Wooden saddle-trees from Yaloman II in the Altai: an interdisciplinary analysis

Автор: Mylnikov V.P., Tishkin A.A.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 3 т.44, 2016 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145272

IDR: 145145272 | DOI: 10.17746/1563-0110.2016.44.3.047-055

Текст статьи Wooden saddle-trees from Yaloman II in the Altai: an interdisciplinary analysis

The purpose of the saddle for horse-riding is not only to provide the rider with the maximum comfort and protect the back of the horse from constant friction and hits from the body of the rider, but also to foster the right posture of the rider for ensuring the contact with the horse and the ability to control the horse during riding. The structure of the saddle-tree (the frame) is of great importance for accomplishing these goals (Myuzeler, 1980: 13; Gubarev, 1970: 289; Borris, 1998: 82–98).

The culture of modern peoples who follow the traditions of ancient and medieval nomads is a complex heterogeneous phenomenon, which has evolved over thousands of years through broad ethnic and intercultural contacts. The analysis of the artifacts belonging to that richest civilization of the Eurasian steppes (the Altai, the Sayan Mountains, Siberia), performed using the archaeological complexes containing horse burials, makes it possible to obtain a more objective view on the ethnic history and cultural genesis of the peoples inhabiting this vast region than was previously possible. Today, the elements of horse equipment are one of the most numerous categories of archaeological finds.

The genesis of saddles “with rigid base” (Kyzlasov, 1969: 135–139) has equal importance in the study of forms and structures of saddles as one of the main components of horse-equipment. The materials on this subject, which have been accumulated over many decades, are mostly published and well analyzed; which allows scholars to conduct interdisciplinary and historical-ethnographic

studies, across a wide chronological range, of the ridingequipment used among the nomads of Siberia and Central Asia (Tkachenko, 2009).

Wooden objects with various functions, including rigid saddle-trees from the burials of the second half of the 4th–first half of the 5th century at the Yaloman II cemetery (the Russian Altai)*, which were found in the 2000s, provide additional opportunities for special interdisciplinary studies with the participation of experts in wood-processing, dendrochronology, and xylotomy (Tishkin, Mylnikov, 2007, 2008; Mylnikov et al., 2012). The findings of these studies provide further data on the above sources for scholarly use.

Almost completely preserved parts of a rigid wooden saddle-tree without stirrups (Collection No. 181/301– 303, 337–340), and archaeologically intact bars and fragments of other parts of a second saddle (Tishkin, Gorbunov, 2003: Fig. 2, 4–7 ; Tishkin, 2005: 61, fig. 354–359; Tishkin, 2011: 175, fig. 5), were found in grave No. 1 during the excavations of burial-mound No. 33 at the site of Yaloman II. The grave-pit of burialmound No. 29 at the same site contained numerous fragments of wood. Their analysis made it possible to identify them as elements of one more wooden saddletree. Similar objects were found in burial-mounds No. 30 and 31 (Tishkin, Mylnikov, 2008: 98–99; Tishkin, 2011: 174). The discovered objects constitute important sources for understanding the stages in the evolution of horse equipment (Savinov, 2005; Komissarov, 2005; Hudiakov, Komissarov, 2003).

