Development of new food products from millet

Автор: Kenenbay Sh. Y., Badmaeva I.I., Sovetkalieva Zh. R.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 4 (138), 2022 года.

Бесплатный доступ

Proper nutrition can give us health, longevity and beauty. It assumes that the body regularly needs the necessary amount and many nutrients such as proteins, carbohydrates, fats, water, minerals, vitamins should be supplied in optimal proportions. In Kazakhstan, wheat is industrially produced only millet and semi-artisanal products such as "tari", "talkan" and "zhent" are produced. And wheat is an ideal product that can be attributed to the right raw materials, since the fact that it does not contain gluten, the raw materials are rich in B vitamins and protein. The research and development of the technology of the national cereal product talkan, creates an opportunity to expand the range of products, enrich the food market and the consumer's diet with a new cereal product rich in irreplaceable components, and developed taking into account forgotten original traditions and national culture. The analysis was carried out in the laboratory of Almaty Technological University. The calculated part of the finished product was analyzed to determine the chemical composition, the content of micro and macroelements. We have developed the technology of PN Talkan preserving all the useful properties. At the stage of approval of regulatory and technical documents for the production of PN Talkan. In this research work, the traditional product was improved in a new, most useful format. The technology of low-calorie millet talkan has been developed.

Wheat, talkan, millet, proper nutrition, lactose, buckwheat milk powder

Короткий адрес: https://sciup.org/140296394

IDR: 140296394 | УДК: 664.76 | DOI: 10.48184/2304-568X-2022-4-158-164

Текст научной статьи Development of new food products from millet

Millet is the most common type of cereal. In the market, wheat occupies the fifth place in terms of consumption after rice, buckwheat, oatmeal and peas. And in terms of taste and nutritional advantages, millet ranks first among cereals, is also the most nutritious and less allergenic.

According to the place of origin, wheat can be of different varieties. It is divided into three grades: the highest, the first, the second.

In terms of fat content, only oatmeal is ahead of millet, and in terms of protein content it surpasses rice and barley. But 100g of the product is biologically 3.5% fat, 3.25% ash, 13.8% protein, 19.9% carbohydrates, 8.67% water. Wheat is rich in vitamins, especially B vitamins and amino acids, starch, fiber and minerals. In particular, the composition contains thiamine, nicotinic acid, folic acid, vitamins B6, B2, B3 and biotin [1].

By origin, millet – shingle represents whole grains, but in the process they are cleaned of flower films.

Light bitterness and characteristic shine -this is the feature of the grain, because of this characteristic it is rarely used in the preparation of cereals. With the help of special grinding or crushing, wheat is cleaned from flower films, partly from fruit and seed shells. Such wheat does not shine like millet shingles, but has a bright yellow color. And this property allowed it to cook faster than normal, and it is ideal for cooking casseroles and porridges. A by-product from millet processing is also used - millet crushed. Due to the crushed kernels, it cooks very quickly. From dark wheat, crumbly porridge is obtained, and from light on the contrary.

The nutritional value wheat is very high, during cooking the volume increases 6-7 times [2].

Millet in the future will play an important role in ensuring food security not only in African and Asian countries, but also in Kazakhstan. Cereals obtained from millet have high nutritional value and good taste qualities, it is also added to various flour, meat and dairy products.

Traditional millet foods and beverages are produced and consumed by the inhabitants of Africa, India, China, Eastern Europe and Eurasia. Porridge, tortillas, soft drinks, alcoholic beverages, snacks and various seasonings are prepared from millet [3].

Millet can be used as an alternative product to control weight and reduce the risk of developing chronic diseases such as diabetes mellitus [4].

According to the conclusion of the literary review, the Kazakh national cereal product talkan is a good basis for the production of instant food concentrates. It has a shortened duration of bringing to full readiness or it can be eaten independently, in some cases mixed with flavoring additives.

The purpose of this work is to develop the technology of a national cereal product of high quality.

To achieve this goal, the following tasks were defined:

-

• Sorption properties of millet have been studied and the optimal solution of the technological process has been determined;

-

• Studies have been conducted to improve the overall nutritional and sensory characteristics of food;

-

• Quality analyses of the received products were carried out;

-

• Formulations based on talkan have been developed, regulatory documents (patents) have

been approved and cost-effectiveness assessments have been carried out.

The problem of the study is that the production technology of the finished consumed talkan contains sugar, which in turn is contraindicated for people suffering from diabetes.

The way to solve this problem is to replace granulated sugar with stevia. Stevia is a sweetener, does not increase blood sugar levels due to the low carbohydrate content of the composition (0.1g per 100g of the product).

