Analysis of the influence of heating temperature on the convective drying process

Автор: Alexeyeva N.V., Satayev M.I., Azimov A.M., Shakiryanova Z.M., Duisebayev Sh.E., Ashirbayev Zh.S.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 2 (144), 2024 года.

Бесплатный доступ

The study examines the influence of heating temperature during the convective drying of fruits on the mass fraction of moisture in the finished product. Convective drying is a promising method for preserving products, allowing the production of dried fruits that can provide essential nutrients year-round. The experiments detailed in this article aim to establish optimal fruit drying modes. Standard methods were used to analyze the experiments according to regulatory documents in force in Kazakhstan. The authors proposed diagrams of convective drying of the fruits in the south of Kazakhstan. According to the constructed schemes, it can be seen that the heating temperature during the drying process affects the final product. According to the analysis, an increase in heating temperature results in a decreased drying time. At the specified time, the highest conversion rate of the relative mass of the dried product is detected. Additionally, it was obtained that the temperature, size, and structure of fresh raw materials affect the period of maximum moisture volatilization rate. The authors carried out a sensory evaluation of the main quality indicators: taste, color, odor and consistency. The optimal characteristics of the indicators were determined. They were extracted at a heating temperature of 50 ....65 °C. Numerous experiments have shown that it is necessary to offer such convective drying parameters. Convective drying temperature for apples is 50-55 °C, for apricots - 55-65 °C, for prune plums - 60-65 °C. Such results will be useful in the technology of fruit and vegetable processing.

Convective drying, temperature, fruits, mass fraction of moisture, organoleptic evaluation, analysis

Короткий адрес: https://sciup.org/140305894

IDR: 140305894 | УДК: 65.35.03 | DOI: 10.48184/2304-568X-2024-2-63-70

Текст научной статьи Analysis of the influence of heating temperature on the convective drying process

SRSTI 65.35.03

Convective drying is an advanced method of food preservation [1]. The best possible results of the drying stage are achieved by carrying out numerous experiments. Therefore, it is necessary to select the preferred characteristics of drying regimes on a scientific basis. The result will be high-quality finished products. It is important to demonstrate the sensory and physicochemical properties of the dried product [2].

Through the method of convective drying, a diverse range of fruit raw materials can be preserved. Since fruits are seasonal products, producing dried fruits ensures their availability to the population year-round, thereby enhancing the nutritional structure of diets. Dried fruits can be sold as standalone products or used as food температура, плоды, массовая доля влаги, additives in various products to enrich them with vitamins and trace elements.

The purpose of the study: selection of temperature regimes of convective drying of fruits.

Objects of research. The objects of the study were fruits such as apricots, prune plums, apples.

Materials and research methods

Experimental studies were carried out in the testing regional laboratory of engineering profile "Structural and biochemical materials" of the M. Auezov South Kazakhstan University (Shymkent, Tauke Khan str. 5), InnovTechProduct LLP, Shymkent. The experiments were conducted during the spring and summer months.

Generally accepted standard methods of raw material research were used to implement the tasks. The raw materials were sourced from the southern region of Kazakhstan.

The range of analyzed convective drying modes was selected in such a way as to ensure the preservation of useful elements in fruits [5]. The experiments were carried out on a laboratory convective drying unit at heating temperatures from 40 to 80°C in increments of 5 degrees. The fruits were dried on pallets in one layer. The control parameters of drying were the drying heating temperature (0 °C), the mass fraction of the moisture of the fruit (%) [6]. Regulatory documents were used for comparative characteristics of the products obtained.

Results and discussion

For the experiments in question, we selected apricots. The apricots were dried in one layer, previously divided into two halves. At the stage of apricot cleaning, the seeds were removed. The halves of apricots were laid out on sheets of convective drying with the pulp facing up. The apricot fruits did not touch each other. The specimens were subjected to convective drying using a blowing fan. The set drying time at a temperature of 50 degrees is 18-24 hours. At a temperature of 65 degrees, the drying time was 18 hours. Apricot drying was stopped when the mass fraction of dried fruit moisture reached 10-20%.