Results

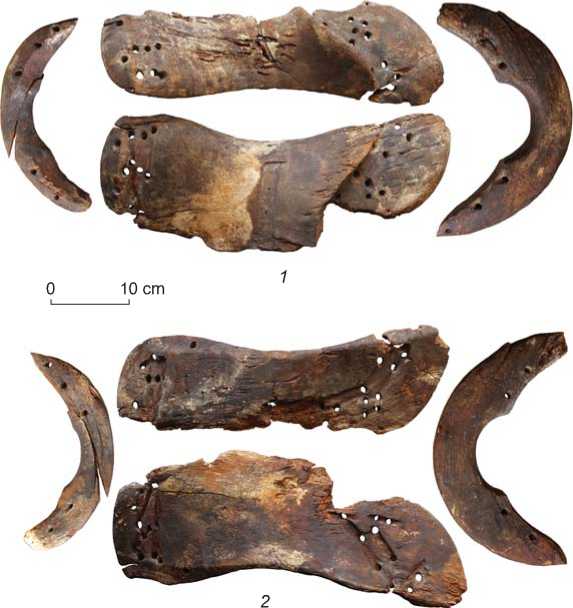

The entire process of manufacturing a rigid wooden saddle-tree can be reconstructed from the technical and technological analysis of archaeologically intact artifacts belonging to a single object: two bars, a pommel, and a cantle from grave No. 1 in burial-mound No. 33 at the Yaloman II cemetery (Fig. 1). They preserve all traces of processing and the units needed for technological and graphic reconstruction of the object. During the final assembly, the elements were connected together by a series of through holes, grooves, and leather straps in a sufficiently rigid, durable, and comfortable frame—the saddle-tree.

The dendrochronological analysis determined the approximate age of the trees that provided timber for the bars, the pommel, and the cantle, while the xylotomic analysis showed that all the blanks were made of birch-trunks of large diameters. The middle part of the trunk that remained after splitting off one third of its diameter on the opposite sides was used for producing each bar of the saddle. The pommel and cantle were carved from the split sides of the same trunk. The technological analysis of the traces remaining from the blades of woodworking tools, and their comparison with the original tools found in the burial-grounds of the same period (Soyonov, Konstantinova, 2013), made it possible to identify an approximate set of carpenter’s tools used in the Hunno-Sarmatian time, which included axe, adze, set of chisels, knife, and flat drill (reamer).

