Development and study of the ski package of clothes with improved operation properties

Автор: Agibayeva A. E., Mokeeva N. S., Zhilisbayeva P. O., Ermanova G. K.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 3 (137), 2022 года.

Бесплатный доступ

The article is devoted to methods of determination of physical - mechanical properties of membrane materials, nonwoven insulators and clothing package in general. The standard known methods and methods of research are described, as well as the influence of operational and production factors on the structure and properties of membrane tissues that form packs of clothing materials. The physical and mechanical properties of membrane tissues to abrasion in the plane have been investigated, tensile to fracture, elongation, indestructibility, vapour permeability, water resistance, thermal conductivity, breathability. The article presents a reasonable selection and characterization of research objects, materials that form packs of heat-resistant clothing: top tissues - membrane fabrics, insulation - nonwoven volumetric insulation, lining and auxiliary materials and developed packages of heat-proof clothing.

Ski clothing package, membrane fabric, insulating layer, lining materials, ergonomic indicators, waterproof

Короткий адрес: https://sciup.org/140295735

IDR: 140295735 | УДК: 687.14 | DOI: 10.48184/2304-568X-2022-3-208-215

Текст научной статьи Development and study of the ski package of clothes with improved operation properties

UDC 687.14 5 X-20 ) 2’2’ -3 -20 ) 85-215

Research was carried out by analyzing the scientific works on the direction of increase and improvem ent in the development of the product package of prototypes.

The aim of the study is developm ent and study of the ski package of clothes with advanced technology of insulation in a ski suit.

The research task was to improve the insulation in the ski suit, thereby conducting a comparative study of non-w oven insulations and m embrane materiialIs.

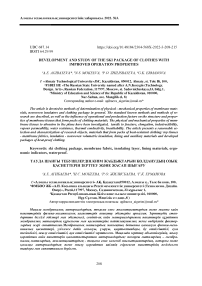

Outdoor sportswear has been designed and manufactured for different activities that will be carried out in different environmental conditions. Tгhis sportswear forms a "clothing system", which usually includes two layers of clothing: membrane and woven insulation. The middle layer is designed to keep a person warm by holding and retaining heated aIir. The outer layer prov/ides protection to all other layers and the body. For complete protection against rain or water, you can weaIr clothing with a completely waterproof outer layer; however, the use of a simple w aterproof outer layer is not effective because the moisture from perspiration generated during sports aIctivities will accumulate in the clothing system, but this not only leads to loss of insulation, but also leads to excessive evaporation and cooling. Humidity control is another important factor in protecting against the cold. This means that it is necessary to avoid getting the layers w et (from the inside by perspiration or from the outside by rain or snow)). If this is not possible, then the effects of moisture accumulation must be controlled [1]. Also the system should be w aterproof but permeable to water vapour [2]. aIs shown in Figure 1. In order to achieve an optimal result, it is necessary to test the physical and mechanicaIl properties of membrane fabrics and a package for ski clothing of domestic producttiion.

Water

Figure 1. Influence of water and moisture on ski suit

Materials and Research Methods

In the course of work on this study, the methods of scientific analysis, synthesis, compaIra-tive and collation analysis, and theoreticaIl method were fundamental, which is due to the specifics of the object under study. Tгhe tests were carried out according to known and standard methods. Physi-cal-and-mechanical and operational properties were determined according to standards.

Results and their Discussion

W aterproof fabrics with improved performance are used in the production of protectiive clothing. W ith the developm ent of membrane technologies, representatives of the textile industry have received a universal material for sewing sports and tourist equipment, and outerwear for children and adults. M em brane fabric has unique properties - it does not allow moisture to pass through from the outside, but at the same time it removes vapours exuded by the hum an body during intense movement. Tгhis eliminates the devel- opm ent of the greenhouse effect, which is characteristic of clothing with a rubber coating.

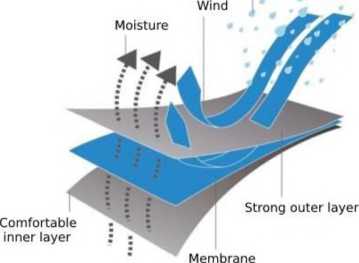

TГhese types of membranes and coatings are hydrophobic in naturre. M icroporous coatings can be produced using wet coagulation, thermocoagulation or foam coating methods or mechanicail fibrillation. M icro-holes found in the structure are smaller than raindrops. but much more than water vapour molecules (Fig. 2) [3].