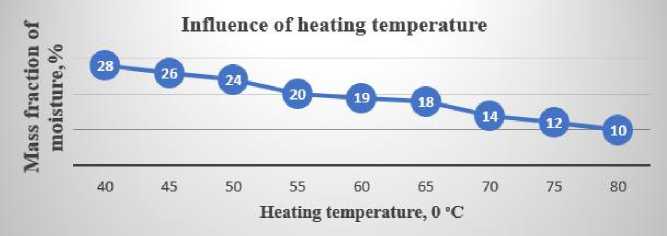

Below we present a graph of the decrease in the mass fraction of apricot moisture during convective drying (Fig.1).

Figure 1. Influence of heating temperature during convective drying of apricot on its mass fraction of moisture

The graph shows that the dynamics of the decrease in the mass fraction of apricot moisture is an uneven process. The value decreased at a drying temperature of 40 °C from 28% to 10% at a drying heating temperature of up to 80 °C. The optimal results were obtained with the values of the mass fraction of dried apricot moisture of 1820% at a drying heating temperature of 55-65 °C.

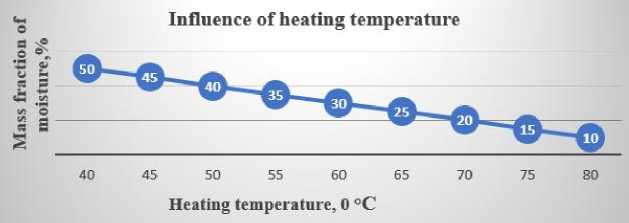

Next, we aimed to establish the influence of the heating temperature during the drying of plums on the reduction of their mass fraction of moisture. Drying of the prunes was stopped when the mass fraction of moisture in the dried fruit reached 20-25%. The plums were dried in a single layer, having been previously divided into two halves. At the stage of plum cleaning, the seeds were removed. The plum halves were laid out on sheets of convective drying with the pulp facing up. The plum fruits did not touch each other. They were thoroughly blown by a convective drying fan. The set drying time at a temperature from 4550 °C to 70 °C for the finished product is 16 hours.

We will present a graph illustrating the decrease in the mass fraction of moisture in prunes during convective drying, depending on the drying heating temperature (Fig. 2).

Figure 2. The influence of the heating temperature during convective drying of the plum on its mass fraction of moisture

The research diagram demonstrates the following effective characteristics. The normative values of the mass fraction of moisture of prunes at the drying stage in the region of 20-25% were noted at a heating temperature of 65-70 °C [5].

The subsequent experiments were conducted on apples. The initial study examined the heating periods and their impact on the mechanical properties of apple slices. The findings of the study indicate a need for energysaving measures to facilitate rapid drying. The product obtained exhibited preserved properties of high quality in comparison with conventional drying [6].

The next object of the experiments was also apples [7]. We made semi-finished products from apples with a thickness of 1 mm, 4 mm, 5 mm, and 6 mm. The prepared semi-finished products of fresh apples were placed on a convective drying mesh pallet in one layer. At the end of convective drying, the following results were observed, which are shown in Table 1.

Table 1. Results of convective drying of apples

|

Mode |

Thickness of the semifinished product 1 mm |

Thickness of the semifinished product 4 mm |

Thickness of the semifinished product 5 mm |

Thickness of the semifinished product 6 mm |

||||

|

Product Readiness |

Mois-ture, % |

Product Readiness |

Moisture, % |

Product Readiness |

Moisture, % |

Product Readiness |

Moisture, % |

|

|

1 |

Ready |

20 |

Ready |

20 |

Not ready, drying |

30 |

Not ready, drying |

35 |

|

2 |

Ready |

20 |

Ready |

20 |

Not ready, drying |

30 |

Not ready, drying |

35 |

As indicated in the table, the thickness of the semi-finished product significantly influences the degree of drying of the finished product [8]. When the thickness of fresh apples is 1 mm, apple chips with a visually appealing appearance and pleasant taste are obtained, and the moisture content of the finished product conforms to standard values. We observed that with thicknesses ranging from 1 mm to 4 mm and under modes 1 and 2, we consistently produce dried fruits with physical-chemical properties meeting standard specifications. However, when the thickness of the semi-finished product increases to 5 or 6 mm, inadequate drying of the finished product occurs, resulting in an excess of moisture content above normative levels. Both drying time and temperature significantly influence the production outcomes.

