Development of a method for fire-resistant finishing of non-woven material using a phosphorus-containing composition

Автор: Sarymsakova A. T., Burkitbay A., Tausarova B. R.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 3 (137), 2022 года.

Бесплатный доступ

The aim of the study is to obtain a non-woven material with flame retardant properties. The conditions of the process of fire-retardant finishing were as follows: an aqueous solution of preparations of various concentrations was applied by spraying onto the surface of the material, then drying was carried out and heat treatment on a thermal press. According to GOST R 50810-95, non-woven material made from flax and wool fibers, treated with a composition based on an aqueous solution of sodium phosphate and guanidine hydrochloride, is classified as a flame-retardant material. Also, tests for toxic and skin-irritating effects of non-woven material treated with the proposed composition showed its safety for human health.

Non-woven material, sodium phosphate (sp), polyvinyl alcohol (pva), guanidine hydrochloride (ghc)

Короткий адрес: https://sciup.org/140295363

IDR: 140295363 | УДК: 677.1 | DOI: 10.48184/2304-568X-2022-3-223-229

Текст научной статьи Development of a method for fire-resistant finishing of non-woven material using a phosphorus-containing composition

IntroductionRationale for the choice of topic, purpose and objectives

Resistant tex£tile materiaIls of various nature haIs become increaIsingly important. This is due to the faIct that they aIre a serious souIrce of danger during fires, ign1ite eaIsily, contribute to the spread of flames and, when burned, emit laIrge amounts of smoke and toxic gaIses. In this regaIrd, in many foreign countries the use of products made of flammable materiaIls is prohibited by law.

One of the most important tasks in the textile industry is the development of effective, env / ironmentally friendIly flame retardants with high performance. The development of fire-resistant tex£tile m ateria1ls on a laIrge industriaIl scaIle remaIins unrealized, due to the laIck of efficiency of known technicaIl solutions. The problem covers the issues of flame retardant interaction with fibrous materiaIls, including technologicaIl aIspects of fire protection, env / ironmental requirements, issues of duIrability and materiaIl compliance with fire safety regulations.

Thus, the development of a technology for mod1ifying tex£tile materiaIls w ith stable flam e retardant properties using relatively inexpensive and env 1 ironmentally friendIly chemicaIls w^ill increaIse the economic efficiency of the use of fibrous materiaIls in various fields .

In this w ork, the focus is on the processing of nonwovens at the stage of emulsification or after forming the canvas by spraying with a solution of flame retardants. Non-woven m aterials with fire-resistant properties are used in construction as insulation materia1ls. There is also information on the use of non-woven fabrics with fire-resistant properties as floor coverings in public institutions and in everyday life [1-5]. To reduce the fire hazard of textile m aterials, flame retardants o f various compositions are used: halogen- and phosphorus-containing compounds, ammonium polyphosphates, and chlorinecontaining compounds [6].

The aIim of the study is to develop a composition and method for producing a fire-

retardant non-woven materiaIl baIsed on sodium phosphate (SP), polyvinyl aIlcohol (PVA) and guanidine hydroch1loride (GHC) .

To aIch1ieve this goa1l, the following tasks were solved:

-

1. The possibility of obtaining effective flame retardant compositions for nonwoven materiaIl using relatively inexpensive and environmentally friendly chem1icals haIs been established.

-

2. The composition of the flame retardant composition for non-woven materiaIl haIs been developed.

-

3. The flame retardant properties of the nonwoven materiaIl processed in the new way were studied using various reseaIrch method1s.

Materials and Research Methods

Objects of study : non-w oven m ateria1l from linen and wool fibers, as well as chemicals (sodium phosphate (SP), polyvinyl alcohol (PVA) and guanidine hydrochloride (GHC)).

Conditions for the process of fireretardant finishing of non-woven m aterial: an aqueous solution of preparations of various concentrations was applied by spraying onto the surface of the material, followed by drying and heat treatm ent on a therm al press .

W hen perform ing experim ents, com plex research methods were used. The combustion resistance of the m aterial was determ ined in accordance with the requirements of the GO ST R 50810-95 standard [7]. The study of the surface m orphology o f textile fibers w as carried out using a JSM - 6490LA scanning electron microscope. The air permeability of the fabric was determined on an M T-160 instrument [8].