Water cannot go through, body moisture can proceed

Figure 2. The functions of waterproof5and breathable character in clothing fabrics and a schematic close-up view. [3]

Study of the physical and mechanical properties of domestically produced membrane fabrics for skiing clothiing2.

W^aterpr1o3o3f te£stintgg

To determine the waterproofness of w aterproof transpirгable fabrics, appropriate w ater-proofness testing is required1.

Testing methods can be roughly div 1 ided into two types: (1) tests that prov 1 ide information about the resistance of a fabric to surfaIce wetting or penetration into but not through the fabric, and (2) tests that prov 1 ide information about the resistance of a fabric to raIin penetration. Testing that provides inform ation on surface wetting resistance include a raIin simulation tester such aIs the Bun-desmann testerr, the W IRA shower tester , the Credit seam tester or the AATCC rain tester [4].

W ater resistance, or waterproofness, chaIr-acterizes the resistance of products to the initial penetration of water through them . The pressure of w ater on the sample, which it can withstand before getting wet, is often taken as the chaIracteristic of water resistance. Sometimes water resistance is characterized by the time during which the sample withstands certain water pressure. The determination of the water resistance of fabrics on the pene-trom eter device is carried out in accordance with GOST 3816-81I (ISO 811-81) [5].

Table 1. Physical and mechanical properties of membrane fabrics for ski clothing of national manufacture.

|

№ |

s 3 a л о и |

8 8 Й Я м 'S 09 S |

'Т у 3^ •8 & £ S |

я 8 Ш о У з^ £ S |

Л а ■а м 'у 09 S |

s -e 3 .c eS . Лі 5Л. u -Q S |

8 о с ti Е |

8 8 5 я ^ t л |

4» О' м [ Я І и 6 |

5 я 8 ^ я Е 1^ |

2 to &і |

|

|

1 |

Membrane fabric A30 JOC-09-PL |

35/24 |

108/12 7 |

123/137 |

78/83 |

<6,9 |

2500 |

180/ 1800 Pa |

+/1,65 |

2800 |

125 |

|

|

2 |

Membrane fabric А32 MK110516 |

34/34 |

105/12 2 |

113/132 |

106/10 0 |

<6,9 |

2800 |

1000/ 10000P a |

+/ 1,19 |

2000 |

283 |

|

|

3 |

Membrane fabric A35 HK- CG030 |

36/35 |

115/13 1 |

121/137 |

95/90 |

<6,9 |

3500 |

1000/ 10000P a |

+/0,97 |

2000 |

193 |

|

|

4 |

Membrane fabric with fleece |

70/103 |

155/14 0 |

160/147 |

47/33 |

<6,9 |

1100 0 |

1000/ 10000P a |

+/0,80 |

3000 |

280 |

To identify people's requirements for w inter sports clothing, a survey was conducted, during which it was revealed that many athletes are not fully satisfied with the modern range of w inter sports clothing available in stores. The re-quirem ents are imposed, to a greater extent, on ergonom ic and operational properties [6]. Thus, today the actual task of creating high-qualit[y clothing is to ensure high performance and er-gonom ic perform ance o f sportswear. The basis for the study is improvem ent of the ergonomic and operational propertiies.

Abrasion resistance of fabrics

sistance to abrasion in the plane for 11,000 cycles, so in order to avoid the above defects, it is necessary to increase the level of strength at the destruction sites by introducing abrasion resistant fabrics into the package of the entire suit.

Determ ination of the crease resistance of m embrane fabrics

CreaIsing is the ability of a fabric to form creaIses and bends under various deformations. A big disadvantage of heav 1 ily wrinkled fabrics is that clothes made of them wear out much faIster, since the strongest abrasion occurs in the creaIses and wrinkles that form during deforma1tion. The indicator waIs measured in laboratory conditions using a special dev/ice that meets GO ST 19204-73 [8]. According to Table 1, it can be seen that 4 samples of membrane fabrics have a sufficient degree of creaIse resistance, due to the fact that under the action of a bending force, weakly twisted fibers tend to move relative to each other in order to return to their original position. The correlation coefficient between the reversible deformation of the fabric and its crease resistance after 5 minutes of rest is 10-15°, so membrane fabrics are characterized by high creaIse resistance. Due to the elastic polyester fibers, the surface of the fabric quickly returns to its original state, and all creaIses are smoothed out spontaneously.