The practical significance of this research work lies in the fact that the production of this product under study from millet will create a product that meets the requirements of the modern consumer.

Crushed talkan itself, as a raw material, is a 100% natural product. It has no sugar, additives and preservatives. This is not a dietary supplement, but a full and healthy meal.

Millet contains: proteins, carbohydrates, zinc, magnesium, iron, calcium, copper, selenium, as well as dietary fiber.

Table 1 – Nutritional value of wheat.

|

Product name |

Content in 100g, % |

Energy value 100g, kcal |

|||

|

Wheat |

Proteins |

Fats |

Carbohydrates |

Water |

162,93 |

|

5,88 |

1,50 |

33,58 |

7,77 |

||

Table 1 shows the indicators of the nutritional value of wheat per 100g of product.

It has been established that technological and hydrothermal millet processing, soaking, fermentation and malting affect the content of phyto chemicals and their antioxidant activity of cereals is proposed. An innovative method [5], and degreasing and hydrothermal treatment of millet affect the phenolic content and antioxidant potential of the grain. Millet-like cereals have beneficial health-improving properties, in particular antioxidant activity [6].

There are a variety of millet products, including porridge, tortillas, steamed and rice products, soft drinks, alcoholic beverages (beer, wine and alcohol), snacks and spices [7].

Materials and methods

Production of PN Talkan using specially selected millet.

For the development of Talkan PN, specially selected wheat with a special cleaning and crushing technology was chosen as the object of research.

Technological process of grain peeling:

At the beginning of the process, the millet goes through primary processing. Fried until medium golden brown on the appropriate equipment.

When wheat is fried at 160C for 15-20 minutes, the grain peeling coefficient is much lower compared to non-fried grains by 3.13.6%. These indicators are within the recommended peeling rate. If the temperature is increased during the peeling process, the duration of the peeling coefficient treatment is significantly reduced below the recommended norm.

Studies have shown that some varieties of millet wheat may be suitable for fresh pasta, but quality improvement is provided by optimizing the formulation or processing [8].

During the production of talkan, grains of various cereals (wheat, barley, etc.) are subjected to heat treatment with subsequent grinding. The grains are cleaned from foreign impurities, heat treated (10 minutes at a temperature of 1500C), cooled, crushed (0.25-0.7 mm). To reduce the duration of heat treatment, the grains are first crushed, and then fried [9].

This leads to a tighter fit of the color films to the core after intensive heat treatment. The minimum peeling coefficient at a temperature of 190C for 30 minutes is 90.3%, compared with the norm, it is 4.7% lower.

It is investigated that it is impossible to obtain a whole grain kernel when peeling. Its content decreases from 3.62% to 0.07% due to an increase in the intensity of frying.

Temperature from 160C (15 minutes) up to 200C (45 minutes). At a temperature of 180 or 190C with 45 minutes, the flour content reaches maximum values. This means that the degree of change in the mechanical properties of millet is proportional to the degree of temperature change [10].

The next process is the grinding process.

Crushed wheat is called "talkan". In a separate container, 30 g of ready-made talkan, 10 g of buckwheat milk powder, 2 g of stevia and 0.1 g salt are added. Thoroughly mixed. Add the finished portion to a special eco cup, 250g in size.

Studies on the indicators of quality, protein, fats and carbohydrates of products were carried out in the laboratories of the Almaty Technological University.

Research results and their discussion

During the execution of all the tasks of the research work, several analyses were carried out at the ATU University. Patents and literature sources on the topic of millet and millet were analyzed.

Production technology of PN – Eco Talkan:

Grain processing for talkan production was carried out in the following sequence:

-

• Cleaning of grain from impurities on a sieve with a diameter of 2 – 3 mm;

-

• Obtaining good-quality grains by the descent of a sieve with a diameter of 1.5 mm;

-

• Grinding of grain to the size of 1 mm; 2 mm; 3 mm; 4 mm; 5 mm;

-

• Heat treatment of grain grinding products in a convective dryer at temperatures of 150C; 160C; 170C; 180C; 200C with an exposure of 15 to 50 minutes;

-

• Cooling of the resulting talkan to a temperature not exceeding the ambient air temperature by more than 6 – 8C.

The ingredients described in the recipe were selected.

The formulation and technology of which is given in Table 2.

Table 2 – Formulation of PN Talkan.

|

Names of components |

Net weight, g per 42g of product |

|

Wheat |

30 |

|

Buckwheat milk powder |

10 |

|

Stevia |

2 |

|

Salt |

0,1 |

|

Output |

42 |

Table 2 shows the required amount of ingredients per serving of the product.