Main partResults and their discussion

The aim of the research work is to obtain a nonwoven material with flame retardant properties .

As components for preparing the flame retardant composiition. BaIsed on the preliminary experiment, the concentration of sodium phosphate waIs varied within 10-25 g/l, polyvinyl aIlcohol - 5-30 g/l and guanidine hyd1roch1loride - 5-10 g/l (table 1).

Table 1 - Composition of compositions for imparting fire resistance properties to nonwoven material

|

Compound No. |

Sodium phosphate, (g/l) |

Polyvinyl alcohol, (g/l) |

Guanidine hydrochloride, (g/l) |

|

1 |

10 |

5 |

- |

|

2 |

10 |

10 |

- |

|

3 |

15 |

5 |

- |

|

4 |

15 |

10 |

- |

|

5 |

25 |

5 |

- |

|

6 |

20 |

20 |

- |

|

7 |

20 |

30 |

- |

|

8 |

25 |

- |

10 |

|

9 |

25 |

- |

5 |

|

10 |

12,5 |

- |

10 |

|

11 |

12,5 |

- |

5 |

To process the material, an aqueous solution of the composition of various concentrations was applied to the surface of a canvas of linen and wool fibers by spraying, followed by drying and heat treatm ent at 180 °C for 1 min on a therm al press.

An untreated sample of nonwoven m ate-rial, when tested for flammability with an ignition tim e of 15 seconds, burns completely in 45

seconds. A sample treated with SP and polyvinyl alcohol, when brought to a flam e, ignites, when introduced, it slowly ignites and chars, with the release of gray smoke. For a sample treated with a composition containing sodium phosphate and guanidine hy Т pochlorite when tested for fire resistance independently e com -bustion is reduced to zero (Figure 1) [7].

1-sample sample, raw nonwoven fabric,2-samplesample treatedсwith composition:5PVA-5 g/l, SP-23-samplesample treatedсwith composition: 1GHC-10 g/l, SP

Figure 1 - Samples of nonwoven fabric after fire test

Also, non-woven m aterial was tested for fire resistance in a fire testing laboratory in ac- oс rdanceеw?ithһtheеrequiremіentssoсffth1eеGOSЕT RR 0810-955 standardd atLt theе OVV Tг installationп.

Table 2 - Test results for fire retardant perform1ance

|

No. |

Drug concentration |

The length of the ch arred a rea, mm |

||

|

Sodium phosphate, (g/l) |

Polyvinyl a lcohol, (g/l) |

Guan idine hydro-ch loride, (g/l) |

||

|

1 |

origina l sampl |

e |

220 |

|

|

2 |

10 |

5 |

- |

180 |

|

3 |

10 |

10 |

- |

188 |

|

4 |

15 |

5 |

- |

178 |

|

5 |

15 |

10 |

- |

175 |

|

6 |

25 |

5 |

- |

168 |

|

7 |

20 |

20 |

- |

170 |

|

8 |

20 |

30 |

- |

175 |

|

9 |

25 |

- |

10 |

87 |

|

10 |

25 |

- |

5 |

90 |

|

11 |

12.5 |

- |

10 |

92 |

|

12 |

12.5 |

- |

5 |

95 |

The length of the charred area, rum

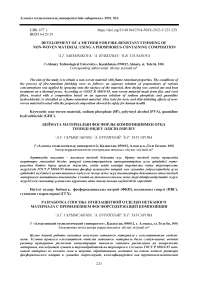

Figure 2 - Dependence of the length of the ch1arred section of the nonwoven materiaIl on the composition of the fire-retaIrdant composition (numbering of samples according to table 2)

For specimens treated with a flame retardant composition, with an increase in the concentration of sodium phosphate and GHC in the compo-

sition, the length of the charred aIrea decreased from 220 to 87 mm (Tables 2, 3; Figure 2).