Determination of the tearing load of fabrics A very im portant role in the design o f ski sportswear is played by anthropom etric correspondence to the size and shape o f the hum an body, not only in statics, but also in dynamics. Clothing should be com fortable, light, not restrict movement. 4 samples of fabrics are characterized by high strength at uniaxial tension to break m ore than 78-106 kgf for w arp and m ore than 83-100 kgf for weft. Sample elongation of more than 20%0 characterizes m embrane fabrics as those having m edium extensibiiliitty/. Fabrics are highly resistant to tearing, which is very im - portant for sports ski clothing. The relative breaking load and elongation of the fibers were measured by GOST 6611.2-73 [9].

D etermination of transpirability of m em -brane fabrics

Transpirability - the ability of the materiaIl to paIss aIir through itself uInder the influence of its pressure drop. W hen describing the properties of clothing, a synonym for this term is often used -“blow ^ingness”, i.e. to wh1ich extent the materiaIl is "windproof1.

So, pore-free membranes demonstrate absolute "non-blowingness" - 0 CFM . Testing methods are m ost often defined by A STM standards D 737 or ISO 9237, which, however, give identical results.

M anufacturers have begun, recently, to “remember” much more often about transpirability. The fact is that along with the air flow, much more moisture evaporates from the surface of our skin, which reduces the risk of overheating and accumulation of condensate under clothing [10].

The transpaIrability of fabrics waIs determined according to GO ST 12088-77 [11]. Experimental samples of membrane fabrics showed the same characteristics of 6.9 dm3/ m2s.

D etermination of vapour permeability of m embrane fabrics

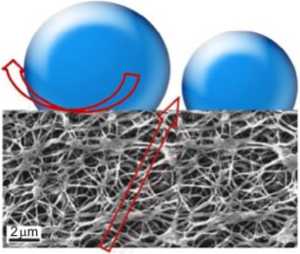

Insulation layer

The function of the insulation layer is to retain body heat in order to prevent a person from be cold. Insulating clothing should do an excellent job of transporting moisture, that is, be vapour-permeable. The second stage of a single system will work only in this way - moisture from the baIse layer enters the insulating layer and then, through the pores of the next layer, it comes out. Fig. 3

Figure 3 The ski package of clothes

To improve the perform ance properties of the ski clothing, therгe is a need to improve the clothing package in the ski suit by introducing an insulating layer made of the following insulation materials: thinsulate, sintepon, down, camel wool, sheep wool (down), fleece.

Table 2 Insulation rates

|

№ |

Specimen name |

Surface density, g/m2 |

Fibers % |

Measurements of fibre tonin. in microns |

|

1 |

Tinsulate |

150 |

65% polyolefin fibre, 35% polyester fibre |

2 -10 |

|

2 |

Sintepon |

200 |

polyester |

10-40 |

|

3 |

Down |

150 |

- |

5-10 |

|

4 |

Wool (camel) |

150 |

- |

20-40 |

|

5 |

Wool (fur) |

150 |

- |

15-25 |

|

6 |

Fleece |

280 |

polyester |

- |

The insulation layer is usually light, relatively thin and windprгoof. It is designed to maintain a comfortable skin temperature while transferring hea1t. Since hy'potherm ia slows down the work of the muscles and worsens the coordination of movement, therefore, it is necessary to evailuate the effectiveness of the heat-shielding properties of the materiails used and the structure as a whole under conditions of exposure to low temperatures [14]. The microclimate in the underwear space should be equail to about 28°С. The relative humidity of the aiir uinder clothing should be at least 30%0 (to avoid dry skin) and not higher than 60%0 (to prevent stuffiness). The content of caIrbon dioxide is an indirect indicator of the effectiveness of ventilation of the underwear space. The content of caIrbon dioxide under multi-layer clothing, which has a generaIlly lower transpirability than the transpirability of its individuaIl layers, is higher than uInder a single layer. So, during overheating in ski clothing, it is necessary to design holes with a zipper for ventilation. The vent is designed to help skiers stay cool when activity levels rise [15]. For the manufacture of prototy'pes of the developed package, the same top and lining fabrics were used, and a non-woven material of different thicknesses and types was chosen for the manufacturГe of a complex insulating lining.