Table 3 – Nutritional value of PN Talkan.

|

Product name |

Product weight, g |

Content of components in the product, g |

EC, kcal |

||

|

Proteins |

Fats |

Carbohydrates |

|||

|

Prototype of Talkan from wheat |

100 |

10,2 |

1,3 |

67,7 |

428,6 |

|

PN – Eco Talkan |

100 |

7,57 |

0,78 |

42,3 |

303,8 7 |

According to Table 3, it was found that the nutritional value of PN – Eco Talkan is equal to the following indicators: proteins-7.57

g; fats-0.78 g; carbohydrates-42.3 g and energy value-303.87 kcal per 100 g of the product.

The nutritional value of the prototype – wheat Talkan is equal to the following indica- tors: proteins-10.2 g; fats-1.3 g; carbohydrates-67.6 g and energy value-428.6 kcal per 100 g of the product.

Comparing these results, it can be concluded that PN – Eco Talkan contains a small amount of carbohydrates compared to the prototype. This study means that the product is usable for people who want to stick to proper nutrition.

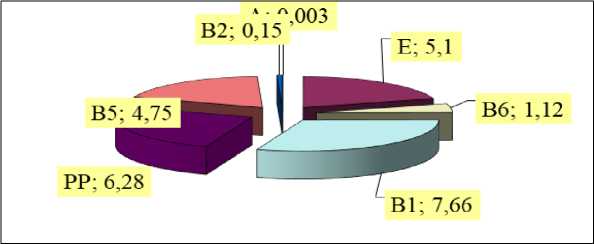

Figure 1. Vitamin content in the product, (mg%)

The amount of vitamins in the product according to Figure 1,%:

Vitamin A – 0.003%; vitamin E – 5.1%; B6 – 1.12%; B1 – 7.66%; PP – 6.28%; B5 – 4.75%; B2– 0.15%.

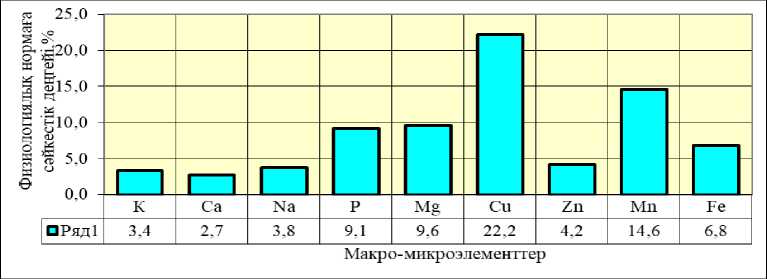

Figure 2 – The content of macronutrients and trace elements, mg/% in the product

In Figure 2 in the diagram, the indicators of macro-microelements in the product are calculated. The largest indicators are: Cu – 22.2%; Mn – 14.6%; Fe – 6.8%.

The composition of the product is very rich in macro - and microelements. Due to this, it is recommended to consumers as a very digestible and nutritious product. Due to the fact that one-day energy is well absorbed by our body, consumers feel very cheerful during the day.

Figure 3 – The content of MNFA (Monounsaturated fatty acids), PUFA (Polyunsaturated fatty acids), EFA (Essential fatty acids), %

Figure 3 shows the content of MNFA, PUFA, and EFA in the product. The diagram shows that the content of various fatty acids is significantly less.

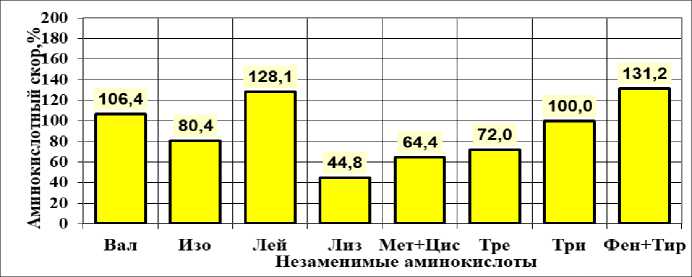

Figure 4 – Amino acid rate indicators, %

Figure 4 shows the result of the amino acid rate indicators. The result shows that the amino acid rate of Valine is 106.4%; Leucine is 128.1; Tryptophan is 100% and Phenylalanine is 131.1. These indicators mean that the developed product contains a sufficient amount of amino acids for the daily norm.

According to the parameters of the talkan PN, the physico-chemical parameters of the finished product were shown in Table 4.