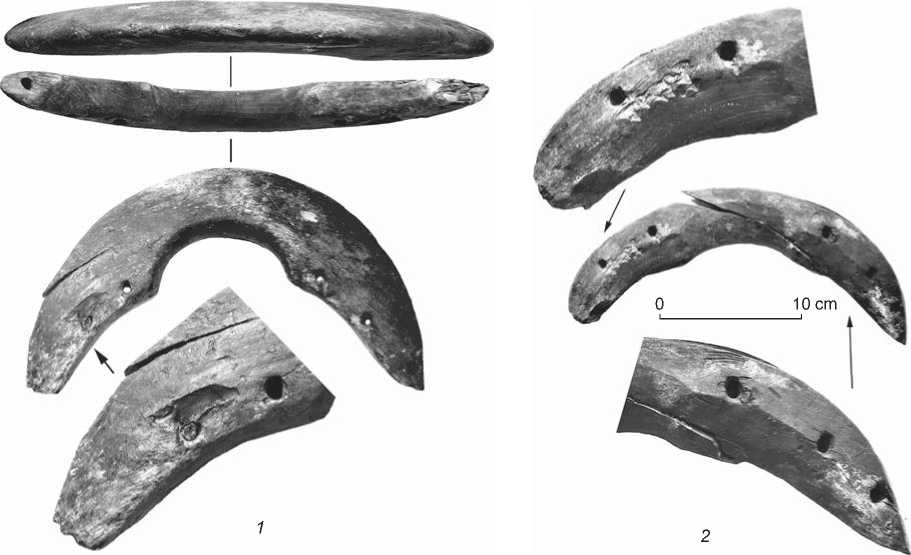

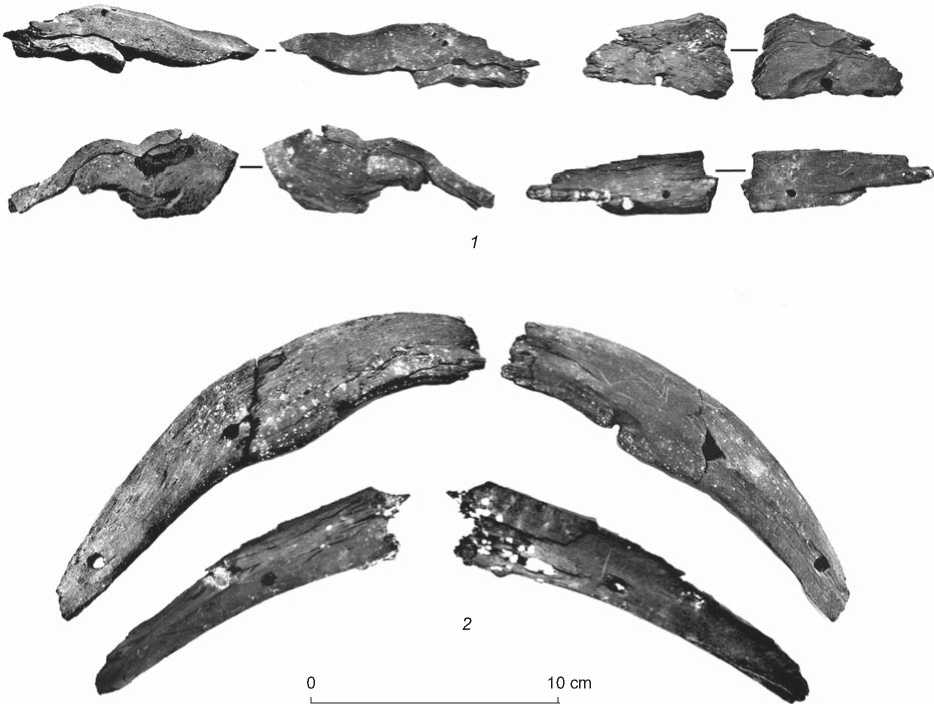

Bars are two ornately shaped boards of curved profile with wide recesses-cavities made with chisels for attaching the pommel and the cantle (Fig. 2). The length of the left bar is 41.5 cm; its width near the rectangular recess for attaching the girth strap is 13.8 cm. The length of the right bar is 42 cm; the greatest width of the surviving part is 11.2 cm. The upper edge of each bar has a smooth arched groove 4–5 cm deep. The width of the surviving parts of elements at the pommel is 12.8– 13.9 cm; at the cantle it is 12.2–14.4 cm. Thickness of bars at the point where the pommel was attached is 1.6– 2.5 cm; that at the point where the cantle was attached is 1.5–5.0 cm. The width of the groove for the pommel is 8–10 cm; its depth is 2.3–2.6 cm. The width and depth of the groove for the cantle are 2.8–3.7 and 0.5–0.8 cm respectively. Ten to twelve holes with diameters from 3.6 to 7.9 mm were drilled at the ends of each bar at the place where the pommel and cantle were attached; two smaller holes (2 mm in diameter) were drilled behind each group of larger holes. Bars have an arched profile in longitudinal section, corresponding to the curve of the rider’s thighs (Fig. 2, 1 ). Apparently, the craftsman deliberately chiseled down this shape with a pick adze, and then trimmed it with a finishing adze or the end of the axe-blade to produce a more comfortable seat for the rider. Faint traces of these tools of primary treatment can be seen on the reverse sides of the bars; the frontal sides, which underwent secondary treatment, are smoothed. Pommel and cantle were attached to the bars using the pairs of holes. For firmer attachment, the planes of the bases of pommel and cantle were fitted to the arched outline of the fitting places (Fig. 2, 2 , 3 ) by fine and frequent whittling with a knife.

Grooves-sockets were carved with a narrow-bladed chisel on the reverse planes of the bars (the inner surfaces adjacent to the back of the horse) between the holes for mounting rawhide straps or tendons. These grooves were intended to hide flush the straps and their knots which could damage the horse’s back during riding (Fig. 1, 2 ). Presumably, the outlines of the grooves were cut with a knife.

Four cavities 2 mm in diameter were drilled in one bar in the oblique groove (25–30 mm wide, 2 mm deep) for girth straps at a distance of 20 mm from each other; in

Fig. 1. Complete set of a rigid wooden saddle-tree: bars, pommel, and cantle.

1 – front side; 2 – reverse side.

Fig. 2. Side view of the bars ( 1 ) and the fragments, showing the technology of manufacturing fitting places and elements at the ends of the bars for attaching the pommel and the cantle ( 2 , 3 ).

one of the cavities, a small wooden nail with a flattened cap has survived (Fig. 3). With the help of five or six of such nails on each side, girth leather straps were securely fastened to the bars, allowing the saddle to be rigidly mounted on horse’s back.

