared to be possible to use such an effect at emulsions separation of different kind, specifically water-oil emulsions. The separation of two fluid immiscible phases during the filtering process occurs due to the combination of several by-effects. At the primary stage of the filtering the incoming fine emulsion drops are statically blocked in the intergranular space at stagnant places where the flow rate is lagged (Fig. 6b). Further on, the coalescence of several drops held together takes place. At the beginning, this feature is accompanied by petrol drops size increase and then by filling the intergranular space by oil phase (Fig. 6c). When a specific amount of the oil and petrol products entrapped by filter is reached, the filter effectiveness is growing. It is associated with the formation of the prolonged structure created by the oil and petrol products entrapped, which was called by the authors a “fluid net” (Fig. 6d). Due to the non-wettability of the filtering material by oil and petrol products, between granules and the “fluid net”

the channels are remaining the size of which is comparable with the size of incoming emulsion drops and this is then the reason for water purification quality increase. During the filtering process the accumulation of oil and petrol products in the filter leads to the extension of the “fluid net”. The filtering process ends when the limit of the petrol products entrapped reaches the filter output and the “breakthrough” there of begins.

The presence of mechanical impurities in the actual samples of water-oil emulsions (e.g. produced water) enhances the coalescence effect and fluid phases separation.

CONCLUSION

Following the results of the comprehensive research it can be said that the nano-porous granules of the obtained filtering material possess super hydrophilic features and due to the water shell created around them provide the following:

-

• granules protection from contamination with oil and petrol products contained in water to be treated;

-

• effective and not decreasing with time filter regeneration by means of backwashing in fluidization mode;

Fig. 6. The process of petrol accumulation in granulated filtering bed and formation of «fluid net» in intergranular space

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

-

• quality of water purification from oil and petrol products at the level of the most expensive purification methods.

Water purification quality increase is linked by the authors to the creation of a “fluid net” in the gaps between the granules, which threads (bundles) located between the granules reduce the channels size and divide channels to finer ones followed by increase of entrapping (jamming) effectiveness of finer drops of oil and petrol products. Besides, the reduction of the channels crosssection between granules and “fluid net” threads leads to the increase of the fluid movement speed, which enhances the coalescence. Theoretical predictions with model materials (granules of spherical shape and of equal size) show that the cross-section of channels between granules and “fluid net” threads (after formation of the stable “fluid net”) is reduced by 6,8 times.

PROSPECTIVE FIELDS OF APPLICATION

The filtering material in the form of granules obtained at LLC “Voronezhpenosteklo” is used in the emulsions separation method developed and patented in Russia [20, 21] and in the equipment designed for implementation of this method [22, 23]. The decision on granting the European patent for the method of emulsions separation [24] was made by the European patent agency. Patent applications for the method of emulsions separation are being pended in other countries.

At present, the “OreFilter” technology becomes widely used in water treatment and water purification which, first of all, concerns the constant volume increase of petrol products usage as well as of vegetable and animal fats which have a very unfavorable property – a high adhesion to the filtering materials surface. Gripping on the surface of filtering materials, the petrol products and fats intermix with mechanical impurities and form an impermeable tight layer, practically a road concrete mix. To wash clean the filter from such impurities without affecting the filtering material is almost impossible.

“OreFilter” technology has passed the experimentalindustrial assessment at more than fifty plants of different industries (mainly at those connected with oil production and oil refining) in several countries:

-

• Russia (PAO “Tatneft”, PAO “Gazprom”, PAO “Lukoil”, ООО “RITEK”, “NK “Rosneft” and others);

-

• Kazakhstan (АО “NK “KazMunayGaz”, “Aktobe Oil”);

-

• Germany (“Confidential”, “Becker”, “Kummetat”);

-

• France (“Confidential”, “Nantes Seaport”);

-

• Italy (“ENI Genua”, “Petrolteknica”, AOC);

-

• Sweden (“Ragnsells”, “Fortum”).