Table 4 – Physical and chemical parameters of Talkan PN, %.

|

Physico-chemical parameters, % |

|

|

Mass fraction of proteins |

10,17± 0,15 |

|

Mass fraction of fats |

1,14± 0,02 |

|

Mass fraction of carbohydrates |

67,45±1,01 |

|

Mass fraction of ash content |

1,56±0,02 |

|

Mass fraction of starch |

51,89±0,77 |

|

The mass fraction of fiber |

5,04±0,07 |

|

Dry matter content |

89,86±1,34 |

|

Mineral elements, % |

|

|

Calcium |

9,27±0,13 |

|

Carbohydrate composition, % |

|

|

Sucrose |

4,45±0,05 |

|

Maltose |

1,14±0,03 |

|

Glucose |

3,55±0,05 |

|

Fructose |

0,95±0,02 |

|

Lactose |

Not detected |

Based on the results of the research of this scientific work, we have created a product that meets all the requirements of a healthy diet, for modern consumers, including people with high blood sugar, and for those who keep a healthimproving diet, and this product will help improve the body.

Conclusion

In the process of researching the development of PN Talkan technologies, a thorough study was carried out, an individual approach was made to each ingredient, a series of analyses were carried out to determine the quality indicators of the product. The analysis was carried out in the laboratory of Almaty Technological University. The calculated part of the finished product was analyzed to determine the chemical composition, the content of micro and macroelements. We have developed the technology of PN Talkan preserving all the useful properties. At the stage of approval of regulatory and technical documents for the production of PN Talkan.

Список литературы Development of new food products from millet

- Technology of food production: Textbook. In 2 parts. Part 1 / G. Esirkep. - Almaty: "Bastau", 2017. - 304 p.

- Yanova M.A., Kolesnikova N.A., Muchkina E.Ya., Research of millet and its processed products [Text] // Bulletin of KrasGAU. - 2015. No.11, pp. 130 - 135. URL: https://cyberleninka.ru/article/n/issledovanie-prosa-i-produktov-ego-pererabotki.

- Potential use of pearl millet (Pennisetum glaucum (L.) R. Br.) Eurasian Union of Scientists (EU) #7(76), 2020 in Brazil: food safety, processing, health benefits and food products. International Food Research, Volume 109, pp. 175-186. Amanda M. Diaz-Martins, Kenia Leticia F. Pessanha, Sidney Pacheco, Jose Avelino S. Rodrigues, Carlos Vanderlei Peeler Carvalho.

- Potential use of pearl millet (Pennisetum glaucum (L.) R. Br.) in Brazil: food safety, processing, health benefits and food products. International Food Research, Volume 109, pp. 175- 186.Amanda M. Diaz-Martins, Kenia Leticia F. Pessanha, Sidney Pacheco, Jose Avelino S. Rodrigues, Carlos Vanderlei Peeler Carvalho.

- Chapter 41: Millet grain processing and effects on non-nutritive antioxidant compounds. Processing and impact on the active components of food products, 2015, pp. 345-352.Fereydun Shahidi, Anoma Chandrasekhara.

- The effect of processing on the antioxidant activity of millet grain. Food Chemistry, Volume 133, Issue 1, July 1, 2012, pp. 1-9. Anoma Chandrasekhara, Marian Naczk, Fereydun Shahidi.

- Chapter 9: Traditional sorghum and millet food and beverages and their technologies. Sorghum and Millet (second edition), 2019, Pages 259-292. John R. N. Taylor, Kwaku G. Duodu.

- Culinary qualities, digestibility and sensory properties of millet pasta under the influence of amylose content and prolamine profile.LWT, Volume 99, January 2019, Pages 1-7 Ingrid G. Cordelino, Catherine Teal, Loma Inamdar, Zata Vickers, Baraem P. Ismail.

- D.M. Borodullin, M.T.Shulbaeva, O.N.. Musina, B.M. Shepieva. Innovative technology for obtaining talgan as a component of functional food products that take into account national food traditions. ISSN 2313-1748 Food Processing: Techniques and Technology, 2017, Vol,46, No 3.

- Zharkeev, Murat Kakimzhanovich. Development of technology of the national cereal product: dissertation... Candidate of Technical Sciences: 05.18.01 / Murat Kakimzhanovich Zharkeev; [Place of protection: Moscow State University of Technology and Management named after K.G. Razumovsky].- Moscow, 2011.- 176 p.: ill. RGB OD, 61 12-5/685.URL: http://www.dslib.net/texnologia-zernovyx/razrabotka-tehnologii-nacionalnogo-krupjanogo-produkta.html.