The inner surface on one of the bars shows faint traces of axe and adze blades. Obviously, the manufacturers of rigid saddle-trees did not always pay due attention to careful secondary processing of the inner surfaces of the bars. They might have hoped that felt saddle-blankets placed under the saddle would protect the back of the horse from being injured by individual defects of primary treatment. The outer surfaces of the bars, the pommel, and the cantle are smoothened, apparently as a result of the frequent use of the saddles.

10 cm

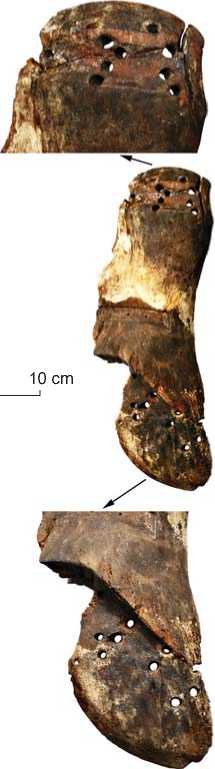

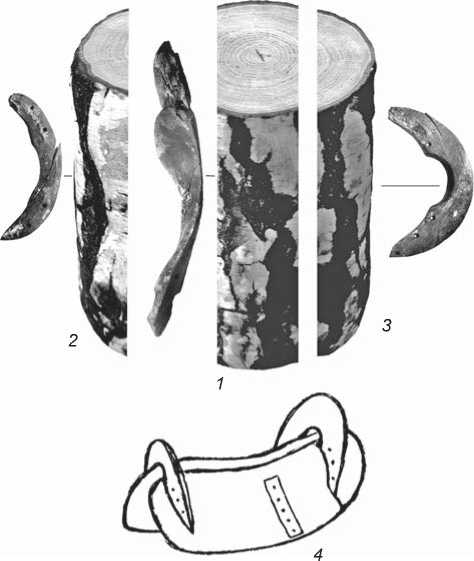

Pommel (Fig. 4, 1 ) is a plate in the form of an arch in a half-circle; it is an elongated oval in cross-section, with two flattened bases adjusted to the profiles of the fitting-places on the bars. The height of the arch is 19.2 cm; its width at the bases is 29 cm. Two holes with the diameter of 6–7 mm for attaching the pommel to the bars were drilled in the edge of each base. They are finely polished, indicating long-term use of the saddle. A piece of tendon has survived in one of the holes. In the middle, the plate has an arched recess 8 cm wide and 5.3 cm high. Both the width and thickness of the plate are 2.5 cm at the bottom and 1.6 cm at the top. All planes and faces of the pommel, which were given oval shapes, preserve the traces of secondary treatment (smoothing and polishing). On one edge, a widening crack along the annual rings, caused by the climatic impact on wood in the burial pit, cuts through the plate.

Cantle (Fig. 4, 2) is a plate in the form of a low arch in one-third of a circle. The height of the arch is 10.5 cm; its width at the bottom is 24 cm. On one side of the plate, the surface is flat with a barely visible convexity; on the other side, two faces were rasped away edgewise in the middle. The width of the plate is 3.8–5.2 cm; its thickness is 1.4 cm at the bottom and 1.6–2.1 cm at the top. Unlike those in the pommel, the fastening holes in the cantle are 6–7 mm in diameter, and they were drilled with a significant shift from the edge of the base: three holes on the right are almost in the middle

Fig. 3. Fastening devices at the ends of the bars on the external plane of the saddle.

0 10 cm

Fig. 4. Pommel ( 1 ) and cantle ( 2 ).

of the plate; two holes on the left are closer to its upper edge. The plate is almost entirely broken obliquely along an annual ring. At the breakage, the traces of the cracks can be seen that have occurred for the climatic reasons mentioned above. The left end of the cantle is blunt as a result of the process of decay and degradation of wood.