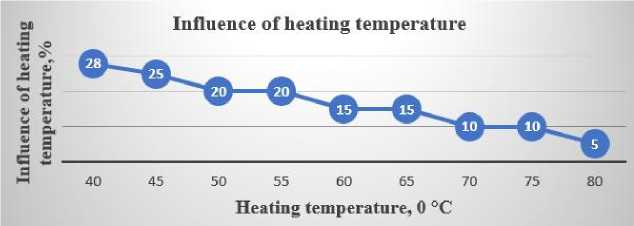

We will consider a graph illustrating the decrease in the mass fraction of moisture in apples during convective drying, depending on the drying heating temperature (Fig. 3).

Figure 3. The influence of the heating temperature during convective drying of apples on its mass fraction of moisture

Based on the conducted experiments, the duration of drying and the yield of finished fruit products during convective drying were established (Table 2).

Table 2. Duration of drying and yield of finished fruit products during convective drying

|

Name dried fruits |

Drying time in hours |

Output of finished products |

|

Dried apricots |

18-24 |

13-18 |

|

Prunes |

16-18 |

19-20 |

|

Apples |

2 |

18-20 |

The chemical composition of dried fruits post-convective drying is detailed in Table 3 [9,10]. The work investigated the effect of convective drying of feijoa on the physicochemical characteristics, as well as drying parameters (energy consumption and drying speed). Feijoa fruit pieces were dried at temperatures of 50, 60, and 70°C, air speed of 0.5 and 1 m/s, and thickness of 0.003 m and 0.005 m. Optimal conditions were a temperature of 50.83 °C, air speed of 1 m/s, and thickness of 0.003 m. The results show that convective drying is a suitable and cost-effective method for obtaining functional ingredients while maintaining biocompounds and biological activity [11].

Table 3. Chemical composition of dried fruits during convective drying

|

Name of indicators |

Meaning |

|

Dried apricots |

|

|

Moisture, % |

13-18 |

|

Proteins, g |

4,0-4,8 |

|

Fats, g |

0,085-0,1 |

|

Carbohydrates, g |

44-48 |

|

Prunes |

|

|

Moisture, % |

20-25 |

|

Proteins, g |

0,96 |

|

Fats, g |

0,16 |

|

Carbohydrates, g |

28,08 |

|

Apples |

|

|

Moisture, % |

20 |

|

Proteins, g |

2,3 |

|

Fats, g |

0,1 |

|

Carbohydrates, g |

83 |

Practical research yielded the duration of ranging from 40°C to 80°C, with increments of 5

convective drying for all objects at temperatures degrees (Table 4).

Table 4. Duration of convective drying of fruits at temperature selection, h

|

Type of fruit |

Drying temperature, °С |

||||||||

|

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

|

|

Apricot |

36 |

32 |

24 |

22 |

20 |

18 |

16 |

14 |

12 |

|

Plum |

26 |

24 |

22 |

20 |

18 |

16 |

14 |

12 |

10 |

|

Apple |

3,5 |

3,0 |

2,5 |

2,0 |

1,5 |

1,0 |

0,5 |

0,2 |

0,1 |

The whole process of convective drying can be represented in three stages. During the first stage, the temperature of the product decreases by several degrees, and the relative mass decreases by 2-5%. At this phase, the moisture of the macro capillaries of the product is removed. After 10 minutes, when the temperature in the chamber reaches the required level, the temperature and the rate of dehydration of the product begin to increase, and the second stage of dehydration begins [12].

Convective drying is characterized by the presence of a second stage of drying. During this period, there is an increase in the drying rate. With numerous fruit varieties globally, each fruit possesses unique characteristics. After conducting multiple experiments, it was observed that an increase in heating temperature correlates with the highest rate of variation in the relative mass of the final object [13].