The technology is now being tested at industrial sites of Near East, Canada, USA, Brazil and Australia.

The industrial filtering rigs using “OreFilter” technology have been already utilized at Russian enterprises of PAO “Tatneft” and also have been used in Sweden and Germany.

In oil producing branch the “OreFilter” technology enables an effective petrol products removal (down to 1–5 mg/l) from produced water containing up to 300 mg/l of petrol products and coarse dispersion. Filter regeneration is performed with normal water and allows collecting the petrol products entrapped. At cleaning of 13 400 m3 of produced water per day with petrol products concentrations from 40 mg/l the “OreFilter” material filled into the pressure sand filters of 3.2 m diameter, in 4 years’ time of utilization (without changing the filtering material) makes it possible to:

-

• clean 19 564 thousand m3 of produced water;

-

• entrap 782.5 MT of petrol;

-

• return back into production over 670 MT of petrol as a product.

“OreFilter” technology, based on standard pressure sand filters, reduces the cost of produced water purification from 30–70 RUR (in case of usage the technologies based on non-regenerable sorption filtering elements, ceramic membranes, ultrafiltration membranes etc.) down to 2,6 RUR for 1 m3 of water net of equipment depreciation during 10 years.

In EU countries (Sweden, Germany, Italy) the “Ore-Filter” technology is demanded at the objects of wastewater treatment and oil contaminated water treatment with a high content of suspended solids, dissolved organic compositions, heavy metals and other chemical compositions that require application of combined physicalchemical methods of water cleaning.

The application results of “OreFilter” technology have shown, that the purification cost of highly polluted waste water is reduced from 50–80 Euro (at implementation of chemical and electrocoagulation, ceramic membranes, ultrafiltration membranes with replacement rate of filtering elements at least once in 2–3 months) down to 4–9 Euro for 1 m3 of water subject to equipment depreciation (10 years) and application of chemical water cleaning methods (from diluted organic elements and heavy metals).

At pulp and paper mills (PPM) in Sweden and Germany the “OreFilter” technology provided an efficient petrol products and conifer trees oils entrapping at waste water treatment and significantly improved the operation of biological cleaning systems (PPMs are mostly rigged with biological cleaning systems of waste water prior to release to the municipal sewage or natural water sources). Similar requests have been already coming from Russian PPMs.

The “OreFilter” technology had passed the testing at metal industry plants where the origin of petrol products in water are processing leakages of lubricants

THE STUDY OF THE PROPERTIES OF NANOMATERIALS and hydraulic oils as well as of special protecting grease compounds for metals swaging and protection of surface from oxidization. Test results demonstrated a high grade of polluted water purification from petrol products, mechanical dispersions and specific pollutions of metal processing industry – slag (high density metal particles).

The experimental-industrial tests proved the efficiency of the developed technology application in:

-

• food industry (sugar and alcohol manufacturing plants (condensate purification from organic fats);

-

• detergents and soap manufacturing plants (condensate purification from vegetable fats);

-

• mining and processing works (waste water purification from petrol products residues of synthetic and organic origin);

purification of ballast and bilge water at ports; at purification of polluted water after oil tankers washing. aquaculture, e.g. in fish farming, in particular in trout breeding (дclosed loop water purification prior to systems of water biological purification from fats, the source of which are saturated foodstuffs with increased concentration of vegetable and animal fats); in seaquariums and dolphinariums (Moscow Seaquar-ium at National Economy Achievement Exhibition is Aspro Ocio international contest winner for the third year in a row in the nomination “Most transparent water among dolphinariums of Russia, EU and Near East” as the “OreFilter” technology used in seaquar-ium for the removal of fats and mechanical/organic suspensions from water makes it possible to reach water transparency up to 13 meters).

Список литературы Water purification from oil and petrol products by means of nano-porous super-hydrophilic materials

- Ospanova Zh.H., Khanturin М.R. Phytoremediation of oil polluted waste water. Orenburg State University Bulletin. 2010;12(118):74–77.