Bars of the rigid saddle-tree of the second saddle (Fig. 5) have survived in varying degrees of preservation: the middle and lower parts of one bar are in a worse condition than in the other. The length of the left bar is 40.6 cm; that of the right bar is 41.0 cm; the widths at the recesses for attaching a girth strap are 14.5 and 10.0 cm respectively. The width at the ends of the bars at the place where the pommel was attached is 11.5–12.8 cm, and where the cantle was attached, 12.2–13.2 cm; the thicknesses are 1.5–2.2 and 1.5–5.0 cm respectively. The cavities for the pommel and cantle have a depth of 2.0 and 0.5–0.7 cm, and widths of 7.5–10.0 and

3.2–4.8 cm. Ten to twelve holes with diameters ranging from 3.5 to 8.0 mm, and two small holes behind these (2 mm in diameter) were drilled in the ends of each bar, in the places where the pommel and cantle were attached. Deep grooves for the fastening rawhide straps and their knots were cut on the reverse (inner) planes of the bars between the holes for straps (Fig. 5, 2 ). It can be concluded that in general the design and parameters of the bars from the second saddle are the same as those from the first saddle, which indicates a certain standardization in the manufacturing of rigid wooden saddle-trees.

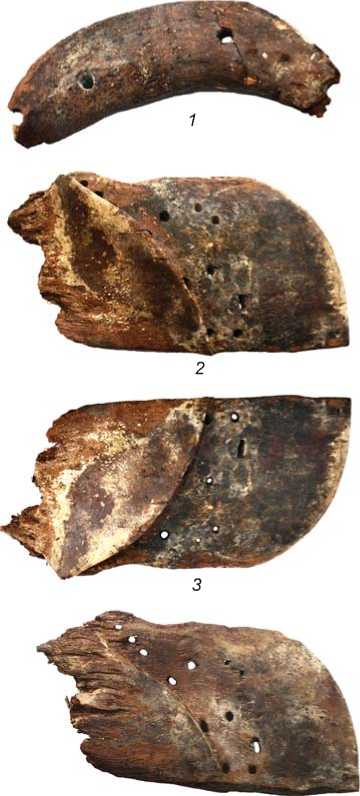

In addition to the elements described above, the following fragments have been identified (Fig. 6): more than a half of the cantle, and three parts of bars with cavities for attaching the pommel and the cantle. These fragments preserved the traces of processing; the analysis of these traces made it possible to reconstruct the technology of producing rigid saddle-trees. The holes

Fig. 5. Bars of a rigid wooden saddle-tree.

1 – front side; 2 – reverse side.

10 cm

0 10 cm 4

Fig. 6. Fragments of a rigid wooden saddle-tree: cantle ( 1 ) and bars ( 2–4 ).

through which the pommel and cantle were attached to the front and rear parts of the bars are mostly round (5–6 mm in diameter), drilled by a flat drill or reamer. Some of them acquired an oval shape from long use. Individual holes were cut by a chisel with a rectangular blade. Round holes 4 mm in diameter, and square holes measuring 4 × 4 mm are located at a distance of 2.2 cm from each other.

Fragments of a saddle-tree have also been identified among the remains of wooden artifacts from burialmound No. 29 at Yaloman II (Collection 621/269). They may include small fragments of bars, pommels, and cantles with traces of secondary processing and use (smoothing), as indicated by the analysis of their configurations, the thickness of the fragments, and the processing features of their planes. The wood has a poor degree of preservation; however, the type of wood can be identified as birch. The collection contains flat fragments and arched pieces of sharpened planks. The sizes of fragments range from 3.0 to 14.5 cm. Many fragments have both intact and partially preserved holes 4–6 mm in diameter. Many of the remains are amorphous. These artifacts presumably include large fragments of saddlebars (Fig. 7, 1). The traces of the secondary treatment are weak. Small smoothened sections of the oval and sharpened ribs have survived. The bars were probably made of blanks with a highly twisted texture. Some fragments preserve small areas with weak traces of trimming. We can reliably identify four large fragments of the pommel and cantle, which represent halves of arched and rounded plates, sharpened at the ends, with the traces of secondary treatment and with three holes 4–6 mm in diameter (Fig. 7, 2). The fragments can be identified with high probability as the pommel and the cantle of a single saddle, or as two cantles of two saddles.

Summing up the results of the studies, we may say that a significant number of wooden objects of a sufficiently good degree of preservation have been found in the last decade during the excavations of burial sites of the so-called Hunno-Sarmatian time in Southern Siberia. The availability of high-quality wooden structures and products with different functions indicates a fairly high level of wood-processing in the Altai in 200 BC–500 AD. Numerous elements of horse-equipment, which were made of wood—in particular, well-preserved elements of rigid saddle-trees—became not only a reliable criterion for establishing the relative chronology of the monuments, but also excellent material for special interdisciplinary studies on woodworking technology, xylotomy, and dendrochronology.