The obtained research results are as follows. The time of the highest rate of moisture removal is influenced not only by temperature but also by the structure and size of the fruits themselves. During the experiments, large parameters and the thickness of the fruit influenced a decrease in the intensity of moisture evaporation from the center of the product to its outer layers. Therefore, there is an increase in time, which is so important to establish the highest rate of moisture removal.

During the second stage, microcapillary moisture and osmotic moisture evaporate during drying [14].

During the third stage, there is a specific reduction in the drying rate, during which mono- and polymolecular adsorption moisture is removed from the material. This period is characterized by the highest binding energy. To evaluate sensory properties, an approach based on indicators such as color, taste, smell, and consistency was employed. The proposed indicators were rated on a scale of 5 points [15]. Thus, the total points ranged around 20 points. Table 6 presents the results of the sensory analysis.

Table 5. Results of organoleptic evaluation of dry fruits when selecting the temperature of convective drying

|

Type of fruit |

Indicator |

Drying temperature, °С |

||||||||

|

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

||

|

Apricot |

Taste |

4 |

4 |

45 |

5 |

5 |

5 |

2 |

2 |

0 |

|

Color |

4 |

4 |

4 |

5 |

5 |

5 |

2 |

2 |

1 |

|

|

Smell |

4 |

4 |

4 |

5 |

5 |

5 |

3 |

3 |

0 |

|

|

Consistency |

2 |

2 |

3 |

5 |

5 |

5 |

2 |

2 |

1 |

|

|

Total |

14 |

14 |

16 |

20 |

20 |

20 |

9 |

9 |

2 |

|

|

Plum |

Taste |

4 |

4 |

5 |

5 |

4 |

3 |

2 |

2 |

1 |

|

Color |

4 |

4 |

5 |

5 |

3 |

3 |

1 |

1 |

1 |

|

|

Smell |

4 |

4 |

5 |

5 |

3 |

2 |

2 |

2 |

0 |

|

|

Consistency |

4 |

4 |

5 |

5 |

3 |

2 |

4 |

2 |

2 |

|

|

Total |

16 |

16 |

20 |

20 |

15 |

10 |

9 |

7 |

4 |

|

|

Apple |

Taste |

3 |

3 |

4 |

4 |

5 |

5 |

3 |

2 |

8 |

|

Color |

3 |

4 |

4 |

5 |

5 |

5 |

3 |

3 |

2 |

|

|

Smell |

4 |

4 |

4 |

4 |

5 |

5 |

3 |

1 |

0 |

|

|

Consistency |

3 |

3 |

3 |

4 |

5 |

5 |

3 |

1 |

2 |

|

|

Total |

13 |

14 |

15 |

17 |

20 |

20 |

12 |

7 |

4 |

|

The optimal technological characteristics of sensory properties in apricots (from 16 to 20 points) were achieved under the following conditions: the heating temperature range of 55-65 ° C. When the temperature rises to 80 °C the scores of organoleptic properties are reduced to 2 points.

The maximum scores of sensory characteristics were obtained at the heating temperature of 50-55 °C for drying apples (Table 5). Indicators corresponding to the standard for prunes were observed at a temperature of 60-65 °C.

Conclusion

The proposed method was used to study the effect of heating temperature on the efficiency of the fruit drying process during convection. Taking into account the optimal ratio between the dehydration time and the degree of preservation of important fruit components, the following values of the heating temperature during drying should be recommended for the production of fruit processing: for apples - 50-55 ° C, apricots - 5565 °C, prunes 60-65 ° C.

Funding

This research was supported by the Ministry of Science and Higher Education of the Republic of Kazakhstan, grant AP19678142 (2023-2025).

Список литературы Analysis of the influence of heating temperature on the convective drying process

- Gridneva E.E., Kaliakparova G.Sh., Kalmanova N.M. Plodoovoshnaya otrasl' yuzhno-kazakhstanskogo regiona: sostoyanie i perspektivy. Problemy agrorynka. Forsait-Kazakhstan, №3, s. 180-186, 2020.

- Evlash V. V., Gavrish A.V., Kravchenko A. I., Nemirich, Tarasenko T. A., Vasheka A.M. Teoreticheskoe issledovanie sposobov sushki ovoshei i fruktov. Naukovii Vіsnik L'vіvs'kogo Natsіonal'nogo Unіversitetu Veterinarnoї Meditsini Ta Bіotekhnologіi Іmenі S.Z. Ґzhits'kogo, №17, № 4 (64), s.148, 2015.