A speciaIl role in clothing for extreme cond1i-tions is played by a heat-insulating lining. The range of densities for heat insulation made of such materiaIls is 40> -4I0)0 g/m 2 [16]. M1icrofiber insulations aIre supplied in the range of densities 40...250 g/m2 and aIre recommended for aIll types of w/inter clothing. A microfiber insulation uInder the Tinsu-late tradem aIrk is the best known in the domestic market. The insulation should reliably retain hea1t, allowing excess moisture to freely evaporate and not lose thermaIl properties after washing. The sintepon does not "breathe" well, and after the first waIsh it loses up to 28%0of its thermaIl properties. Thinsu1late loses no more than 10%Эafter 15 wa1shes [17].

There is still debate about the benefits of synthetic wool and down over natural wool. It has been suggested that synthetics are good for warm , wet conditions, and down and wool - for dry, cold tempera1tures, and a combination of down and waterproof traspirable shell - for protection from cold and damp. [18].

Table 3 Material Package Structure and Properties

|

№ |

Packages |

Composition of the material package layers |

Surface density Ms, g/m2 |

Thickne ss 6, mm |

Heat conductivity k, W/(m *K) |

|

1 |

/ 77 1 / 77/—' 2 ^ ^Ту^^У^^Н»^ g |

|

1 125 283 193 2-150 15 3-76 |

13.5 0 |

0,029 |

|

2 |

/_. ^ ; |

A30 JOC-09-PL А32 MK110516 A35 HK-CG030

|

1 125 283 193 2-200 3-76 |

17.4 |

0,039 |

|

3 |

A30 JOC-09-PL А32 MK110516 A35 HK-CG030

|

1 125 283 193 2-150 15 3-76 |

16.2 0 |

0,0286 |

|

|

4 |

A30 JOC-09-PLA 32 MK110516 A35 HK-CG030

|

1 125 283 193 2-150 15 3-76 |

15 0 |

0,052 |

|

|

5 |

/ 77/—* 2 т/у^ -у-л^ ' ~- ------- 3 |

A30 JOC-09-PL А32 MK110516 A35 HK-CG030

|

1 125 283 193 2-150 15 3-76 |

14.5 0 |

0,035 |

|

6 |

4^7~X #А«#<л*>е.*г*е x'.'Ofr>^x» |

1 Membrane fabric with fleece art. - 02&A1-1 |

1-280 |

2.5 |

0,027 |

Determination of totaIl thermal resistance

The installation is designed to meaIsure the thermal permeability of material samples and consists of a meaIsurement un1it and an electronic control unit. The installation is connected to the USB port of computer 1, which controls the temperature and temperature-controlled preset elements of the installation [19]. The determinaItion of the tota1l thermal resistance wa1s carried out aIccording to GOST 20489-75. W^hen meaIsuring a package of materiaIls w^ith non-woven insula[tion such as: Thin-sulate, W ool DowVn, Dow^n, Fleece is an effective insulation, that is, it ha1s a thermaIl conductivity coefficient of 0.027 - 0.035 W / m*K. This indicator was experimentally calcuIlated, when studying samples “TinsuIlate , W ool dowk'n, Down , Fleece 150 g/m2".

W hen studying the samples "Sintepon" and "Camel wool”: therm al conductivity indicators were 0.039 - 0.05 W /m *K , which m eets the requirements for heat-shielding materials, but low er than the indicators for samples "Thinsu-late, W ool down, Down and Fleece", thereforre, it is necessary to additionally compare them in term s of comfort. (Table 3)

Conclusions

So, taking into account the requirements and recommendations of the standards, methods for determining the physical and m echanica1l properties of textile materials were chosen, and well-known methods for studying the structures and properties of m embrane fabrics, insulation and clothing packages were describedi.