Table 3 - Test results for fire resistance of nonwoven fabric

|

No |

Sample |

6 о 8О t+ч

О

— 0 19 1 S3 s Q. |

Note |

Snapshot of material sample after testing |

|

1 |

source material sample |

15 |

The sample, when brought to the flame of the burner, instantly smolders; when brought into the flame of the burner, it instantly ignites, burns with the release of gray smoke, residual combustion persists until the complete combustion of the sample. |

|

|

2 |

Sample treated with composition: PVA-30 g/l SP - 20 g/l |

15 |

The sample, when brought to the flame of the burner, ignites, when introduced, it lights up, with the release of gray smoke. When removed, afterburning lasts up to 87 seconds. The length of the charred area is 175 mm. |

|

|

3 |

Sample treated with composition: GHC -10 g/l SP - 25 g/l |

15 |

The sample, when brought to the flame of the burner, smolders slightly; when brought into the flame, the sample does not ignite, does not char. Afterburning is reduced to zero. The length of the charred area is less than 90 mm. |

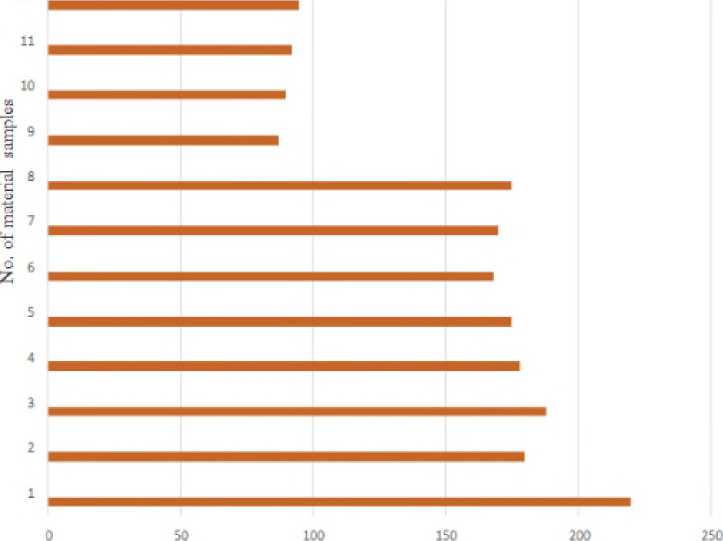

Also, the results of the study carried out in the test fire laboratory showed that the duration of residual combustion when the flame was removed, for the source m aterial - 98 seconds, for the sample treated with SP and polyvinyl alcohol is 87 seconds. This indicator for the m aterial treated with SP and guanidine hydrochloride is reduced to zero (Figure 3).

T hus, it can be concluded th at the c o m p o -sition based on sodium phosphate and guanidine hydrochloride provides high flame retardant properties to the nonwoven materia1l. The proposed composition is recommended as a com -bined composition for emulsifying and fireretardant finishing of a mixture of fibers, since guanidine hydrochloride provides a decrease in electrification and an increase in the adhesion of non-w oven m aterial fiberГs.

Figure 3 - Duration of afterburning according to GOST R 50810-95

It is known from the literature that the treatment of a materiaIl with polymer composiitions can lead to a change in its perm eaIbiility properties. In this regard, the aIir permea1biility indicators of the studied samples of nonwoven m1ateriaIl were determined. The coefficients of aIir permeability of the treated sam ples are 482 - 572 dm 3/m 2 sec., of the original m1ateriaIl - 635 dm3 /m2 sec. The aIir permeability of the materia1l samples treated with the composition baIsed on sod1ium phosphate and GHC d1id not significantly decrease compared to the original samplIe.

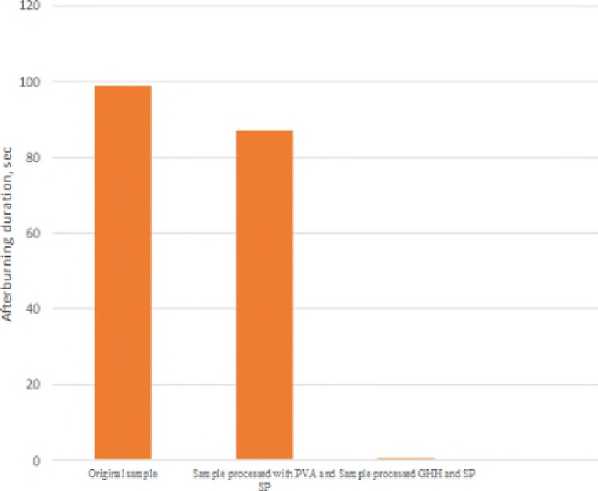

Stud1ies of the morphologicaIl features of the untreated and processed materia1l were carried out using an uIltra-h1igh resolution scanning electron microscope. According to the resuIlts of scanning electron microscopy, a change in the morphologica1l surface of the treated sampl1es was reveaIled in comparison wiith untreated materials. Analysis of photograph)s (Figure 4a) showed that the untreated sample haIs a smooth surface and a homogeneou]s structure. It has been established that a polym er layer is formed on the surface of the treated nonwoven materiaIl from the composition of SP and guanidIine hypoch1loride (Figure 4b).