- Kuznetsova V.M., Ovsyankina А.V. Modern look at waste water purification methods at oil processing plants and enterprises. Young scientist. 2017;32(166):4–9.

- Veprikova Е.V., Tereshchenko Е.А., Chesnokov N V., Shchipko М.L., Kuznetsov B.N. Specifics of water purification from petrol products using oil sorbents, filtering materials and active carbons. Journal of Siberian Federal University. Chemistry. 2010;3:285–304.

- Chernenko Т.V., Imatullina G.K., Rezuanov D.А., Kireyeva А.Т., Khalitov А.К. Methods of waste water purification from petrol products. In: Problems and outlooks of modern science: Proceedings of the Fourth International Teleconference «Basic sciences and practice». Tomsk. 2011. Vol. 3, № 1. Available from: http://masters.donntu.org/2012/feht/shirokorodova/library/article9.htm (access date: 16.03.2021).

- Kuligin S.V., Ishkov А.D., Kosyakov А.V. et al. Granule of the filtering material for demulsification. Russian Federation Patent 2652695. 2018-04-28.

- Kosyakov А.V., Ishkov А.D., Kuligin S.V. et al. Granule of the filtering material for separation of emulsions. Russian Federation Patent 2661228. 2018-07-13.

- Demin М.V., Ishkov А.D., Kosyakov А.V. et al. Granule of the filtering material for separation of emulsions. Russian Federation Patent 2661233. 2018-07-13.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Method for producing granular filter material. Russian Federation Patent 2630554. 2017-09-11.

- Kosyakov А.V., Blagov А.V., Rovovoj V.V. et al. Granular filter material. Russian Federation Patent 2628391.2017-08-16.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Granulated filtering material. Russian Federation Patent 170334. 2017-04-21.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Unit for manufacturing of granulated filtering material from diatomite. Russian Federation Patent 168903. 2017-02-27.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Filter material. Russian Federation Patent 2641742. 2018-01-22.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Filter and/or sorption material. Russian Federation Patent 173572. 2017-08-31.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Granulated filtering and/or sorbing material. Russian Federation Patent 2640548. 2018-01-09.

- Kosyakov А.V., Blagov А.V., Kuligin S.V. et al. Granulated filtering and/or sorbing material. Russian Federation Patent 176291. 2018-01-16.

- Kuligin S.V., Ishkov А.D., Kosyakov А.V. et al. Granule of the filtering material for demulsification. Russian Federation Patent 179222. 2018-05-04.

- Kosyakov А.V., Ishkov А.D., Kuligin S.V. et al. Granule of the filtering material for demulsification. Russian Federation Patent 176145. 2018-01-09.

- Demin М.V., Ishkov А.D., Kosyakov А.V. et al. Granule of the filtering material for emulsions separation. Russian Federation Patent 176482. 2018-01-22.

- Kim P., Wong T.-S., Alvarenga J. et al. Liquid-infused nanostructured surfaces with extreme anti-ice and antifrost performance. ACS nano. 2012;6(8):6569–6577.

- Belov P.V., Ishkov А.D., Kosyakov А.V. et al. Method of emulsions separation. Russian Federation Patent 2664936. 2018-08-23.

- Kosyakov А.V., Belov P.V., Ishkov А.D., Lapenko А.А. Technology of water purification from petrol and oil and petrol products using “aqueous” filter on mineral porous carrier. Equipment and technologies for oil and gas industry. 2021;1(121):32-37.

- Kirin М.P., Ishkov А.D., Kosyakov А.V. et al. Device for separation of emulsions. Russian Federation Patent 2652255. 2018-04-25.

- Kirin М.P., Ishkov А.D., Kosyakov А.V. et al. Device for separation of emulsions. Russian Federation Patent 178810. 2018-04-19.

- Belov P.V., Ishkov A.D., Kosyakov A.V. et al. Method of emulsion separation. European Patent 3513853. 2019-07-24.