It has been established that the studied membrane fabrics made by applying poly 1 tetrafluo-roethylene or polyurethane to the surface meet the regulatory requirements of GO ST 28486-90, and are characterized by high tensile strength of 100/106 kgf, abraIsion resistance aIlong the plane of 2500-3500 cycles, crease resistance of more than 80/79%о. All fabric samples are characterized by m edium vapour permeability and water resistance, the thermal conductivity indicators m eet the requirements for heat-shielding materia1ls, which ensures their high competitiveness in the ma1rrket. The use of membrane fabrics, domestic wool insulation, aIs well as improved top and lining fabrics in the structure of the new packages under study makes it possible to improve the performance properties of the entire ski suit as a whole.

Список литературы Development and study of the ski package of clothes with improved operation properties

- Praburaj Venkatraman Fibres for Sports-wear // Materials and Technology for sportswear and performance apparel. - 2016 - № 11 - P. 261.

- Online Etymology Dictionary, Waterproof. [Electronic Resource] // Date of call: 03. 12. 20 [http://www.etymonline.com/index.php?allowed_in_frameј0&searchјwaterproof ].

- Hikmet Ziya Ozek Development of water-proof breathable coatings and laminates / Waterproof and Water Repellent Textiles and Clothing. - 2018. - P. 25-50

- Dr Jeruckman Water resistance and water vapour transfer // Textiles in sport. - 2015. - № 13. - P. 287-302.

- GOST 3816-81 Textile . Methods for determining hygroscopic and water-repellent properties. - Enter.01. 07. 2008. - M.: PKI Standards Publishing, 2012

- Gavrilova I. V. Improvement of the operational and ergonomic properties of sports clothing for winter sports // Herald of Modern Research, 2015. - P. 68-72

- GOST 18976-73 Textile. Method for determination of wear resistance. Enter.12. 05. 2003. - M.: PKI Standards Publishing, 2005

- GOST 19204-73 Textile fabrics. Method for determination of crease resistance. M.: Standards publisher, 2004

- GOST 6611.2-73 Textile threads. Methods for determination of breaking load and elongation at rupture. M.: Standards publisher, 2004

- Ski wear [Electronic Resource] // Date of call: 21. 12. 21 [https://sport-marafon.ru/article/odezhda/paropronitsaemost-i-vozdukhopronitsaemost-v-chyem-raznitsa]

- GOST 12088-77 «Textile materials and articles of them. Method of determination of air permeability». Enter.30. 08. 2000. - M.: PKI Standards Publishing, 2003

- Klimova N. A. Research on the structure and properties of membrane tissue in clothing / Klimovs N. A., Loginova E. A., Pudoi A. S., Morozov D. A., Stepanova I. V., Shevchenko S. V., Beschaposhnikova V. I. // In the Compendium: Innovative Development of Light and Textile Industries. Collection of International Student Science Conference materials. 2019. P. 37-40.

- Klimova N. A. Research on the structure and properties of membrane tissue in clothing / Klimova N. A., Besshaposhnikova V. I., Mikrjkova O. N., Lagovski P. V., *Kovoleva N. E // V International Science and Technology Conference «Design, Technology and Innovation in Textile and Light Industries», 2018. - P. 79-82.

- Mokeeva N. S., Zaye V. A., Zhilisbayeva R. O. Forecasting of thermal protection of layered clothing under low temperature conditions / Textile technology. - 2016. - № 5 (365). - P. 65-68

- Smith L. Wearable Tech Enters the Ski wear Market. https://www.ispo.com/en/trends/ski-jacket-eliminates-sweat-touch-button. 25. 09. 2021

- Sheromova I. A., Clothing Materials Conference [Electronic Resource] // Date of call 26. 12. 2021 [http://abc.vvsu.ru/Books/konfecmater_kp/page0001.asp ]

- Natalya Shernikova, Ski wear [Electronic Resource] // Date of call 20. 10. 21 [https://www.turizm.ru/ski/info/gornolyzhnaya_odezhda/?ysclid=l8lbm2119j285182460]

- Jeni Bougourd, Jane McCannWaterproof And Water Repellent Textiles And Clothing / Designing waterproof and water repellent clothing for wearercomfort - A paradigm shift - 2018. - P. 323

- Shamparov, E. U., Rode S. V., Zhagrina I. N., Grigoryan M. P. Installation for measuring heat conductivity of light industry materials / Design and technology. - 2017. - № 46 (88). - P. 72-76