- Górnicki K., Janaszek M., Kaleta A., Martynenko A., Winiczenko R. Multi-objective optimization of convective drying of apple cubes. Computers and Electronics in Agriculture. vol 145, pp. 341-348, 2018.

- Aleksanyan I.Yu., Fedunova Yu.S., Maksimenko Yu.A. Issledovanie vliyaniya temperatury na gigroskopicheskie kharakteristiki plodoovoshchnykh produktov. Tekhnologii pishchevoi i pererabatyvayushchei promyshlennosti APK - produkty zdorovogo pitaniya, №.4, ss. 86-89, 2017.

- Ananskikh V. V., Babushkin V.A., Perfilova, O. V., i dr. Resursosberegayushaya tekhnologiya pererabotki yablok. Tekhnologii pishchevoi i pererabatyvayushchei promyshlennosti APK - produkty zdorovogo pitaniya, № 6 (20), ss. 21-28, 2017.

- Karim M.A., Joardder, Mohammad U.H. Drying kinetics and properties evolution of apple slices under convective and intermittent-MW drying. Thermal Science and Engineering Progress. vol 30, pp. 1-7, 2022.

- Ferreira, S.V., Lima, M.S., Silva, L.C.M., Oliveira, D.E.C., Leão, P.V.T., Silva, M.A.P. Modelagem e cinética de secagem da curcuma longa l. Sob convecção. Modeling kinetics of convective drying of curcuma longa l.1. Revista Brasileira de Engenharia Agricola e Ambiental, 25 (3), pp. 197-202,2021

- Ali Redha A., Koca I., Pashazadeh H. Effect of convective drying on phenolic acid, flavonoid and anthocyanin content, texture and microstructure of black rosehip fruit. Journal of Food Composition and Analysis. vol 185, pp. 1-8, 2024.

- Amiri Chayjan R, Aghilinategh N, Banakar A., Motevali A, Younji S. Drying kinetics of dill leaves in a convective dryer. International Journal Agrophysics, 2013;27(1): p.39-47.

- Hashim, H., As’Ari, N.A., Yee, C.K. Effect of Drying on Phenolic Content and Antioxidant Activity of Javanese Coriander Leaf (Eryngium foetidum). Kesan Pengeringan terhadap Kandungan Fenol dan Aktiviti Antioksida Daun Ketumbar Jawa (Eryngium foetidum) (2022) Sains Malaysiana, 51 (8), pp. 2559-2571.

- Castro A., Díaz L., Mayorga E., Moreno F. Quintanilla-Carvajal M. Convective drying of feijoa (Acca sellowiana Berg): A study on bioactivity, quality, and drying parameters. LWT - Food Science and Technology. 15 August 2023

- Castro A., Díaz L., Mayorga E., Moreno F. Quintanilla-Carvajal M. Convective drying of feijoa fruits: Pretreatment methods and target. Journal of Hygienic Engineering and Design, 37 (555) (2021), pp. 116-124

- Chikpah S., Korese J., Sturm Barbara, Oliver Hensel. Colour change kinetics of pumpkin (Cucurbita moschata) slices during convective air drying and bioactive compounds of the dried products. Journal of Agriculture and Food Research.Volume 10, December 2022, 100409

- An-An Zhang, Jia-Bao Ni, Alex Martynenko, Chang Chen, Xiao-Ming Fang, Chang-Jiang Ding, Jun Chen, Jian-Wei Zhang, Hong-Wei Xiao. Electrohydrodynamic drying of citrus (Citrus sinensis L.) peel: Comparative evaluation on the physiochemical quality and volatile profiles. Food Chemistry. Volume 429, 15 December 2023. 136832

- Casim S., Contigiani E., Mazzobre F., Rocío Romero-Bernal A. Design of apple snacks - A study of the impact of calcium impregnation method on physicochemical properties and structure of apple tissues during convective drying. Innovative Food Science & Emerging Technologiesvol 85, pp. 1-10, 2023.