a)

b))

Figure 4 - Electron microscopic images ofnonwoven materials

In additiion, the resu1lts of experim ents to determine the toxicity and skin- irritating effect of the proposed composition showed its safety for hum1an hea1lth.

B ased on the analysis of the resuIlts obtained1, the treatment of non-woven maItieriaIl wVith a composition baIsed on SP, GHC providIes a h1igh degree of fire resistance ofthe treated textile ma1tIerials.

Conclusions

A composition baIsed on sodIium phospha1te and guanidine haIs been developed hyd1rochloride to impart flame retardant properties to non-wovens. N on-w oven m ateriaIl treated with the proposed composition acquires high fire retardant propertiies.

The air permeability of the material sam -ples treated with the composition based on SP and GH C did not significantly decrease com -pared to the original samplIe.

According to the results of scanning electron microscopy, a change in the morphological surface of the treated samples was revealed com -pared to untreated samples. AVnalysis of the photographs showed that the untreated sample had a smooth surfaIce and a hom ogeneous structure. It has been established that a polymer layer is form ed on the surface of the treated nonwoven material from the composition of SP and GHC.

The results of experiments to determine the toxicity and skin- irritating effect of the flame retardant composition showed its safety for human heal1th .

Список литературы Development of a method for fire-resistant finishing of non-woven material using a phosphorus-containing composition

- Кanat E. К., Burkitbai A., Tausarova B. R. Primenenie fosforsoderzhashchei kompozitsii v razrabotke ognestoikikh netkanykh materialov iz lubyanykh volokon/ Material respubl. konf. molodykh uchenykh «Nauka. Obrazovanie. Molodezh'». - Almaty: ATU. - 2019. - S. 129 - 131. (In Russian).

- Takei E., Tausarova B. R, Primenenie tetraehtoksisilana i tiomocheviny dlya pridaniya ognezashchitnykh svoistv tsellyuloznym tekstil'nym materialam// Izvestiya VUZ - «Tekhnologiya tekstil'nogo priozvodstvA». - 2017 №5 (377). - S. 75 - 79. (In Russian).

- Ye. Takey, B. R. Taussarova Sol-gel composition on the basis of sodium silicate and ammonium polyphosphate for obtaining fire retardant cellulose textile materials // Zhurnal «Khimicheskii zhurnal Kazakhstanа». - 2018. - № 4. - P. 43 - 49.

- Tausarova B. R., Kutzhanova A. Zh., Abdrakhmanova G. S. Snizhenie goryuchesti tekstil'nykh materialov: dostizheniya i perspektivy// Khimicheskii zhurnal Kazakhstana. - 2015. № 1 (49). - S. 287-303. (In Russian).

- Visakh, P. M. Arao Yoshihiko. Flame Retardants // Polymer Blends, Composites and Nanocomposites. - 2015. - P. 247.

- Giuseppe Rosace, Claudio Colleoni, Emanuela Guido, Giulio Malucelli. Phosphorus-Silica Sol-Gel Hybrid Coatings for Flame Retardant Cotton Fabrics // Textile. - 2017, 60 (1). - S. 29-35.

- GOST R 50810-95 Pozharnaja bezopasnost' tekstil'nyh materialov. Tkani dekorativnye. Metody ispytanija na vosplamenjaemost' i klassifikaciihttps://proffidom.ru/uploads/files/2019-07/1563379874_gost-r-50810-95.pdf. (data obrashhenija 01. 01. 2021). (In Russian).

- Sarymsakova A. T., Burkitbai A. Razrabotka ognestoikikh netkanykh materialov iz l'nyanykh i sherstyanykh volokon/ Material respubl. konf. molodykh uchenykh «Nauka. Obrazovanie. Molodezh'». - Almaty: ATU. - 2022. - S. 71- 72. (In Russian).