Joint efforts of scholars from different areas established the type and approximate age of the trees whose timber was used for making rigid wooden saddle-trees. The technological aspects of selecting the raw material and manufacturing bars, pommels, and cantles for each saddle, as well as the methods of their attachment to each other for forming a single object, have been identified. On the basis of analysis of early sources and also variations of forms and structural features of “soft”, “semi-soft”, and “semi-rigid” saddles of various types (Gryaznov, 1950: 54–58, pl. VII, VIII, XI, XVI, XXII; Rudenko, 1948: 14–15; 1953: 164–214; 1960: 128–132, pl. LXIII, 1–5 ; Vainshtein, Kryukov, 1984: 122; Tkachenko, 2003; Klyashtorny, Savinov, 2005: 189; Stepanova, 2006, 2012, 2014; Kushayev, 1978: 81, fig. 9, 9a; Brosseder, Miller, 2012: 118; Polosmak, Bogdanov, Tseveendorj, 2011: 92, fig. 4, 5; 2013; Bogdanov, 2014: 123; Polosmak, Bogdanov, 2015: 55–56, fig. 3, 12 , 13 ; and others) with wooden bases, it has been suggested that saddles with such bases emerged in the Scythian-Saka period, and were enhanced in the subsequent periods. The classic nomadic type of

Fig. 7. Amorphous fragments of bars ( 1 ) and fragments of pommel and cantle ( 2 ).

saddle with a rigid wooden base received its final form in the Old Turkic period in the Altai (Savinov, 1977, 1984: 36, 45–55; Tkachenko, 2003). All parts of the saddletree began to be made from a single piece of log, and fastened together using a rigid tongue-and-groove joint. The saddles, whose wooden bases have been found in the graves of mounds No. 29 and 33 at the Yaloman II cemetery, are an intermediate variant between the Xiongnu type with a semi-soft base, and the Turkic saddle with a rigid base, the earliest version of which has been found in the Altai (Ibid.).

The comprehensive analysis of all components of the rigid wooden saddle-tree (two bars, the pommel, and the cantle from grave No. 1 in burial-mound No. 33 at the Yaloman II cemetery) makes it possible to propose a graphic reconstruction of the saddle-tree (Fig. 8).

Fig. 8. Reconstruction of a rigid wooden saddle-tree from grave No. 1 in burial-mound No. 33 at the cemetery of Yaloman II.

1 – middle part of tree-trunk used for manufacturing the bars; 2 , 3 – side parts of the trunk used for manufacturing the pommel and the cantle; 4 – graphic reconstruction of the saddle-tree.

Conclusions

Comparative typological analysis of the shape and external appearance of wooden saddle-trees and the genesis of their structural elements, together with their manufacturing features over a period from the Scythian-Saka time to the Old Turkic time, show progressive development and improvement of this essential part of horse equipment. In terms of technology, the saddles known today can be divided into several typological groups, depending on the functional load of the wooden base: 1) with leather cushions (bars), sewed wooden arches (pommels and cantles), bracers and plates with decorative carving—the morphogenic soft type, which goes back to the Scythian-Saka period; 2) with movable, not rigid frame of wooden planks and laths underneath leather cushions, depending on the size and parameters of the material of the base—the semi-soft , semi-rigid type, which belongs to the Xiongnu period; 3) with the base of two bars, the pommel, and the cantle made from a single piece of log and connected by means of combinations of rows of holes and thick rawhide straps or tendons—the rigid type, the product of the Altai tribes of the Rouran (pre-Turkic) period, and 4) with the saddle-tree of two wooden bars, pommel and cantle, fastened together by means of tongue-and-groove joints and fasteners (bone and metal onlays, nails)—the rigid type, the improvement by nomads of the Old Turkic period.

Further study of materials from the archaeological complex described above will make it possible to solve the cultural and chronological problems, and to reconstruct the subsistence system of the Altai population in the pre-Turkic period.